The earth wire shall be installed in conduit where there is a risk of

mechanical damage or damage as a result of exposure to sunlight.

Where installations are located inside of a building and a TN-C-S

system is pre-installed and the vehicle may only be charged inside the

building the PME earth maybe used, In the case of socketed home

charger where the charge cable does not form part of the charger it

should not be installed inside a garage (customers charge cable may

enable charging outside of garage area)

In some installation additional bonding maybe required for external

metallic structures, metal garages, iron fences etc. if the vehicle or

EVSE could come into contact with the structure (i.e. if the structure

and vehicle can be touched simultaneously) .

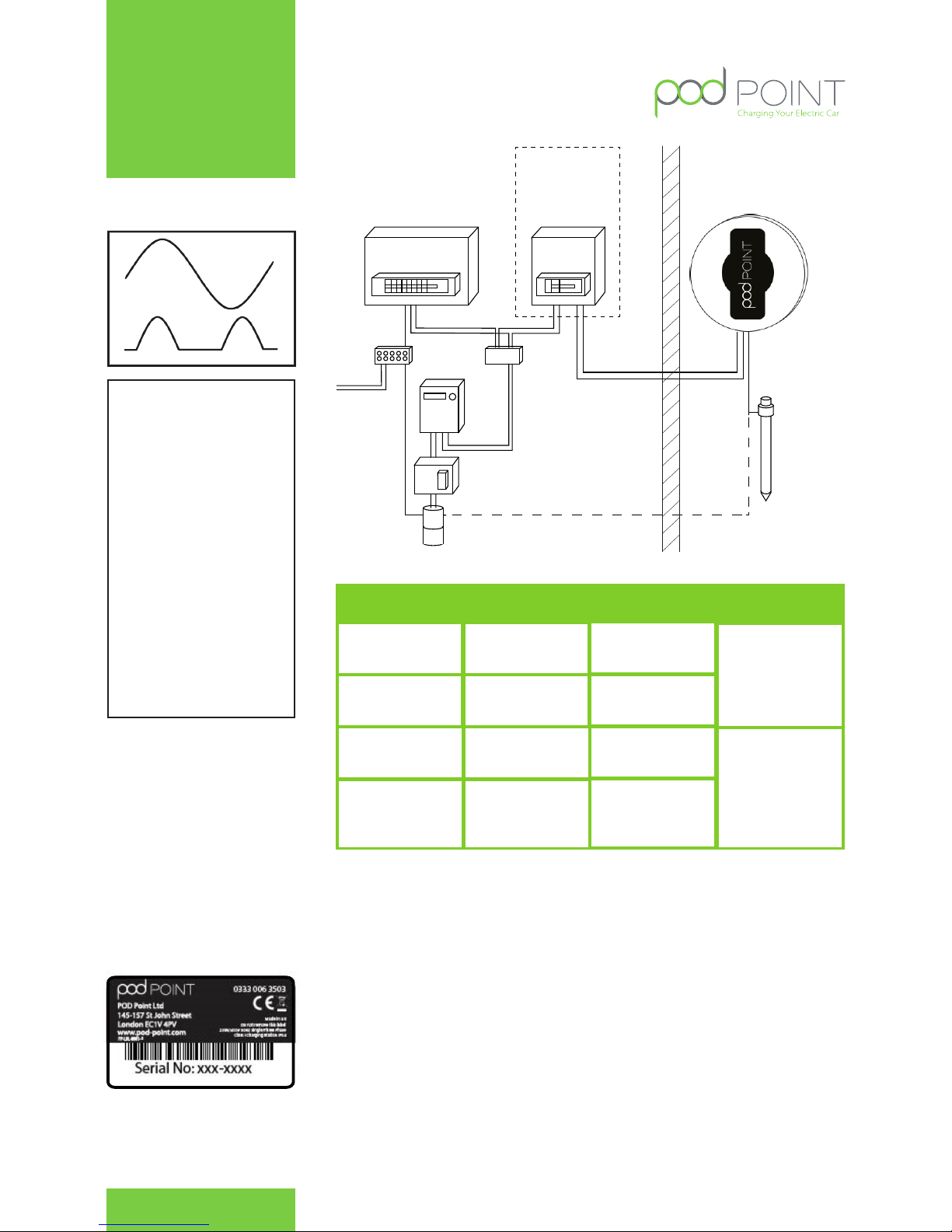

Array systems:

