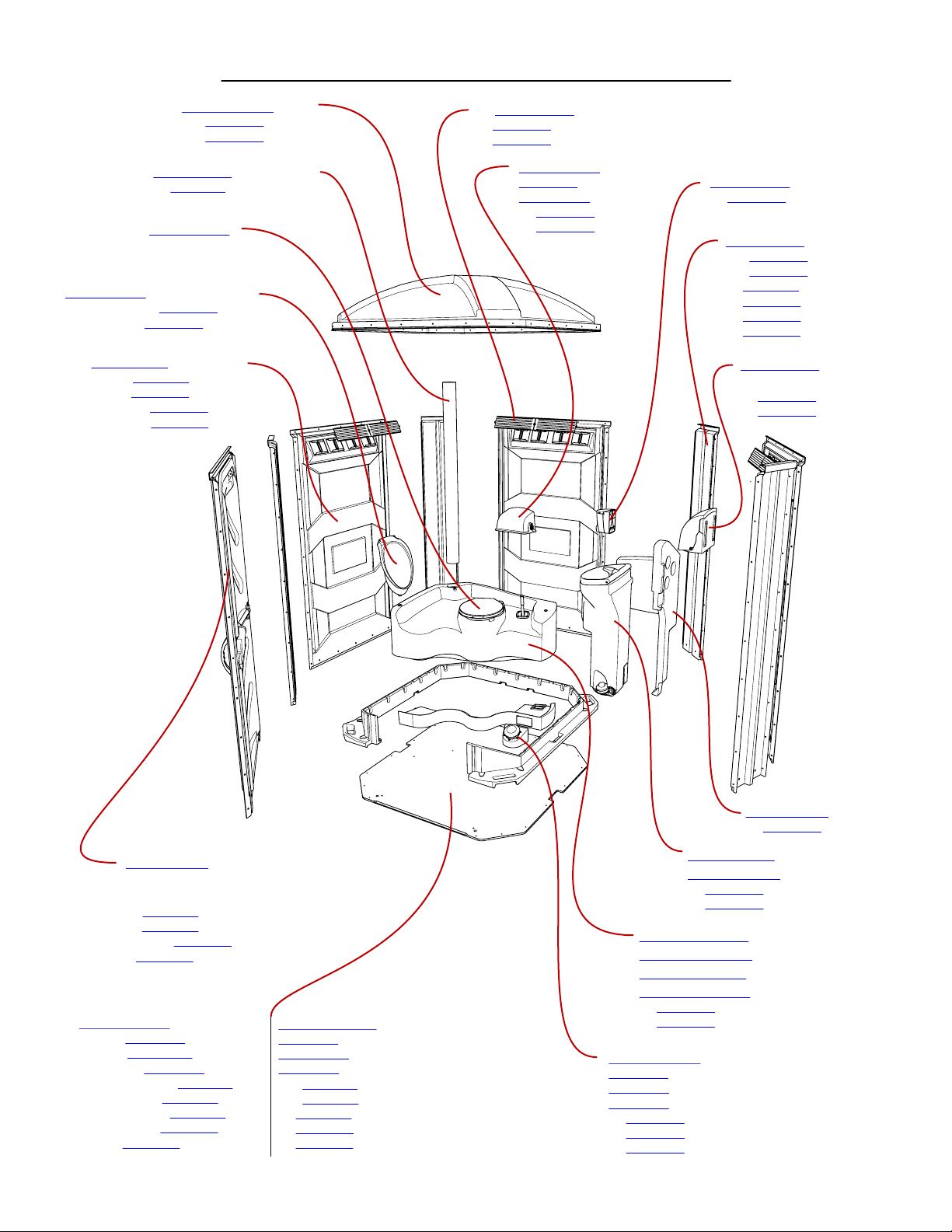

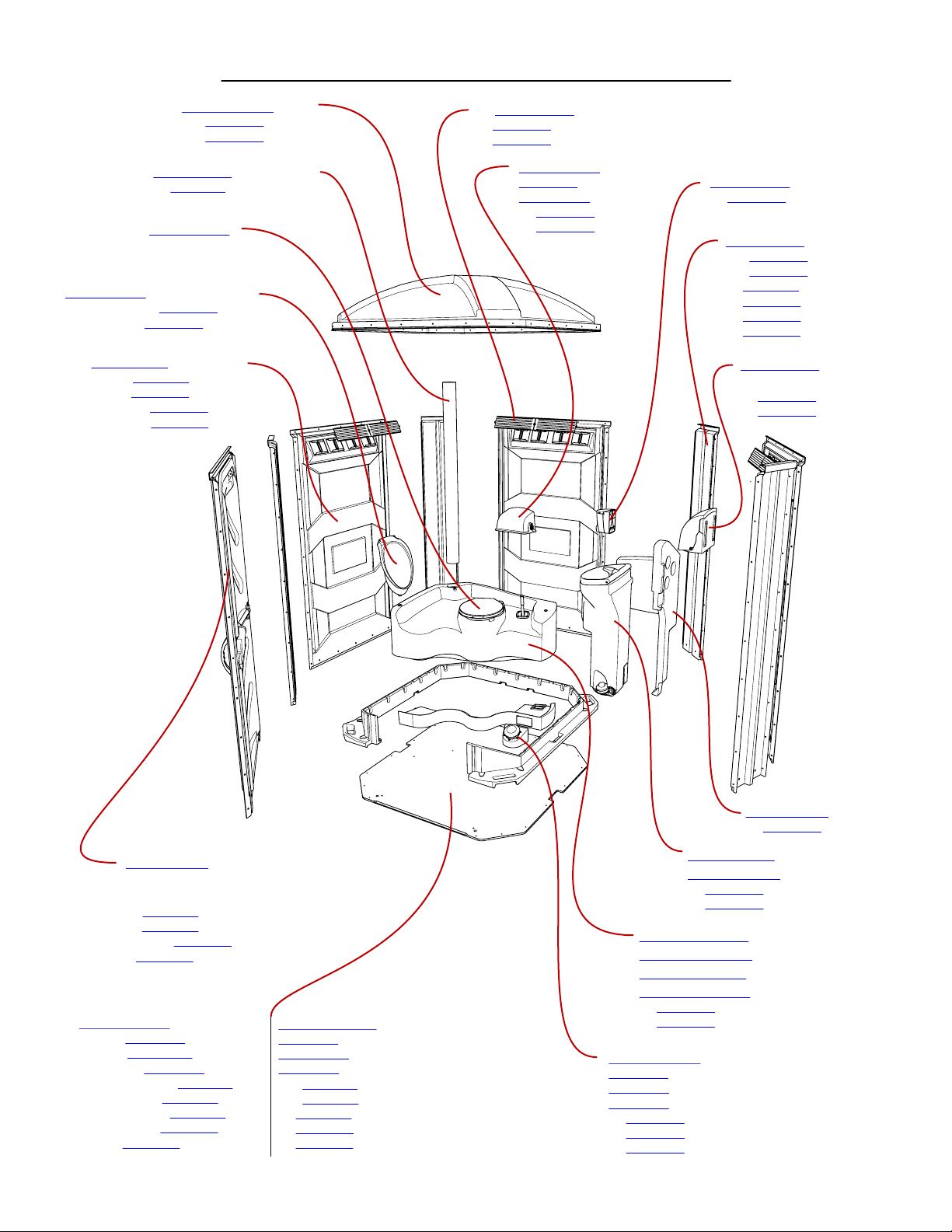

PC-000490 - T.P. Dispenser

PC-000760 - Rod

PC-000205M - Lock

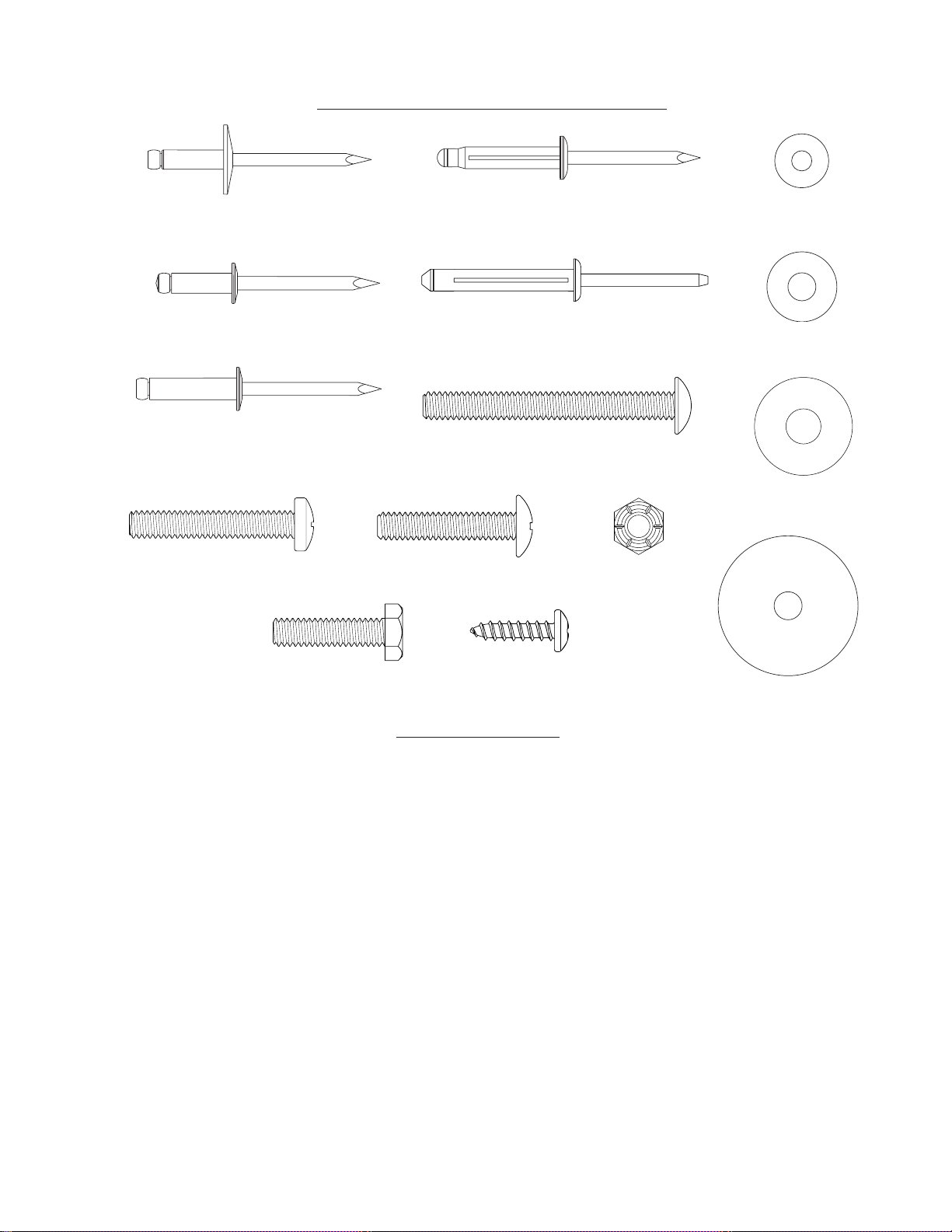

(4) PC-000100 - Rivet

(4) PC-000106 - Washer

(6) PC-000570 - Fly Screen

(9) PC-000100 - Rivet

(9) PC-000106 - Washer

PH01-0010 - Corner Panel

(72) PC-000100 - Rivet

