1

SET

rpm

PEAK

REV COUNTER

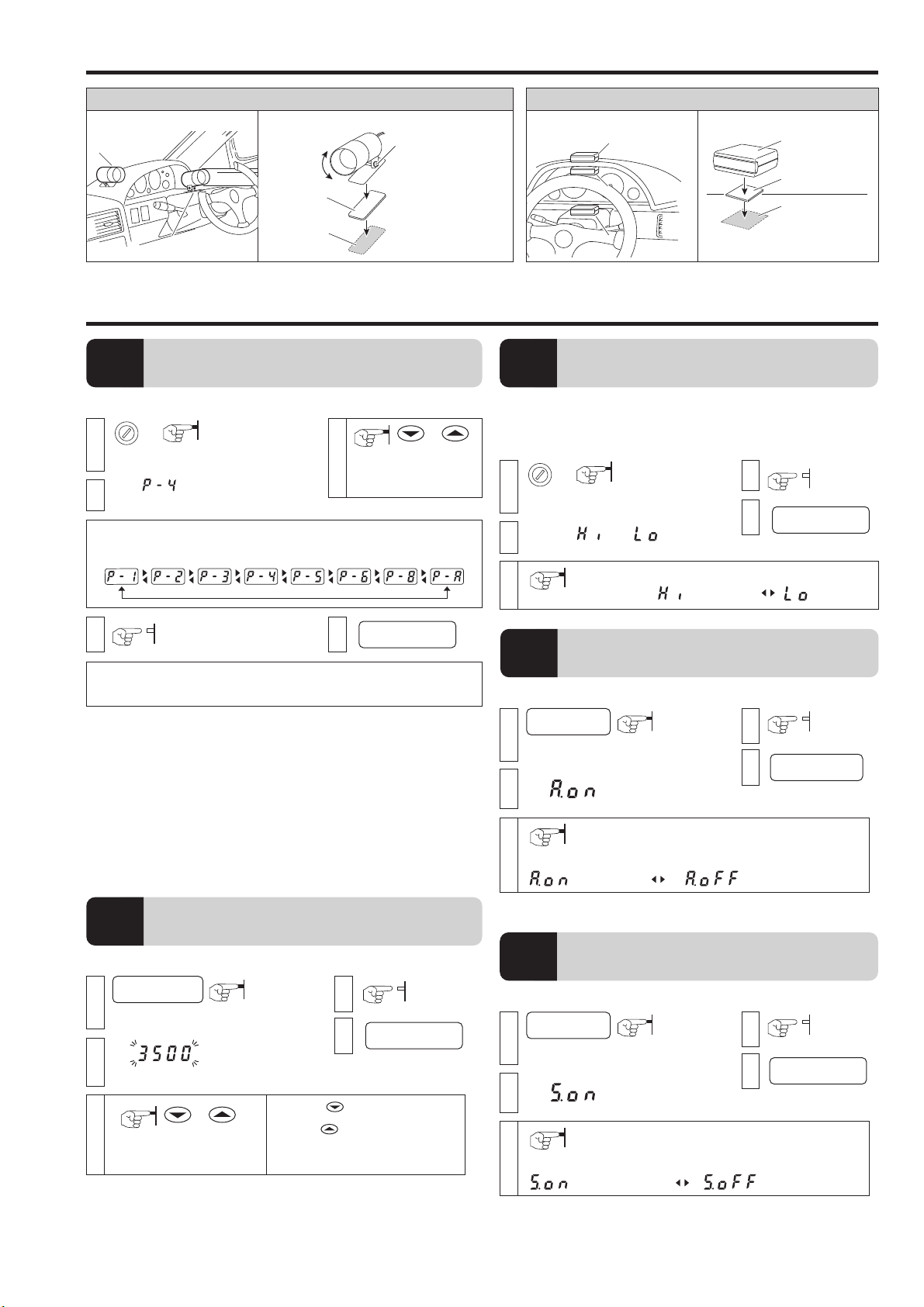

Zip Ties

× 5

Allen

Wrench

Double-sided

Tape

REV COUNTER

SHIFT LAMP & REV COUNTER for Pros

OBD2

Power Cable

with fuse 3A

Shift Lamp

User’s guide

ECU wiring

diagram list

Controller

■ Shift Lamp

Shift lamp lights up when the set rpm is reached.

