MultiSmart®Arm/ENG/USA/CAN/6/16

Energy Saver

For automatic start/stop of fan. Adjustable overrun

period of between 7 sec. to 6 min. Incl. inductive sensor

with 5 m, (16 ft) cable. Built-in contactor

must be fitted with relevant fan-motor overload

(not included). Power supply: 3~¨230/400 V*.

Prod. no ES-90-005 incl. 75 VA/24 V

transformer for hood light.

Prod. no ES-90-006 incl. 75 VA/24 V

transformer. For two arms with lights.

Complementary products and accessories

Fan Airflow

Freeblowing

m3/h, CFM

Motor

kW V

(50Hz)

1300, 765

1300, 765

1800, 1059

2100, 1236

2100, 1236

3000, 1766

4700, 2766

6000, 3532

1300

1301

1800

2100

2101

3000

4700

6000

0,37 kW 3~ 400 V*

0,37 kW 1~ 230 V*

0,55 kW 3~ 400 V*

0,75 kW 3~ 400 V*

0,75 kW 1~ 230 V*

1,10 kW 3~ 400 V*

2,20 kW 3~ 400 V*

4,00 kW 3~400 V*

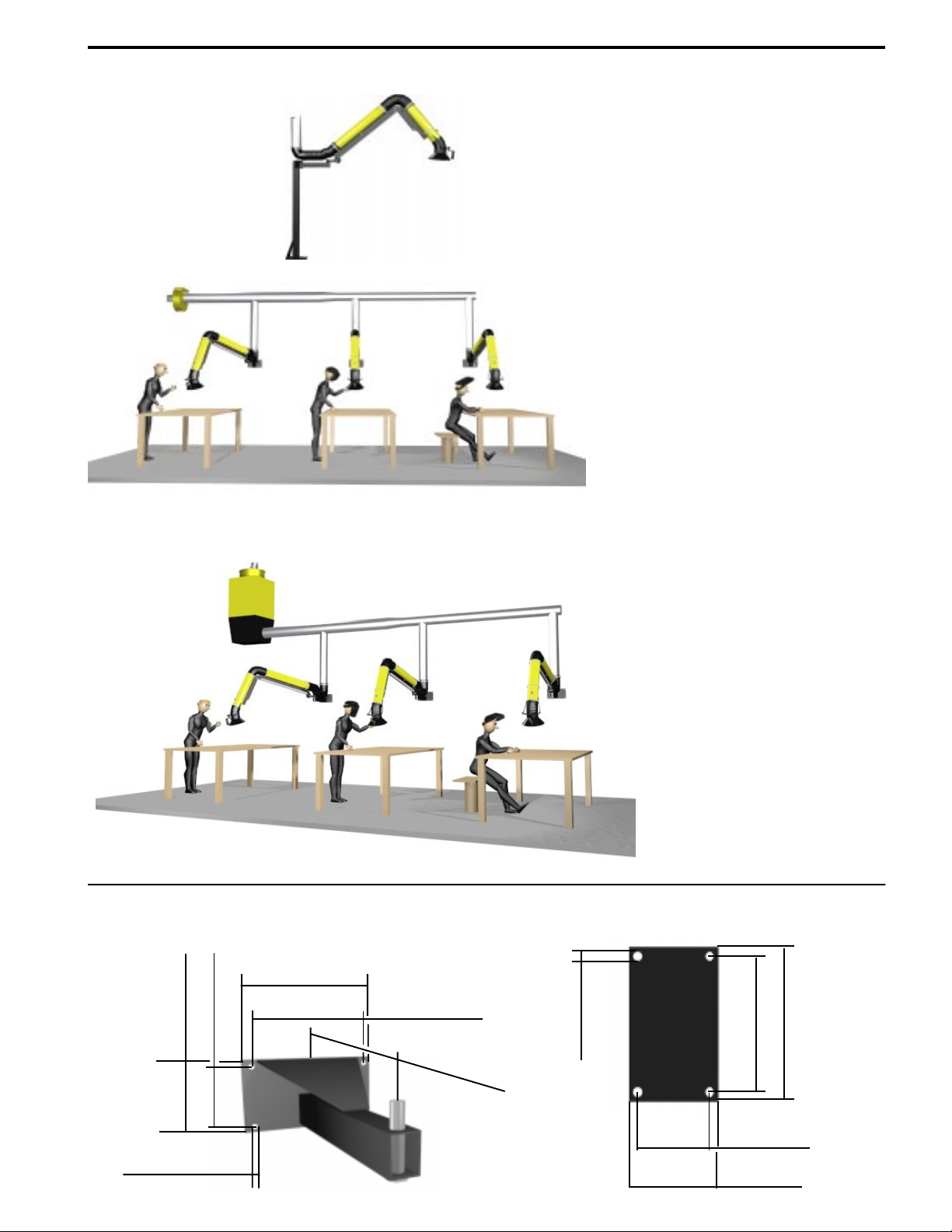

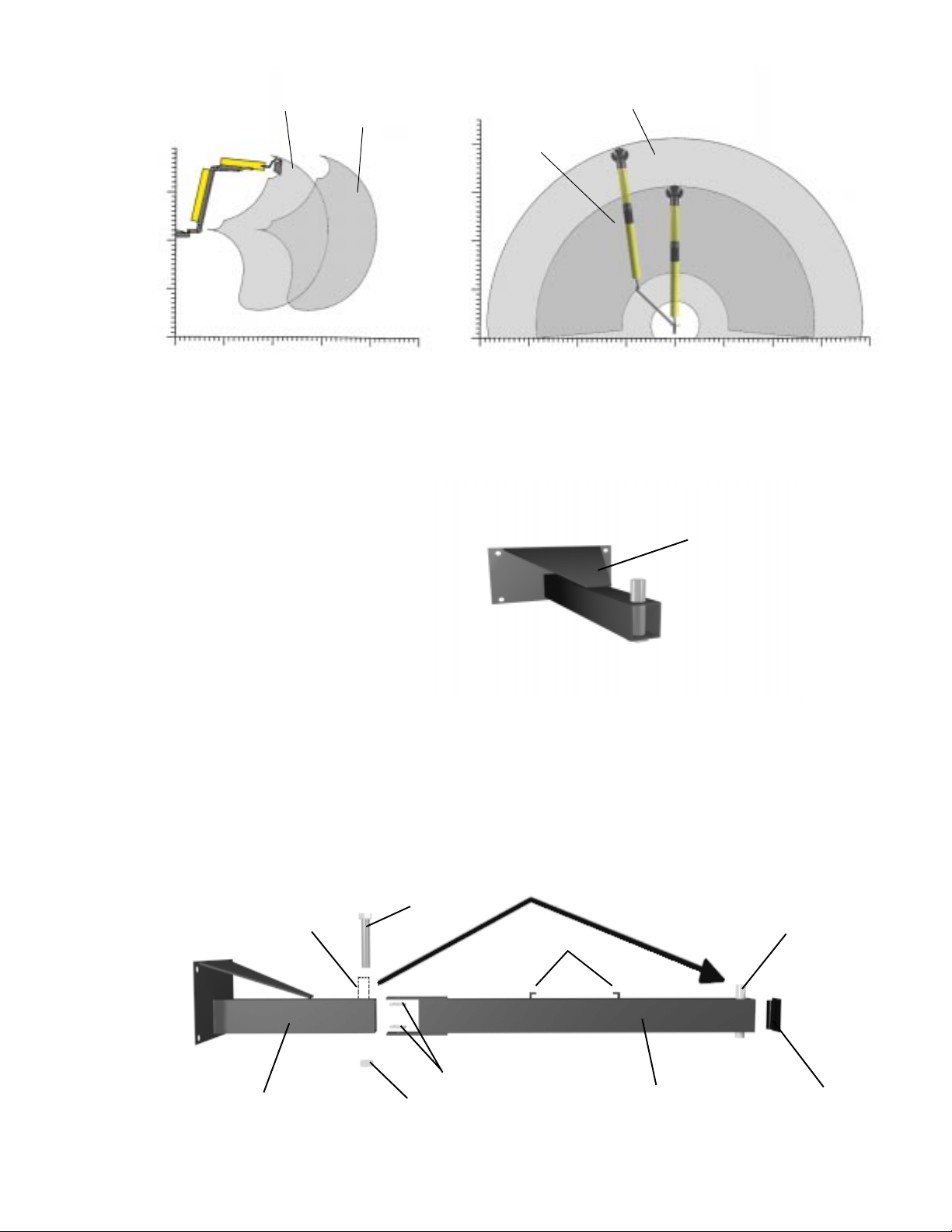

Stanchion

Accessory for ceiling, floor or wall mounting

of MultiSmart®Arm.

