Table of contents

1 Safety guidelines.......................................................................................................................................................... 7

1.1 Organization of safety notices.................................................................................................................. 7

1.2 Safety Precautions ....................................................................................................................................... 7

1.3 Precautions for safe use.............................................................................................................................. 8

1.4 Environmental policy / WEEE .................................................................................................................... 8

2 Composition of acronym ........................................................................................................................................... 9

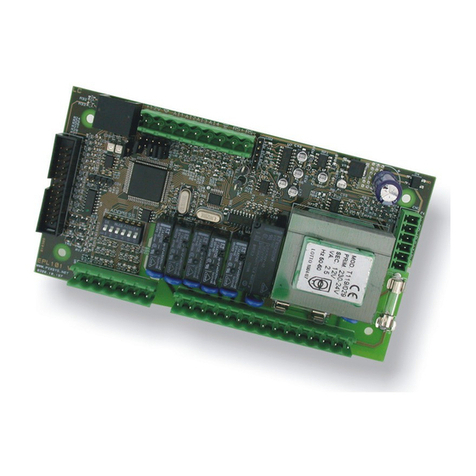

3 Technical data............................................................................................................................................................... 9

3.1 General characteristics ............................................................................................................................... 9

3.2 Hardware characteristics ........................................................................................................................... 9

3.3 Software features....................................................................................................................................... 12

4 Dimension and installation..................................................................................................................................... 12

4.1 Electric connections................................................................................................................................... 13

4.2 Connection to the communication line................................................................................................ 18

5 Device SET-UP ............................................................................................................................................................. 18

5.1 Numeric indicators (internal display).................................................................................................... 18

5.2 Meaning of the status lights (LED) ......................................................................................................... 19

5.3 Changing the configuration parameters from the terminal........................................................... 19

5.4 Changing to the configuration parameters from the MyPixsys app.............................................20

5.5 Table of the configuration parameters that can be accessible from the terminal and via the

MyPixsys app............................................................................................................................................... 21

5.6 Restore to factory settings........................................................................................................................22

6 Table of the configuration parameters for the models MCM260X-1/2/3/4AD ............................................22

6.1 UNIT A - GENERAL CONFIGURATION .....................................................................................................23

6.2 UNIT B - ANALOG INPUTS .........................................................................................................................24

6.3 UNIT C - DIGITAL INPUTS...........................................................................................................................25

7 Table of the configuration parameters for the model MCM260X-5AD.........................................................26

7.1 UNIT A - GENERAL CONFIGURATION .....................................................................................................26

7.2 UNIT B - ANALOG INPUTS .........................................................................................................................27

7.3 UNIT C - ANALOG OUTPUTS.....................................................................................................................29

8 Table of the configuration parameters for the model MCM260X-9AD.........................................................30

8.1 UNIT A - GENERAL CONFIGURATION .....................................................................................................30

8.2 UNIT B - ANALOG INPUTS ......................................................................................................................... 31

8.3 UNIT C - ANALOG OUTPUTS.....................................................................................................................33

8.4 UNIT D - DIGITAL INPUTS ..........................................................................................................................34

9 Modbus RTU ................................................................................................................................................................35

9.1 Characteristics of the Modbus RTU slave protocol.............................................................................35

9.2 Modbus RTU communication areas......................................................................................................35

10 CANopen ......................................................................................................................................................................44

10.1 SET-UP of slave CANopen node ..............................................................................................................44

10.2 Slave CANopen node operation .............................................................................................................44

10.3 EDS Files........................................................................................................................................................44

11 CANopen in detail......................................................................................................................................................44

11.1 Object Dictionary.......................................................................................................................................45

11.1.1 CANopen communication model ...................................................................................................46

11.1.2 CANopen Pre-defined Connection Set ........................................................................................... 47

11.1.3 CANopen identifier distribution.......................................................................................................48

11.1.4 CANopen boot-up procedure ...........................................................................................................48

11.1.5 Communication profile: initialization............................................................................................48

11.1 Communication Profile Area...................................................................................................................49

11.1.1 Device Type ...........................................................................................................................................50

11.1.2 Error Register.........................................................................................................................................50

11.1.3 Pre-defined Error Field........................................................................................................................50

11.1.4 COB-ID SYNC message....................................................................................................................... 51

11.1.5 Communication Cycle Period ........................................................................................................... 51