(72) PC-000106 - Washer

(8) PC-000121 - Washer

(8) PC-000123 - Washer

(8) PC-000139 - Bolt

(8) PC-000140 - Nut

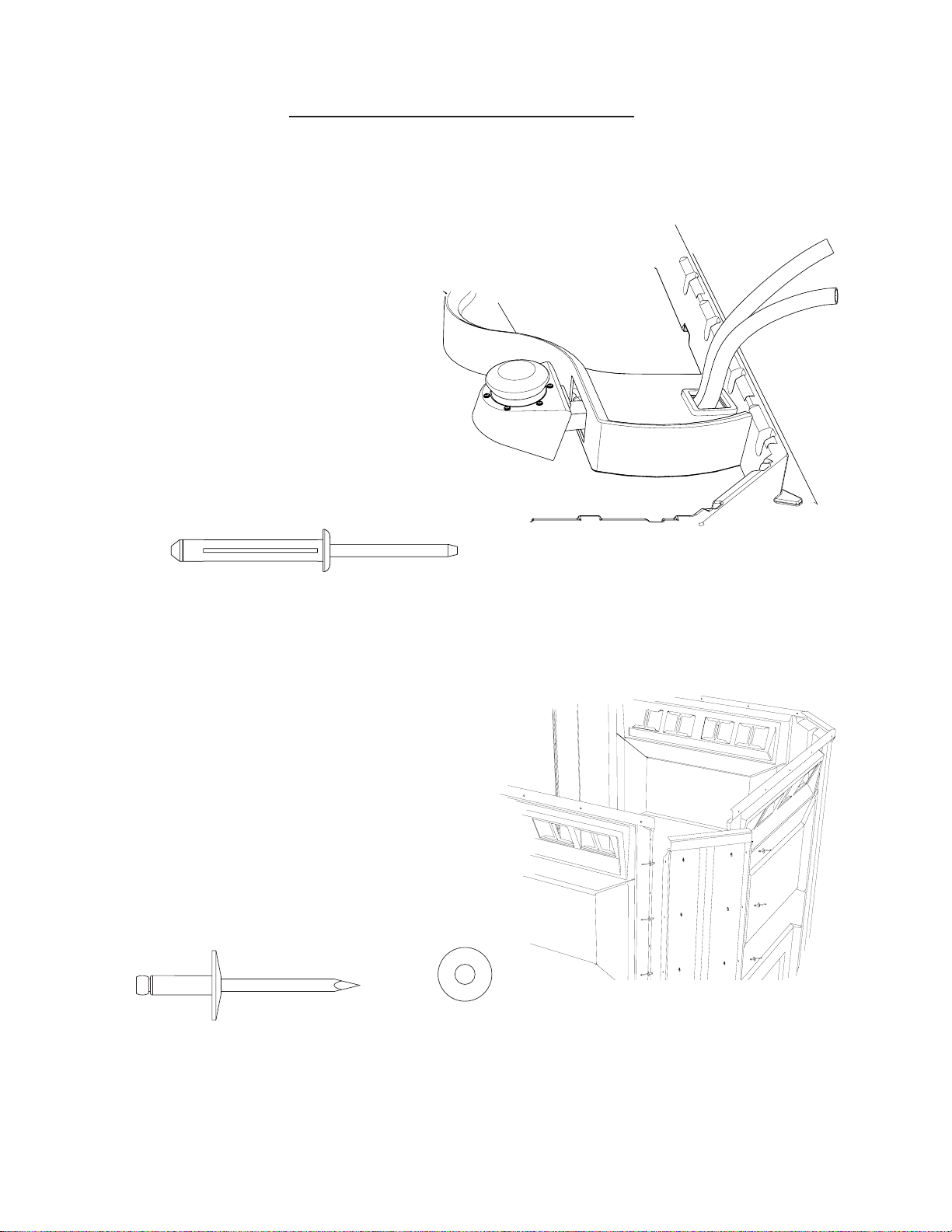

PSD1-1000 - Soap Dispenser

(3) PC-000105 - Rivet

PH03-0008R - Roof

(28) PC-000100 - Rivet

(28) PC-000106 - Washer

PC-000531 - Vent Stack

(1) PC-000117 - Rivet

PC-000495 - Urinal (Optional)

