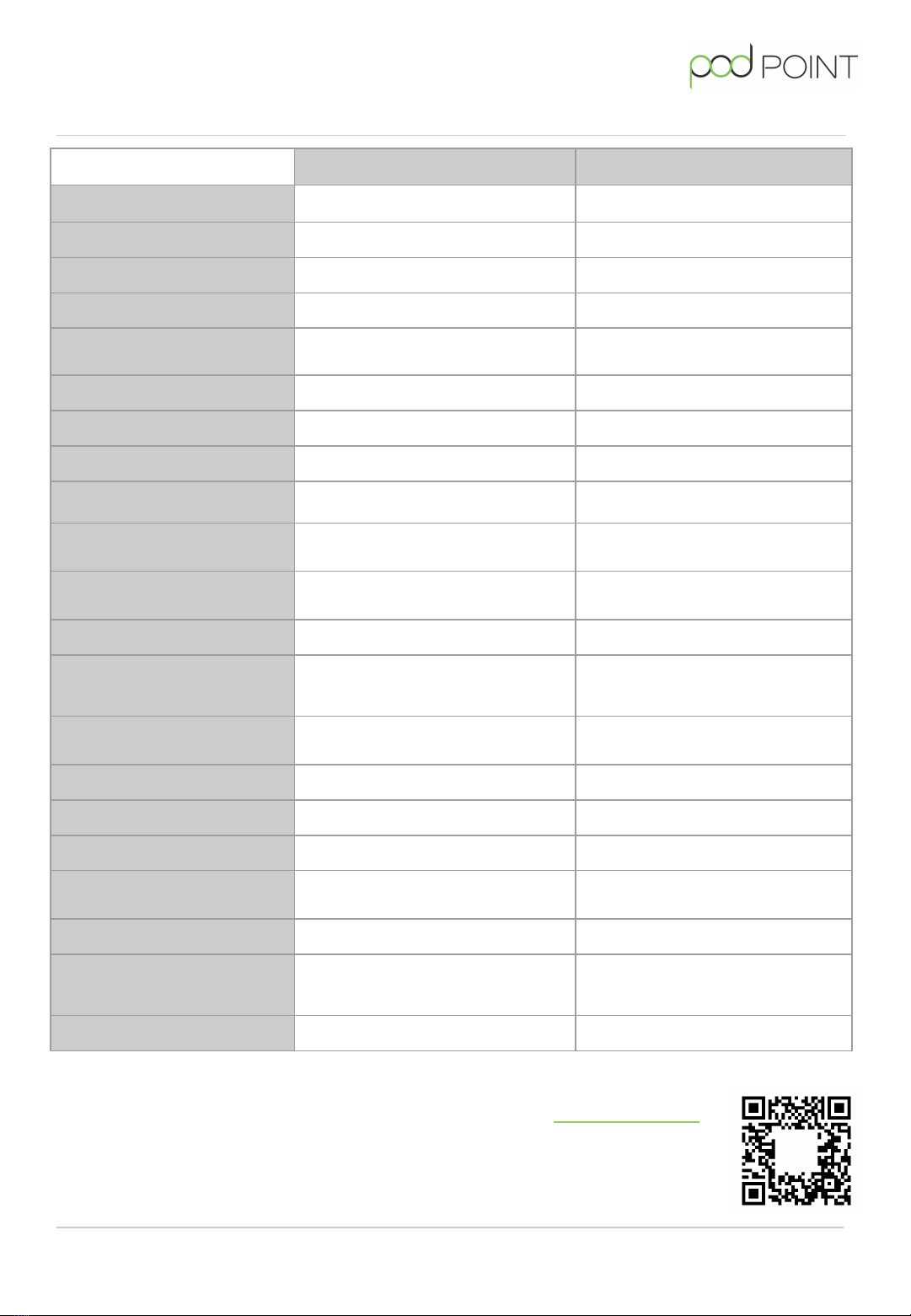

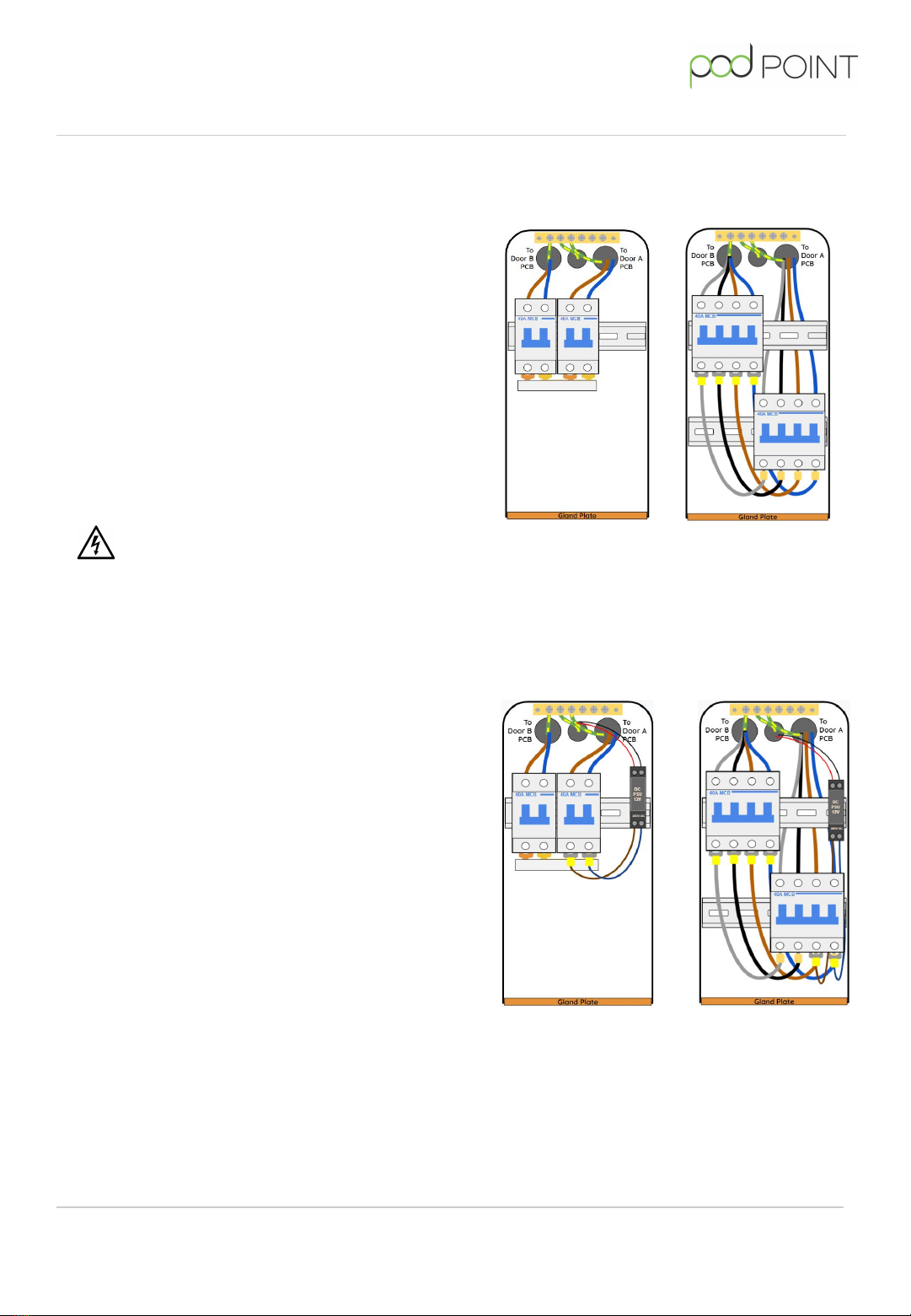

Single-phase (T7) Installations

Single phase T7 Twin Chargers require a 230V AC supply capable of supplying 32A per door. This can

be achieved using a Single Supply, Dual Supply (2x single phase circuits) or a Polyphase Supply (

2

phases of a three phase system and a common neutral

). Cables must be suitable for the installation

method chosen and be adequately protected against mechanical damage / stress. Circuits and

supply cables must be able to carry the nominal load current and combined prospective fault current

for the Twin Charger. The Twin Charger must be protected against overcurrent and fault at the

source of supply by a suitably rated MCB, MCCB or fuse (see below for current ratings).

Single Supply (80A, 1 phase)

1x 3-Core Cable (1 phase + Neutral)

Route the supply cable

into the DBOX through

the cable gland. Install

the Live & Neutral

supply cables into the

cable terminals on the

Right side MCB (Door A).

These should be

pre-connected to the

Left MCB (Door B) via a

pre-installed 2-Pole

4-way Fork Busbar -

verify that the fork

busbar is correctly

connected. Connect the

CPC to the Earthing

terminal at the top of

the DBOX.

Single Supply - Polyphase (80A, 3 phase)

1x 5-Core Cable (2 phase + common Neutral)

Route the supply cable into the

DBOX through the cable gland.

Remove the pre-installed

2-Pole 4-way Fork Busbar,

remove the end cap and

remove the fork busbar rail

connecting the live terminals

together. Replace the end cap

and reinstall the busbar to link

the two neutrals together -

ensure the busbar has been

connected correctly. Install the

L1 & Neutral cables in to the

cable input terminals of the

right MCB (Door A), now install

the L2 cable into the left MCB

(Door B). Connect the CPC to

the Earthing Terminal at the

top of the DBOX.

