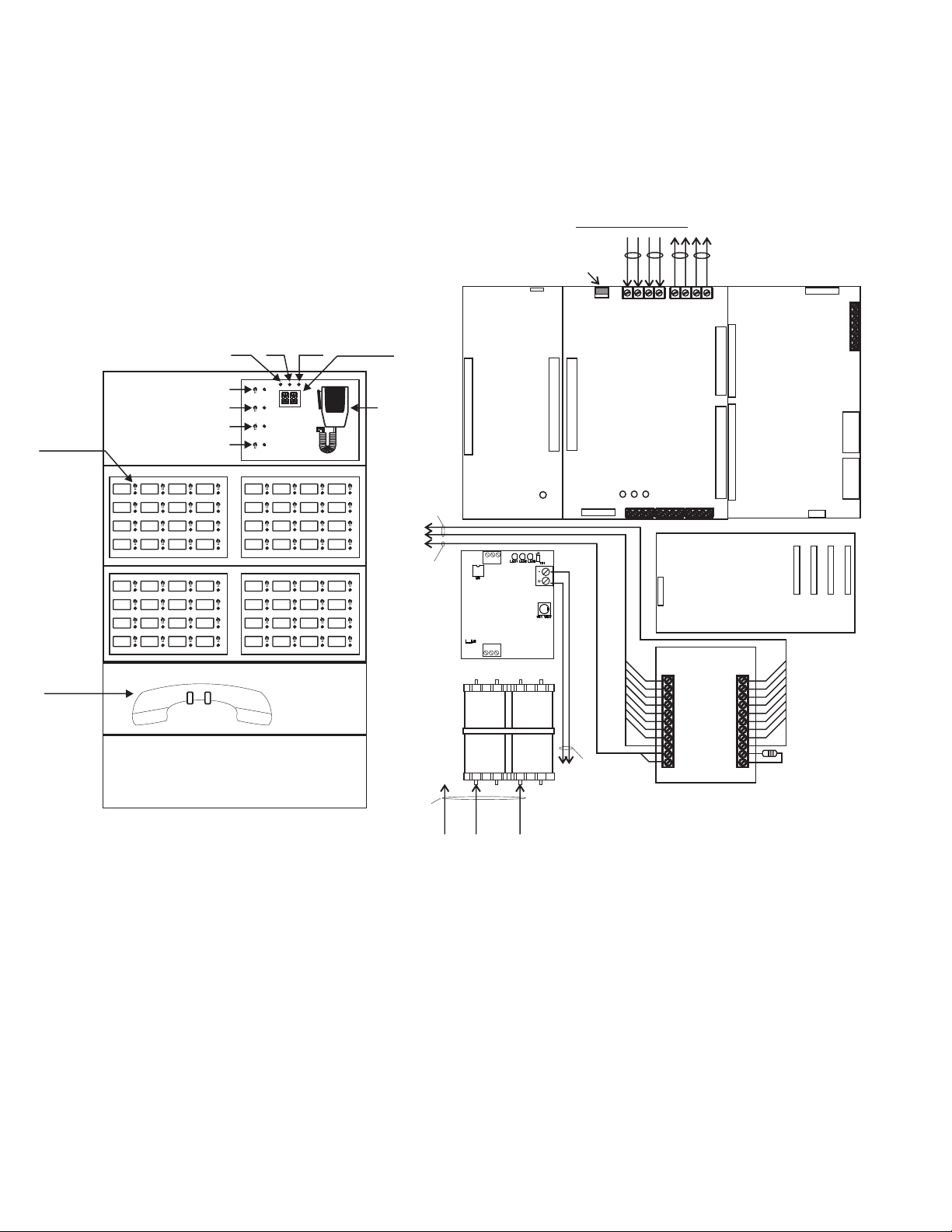

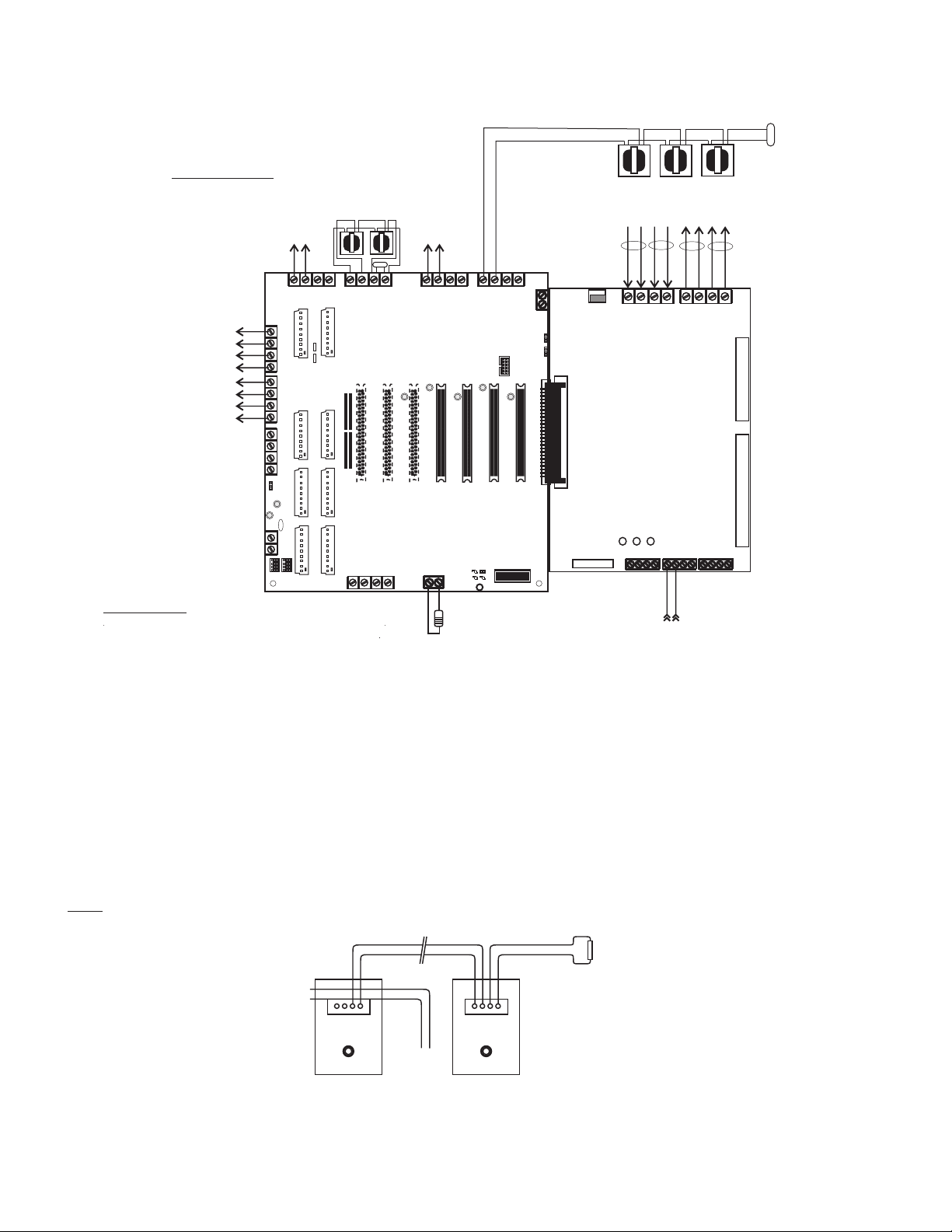

All wiring with exception of

120 VAC and Battery Connection

is Power-Limited.

Route AC power and Battery

wires to bottom-left or lower-left

side K.O.

*1

All Power Limited wiring must

maintain a min. 1/4“ separation

from Non Power Limited wiring.

(This requirement may be waived if

Type FPL, FPLR or FPLP wire is used

for Power Limited circuits)