(2) PC-000102 - Rivet

(2) PC-000106 - Washer

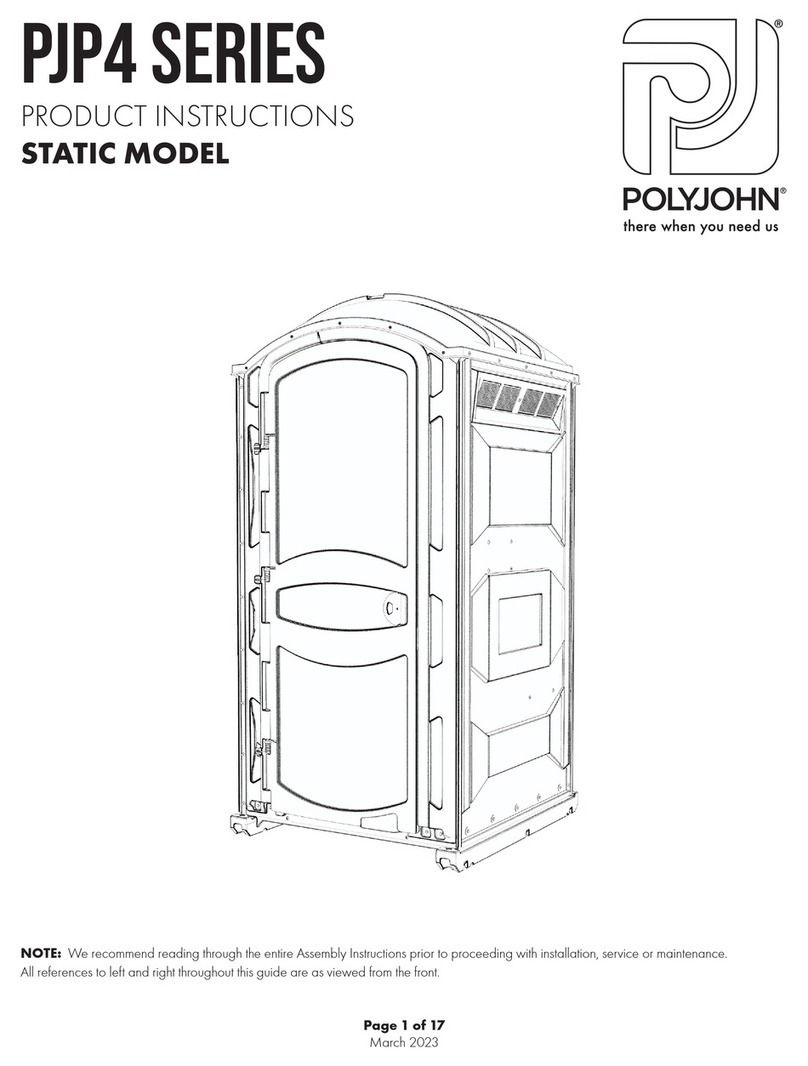

(3) PJ03-0002 - Side Panel

(15) PC-000121 - Washer

(15) PC-000123 - Washer

(15) PC-000139 - Bolt

(15) PC-000140 - Nut