In case of several charging stations connected to the same power

supply line, an additional local ground connection will have to be

ensured in order at least , every 10 outlets. The maximum resistance

for each additional ground connection (taken independently) will

have to be less than 167 ohms. All the ground lines will have to be

connected to ensure a single equi – potential zone.

Transformers

If the earth is not achievable then a transformer is required. In Mode

IT or TT> 150 Ohms: An isolating transformer with separate windings

is placed upstream EVSE. This one must then be fed in mode TN. The

Neutral feed of the transformer shall be connected to PE before the

RCD and MCB (if 2 pole MCB is used), resistance measured between

the EVSE PE and this Earth must be less than 167 ohms.

Mode IT is prohibited

All installations must comply to BS7671 regulations.

Isolation and Switching for Security and

Maintenance

To ensure that the POD Point Solo unit can be “turned off” to enhance

security and enable maintenance and repair activity, a double

pole switch (or isolator) suitably rated shall be installed within the

customer’s property in an accessible location. The switch should be

mounted at a height of between 450mm and 1200mm above finished

floor level to achieve compliance with Building Reg’s. An isolator

switch is a mandatory required for “new builds”, but optional for

existing dwellings (for additional security at customers request).

Installation Procedure

The POD Point Solo has been designed as a wall mounted

device. The installer should confirm that the wall that the unit

is intended to be fixed to is structurally appropriate for the

mounting of the POD Point Solo. The installer should identify

the construction of the wall, and identify the correct and

appropriate fixings to use.

• The Installer has a duty of care to ensure that the POD

Point Solo unit is securely attached to the wall or

structure where the unit is intended to be operated

from.

• Once the location and height of the POD Point Solo

unit has been decided, the installer can begin marking

the wall with indicator points to locate the unit. Use drilling

template to locate the holes.

• Before drilling commences ensure that the installation

wall has been checked for electric cabling or pipework

with a suitable detector.

• It is highly recommended this is done prior to any

installation work commencement (drilling of fitting of

conduit etc) to allow the customer to visualise where

the unit will be installed. Once the installation site is

marked up, confirm with the customer this meets their

expectations.

