The 9950 is a multi-channel, multi-sensor transmitter designed to meet and exceed the

industry standards, and expectations for a small, compact, ¼” DIN transmitter. The power

and versatility of the 9950 allows the use of up to six GF sensors to manage complex water

treatment applications.

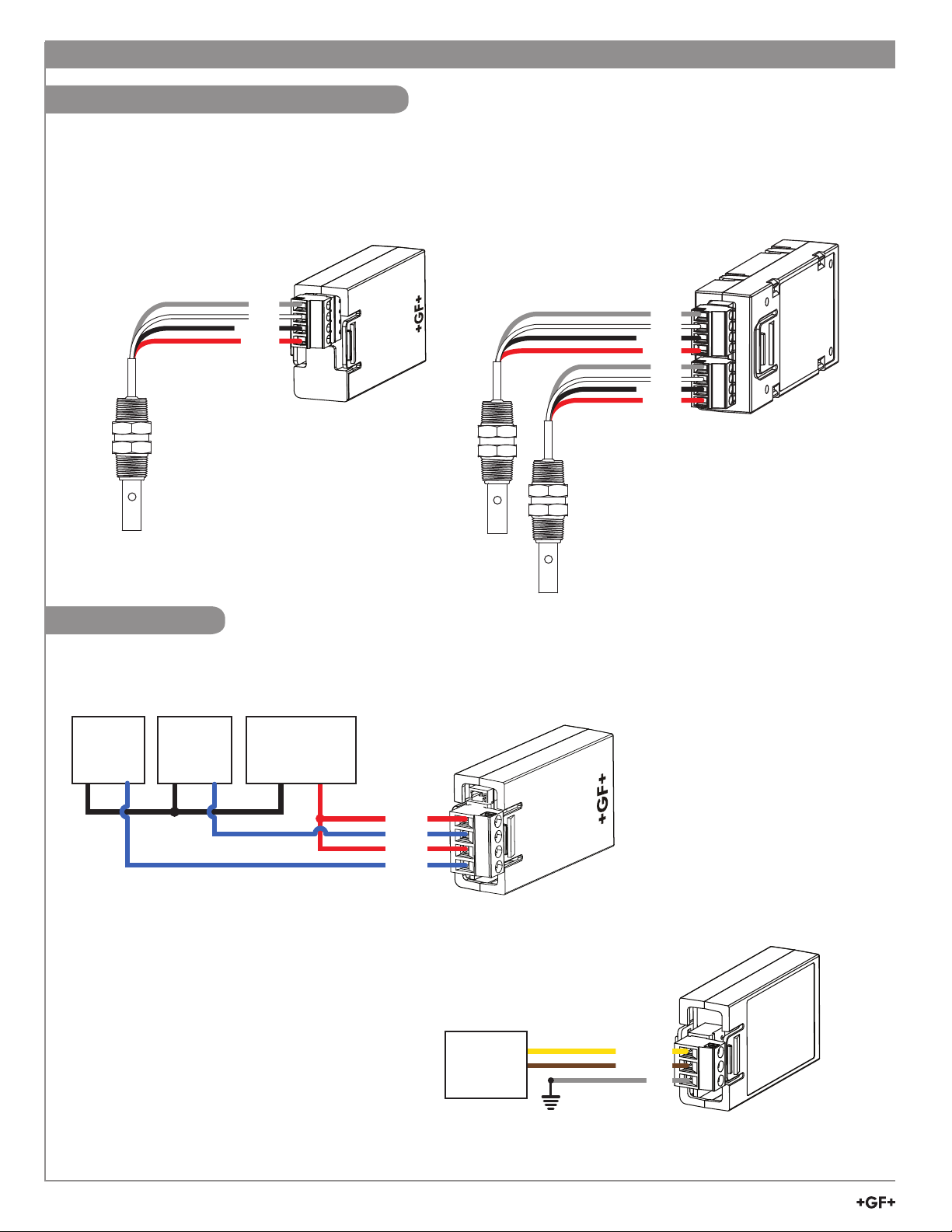

The 9950 analyzer supports all like sensors or a mix of any GF sensors. Sensor types and

accessories supported by the 9950 are GF Flow (frequency and/or digital S³L), pH/ORP,

Conductivity/Resistivity, Salinity, Temperature, Pressure, Level, Dissolved Oxygen and any

device that transmits a 4 to 20 mA signal when used with the single channel

3-8058 iGo® Signal Converter.