Length: 110 cm, 3.6 ft. Prod. no PA-110

Length: 220 cm, 7.2 ft. Prod. no PA-220

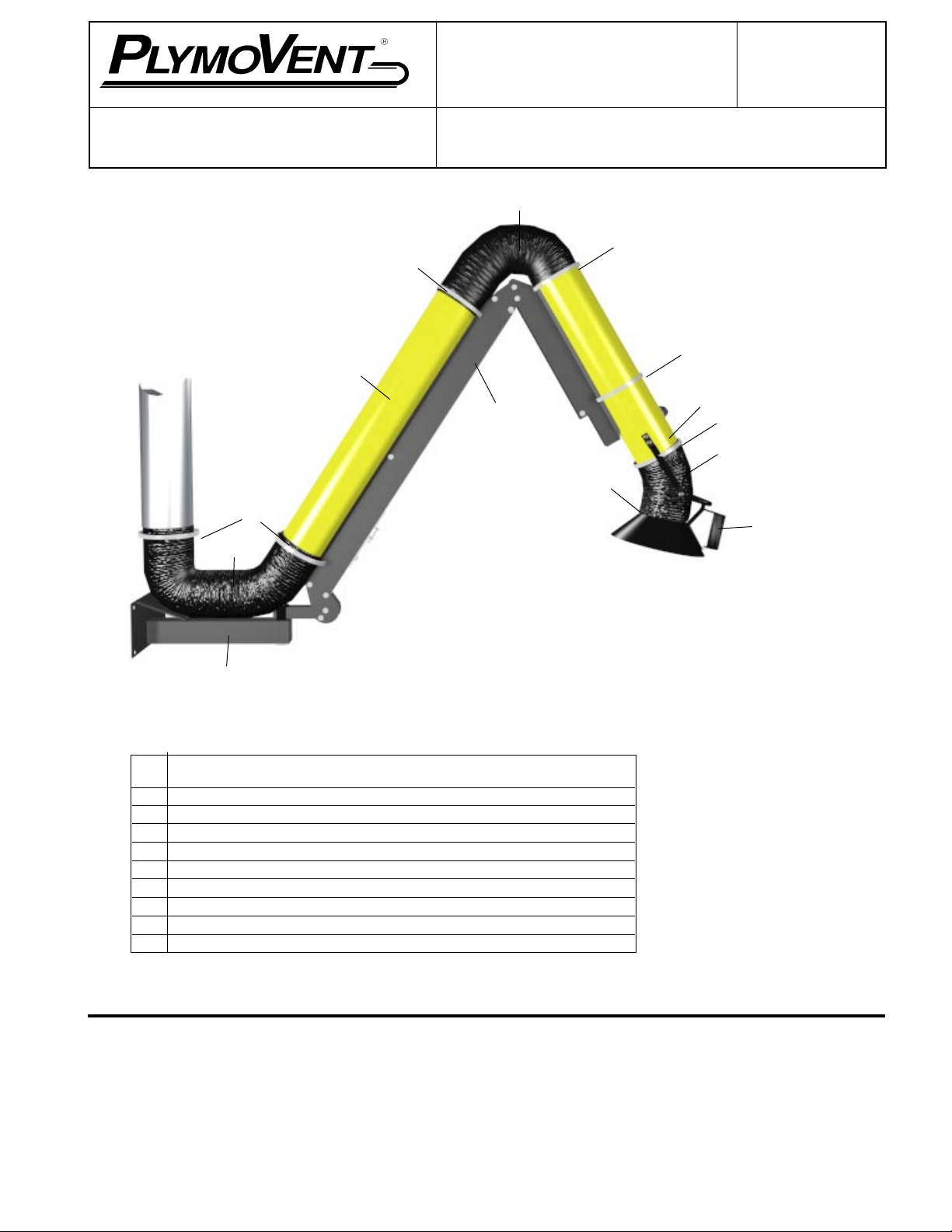

SmartArm Extention kit

Contains all neccesseary items to convert a 3

meter, (10 ft) arm to a 4 meter, (14 ft) arm.

Prod. no SAE-125-4

Prod. no SAE-160-4

Prod. no SAE-200-4

Transformer

230 V* – 24V/75 VA transformer for

halogen lamp cartridge HL-20/24.

Prod. no TR-24/75

Fully automatic damper

Fully automatic motordriven damper for fitting

to Ø 160 mm, 6" Ø duct. Adjustable overrun

period between 7 sec. and 6 min., to

capture after-fume. Inductive sensor

with 5 m (16 ft) of cable is included

as standard. Power supply: 1~ 230 V*.

Can be complemented with switch

assembly (S-100) for manual

control.

Prod. no ASE-12

Control unit

For automatic start/stop of a central fan in

a system with several extractors. To be used in

conjuction with the Energy Saver or Automatic

Damper. Power supply: 3~ 230/400 V*.

Prod. no M-1000

Fans FS and FA

Available in many sizes with free blowing air volumes

from 1300 m3/h, 765 CFM to 6000 m3/h,3532 CFM. A

unique anti-spark impeller made from aluminium gives

maximum security.

NOTE! ALL FANS MUST BE FITTED

WITH RELEVANT MOTOR OVERLOAD

PROTECTION (NOT INCLUDED).

Starter

For manual start/stop of the fan via a switch in

the hood. Complete with switch assembly and

10 m, (33 ft) cable. Built-in contactor must be fitted

with relevant fan motor overload (not included).

Power supply: 3~ 230/400 V*.

Prod. no SA-24/75 incl. 75 VA/24 V

transformer for halogene lamp on one workstation.

Prod. no SA-24/75-2 incl. 75 VA/24 V transformer

for two halogene lamps on two workstations.

Halogen lamp cartridge

To be fitted in the hood. Consists of 20W/

24 V halogen lap, switch assembly and

10 m, (33 ft) cable. Must be complemented

with transformer TR-24 or Starter SA-24.

Prod. no HL-20/24-125

Prod. no HL-20/24-160

Prod. no HL-20/24-200

Switch assembly

Switch assembly with 10 m(10 ft) cable for manual

operation from the hood of fan and light. Also

supplied as standard as part of ES-90 and ASE-12.

Inkl.

Prod. no S-100

Damper kit

Contains all necceseary items to

install a ratchet damper for fine

tuning the airflow through the arm.

Prod. no D-125

Prod. no D-160

Prod. no D-200

* Other voltages and frequences for motors are available.

* Other voltages are available

* Other voltages are available

* Other voltages are available

* Other voltages are available

* Other voltages are available

FS

* Is not available in MSAS

* Not available in MSAS