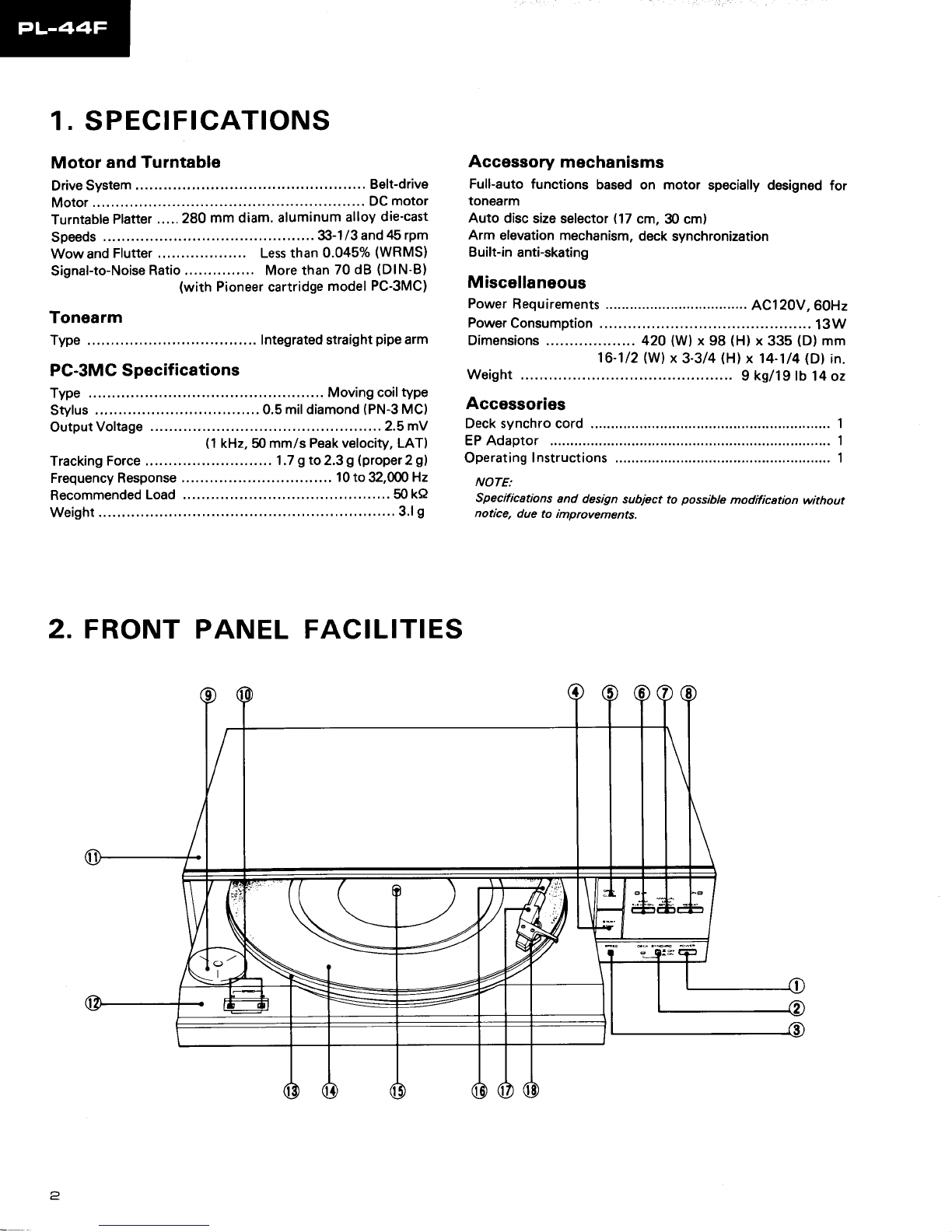

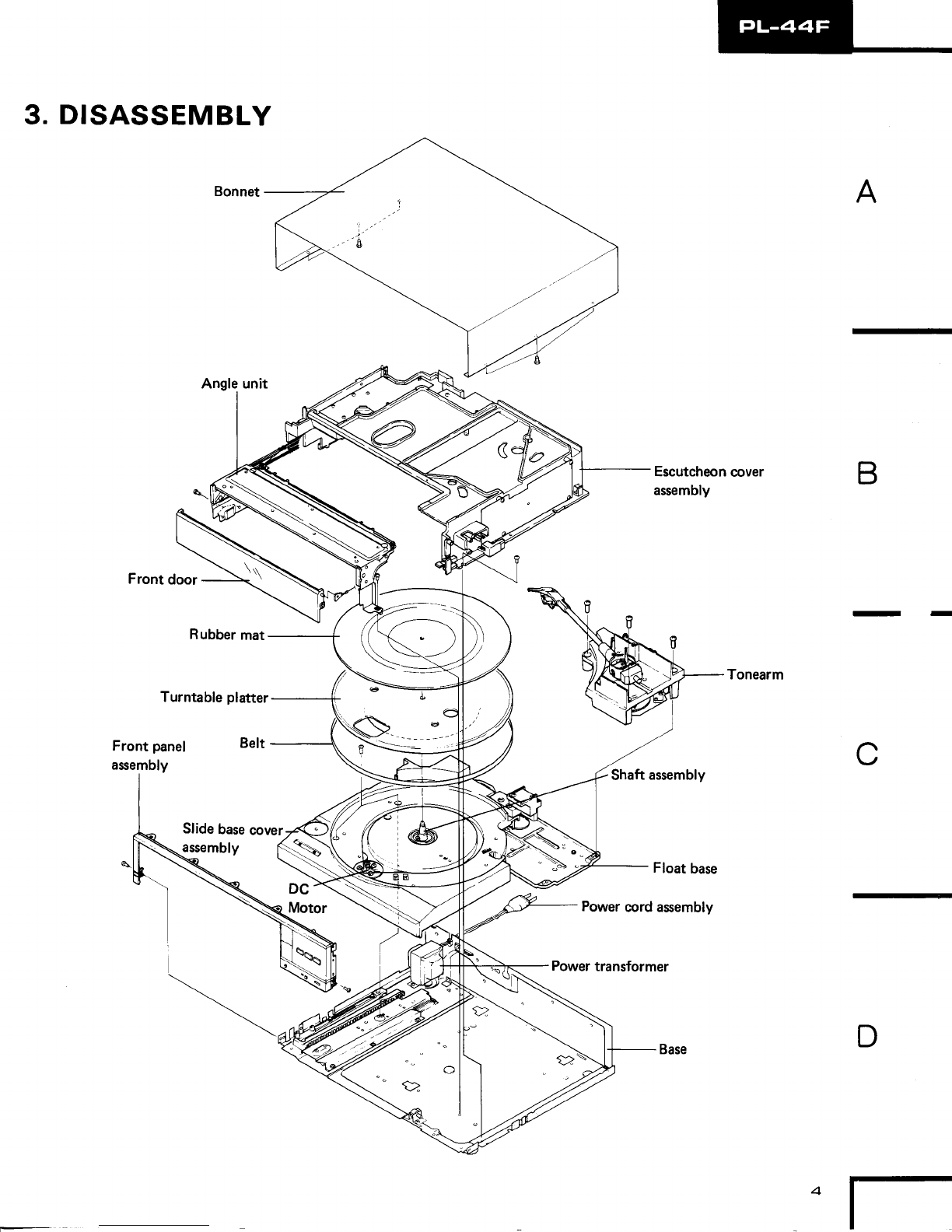

