0000138874 rev. 1.0 3

1.4 WARNINGS

Caution! Risk of electrical shock

I

Check the voltage of the main power source and make sure that it matches the available input voltage

(100-240 Vac) of the transformer inside the WashBasic.

I

Adding or replacing pumps, pump tubes or other components should only be performed by qualified

personnel

I

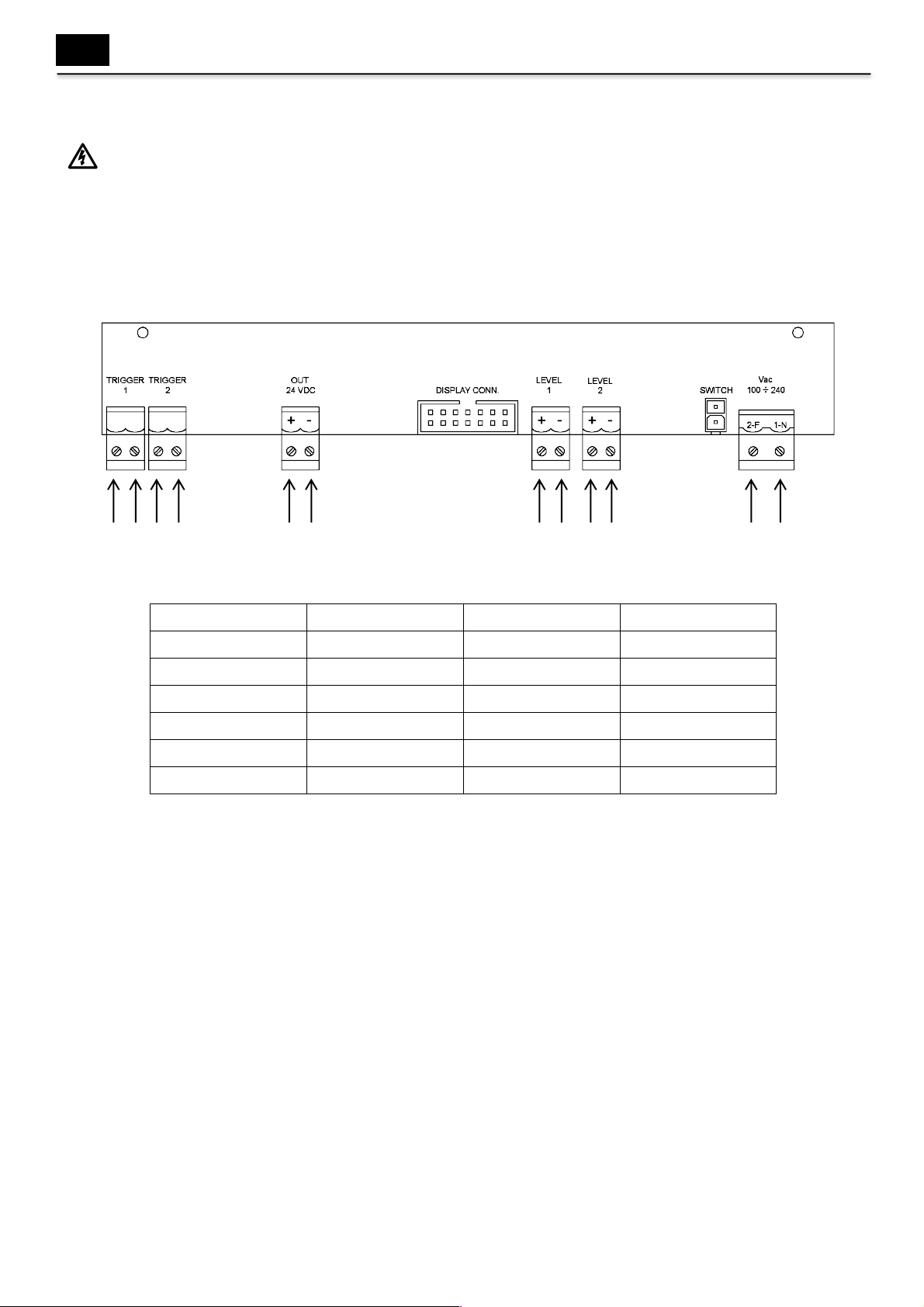

All electrical connections to the WashBasic should first be verified with a meter. Application of

incorrect voltage will permanently damage the unit and is not covered under warranty. Avoid wiring to

any power source that has large fluctuations in voltage and/or is prone to surges. Refer to the wiring

diagram in this manual for all power and signal connections.

I

For all connections, please refer to the circuit board schematic contained in this manual.

I

Check the model of the equipment you have purchased for the references about installation, setting

and programming.

CAUTION: The WashBasic has high voltage connected to the transformer. Always disconnect power

when servicing the unit.

CAUTION: During installation and electrical connections remove all power from the laundry machine.

Ü

Failure to follow these instructions may lead to personal injury, damage to the product or poor product

performance.

1.5 MATERIALS REQUIRED DURING INSTALLATION

• Two pole wire: 2x0.75 - H-05 VVF (qty 2; length 2 mt - for trigger signal);

• Two pole wire: 2x1.5 - H-05 VVF (qty 1; length 2 mt - for power supply);

• 4x6 mm copper tubing (qty 1; length 2 mt - for water solenoid valve).

