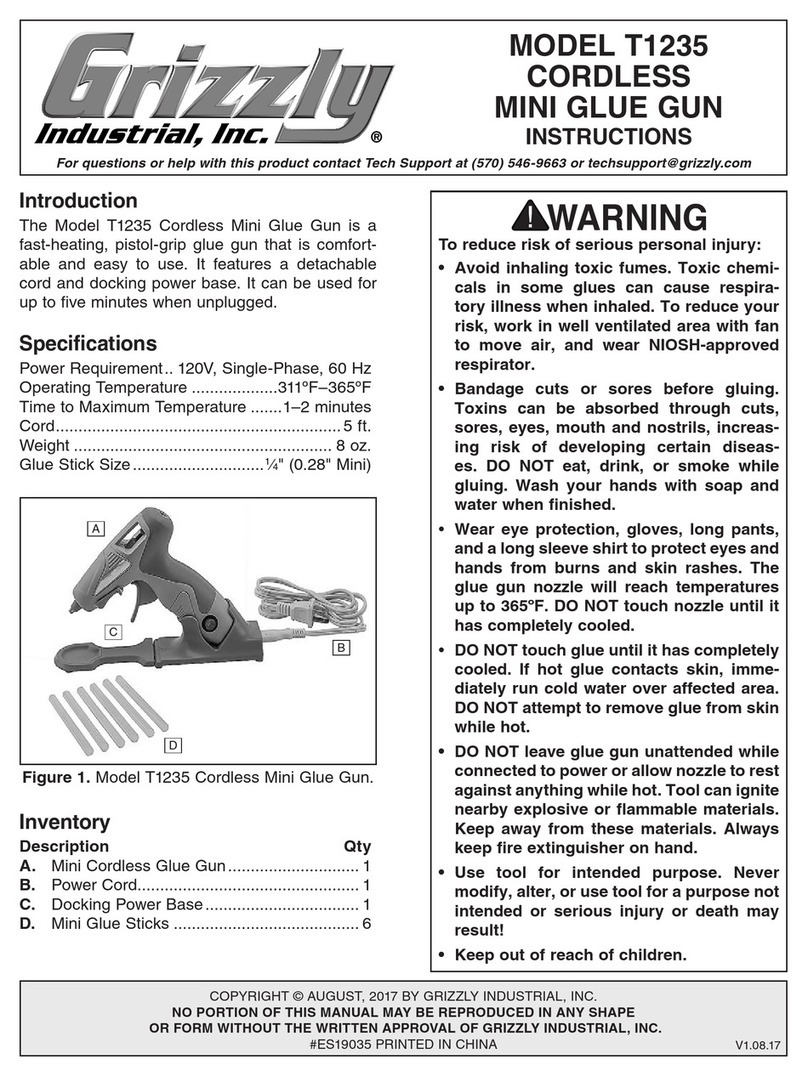

SAFETY INSTRUCTIONS

Do not touch the nozzle or molten adhesive with bare skin as they are

hot - the operating temperature of this tool is approximately 200°C /

392°F (LT 120°C / 248°F). Protective gloves should always be worn.

Careless handling can cause skin burns. If molten adhesive comes into

contact with the skin, immerse the affected area immediately in plenty of cold

water. Seek medical advice if necessary. In addition to the safety instructions

herein, any statutory regulations, local re insurance regulations, or other

generally valid “regulations for accident prevention” must be complied with

when using this tool.

Repairs should only be undertaken by competent personnel with the

adequate electrical knowledge. Before proceeding with any maintenance or

repair operation, disconnect the tool from the mains electricity supply. If in

doubt, contact your supplier.

• WARNING - This tool must be placed on its stand when not in use; do not

leave the tool unattended when switched ON.

• Place the tool on its stand after use and allow it to cool down before storage.

• Never use the tool if it is damaged in any way. If the supply cord is

damaged, it must be replaced by the manufacturer, its service agent or

similar qualied persons in order to avoid a hazard.

• Do not use this tool whilst under the inuence of drugs or alcohol.

• Do not use this tool in damp rooms, and do not expose to rain or moisture.

• Do not use this tool in the vicinity of any heat-sensitive materials, or any

ammable materials, liquids, or gases, and do not apply to the same place

for a long time.

