Plockmatic BM 60 User manual

Other Plockmatic Booklet Maker manuals

Plockmatic

Plockmatic SR85 Cover Feeder User manual

Plockmatic

Plockmatic BLM 35 User manual

Plockmatic

Plockmatic CF5030 User manual

Plockmatic

Plockmatic BLM 35 User manual

Plockmatic

Plockmatic SR85 Cover Feeder User manual

Plockmatic

Plockmatic BM 61 User manual

Plockmatic

Plockmatic BK5030 User manual

Plockmatic

Plockmatic Bm 2000 User manual

Plockmatic

Plockmatic BOOKLET MAKER Pro 30 User manual

Plockmatic

Plockmatic Bm 2000 User manual

Plockmatic

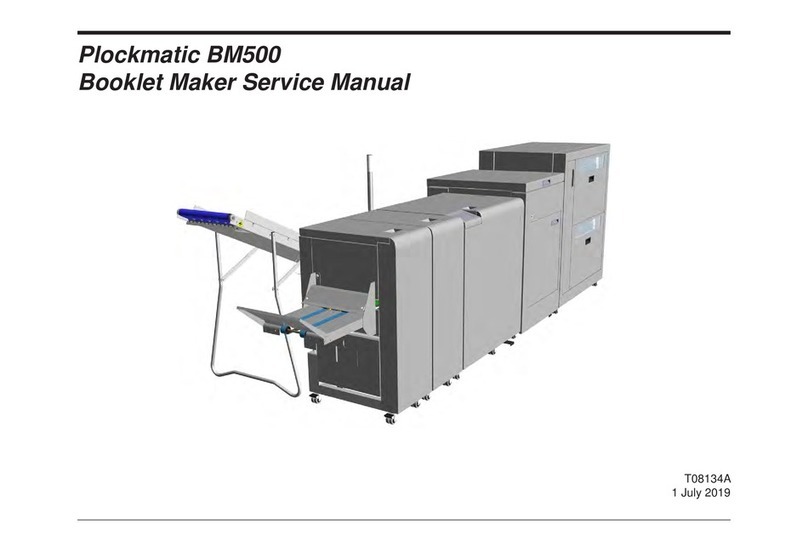

Plockmatic BM500 User manual

Plockmatic

Plockmatic BK5030 User manual

Plockmatic

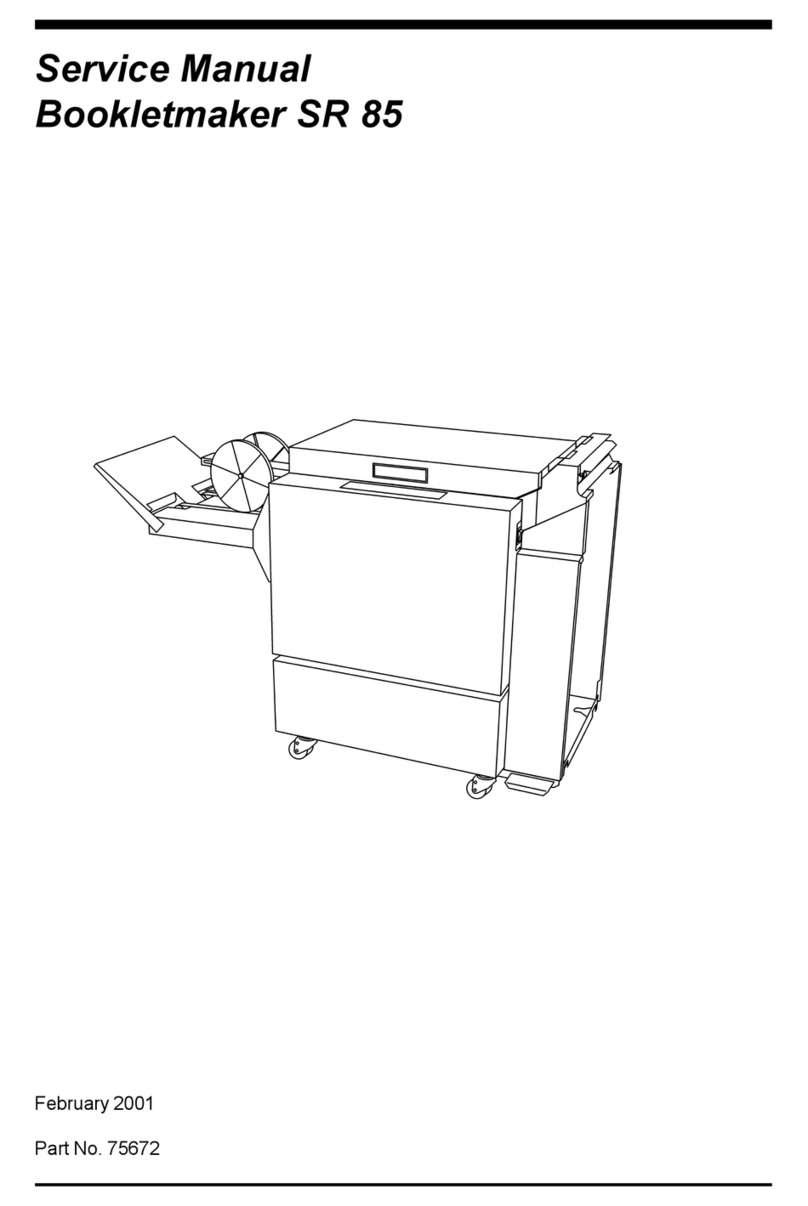

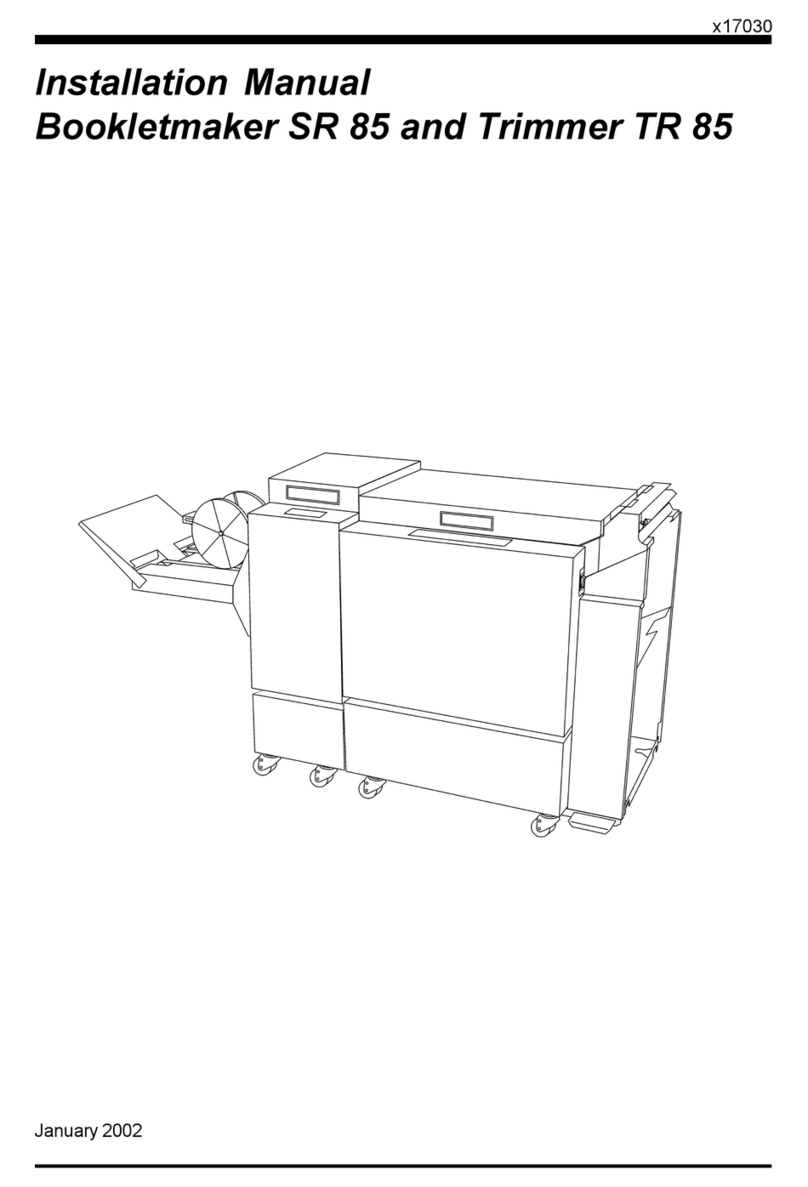