・Ultra bright LED is easy to see even in full daylight.

・For night driving select auto low lighting or synchronize with parking lights.

・High quality aluminum machined body with swivel neck.

■ Digital Tachometer

High precision display for setting shift lamp and viewing rpm.

・High precision display of engine rpm up to 9999 in 1 rpm units.

・Shift lamp settings can be made in units of 100 rpm.

・View real time and peak engine rpm.

・Compact design needs no space.

■ Alarm

Alarm sounds at shift point for 0.5 seconds.

■ Easy Installation

Can be easily installed in some model TOYOTA and DAIHATSU cars

directly by connecting to the diagnostics connector. Other models can be

connected to the ECU.

■ Compatible Vehicles

12 V Gasoline Engine Cars (some diesel engine models)

For 1・2・3・4・5・6・8 cylinder models.

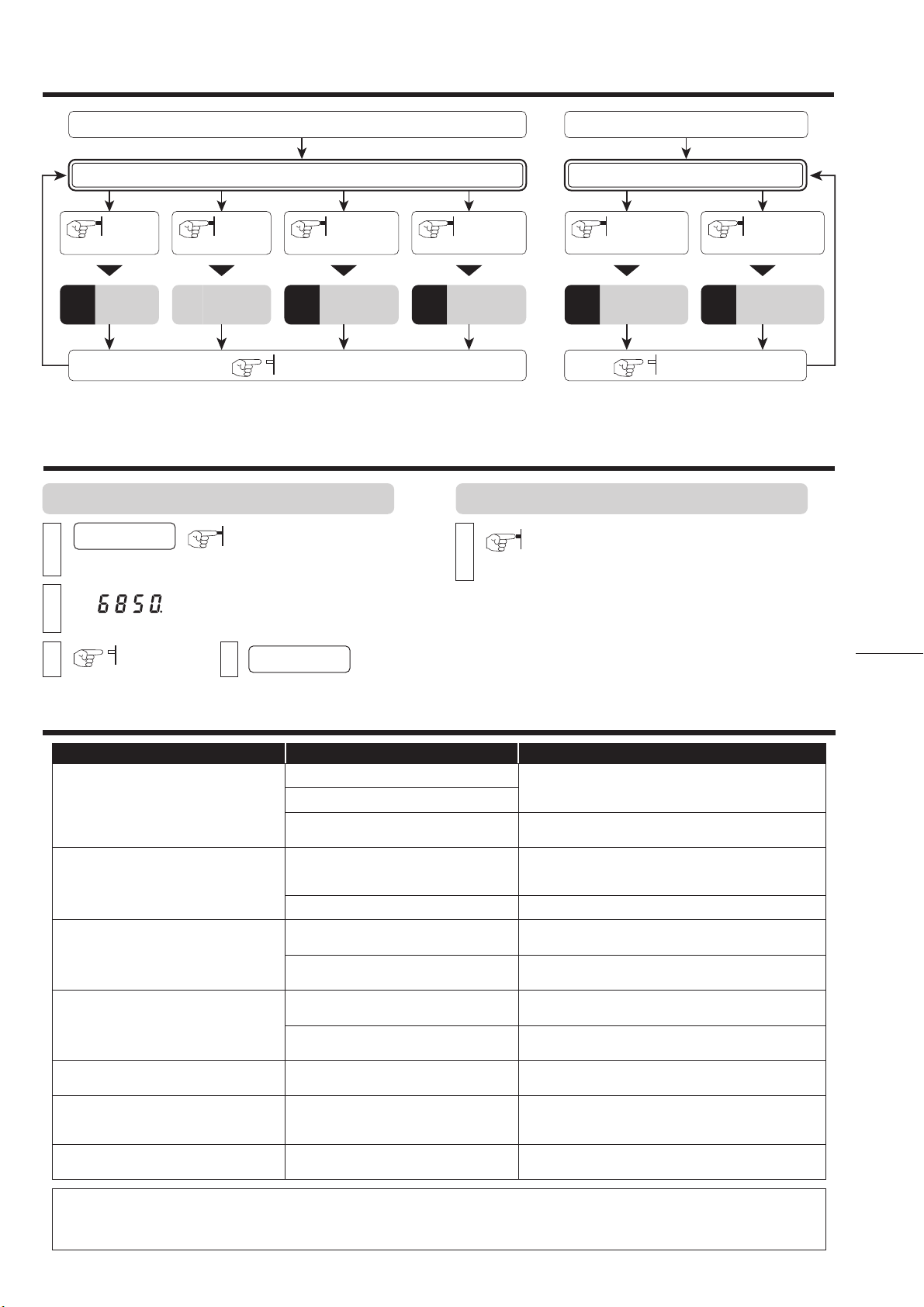

REV COUNTER RCX

■ Size

50

32

46

60

(Front) (Backside)

SET( ) switch

PEAK( ) switch

Display RPM and each setting display

Change each setting

Peak and change each setting

For Automatically low lighting

1

12 6

34 5

2

3

5-pin Connector Connect to the 5-pin Connector of Power cable

2-pin Connector Connect to the 2-pin Connector of Shift Lamp

Light sensor

4

5

6

Part Names of the Controller

20

(Shift Lamp) (Controller)

[Unit:mm]

●Do not work in areas where there is excessive exhaust.

Due to vehicle exhaust emission poisoning or fire may result in a damage to

humans.

●Please securely fasten the product to a stable place.

It is very dangerous if, while in use, the product falls off and interferes with braking.

●Do not crush the cable.

Please be careful that the cable does not get crushed by the seat rail or car door

steel plate, nor cut by any sharp steel plate as this may cause a poor connection or

an electric short leading to fire or other danger.

●Do not operate while driving.