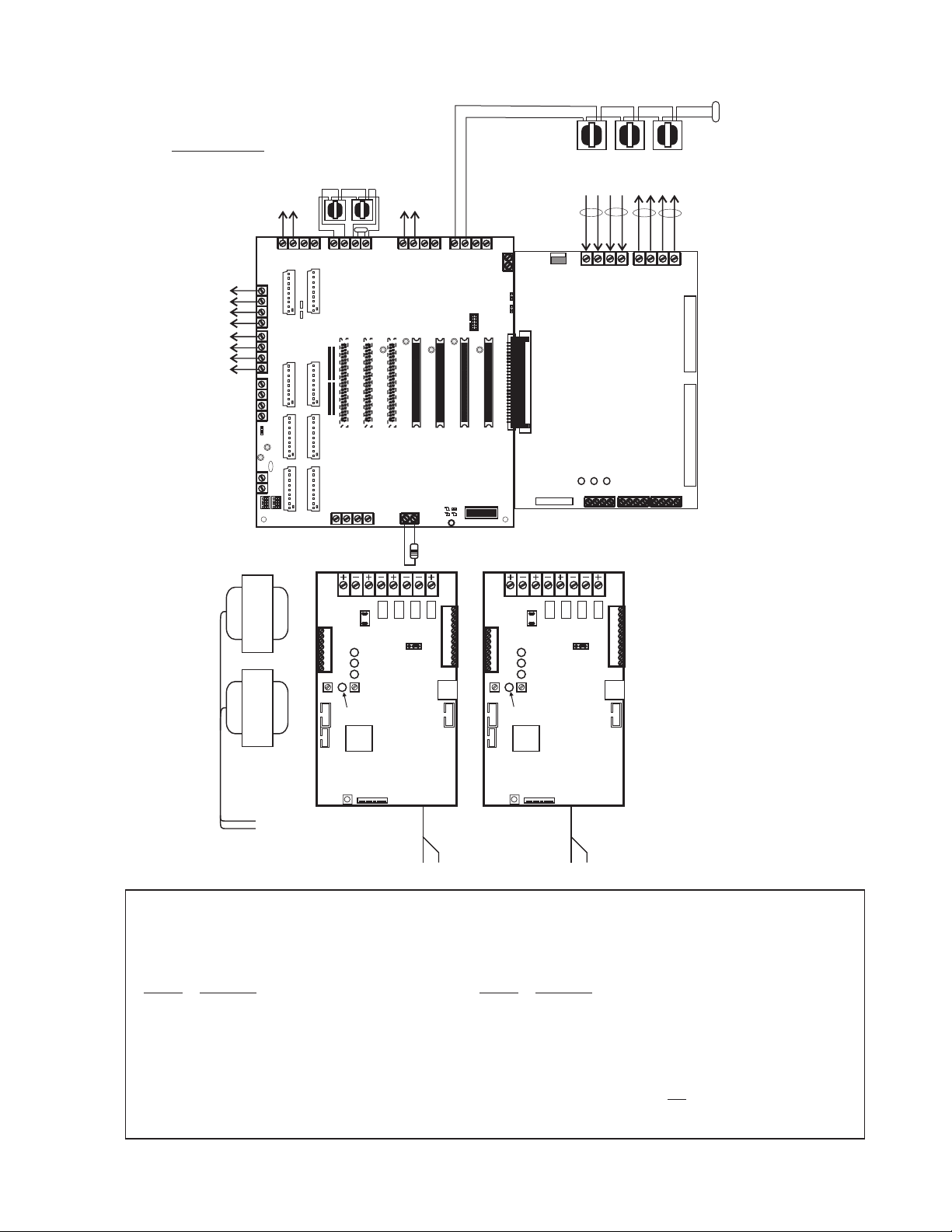

TB1 TB2

TB3 TB4 TB5P1

P2

P3

P4

J3

1

2

3

LED3LED2LED1

NetCom Bus

*A *A

*A - Optional wiring for

Style 7 supervision

+-+-

120 VAC

(Supervised)

*1

24V Battery

(Supervised)