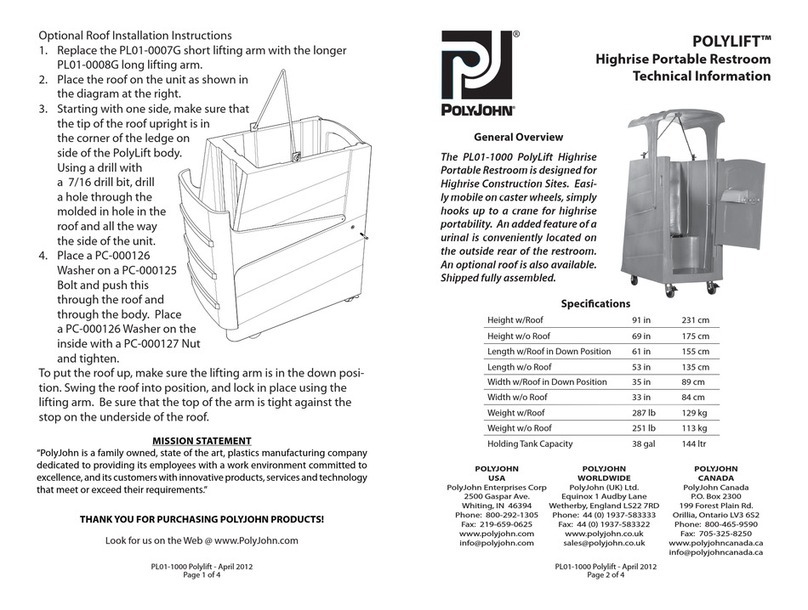

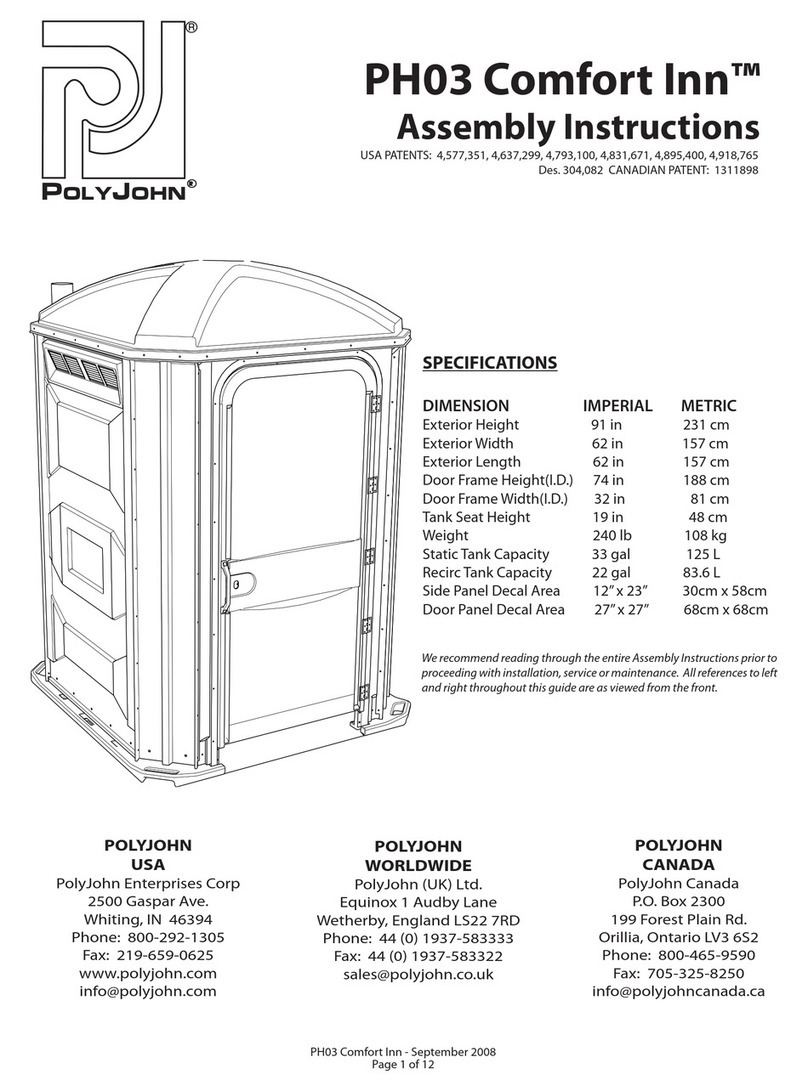

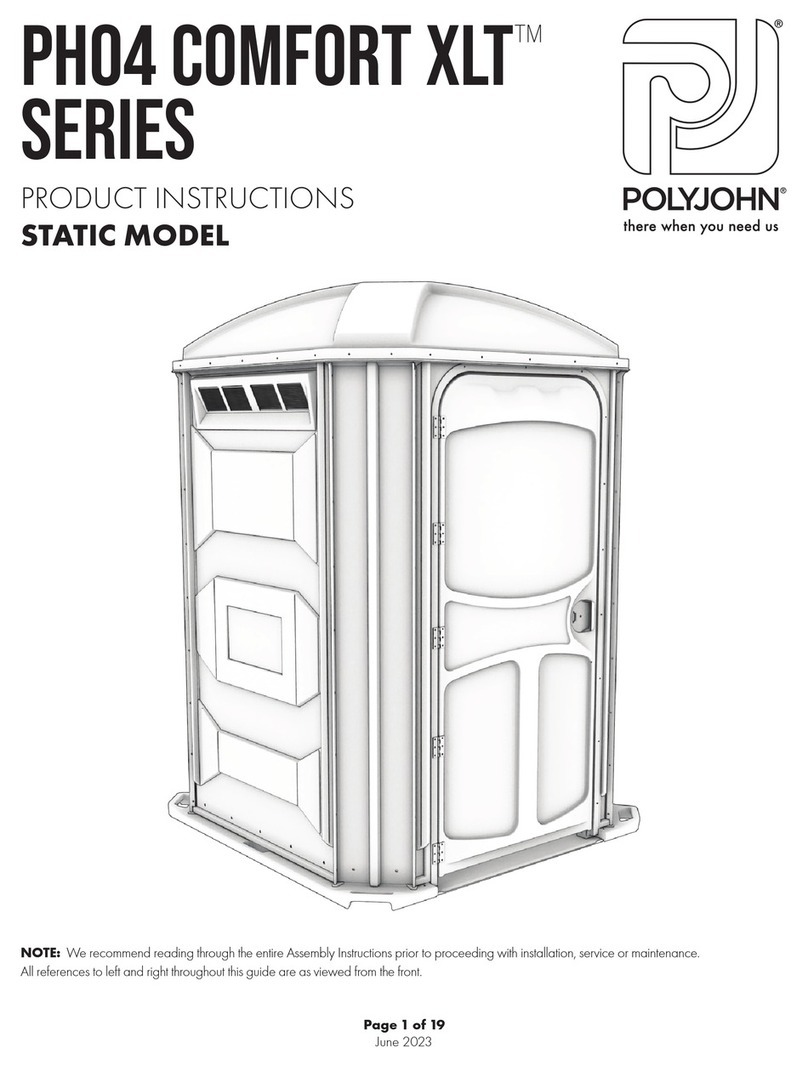

PH03-0003 - Comfort XL

Front Assembly

(See Front Assembly Exploded View)

