PL-560

CONTENTS

1.

SPECIFIGATIONS

4.65

6

enw

eee

a

ewes

ew

eee

2

2;

PANEL,

FACILITIES

s25

600026

e8ee

e039

e458

3

3.

PARTS

LOGATION

32:

s2e5s¢ee20

0294

o

4

A.

DISASSEMBLY

ace

ee

ee

me

ee

5

5:

EXPLODED:

VIEW

snc

ce

wien

os

Gide

ee

boo

7

6.

ELECTRICAL

PARTS

LIST

fe.s

cen

n

cca

sis

13

7.

P.C.

BOARDS

CONNECTION

DIAGRAM

....

14

8.

SCHEMATIC

DIAGRAM

................

15

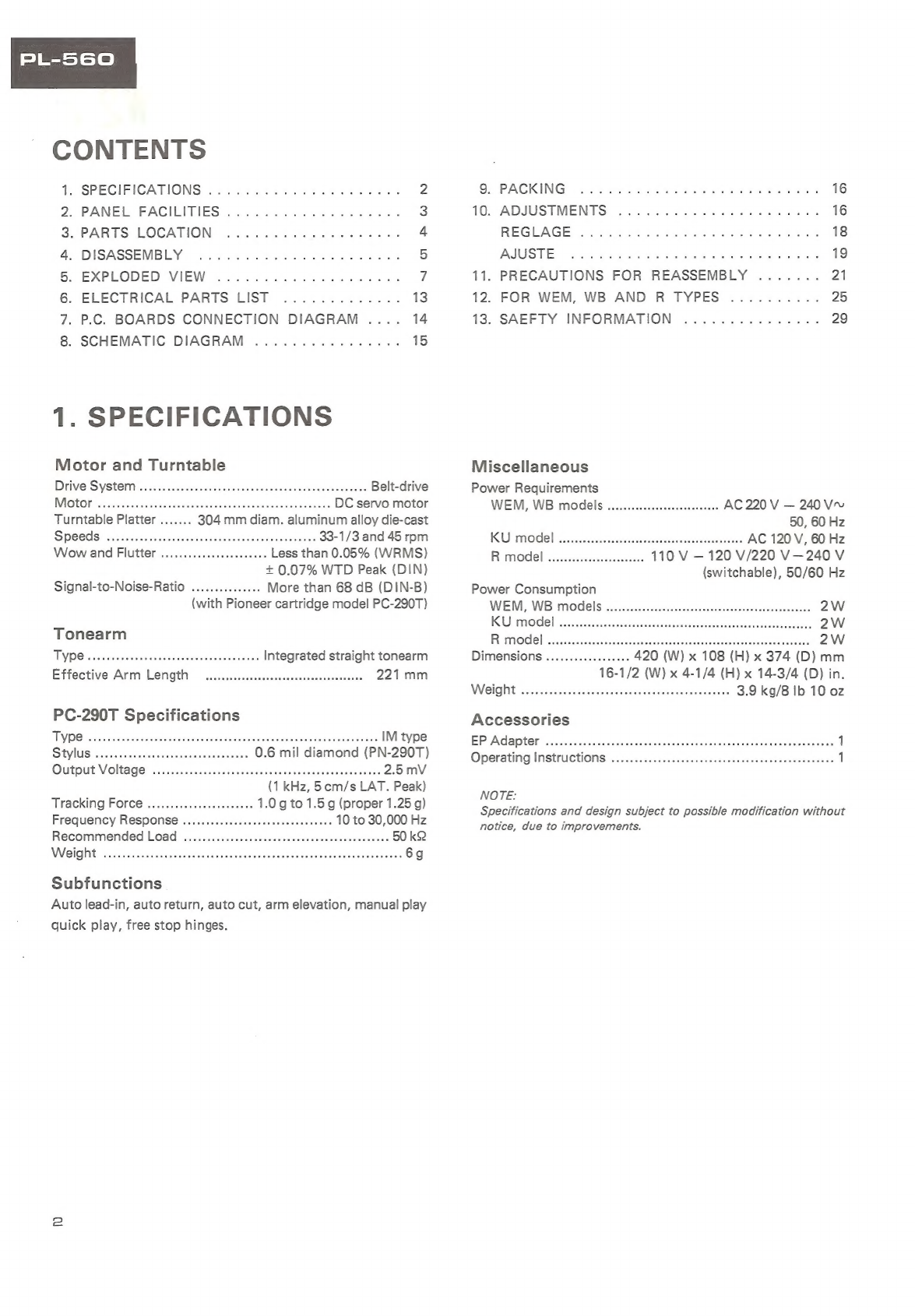

1.