*1

F

I

R

E

E

O

L

EOLR

F

I

R

E

F

I

R

E

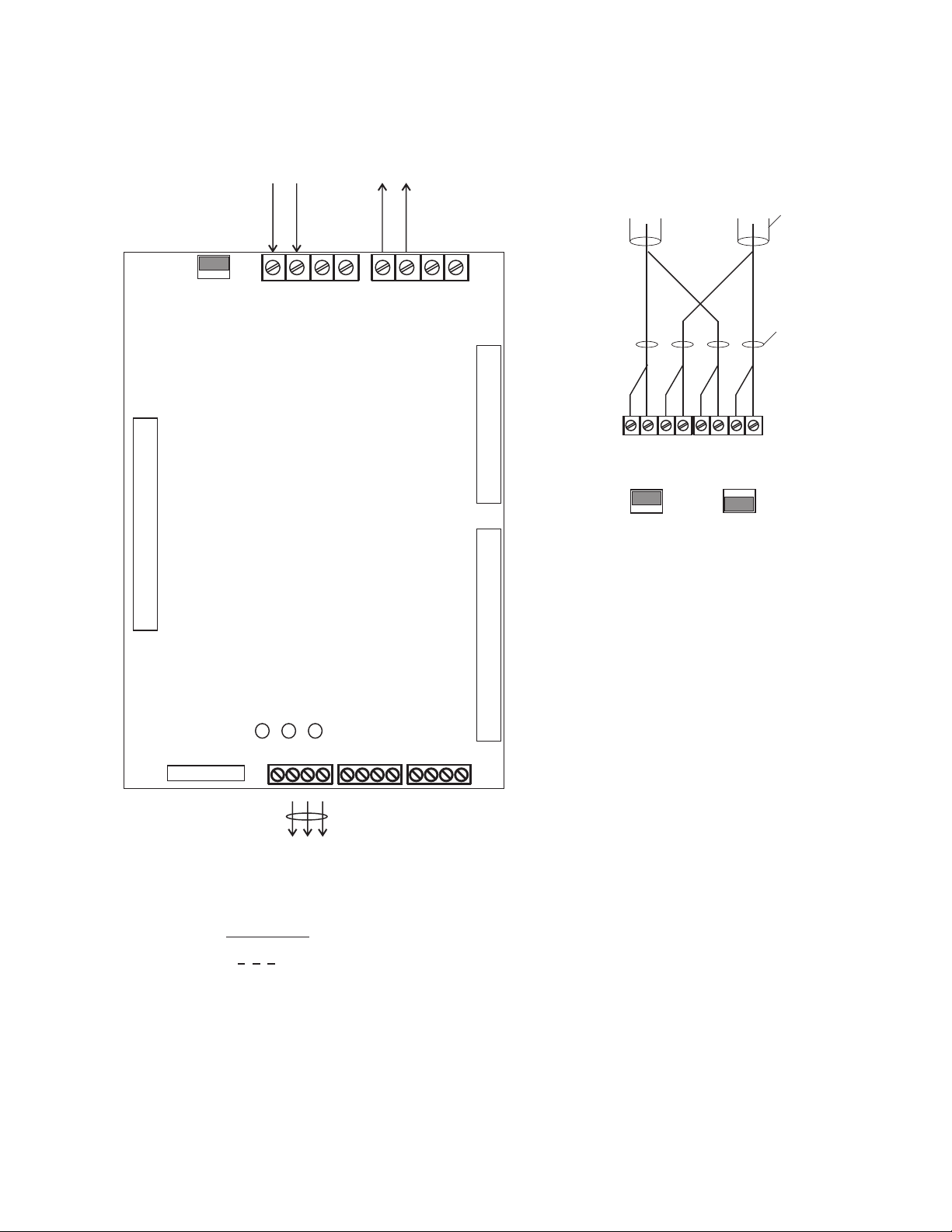

Standard Life Safety Speakers, Strobes connected and powered separately.

Ground faults are indicated at 10K impedance or less.

Break wire to maintain supervision. Do not loop wire around speaker terminals.

CLASS “B” (Style “Y”)

WIRING

Supervised - Power Limited

Fire

Phone

Loop

F

I

R

E

F

I

R

E

EOL

CLASS “A” (Style “Z”)

WIRING

Supervised

Power Limited

Matching

EOLR

MBR

TB2 TB3 TB4

TB10

J5

J6

J7

TB9

TB5 TB6 TB7

TB8

TB11

1 2 3 4

TB1

1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4

J8

J11

J9

J1

J2

J3

J4

LED1

P9

P10

P11

P12

P13

P14

P15

P16

P1 P2 P3 P4 P5 P6 P7 P8

31

1

2

3

4

50W Maximum

Speaker line EOLR must be

equal to Matching EOLR

installed on TB9. All must be

Listed EOL devices.