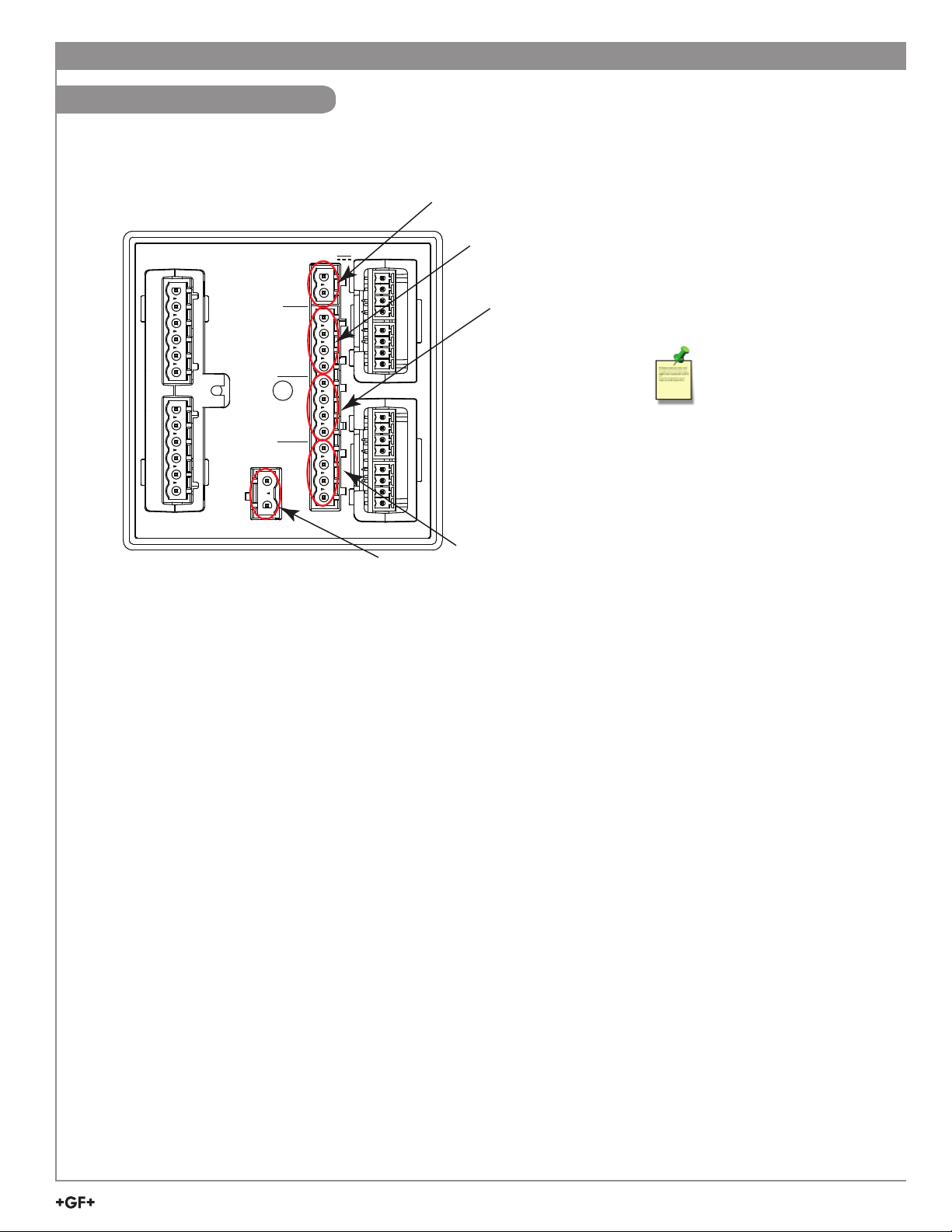

The 9950 base unit comes complete with two each 4 to 20 mA output, two additional dual 4

to 20 mA output modules can be installed to increase the number of 4 to 20 mA outputs to a

total of six outputs.

Four Conductivity sensor measurements are supported with either a single or dual channel

conductivity module. If six conductivity sensors are required, the use of a 3-2850-51-XX

can be added to the main S³L input terminals.

The 3-9950.393-3 Relay Module provides four binary inputs that are compatible with any

open collector or mechanical contacts, such as level switches, flow switches, pressure

switches or other devices. The 9950 offers advanced features such as derived functions,

advanced multiple relay modes (Boolean logic) and timer-based relay functions.

The 9950 Modbus Module allows for remote access to primary and secondary

measurements, derived functions, status of current loop outputs and relays, over a serial

RS485 Modbus automation network.

The 9950 supports the following modules:

• Four Channel Mechanical Relay Module

• Two Mechanical and Two Solid State

Relay Module

• Two Mechanical Relays and Four Binary

Inputs Module

• Single Channel Conductivity

Resistivity Module

• Dual Channel Conductivity Module

• Dual Channel 4 to 20 mA Current Loop

Output Module

• Modbus Module

*3-9950-10.090*

GF 9950 Six-Channel Transmitter

3-9950-10.090 Rev. 1 01/23

3-9950-10, -11

Operating Instructions (Refer to pg. 11)

Description

Compatibility

The 9950 is compatible with all GF products

listed in the column to the right.

• pH/ORP electrodes require the GF 2751

DryLoc® Sensor Electronics

(sold separately).

• Conductivity/Resistivity measurement

requires the GF 2850 Conductivity/Resistivity

electronics or a single or dual conductivity

module and proper conductivity sensor

(sold separately).

English

Sensor

Model

Freq

Output

Digital (S3L)

Output

Requires

8058-1

515 X

525 X

2000 X

2100 X

2250 X

2350 X

2450 X

2507 X

2536 X

2537-5 X

2540 X

2551 XX

2552 XX

258X XX

U1000 XX

U3000 XX

U4000 XX

2260 X

2270 X

2290 X

2291 X

2610-51 X

2751 X

2850-51-XX* X

2850-61* X

2850-63* X

• English

* No conductivity module required

E171559

CUS