Operating or checking the display during driving may cause an accident; please use

with the utmost consideration for safety.

●Please be sure to store bundle away all wires with tape, etc...

It is very dangerous to pull tangled wires by force or allow tangled wires to interfere

with driving.

●This product is for DC12V cars;

Installation cannot be carried out on cars with other voltage batteries.

●Just after installation do not exert any strong force on the product.

When double-sided tape is used for an installation be warned that when hot the

tape temporarily losses adhesiveness.

●Do Not Use Chemical Cleansers.

If the unit gets dirty please wipe with a soft cloth to remove any dirt. Do not use

chemical cleansers such as thinner, benzene, or alcohol.

●Do not install the product in any place subject to high temperature

or any place where water may be splashed.

●Make sure to replace all screws and parts to their original place.

●Do not install the product in a place where it will cause distraction.

●Do not, in any manner, process, take apart, or make changes to

this product.

WARNING Improper use or disregard of these warnings may

result in the injury or death of people. CAUTION Improper use or disregard of these warnings may

cause injury to persons, damage the product and

other things.

USER’S MANUAL

(RCX As of October, 2013 No.1)

Contents Please check the contents of the package

Product +

●If this product is given to

another user, make sure to

include this User’s Manual.

Thank you for purchasing this PIVOT product.

Please read this manual carefully and keep it for future

reference.

Contents / WARNING / CAUTION ……… 1

Features …………………………………… 1

Connecting The Wires …………………… 2

Installing The Product …………………… 3

Settings……………………………………… 3

Basic Operation …………………………… 4

Display The Peak Value and Reset …… 4

Troubleshooting …………………………… 4

Features

Cut Connectors

× 4

White

extension

cord

Earth

terminal