SPEAKER OUTPUT

PVC-25E

PVC-50E

PVC-100E

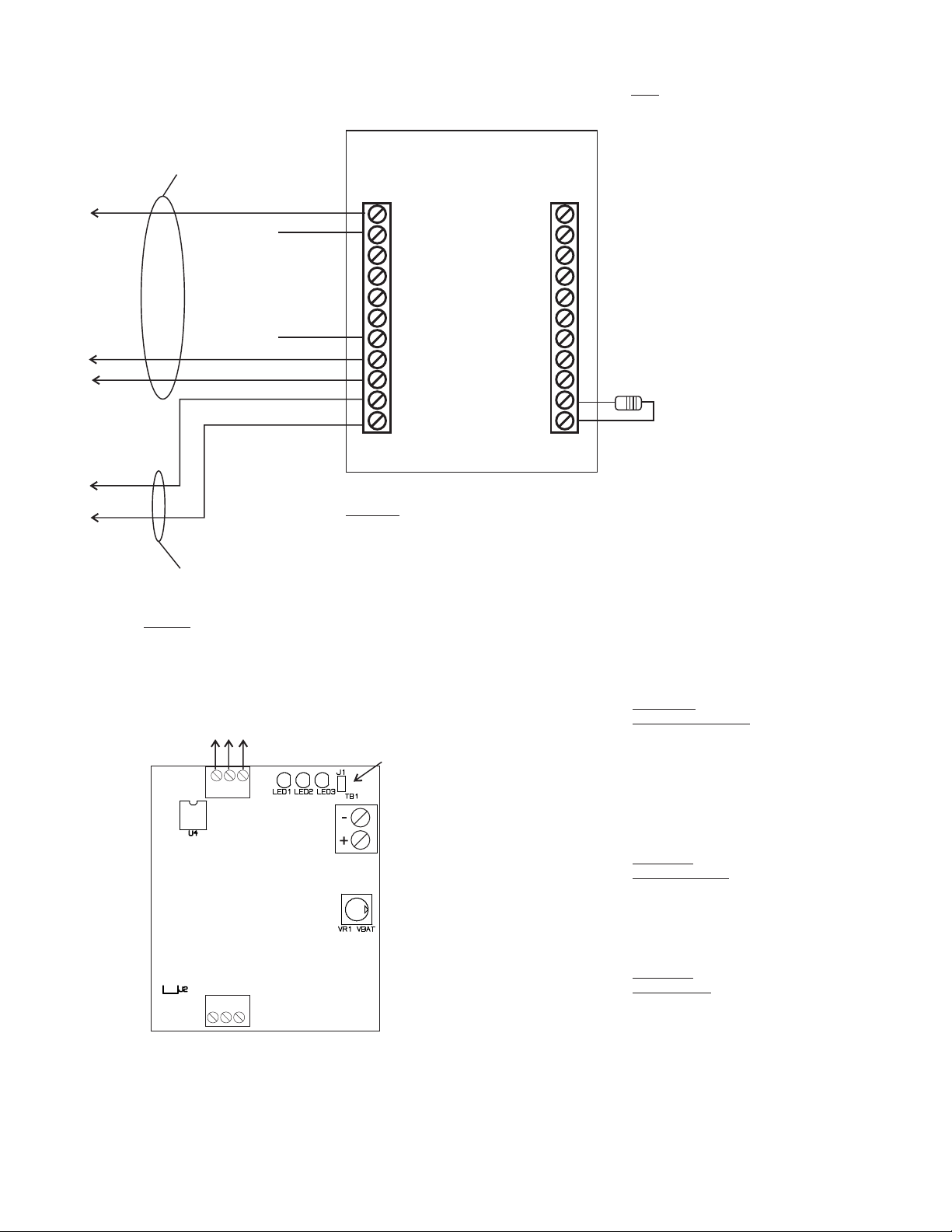

TB1

1 2 3 45 6 7 8

TB3

1

2

3

4

5

6

7

8

MESSAGE

GAIN

MIC

GAIN

FAULT

NORMAL

ALARM

YEL

GRN

RED

TB2

1

2

3

4

5

6

7

8

9

10

11

P2

S1

SN1

1 2 3

J2

J1

1

2

PVC-25E

PVC-50E

PVC-100E

TB1

1 2 3 45 6 7 8

TB3

1

2

3

4

5

6

7

8

MESSAGE

GAIN

MIC

GAIN

FAULT

NORMAL

ALARM

YEL

GRN

RED

TB2

1

2

3

4

5

6

7

8

9

10

11

P2

S1

SN1

1 2 3

J2

J1

1

2

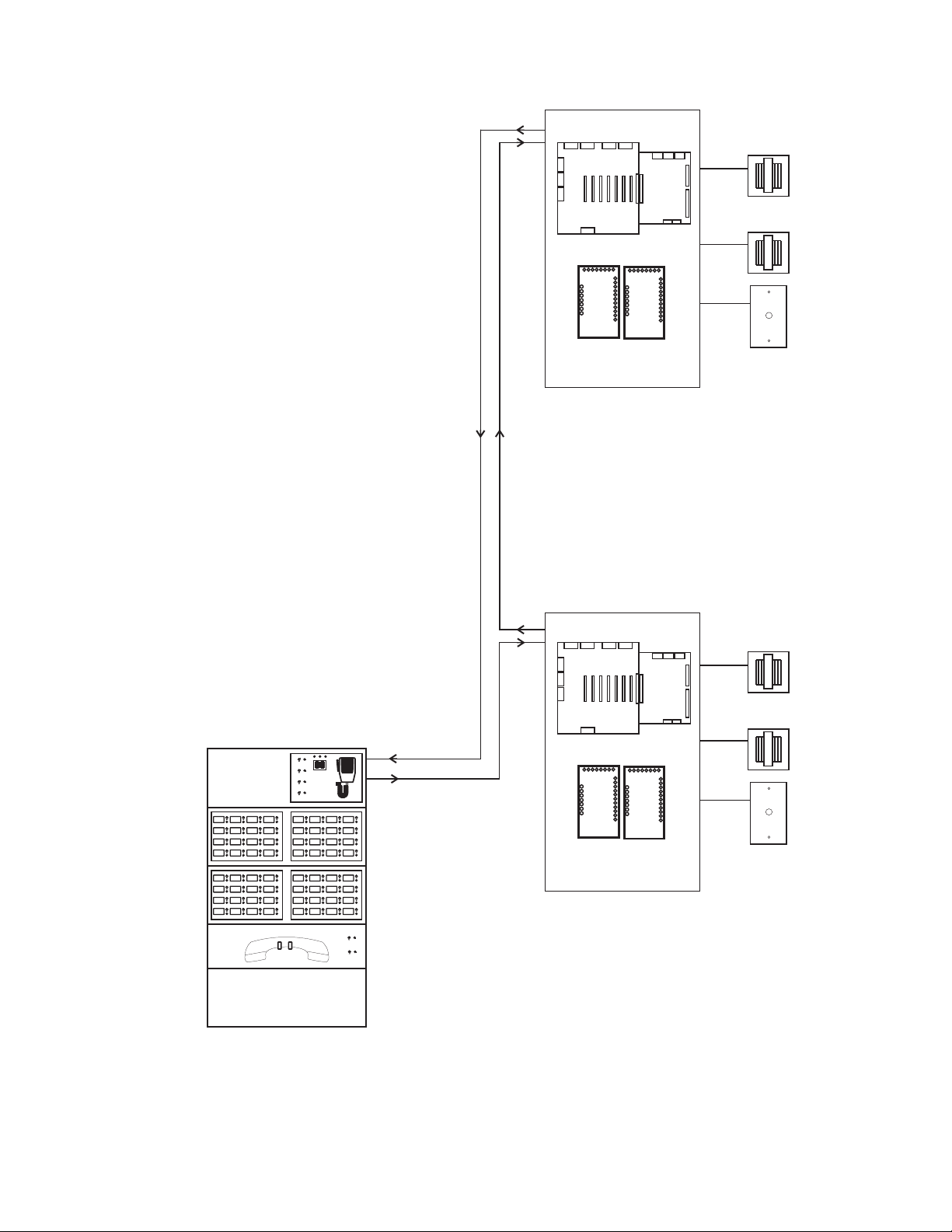

Distributed Panel Wiring

PVC 25(E) / 50(E) / 100(E) TROUBLE CODES

When a unit goes into a Trouble Condition, the Yellow LED wil remain on until the trouble is cleared. The Green

LED will flash a Code to indicate the type of Trouble Condition. There will be a pause between repeats of the

code. When multiple Trouble Conditions occur at the same time, the codes will add together.

The number of flashes and associated Trouble Condition are listed below.

Code Trouble Code Trouble

1 Power Failure 8 Amplifier Trouble

2 Open Speaker Circuit 16 Microphone Trouble

4 Shorted Speaker Circuit 32 Battery Trouble

6 External Trouble / Ground Fault

* 6 flashes typically indicates “External Trouble”, such as an PVC-RM. If LED 4 is on, the 6 flash indicates a ground fault.

If both a ground fault condition and an external trouble occur simultaneously, the fault codes will not combine for 12 flash.

Refer to Installation Instructions P/N PV-5001 for all amplifier specifications

Field wiring connections:

#6-32 wire clamp screw 14-18 AWG

#8-32 wire clamp screw 12-18 AWG

Horizontal wire entry terminal 18-26 AWG

Wire gauge determined by circuit load

LED 4

MIC

GAIN

LED 4

page 7

Supervised, Power Limited

Ground faults are indicated

at 10K impedance or less.

Supervised, Power Limited

Ground faults are indicated

at 10K impedance or less.

Note: Panels may be supplied with

transformers wired for 240 VAC for those

regions where this is required. Please

refer to Ratings section for Primary

Power differences.