• Only use extension cables with a wire cross-section of 1.5mm² / 16 a.w.g.

and no more than 20m / 65 ft in length.

• Never pull on the tool’s connecting cable.

• This tool is not intended for the use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the tool by a person responsible for their safety.

GUARANTEE AND REPAIRS

This tool is guaranteed against faulty workmanship and

materials for a period of 12 months from the date of purchase.

Within this warranty period the manufacturers undertake, at

their discretion, to either repair or replace any tool proved to

be defective (proof of purchase will be required for verication).

This guarantee is invalidated if the tool is opened, or modied in

any way, or if adhesive formulations other than those supplied by

the tool’s manufacturer are used. Warranty claims attributable

to improper, or careless, use or handling, and to normal wear,

are excluded from this guarantee.

The supplier’s and manufacturer’s only obligation shall be to

replace such tools that are proved to be defective. Neither

supplier nor manufacturer shall be liable for any injury, loss or

damage, direct or consequential, arising out of the use, or the

inability to use, this tool. The user shall determine the suitability

of this product for its intended use, and the user assumes all

risks and liability whatsoever in connection therewith.

The manufacturer reserves the right to improve or modify this

product without prior notice.

Do not connect to the main supply at this point!

AVOIDING PROBLEMS

For help with fault nding, please visit our website:

For optional part, please visit our website:

