Chain Hoist PREMIUM PRO-E

5

1 GENERALLY

1.1 Intellectual property

2 WARRANTY

This user and maintenance manual should give your important details for the

saftey and reliability of your chain. It is not a replacement for a service security

edict and the accident prevention regulations stipulated by the employer‘s liabil-

ity insurance coverage respectively the scores of standards which are different

ineachcountry.Pleasefollowthecountryspecicstandardsandregulations.

The actual service security edict, the regulations of the employer‘s liability in-

surance coverage DGUV and the relevant legislation of the association for ma-

chines2006/42/EG(machinedirective)arevalidinGermany.

Hoist models, drawings and engineering are of our exclusive property. It is

expressly forbidden to copy, use or hand over to third parties such information

withoutaspecicwrittenpermission.

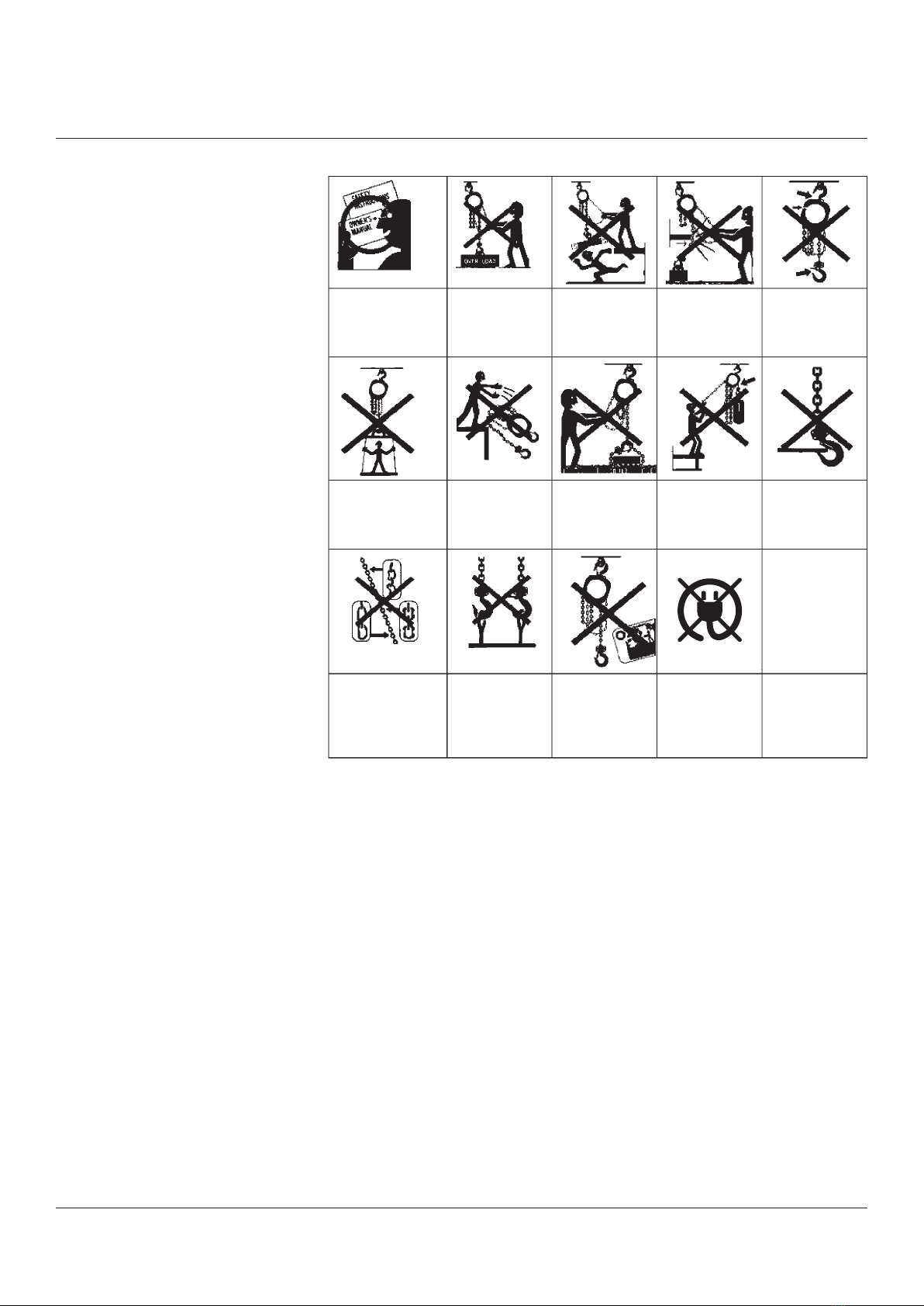

– Read instruction and make it available to operators on the device before use.

– Operator must be instructed properly with the device.

– Never leave the device under load unattended!

– Never exceed lifting capacity indicated on the name plate.

– Do not draw any pull and lifting chains over angles.

– Do not transport persons or loads with the product over areas where per-

sons could be.

– Drive the hoist only with battery powered devices with a maximum revolu-

tionsof25001/min.

– Device must be checked once a year by a technical expert, in case of

harder operating conditions more often. The enterpriser is liable in case of

damagesandhastoprovidetestcerticates.

– Check the device regarding damages, unfastened screws or twisted chain

before using it and eliminate failures.

– Repair works on hoisting devices shall only be carried out by the manufac-

turer or an instructed repair shop by using original spare parts.

– Check load carrying constructions, load securing devices, mountings, cross

beams etc. regarding load carrying capacity and condition of the required

loads by a technical expert.

– Non-observanceoftheinstruction,improperuse,andcorrosionbyinsuf-

cient protection or product alterations without authority result in expiry of the

warranty.

– Risk of corrosion in case of continuous contact with unfavourable atmos-

pheric conditions as for example high humidity or harmful environmental

inuencesatmosphereswithacidvapours,corrosivegasesorhighdust

concentration cause early wear. This effectuates no claim under warranty.

– Further information or spare part lists will kindly be provided by us or your

specialist dealer