SPECIFICATIONS

Motor

and

Turntable

DEIVE

SWStO

RA

sistas

wcrcracrsninwcctarwiereemnieninsnsoued

samaaasiiens

Belt-drive

MO

tor

scccveniad

seawsananin

sanshaxaeanansin

waenead

tenaba

DC

servo

motor

Turntable

Platter

.......

304

mm

diam.

aluminum

alloy

die-cast

SPECS:

sn

Sarauasadsaccanmmbocesass

vedas

teammates

33-1/3

and

45

rpm

Wow

and

Flutter

..............eceeeeees

Less

than

0.05%

(WRMS)

+

0.07%

WTD

Peak

(DIN)

Signal-to-Noise-Ratio

...............

More

than

68

dB

(DIN-B)

(with

Pioneer

cartridge

model

PC-290T)

Tonearm

TY

DG

s

asnasenected

ivneteinenacnnsenvea

cede

Integrated

straight

tonearm

Effective

Arm

Length

.....cccssssssesecssssrseeeesseeeeees

221

mm

MY

DG)

sis

svtiae

eeceannsens

Meeanaaas

tudes

mssmeae

ated

aes

aacuieed

nee

IM

type

SHVUS)

cssies

magna

cimaimcunasanresiemes

0.6

mil

diamond

(PN-290T)

OUTPUT

VOIAGE:

iciscncaccionicnoaninantannbimaaniemeiamaatenasam

en

aeis

2.5mV

(1

kHz,

5

cm/s

LAT.

Peak)

TraCking

FOre)

.

csicscsswssnsciisimnnienin

1.0

g

to

1.5

g

(proper

1.25

g)

Frequency

Response

saves

scsisnsevssaencessacecacnss

10

to

30,000

Hz

RECOMMENAGEE.LOAP)

serie

ssiinewssie

saictonicennie

cteoaendceeereions

50

kQ

WCIGHE:

snaticicunssiaonsitasaeatimecsimameaanesameneaeieceiamensmemedte

6g

Subfunctions

Auto

lead-in,

auto

return,

auto

cut,

arm

elevation,

manual

play

quick

play,

free

stop

hinges.

9.

PACKING

<2s3ianea0e

eae

Pedas

oe

wade

rn

16

10:

ADIGISTMENMS:

a6

a

s03.

6

4odie

eaaraccg!

es

bewrare

ahaa

16

REGLAGE

4.6440

440c000

Gene

beeaea

bn

18

AJUSTE.

2:

scbadenes

seeeedeecne

beau

5

19

11.

PRECAUTIONS

FOR

REASSEMBLY

.......

21

12.

FOR

WEM,

WB

AND

R

TYPES

..........

25

13.

SAEFTY

INFORMATION

...............

29

Miscellaneous

Power

Requirements

WEM,

WB

models?

siccvscssevsucsidssavexauss

AC

220

V

—

240

Vv

50,

60

Hz

WOE

esacensesuedetscossnadenwicesantenenceeeteas

AC

120

V,

60

Hz

RimOdel

ssisaveessvedages

cess:

110

V

—

120

V/220

V—240

V

(switchable),

50/60

Hz

Power

Consumption

WEM,

WB

models

........cccccccecsessseeeeeeeseceeterscneseeenenees

2W

KWiMOGEl:

sctscsrausaincdvenscatyunccieedeisecoestsssardavevacteaunsed

2W

RUM

OGE|

a

deoveveces

cousin

caasseaaverstanred/cxteceoneentamaguee?

2W

Dimensions

.............00008

420

(W)

x

108

(H)

x

374

(D)

mm

16-1/2

(W)

x

4-1/4

(H)

x

14-3/4

(D)

in.

WIIG

atcscciczccietscrescigareinareilevracanina

earnalneersrtetcaaretataat

3.9

kg/8

Ib

10

oz

Accessories

EPAGapten

sscccssrcccasar

cistexasanmamavananvercaesiniaaiandascemenadecaine

oa

1

Operating

INStHU

CONS

is

iesiisisssccadiansian

cocmensinsaaasrnanrdicmanieaaiins

1

NOTE:

Specifications

and

design

subject

to

possible

modification

without

notice,

due

to

improvements.