Page 10 of 20

September 2022

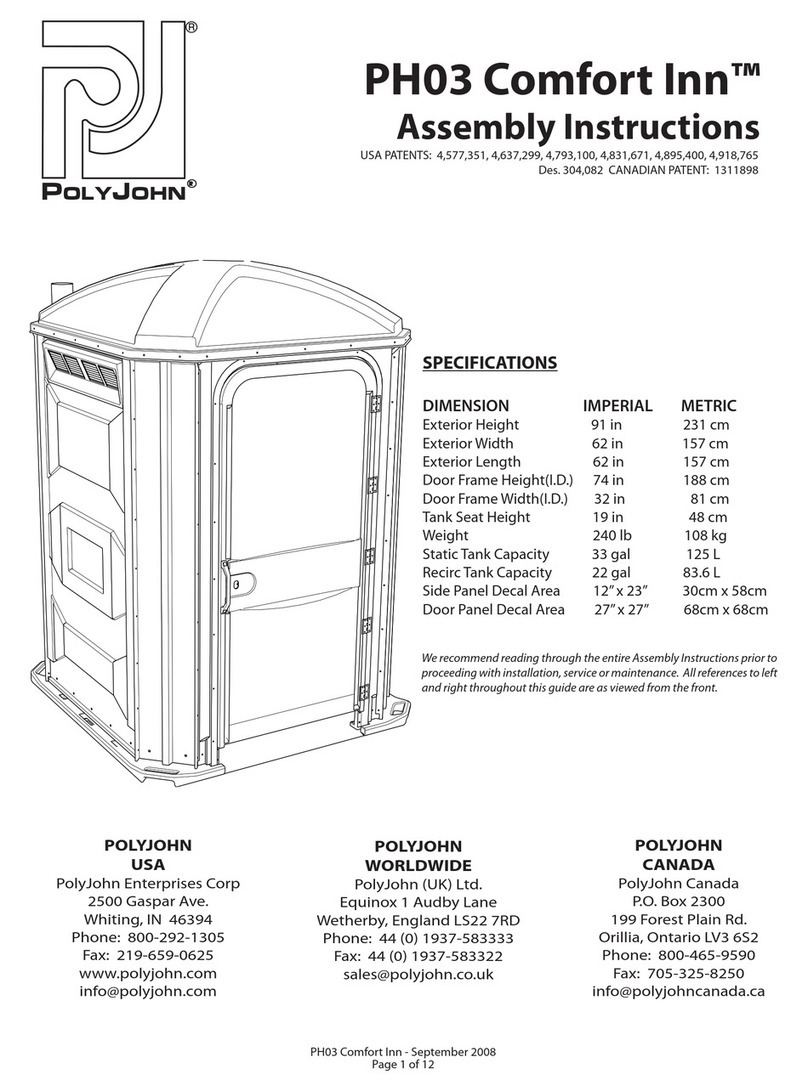

PJN3 SERIES

The sink bowl is attached to the sink tank with (2) PC-000107 rivets that act as hinges.

To Open the Sink Top (follow instructions as illustrated on the right)

overview of optional sink installation

ASSEMBLY INSTRUCTIONS

LEFT WALL INSTALLATION

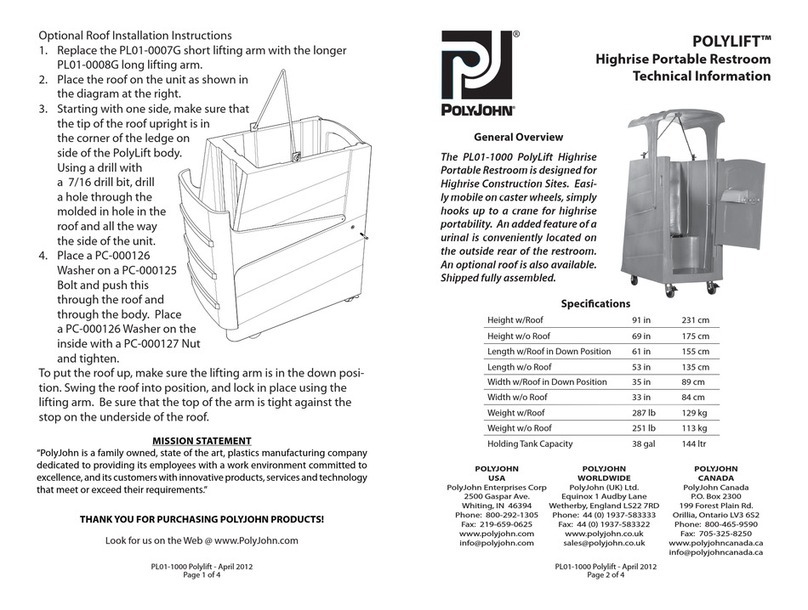

Refer to Illustrations. Before installing the sink, a 1-1/8” drain hole that will accept

the drain hose must be cut in the waste tank. This hole should be located on the top

left front edge of the waste tank approximately 16-1/2” up from the floor.(As shown

on the right, a 1-1/2” plug PC-000560, is available to cover the urinal drain hole.)

NOTE: Make sure the drain hole you are cutting as indicated above is

just below the urinal hole. From the exterior, drill two 13/64” holes (as shown

on the left) through the sidewall and the back of the sink, be sure the sink is pressed

flat against the sidewall. Fasten the sink to the side from the exterior with (2) PC-

000103 rivets and (2) PC-000106 back-up washers on the inside of the sink. Attach

sink to base skid: Drive (1) PC-000158 self-tapping screw in the pre-drilled hole in

the sink mounting plate. Perform a system check by adding a few gallons of water

to the sink. Depress the pump a few times to “prime” it. The pump has a built in check

valve that will hold the prime between uses.

RIGHT WALL INSTALLATION

Before installing the sink, a 1-1/8” drain hole that will accept the drain hose must be

cut in the waste tank. This hole should be located on the top right front edge of the

waste tank approximately 15-1/2” up from the floor.

From the exterior, drill two 13/64” holes through the sidewall and the back of the sink

(as shown on the left) be sure the sink is pressed flat against the sidewall.

Fasten the sink to the side from the exterior with (2) PC-000103 rivets and (2) PC-

000106 back-up washers on the inside of the sink. Attach sink to base skid: Drive

(1) PC-000158 self-tapping screw in the predrilled hole in the sink mounting plate.

Perform a system check by adding a few gallons of water to the sink. Depress the

pump a few times to “prime” it. The pump has a built in check valve that will hold the

prime between uses.

WINTERIZING SINK (IF INSTALLED)

• Drain all water from the tanks.

• Flush tank with a solution of chlorine and water.

• Depress the foot pump to clear lines.

optional sink installation

2. INSERT OBJECT INTO HOLE.

(THIS WILL PUSH LOCKING TAB ALLOWING

ACCESS TO INNER TANK FOR MAINTENANCE.)

3.OPEN SINK LID

1. APPLY DOWNWARD

PRESSURE ON LID

7”

2”

43-1/4”

42-3/4”