5

SAFE OPERATION

This advice on safe operation has been compiled so that you can

avoid incorrect use and unnecessary risks of accidents and should be

read before the drying cabinet is installed and used.

CAUTION: This equipment is only intended to be used to dry textiles

washed in water.

pThe drying cabinet can be used by children over the age of 8 and

persons (including children) with impaired physical, sensory or

mental capacity or who lack experience or knowledge, provided

they have received guidance or information on how to use the

drying cabinet in a safe way and understand the risks that may

occur.

pDo not allow children to play in, on or with the drying cabinet.

Keep an eye on children when they are in the immediate vicinity

of the cabinet.

pIf the mains lead is damaged it must be immediately replaced,

and this work must only be performed by the manufacturer, the

manufacturer’s service agent or similarly qualified persons in

order to avoid danger.

pCleaning and maintenance must not be performed by children

without supervision.

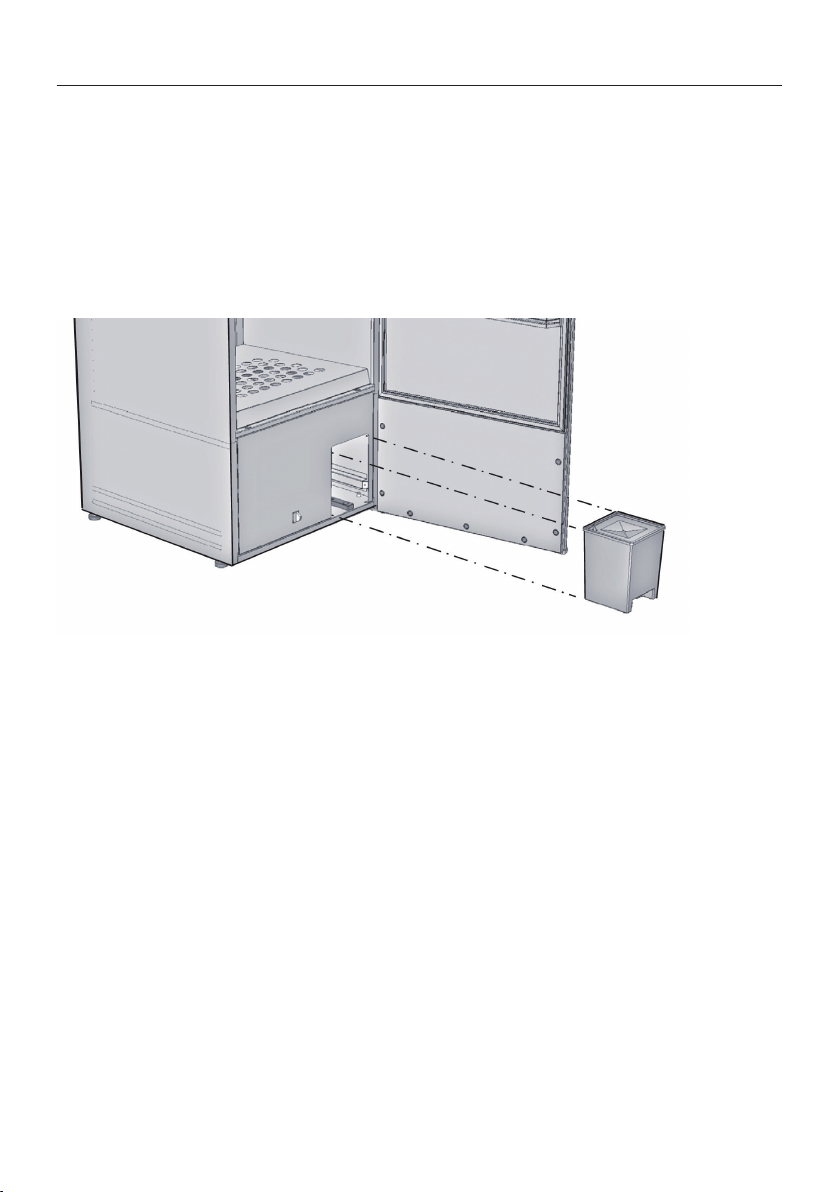

pAvoid hanging textiles that are dripping or soaking wet as the

cabinet is not intended to collect large volumes of water. This

may lead to water escaping onto the floor.

pIf you are hanging items with such a high moisture content

that they are dripping or soaking wet, we recommend spinning

them if possible, and if this is not possible wringing the items

before placing them in the drying cabinet. We also recommend

placing the cabinet on a collecting pan to prevent possible water

damage to the floor.