Plockmatic SR 85 User manual

Plockmatic

Plockmatic SR90 User manual

Plockmatic

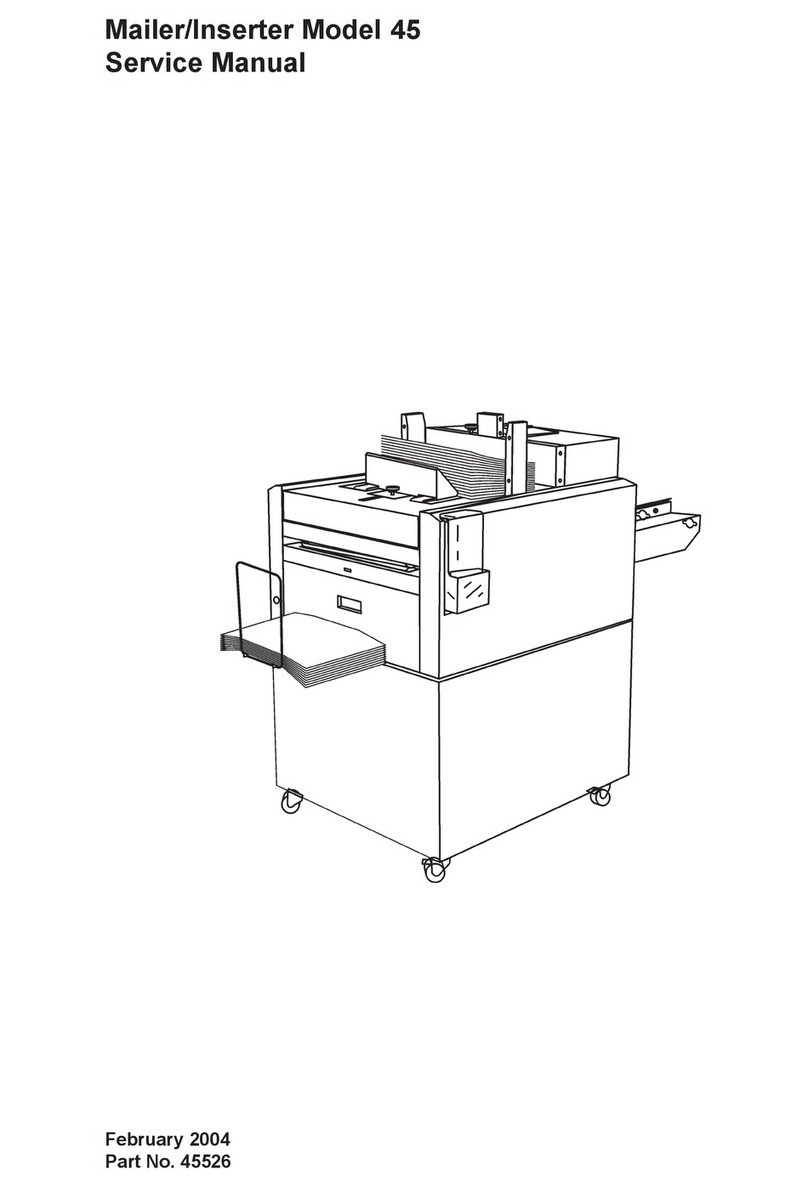

Plockmatic 45 User manual

Plockmatic

Plockmatic Pro50 User manual

Plockmatic

Plockmatic SR 85 User manual

Plockmatic

Plockmatic Bm 2000 User manual

Plockmatic

Plockmatic Morgana PowerSquare 160 User manual

Plockmatic

Plockmatic BM 15 User manual