3.General warnings

4

PARVIS MES SMA POLITEC | INSTALLATION MANUAL - VER.2.6

This installation manual contains important information regarding safety for installation: it is

necessary to read all the instructions before proceeding with the installation.

Keep this manual for future use.

•If you have any questions or doubts during installation, do not carry out any operations and contact

the distributor's support service.

•Use of these products for purposes other than those specified in these instructions is prohibited.

•You must not make any change to the components of the product unless stated in the manual in

order not to void the warranty; such operations can only lead to malfunctions; Politec assumes no

liability for malfunctions or damage due to modified products.

•Depending on the specific situation of use, check for the need for additional devices: detectors or

signalling devices.

•During installation, mounting and use of the product, make sure no foreign objects (solids, metals

or liquids) are able to penetrate inside the open devices.

•Manufacturer's liability:Politec assumes no liability for failures resulting from incorrect installation;

lack of maintenance, incorrect assembly or use.

•Politec is also not liable for incorrect or incomplete operation of the product or failure to detect

intrusion.

•Warranty (summary of conditions):Politec guarantees its products for a period of 2 years from the

production date.The warranty is applied to those purchasing directly from Politec; there is no

warranty for the end user who, in the event of breakdowns or faults, must contact the installer or

dealer.

•The warranty excludes aesthetic parts as well as parts subject to normal wear and parts subject to

normal consumption such as batteries and accumulators.

3.1 Additional warnings for devices powered by mains voltage

This manual is intended only for technical personnel qualified to install such devices.

•Assessing the hazards that may occur during installation and use of the system, in order to achieve

complete safety, it is necessary that installation takes place in full compliance with applicable laws,

methods, rules and regulations.

•Before accessing the internal terminals of the product, it is necessary to disconnect all the power

circuits.

•If automatic circuit breakers or fuses trip, before resetting them it is necessary to identify the fault

and repair it.

3.2 Installation warnings

•Check that all the material to be used is in excellent condition and suitable for use.

•Before proceeding with the installation, check the environmental class of the products in the

"technical specifications" chapter.

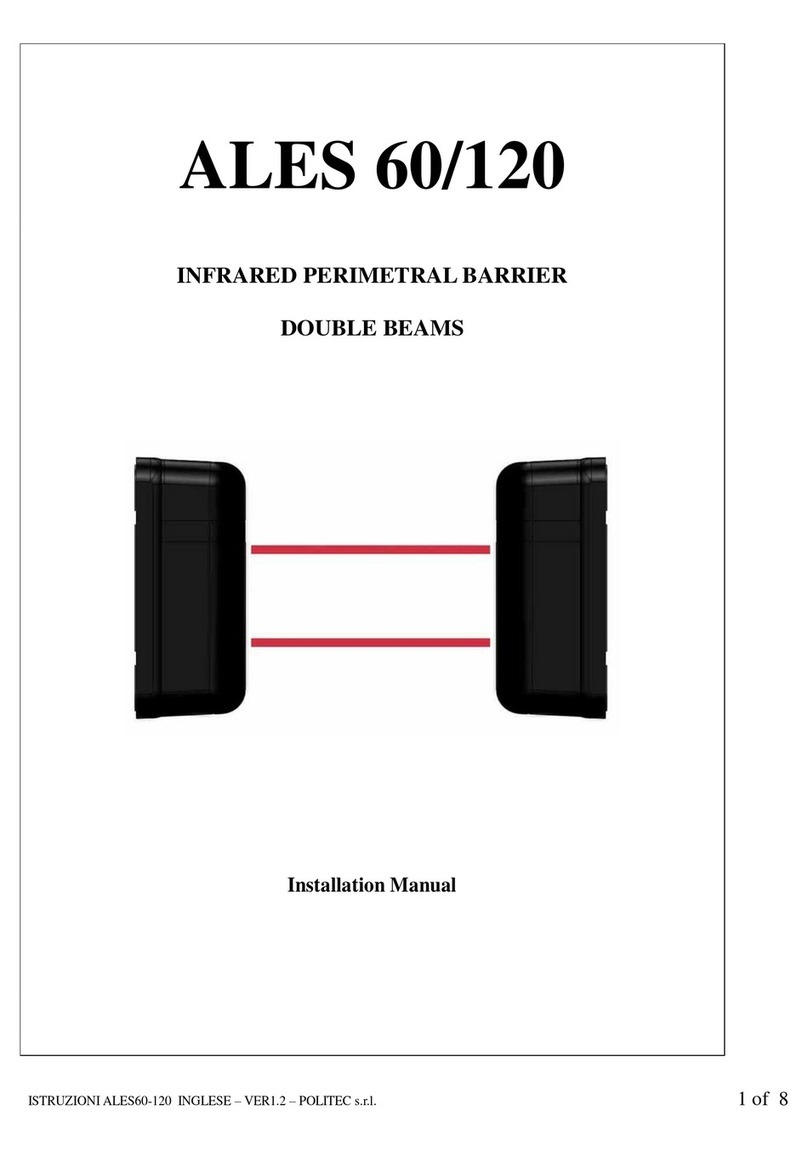

•Check, by comparing with the values shown in the paragraph "technical specifications", that the

range of the devices is equal to or greater than the physical distance between the barriers.

•Check that the barrier is positioned in areas protected against potential impact, in flat areas and on

fixed supports to avoid oscillations.

•Do not place the system components close to heat sources as they could be damaged.

•Each barrier has its own operating principle: check the instructions for choosing the right position

in the respective instruction manual.