(2) PC-000174 - 1-1/4” Screw

(4) PC-000175 - 1-1/2” Screw

(6) PC-000123 - Washer

(6) PC-000140 - Nylon Lock Nut

PC-000204

Toilet Seat

PH04-0001C - Floor Complete

PH03-0001 - Base Surround

PH04-0001T - Tank Support

PH04-0002 - Floor Plate

(25) PC-000117 - Rivet

(20) PC-000121 - Washer

(2) PC-000174 - Screw

(2) PC-000123 - Washer

(2) PC-000140 - Nylon Lock Nut

TD04-1000 - Paper Towel

Dispenser

(4) PC-000100 - Rivet

(4) PC-000106 - Washer

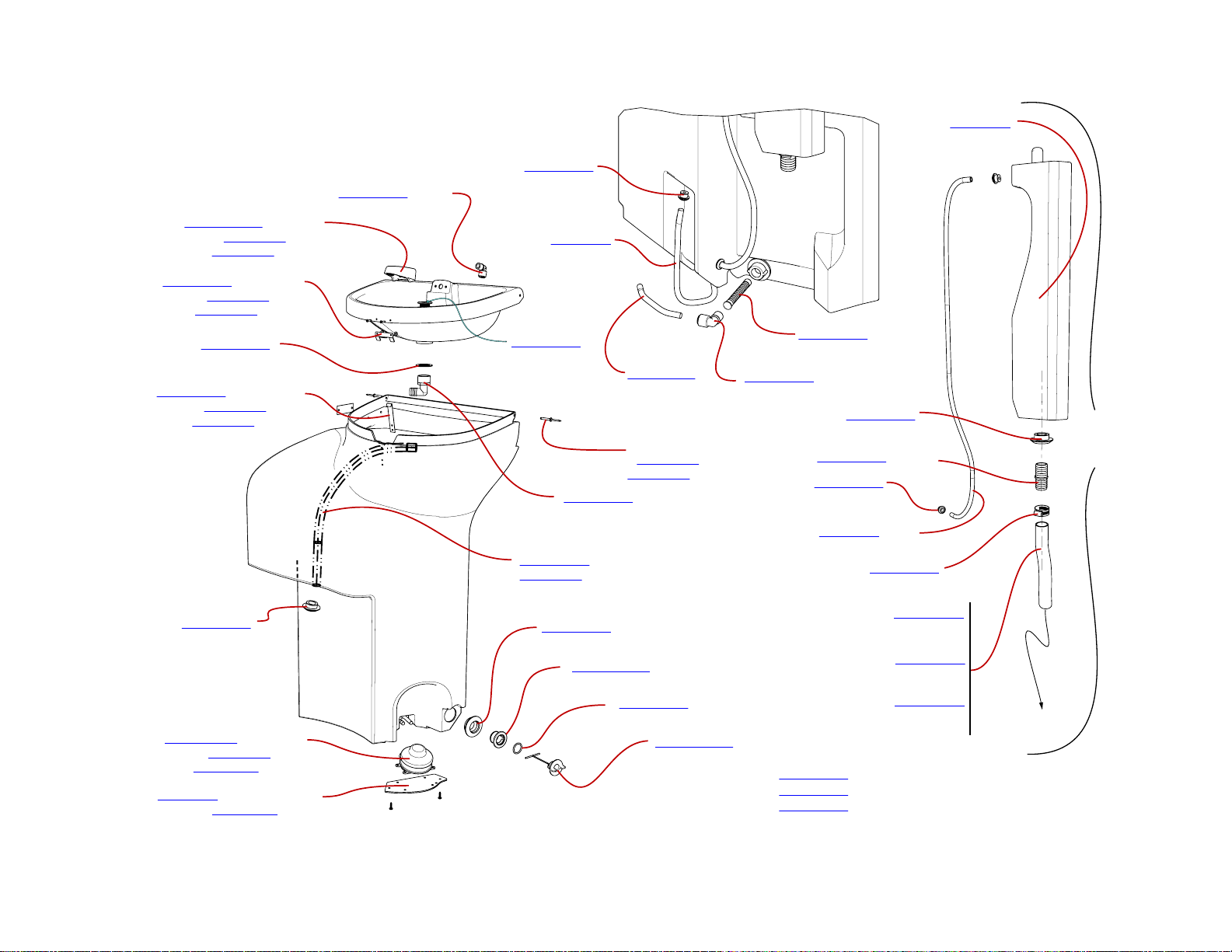

PH04-0025 - Sink Surround

(3) PC-000105 - Rivet

FS3-0026PC - Static Sink OR

FS3-0026PFF - Fresh Flush Sink

(3) PC-000103 - Rivet

(3) PC-000106 - Washer

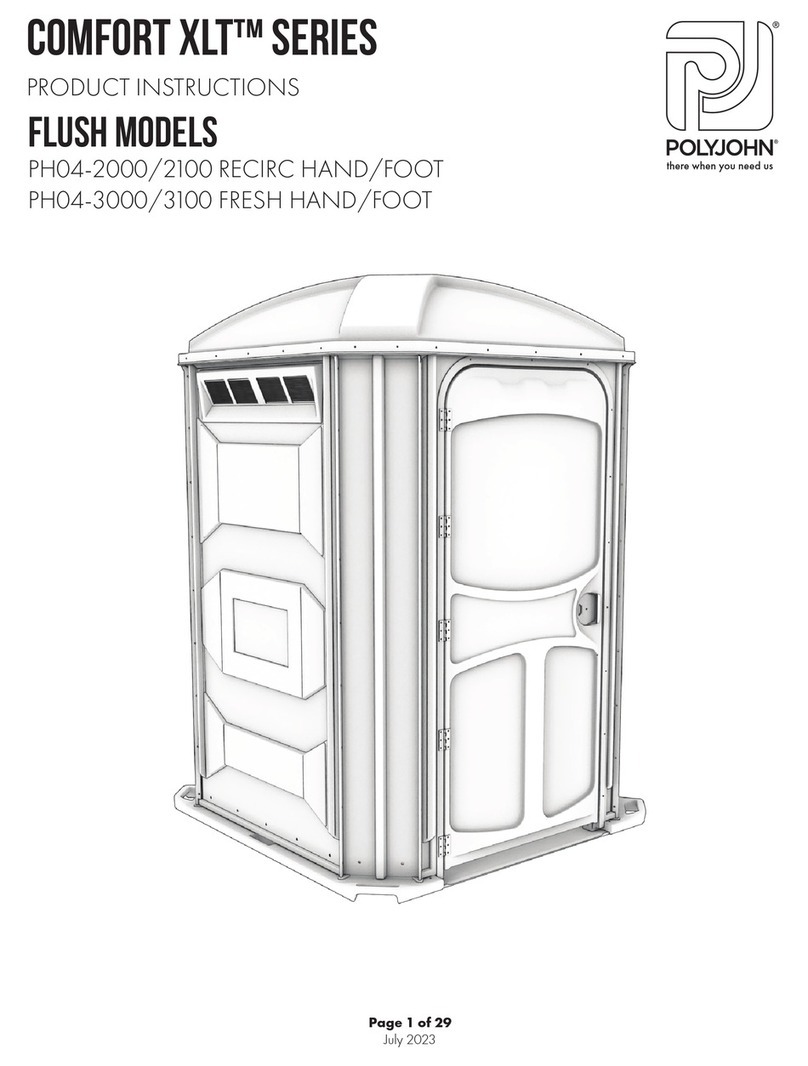

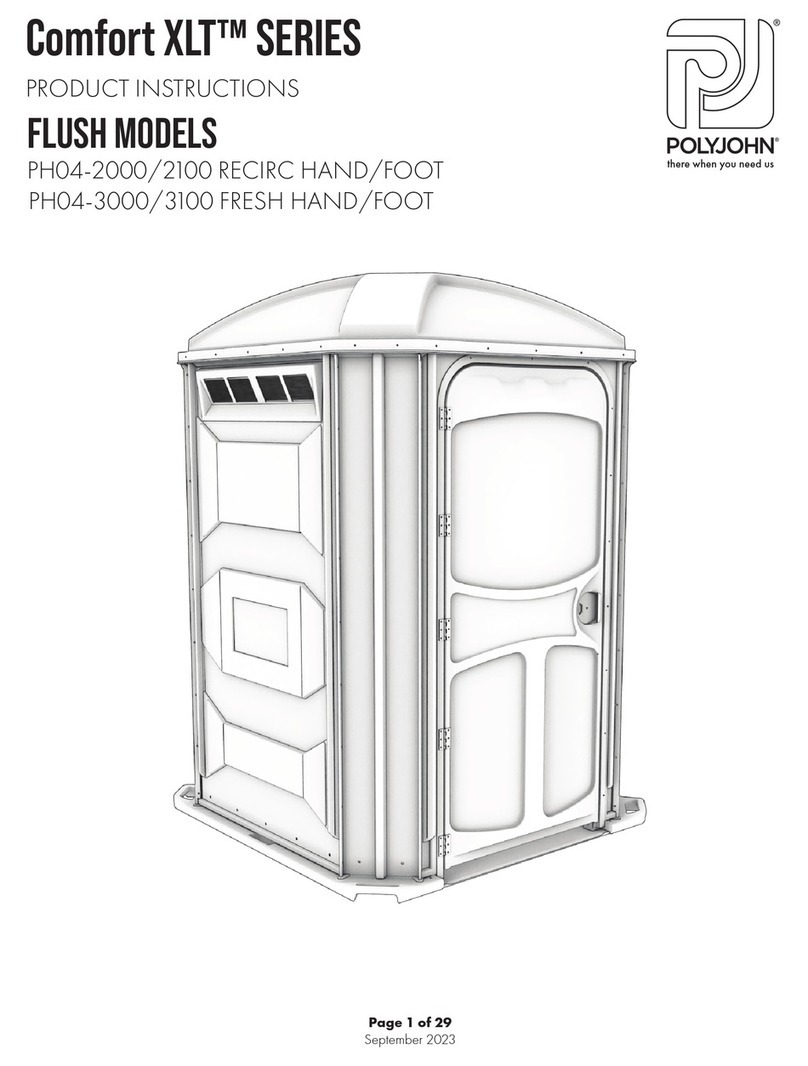

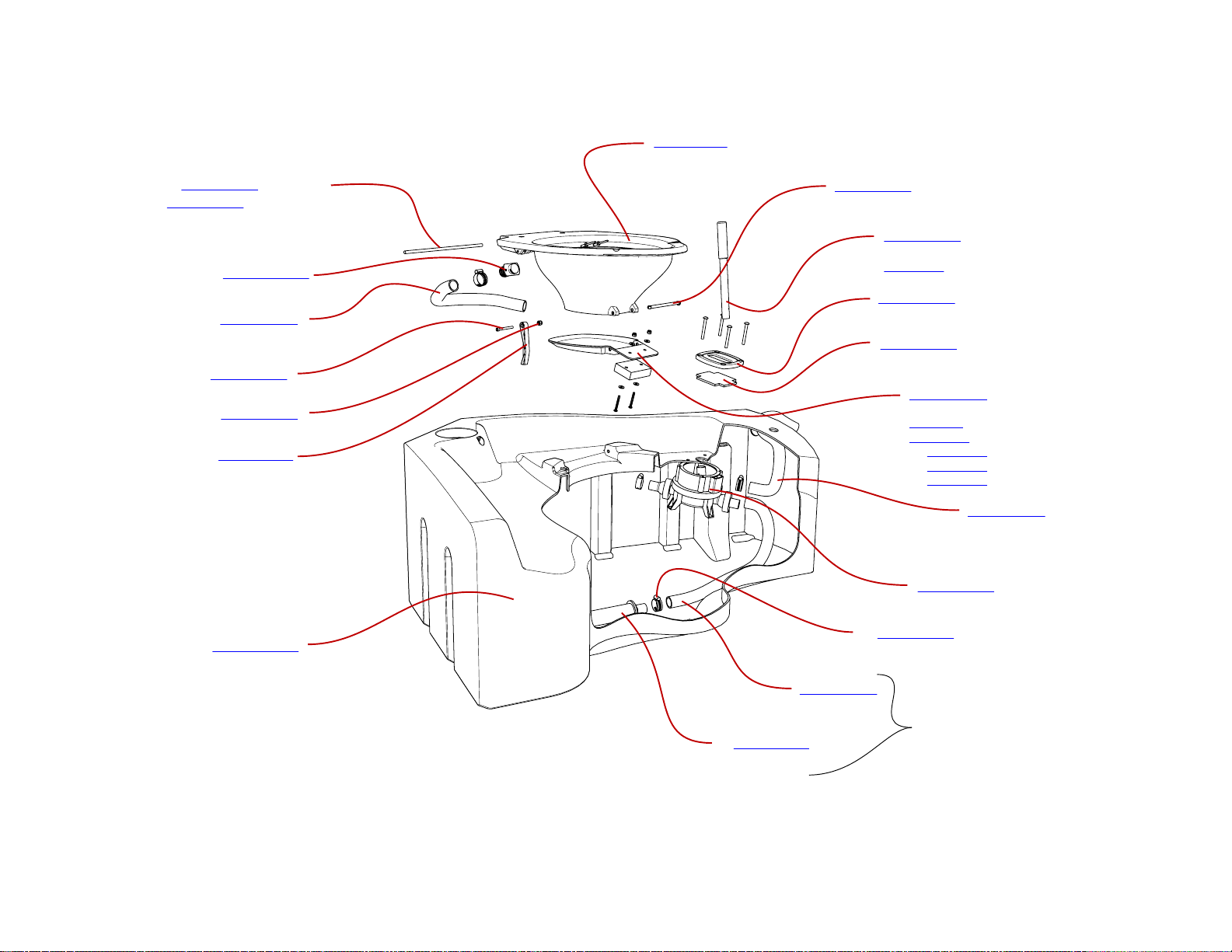

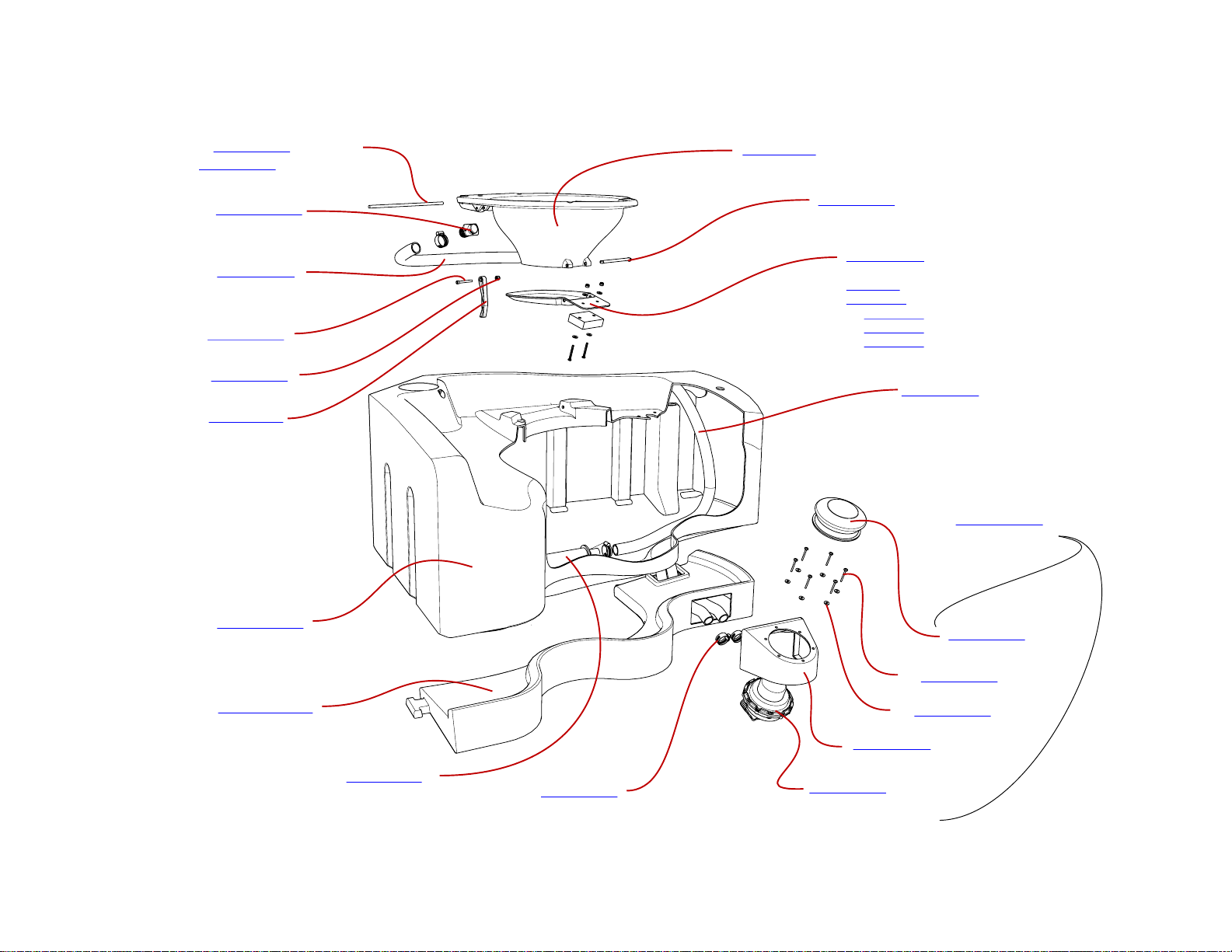

PH04-0009RFC - Recirc Foot Flush Tank or

PH04-0009RHC - Recirc Hand Flush Tank or

PH04-0009FFC - Fresh Foot Flush Tank or

PH04-0009FHC - Fresh Hand Flush Tank

(5) PC-000105 - Rivet

(5) PC-000106 - Washer