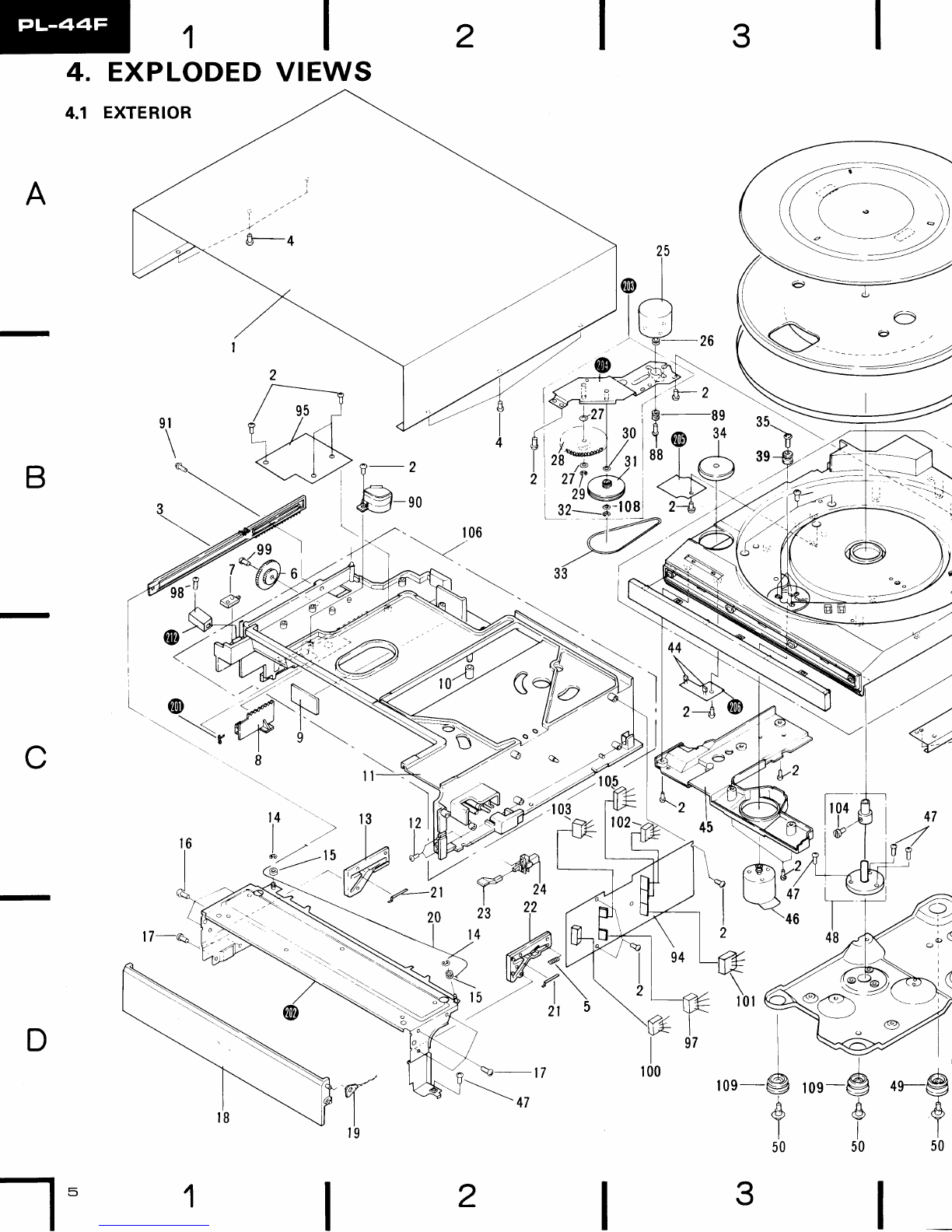

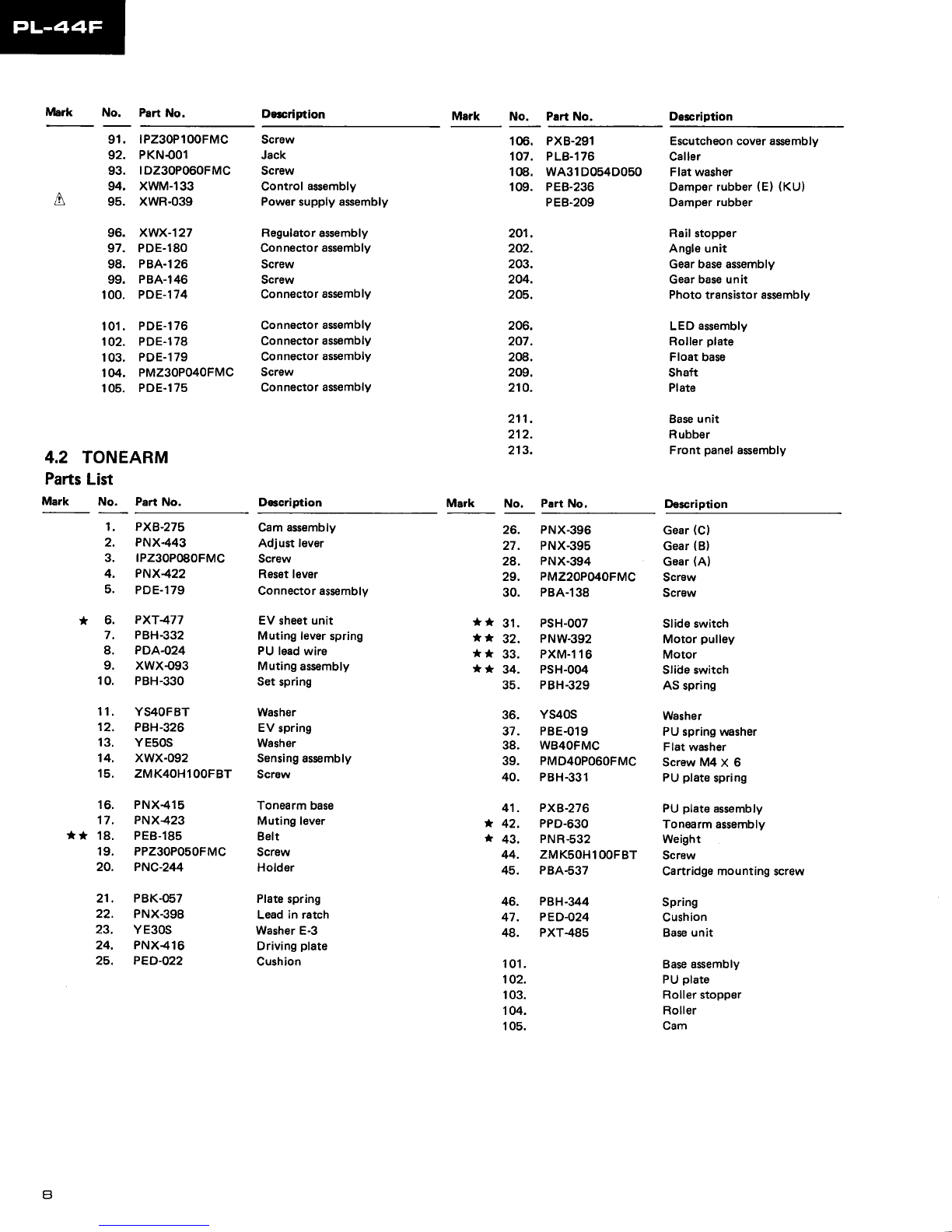

Pioneer PL-44F User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-71 User manual