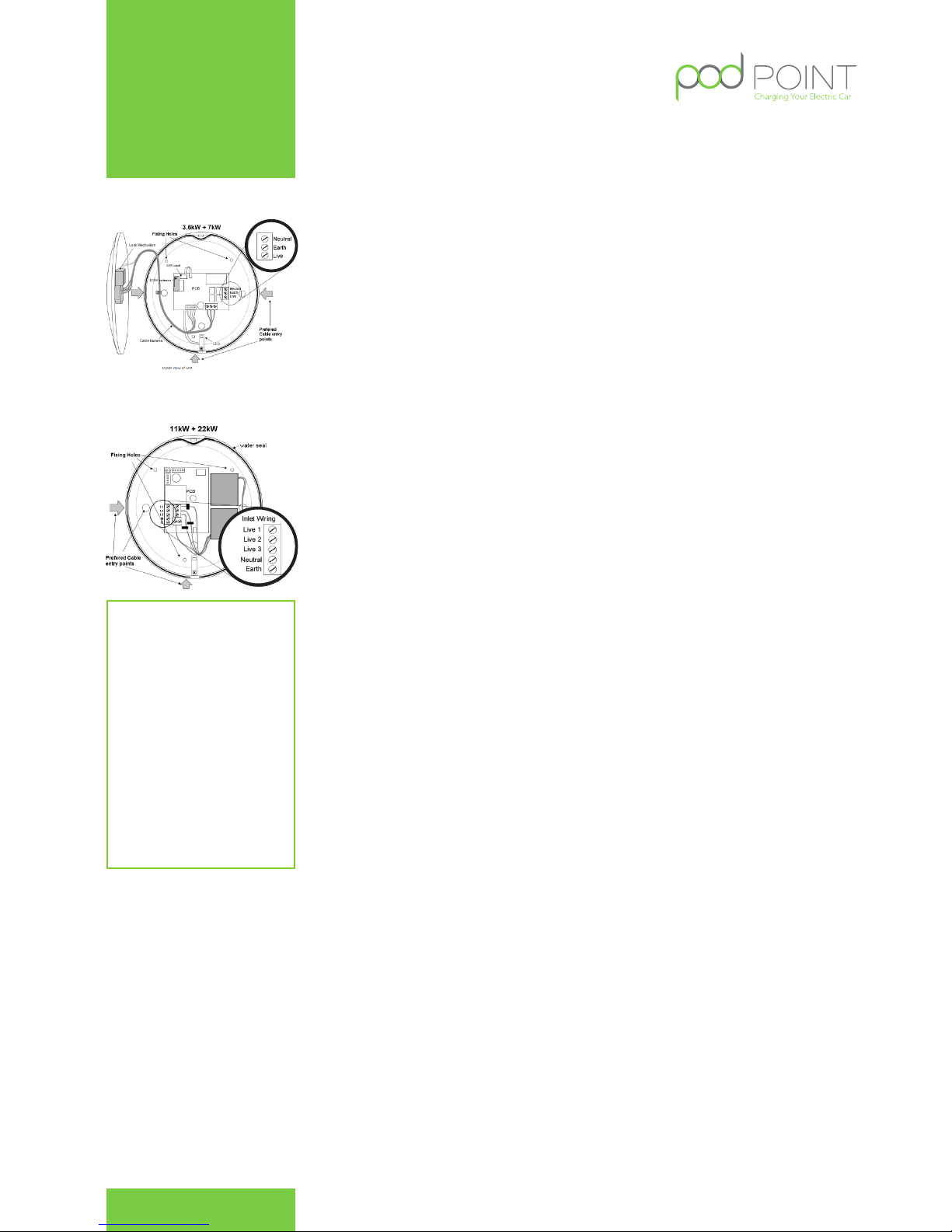

Drilling the Holes for the Electrical Supply

Cable Entry

As the electrical supply to the POD Point Solo may be fed from a

number of directions; the unit has been designed to accept supply

conduit entry on either the left or right sides or via rear entry (if supply

wiring has already been chased into the wall)

The installer should drill a suitable hole for the cable entry grommet/

adapter to be used to accept the electrical supply cables in EITHER the

left, right or rear of the unit (depending on direction that the electrical

supply approaches). Flat surfaces have been provided at either side

of the unit for ease of drilling. Once drilled the installer should fit an

appropriate cable gland or conduit adapter for the type of conduit

being used to supply the unit.

When drilling the case:

1. Only drill in the flat surfaces provided on the left, right or

rear of the unit. Do not drill on any curved surface.

2. Take care not to damage any wiring or components inside

the case. Place a suitable stop (e.g. block of wood) inside

the case when drilling to prevent accidental damage.

3. If any of the wiring or components are damaged during

installation DO NOT CONNECT OR SWITCH ON THE POWER

before consulting with POD Point.

4. The wall can now be drilled for the 3 mounting holes and

depending on the wall structure solid/dry lined or stud

partition, appropriate fixings can be used to fit the unit to

the wall. Do not drill with the unit in position as masonry

dust may damage the unit. Use the recommended drilling

template included in the box.

5. The rear of the unit should then be fitted to the wall by

fitting the top/upper screw first so the remaining 2 screws

positions can be easily aligned and fitted.

6. Once fitted in place, the rear unit should be securely fixed

flush to the wall.

POD Point July 2015

PP - D - 001

POD Point Technical Manual

Contact:

020 72477117

www.pod-point.com

4