PH04-0024C - Foot Pump Housing w/pump

PH04-0024- Foot Pump Hosing

PC-000606 - Foot Pump

PC-000604 - Rubber Cover

(6) PC-000106 - Washer

(6) PC-000231 - Screw

(1) PC-000105 - Rivet

PH04-0001CF - Floor Complete-Foot Flush

PH03-0001 - Base Surround

PH04-0001TF - Tank Support - Foot Flush

PH04-0002 - Floor Plate

(25) PC-000117 - Rivet

(20) PC-000121 - Washer

(2) PC-000174 - Screw

(2) PC-000123 - Washer

(2) PC-000140 - Nylon Lock Nut

Comfort XLT - Flush Tank Parts Diagram

http://www.polyjohn.com/pj03-0002/

http://www.polyjohn.com/pc-000121/

http://www.polyjohn.com/pc-000123/

http://www.polyjohn.com/pc-000139/

http://www.polyjohn.com/pc-000140/

http://www.polyjohn.com/ph01-0010/

http://www.polyjohn.com/pc-000100/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000121/

http://www.polyjohn.com/pc-000123/

http://www.polyjohn.com/pc-000139/

http://www.polyjohn.com/pc-000140/

http://www.polyjohn.com/pc-000570/

http://www.polyjohn.com/pc-000100/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000490/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000100/