Ü

The lengths indicated above are for typical installations. Your installation may require different lengths.

Ü

An installation kit is available.

2. INSTALLATION

Mount the unit on a nearby wall (using suitable hardware) to the laundry machine. Try to keep the unit within one

meter from the final rinse line to avoid long tubing runs.

Locate the WashBasic as close to the chemical product tanks as possible in order to maximize both your motor and

tube life.

Check all applicable plumbing and electrical codes before proceeding with the installation. This will help to ensure

that the system is installed in safe and suitable manner. A wiring schematic of the laundry machine should be used

as reference for making electrical connections, this is typically provided by the laundry machine manufacturer if one

cannot be located on the machine itself.

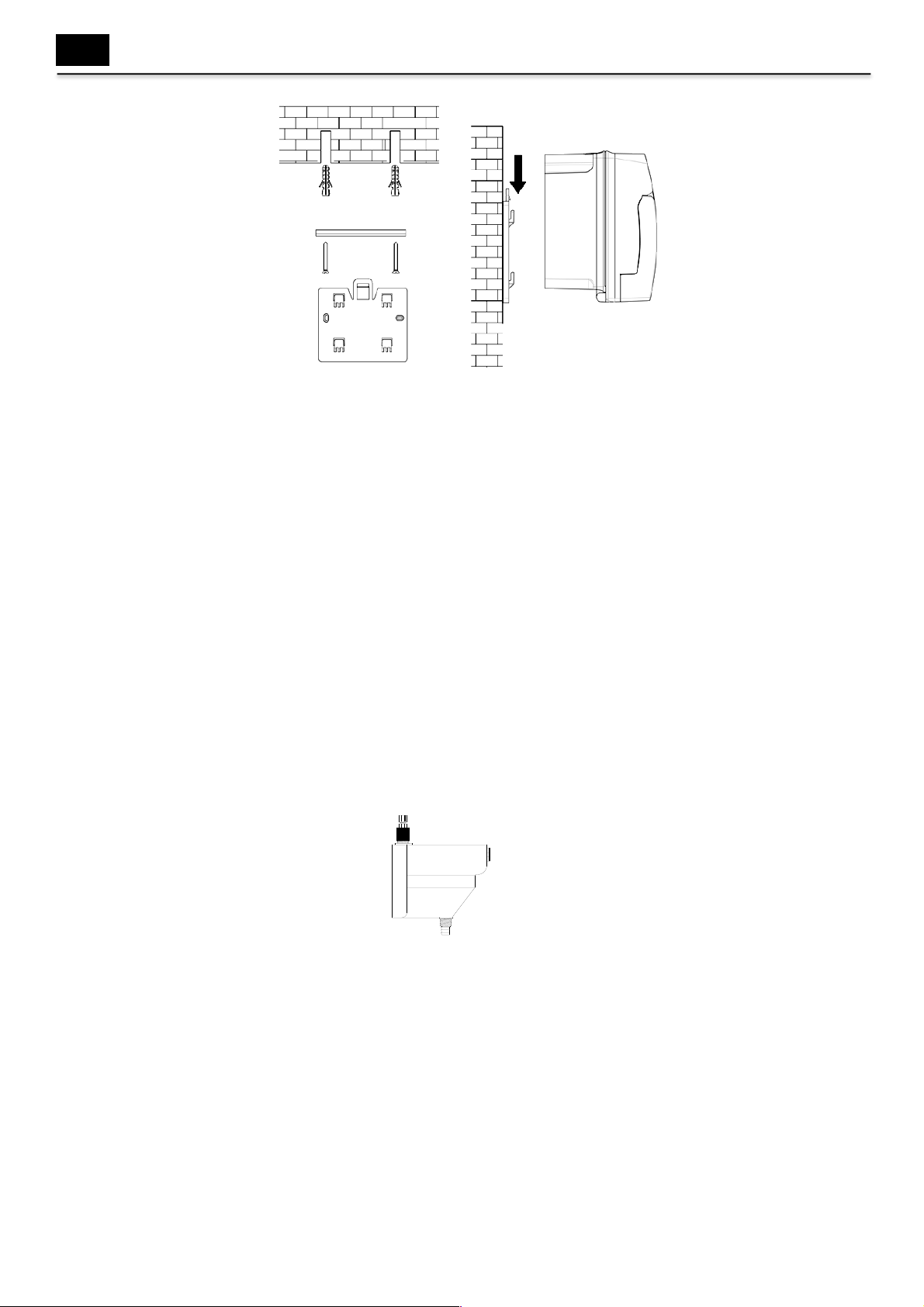

2.1 MOUNTING THE SYSTEM

Apply the panel unit system with the brackets and screws supplied:

• Determine a suitable location for the system;

• Using the bracket as a template, mark and drill holes for bolting the system to the wall;

• Insert the anchors in the holes;

• Bolt the bracket in place with the hardware provided;

• Mount the system with the bracket as the picture below;

• Open the Cabinet Front, unscrewing the upper screws by ¼ of a turn.