Pioneer

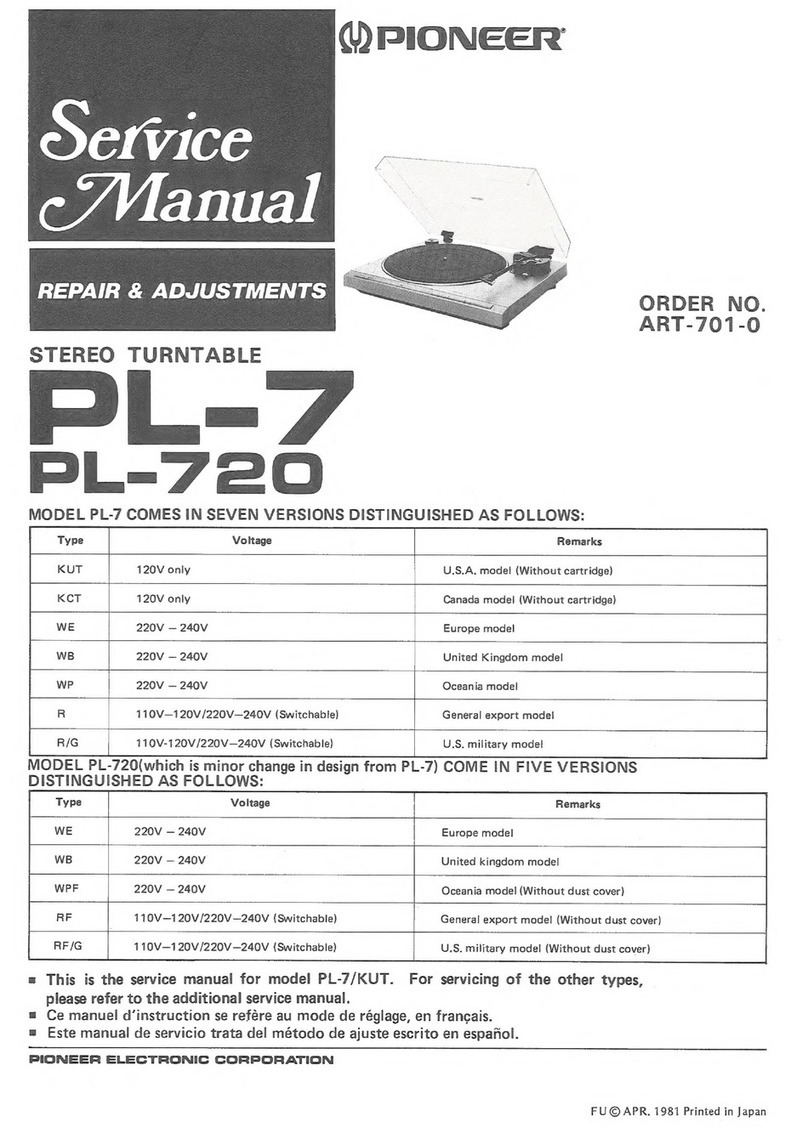

Pioneer PL-7 User manual

Pioneer

Pioneer C-5600DFV User manual

Pioneer

Pioneer PL-530 User manual

Pioneer

Pioneer PL-260 KU User manual

Pioneer

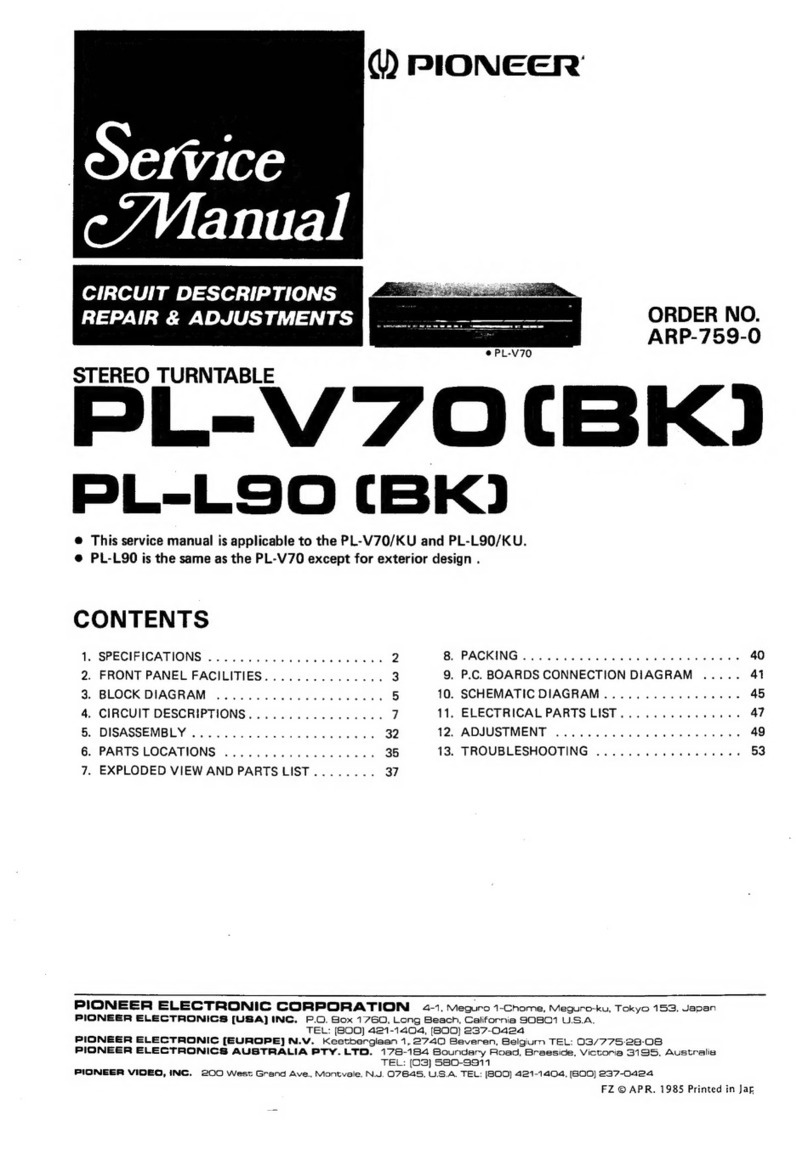

Pioneer PL-V70 User manual

Pioneer

Pioneer PL-117D User manual

Pioneer

Pioneer PL-516 KUT User manual

Pioneer

Pioneer PL-430 WE User manual

Pioneer

Pioneer PL-115D User manual

Pioneer

Pioneer P-15D User manual

Pioneer

Pioneer PL-55 User manual

Pioneer

Pioneer PL-510 User manual

Pioneer

Pioneer PL-570 User manual

Pioneer

Pioneer PL-200 User manual

Pioneer

Pioneer DEH-P6500 User manual

Pioneer

Pioneer PLX-1000 User manual

Pioneer

Pioneer PL-3000/HB User manual

Pioneer

Pioneer PL-518 User manual

Pioneer

Pioneer PL-55X User manual