http://www.polyjohn.com/pc-000205m/

http://www.polyjohn.com/pc-000760/

http://www.polyjohn.com/ph03-0008r/

http://www.polyjohn.com/pc-000100/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000531/

http://www.polyjohn.com/pc-000117/

http://www.polyjohn.com/ph03-0003/

http://www.polyjohn.com/pc-000174/

http://www.polyjohn.com/pc-000175/

http://www.polyjohn.com/pc-000123/

http://www.polyjohn.com/pc-000140/

http://www.polyjohn.com/pc-000204/

http://www.polyjohn.com/ph04-0001c/

http://www.polyjohn.com/ph03-0001/

http://www.polyjohn.com/ph04-0001t/

http://www.polyjohn.com/ph04-0002/

http://www.polyjohn.com/pc-000117/

http://www.polyjohn.com/pc-000121/

http://www.polyjohn.com/pc-000174/

http://www.polyjohn.com/pc-000123/

http://www.polyjohn.com/pc-000140/

http://www.polyjohn.com/pc-000102/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000495/

http://www.polyjohn.com/psd1-1000/

http://www.polyjohn.com/pc-000105/

http://www.polyjohn.com/TD04-1000/

http://www.polyjohn.com/pc-000100/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/ph04-0025/

http://www.polyjohn.com/pc-000105/

http://www.polyjohn.com/FS3-0026PC/

http://www.polyjohn.com/pc-000103/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/FS3-0026PFF/

http://www.polyjohn.com/PH04-0009RFC/

http://www.polyjohn.com/pc-000105/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/PH04-0009RHC/

http://www.polyjohn.com/ph04-002C/

http://www.polyjohn.com/pc-000606/

http://www.polyjohn.com/pc-000604/

http://www.polyjohn.com/pc-000106/

http://www.polyjohn.com/pc-000231/

http://www.polyjohn.com/pc-000105/

http://www.polyjohn.com/ph04-0024/

http://www.polyjohn.com/ph04-0001cf/

http://www.polyjohn.com/ph03-0001/

http://www.polyjohn.com/ph04-0001tf/

http://www.polyjohn.com/ph04-0002/

http://www.polyjohn.com/pc-000117/

http://www.polyjohn.com/pc-000121/

http://www.polyjohn.com/pc-000174/

http://www.polyjohn.com/pc-000123/

http://www.polyjohn.com/pc-000140/

http://www.polyjohn.com/PH04-0009FFC/

http://www.polyjohn.com/PH04-0009FHC/