www.poweradhesives.com

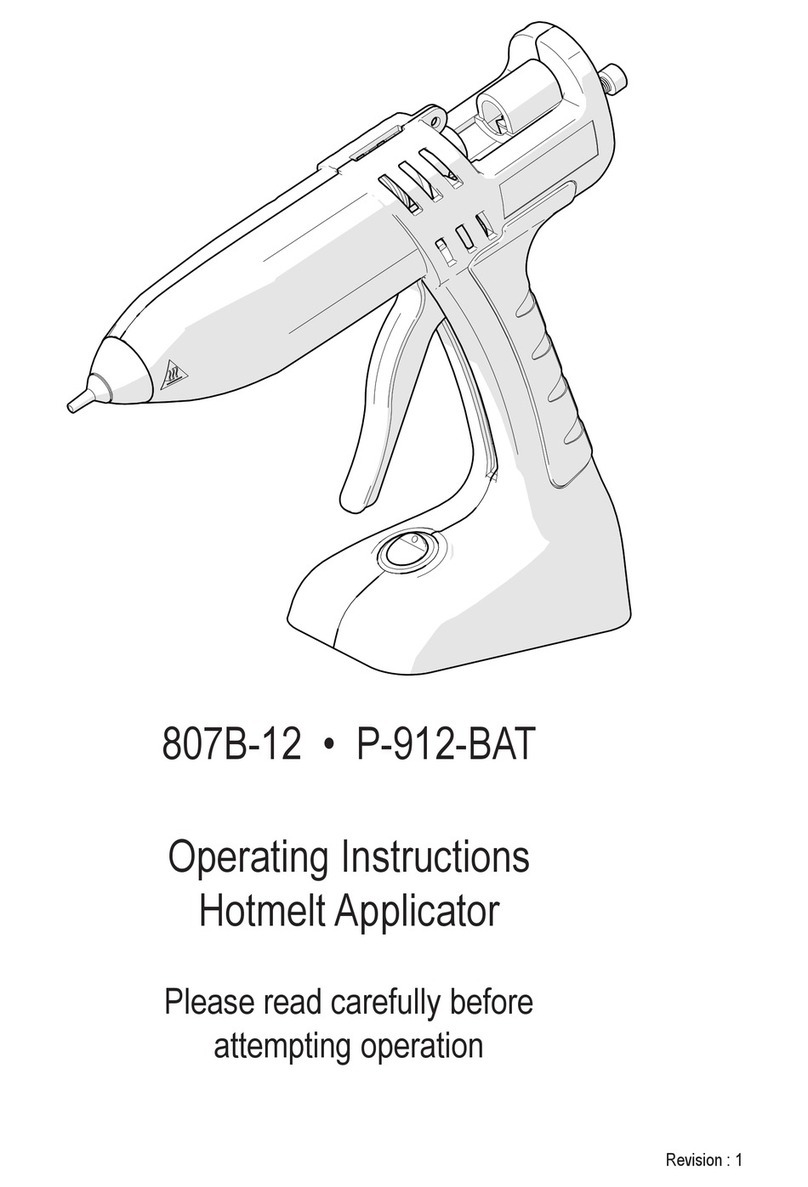

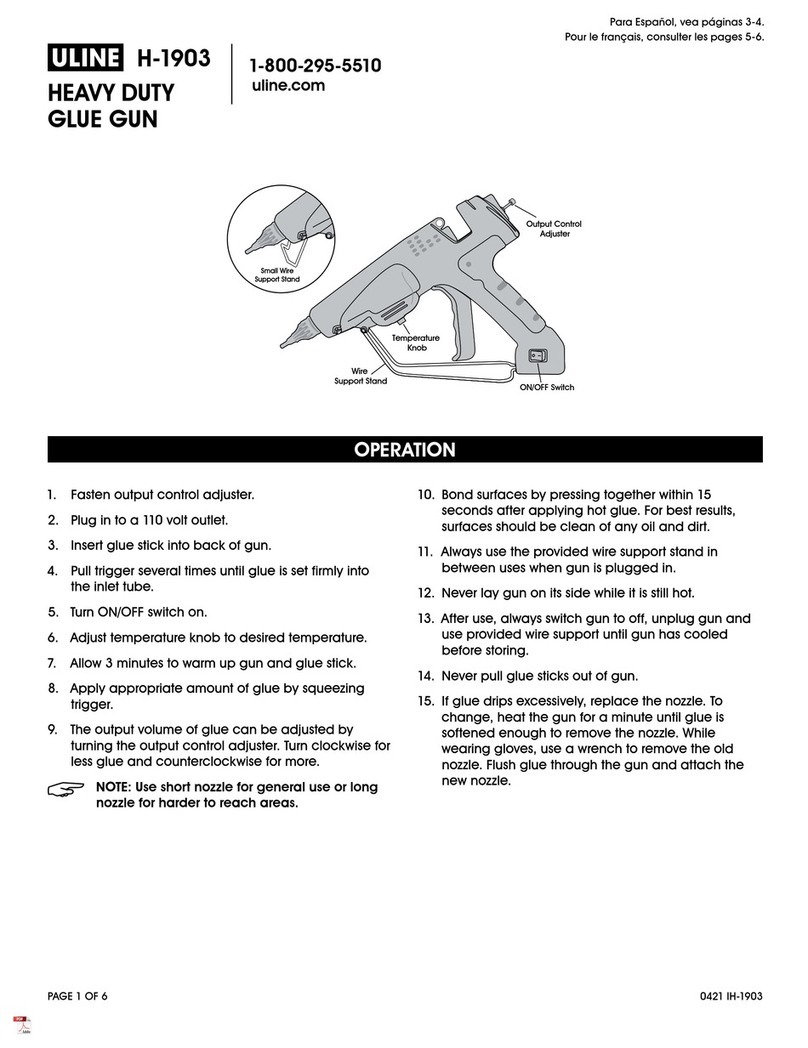

1. Attach the tool stand

2. Connect the air supply

3. Pull the piston back fully and rotate upwards

4. Load 2 adhesive cartridges

5. Rotate the piston down and slide forward

6. Connect to mains supply

7. Red light illuminates

8. Wait 10 minutes

9. Operate trigger to push adhesive forward to the reload

position

10. Reload the tool when the sound of air can be heard

escaping (the piston is now at its most forward point)

11. Adjust the pressure regulator to vary the dispensing rate of

adhesive - ‘+’ increase ow, ‘-’ decrease ow

12. Screw the stand to a table or work surface for extra

stability

13. To switch off the tool, disconnect from the mains supply

• Ensure that tool has reached temperature before

operating.

• Do not leave tool switched on for long periods without use

• If tool is not to be used for more than 40 minutes, switch

off and restart when required.

• Never lay the tool on its side. Always use stand provided,

the optional bench stand or the suspension unit.

• Only use adhesives designed for use with this tool.

1

2

3

4

5

6

7

8

9