Twin Charger

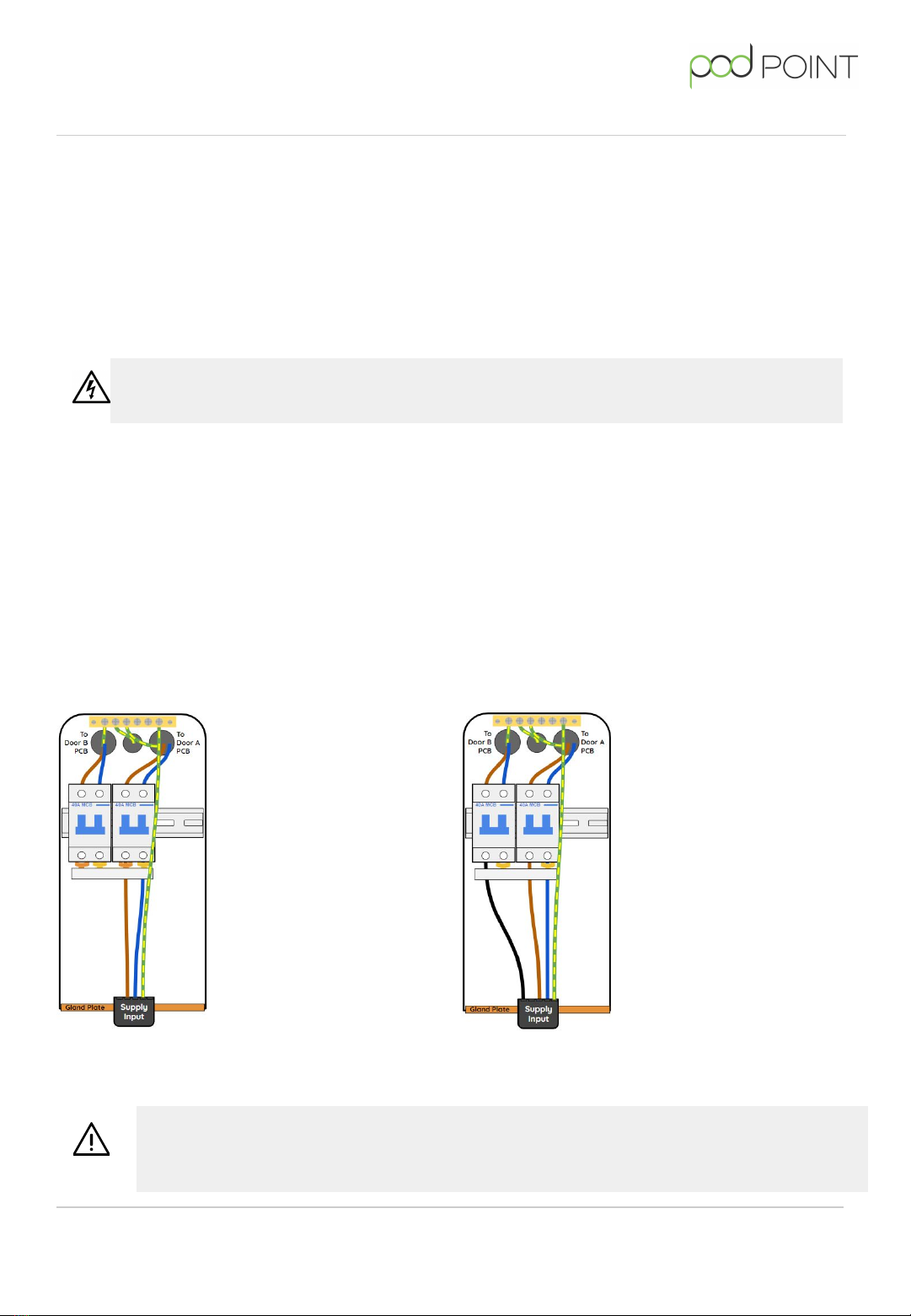

DANGER! If the Twin Charger is to be connected to a TT earthing system, an RCD

must be provided at the source of supply.

IMPORTANT! 5 core supply cable is recommended for a polyphase supply to

ensure a dedicated CPC identified by green & yellow sheathing is provided. Please

ensure spare conductors are safely terminated.

Where there is a requirement for a RCD to be fitted in the supply circuit, for example where a TT

earthing system is being used, it must be of time delayed type with a rating over >100mA to avoid

conflict with the in-built 30mA RCDs - for single supply and polyphase arrangements cumulative DC

leakage currents should be considered - Please ensure compliance to BS 7671 (722.531.3) is met.

For dual supply arrangements (individual circuit per charging socket) the RCD should be at least

type A - type AC RCDs must not be used.

10

PP-D-210456-3

Twin Charger

Installation Guide (Web Version)