PREVENTATIVE MAINTENANCE

∗ When in use, do not lay the tool on its side - always place upright using the stand provided.

∗ Do not use excessive force on the trigger. Ensure that the tool has fully warmed up before

use.

∗ Keep the nozzle clean to prevent adhesive build-up. This is easily done by wiping the nozzle

with clean paper or cloth whilst the nozzle is still warm.

∗ Should “glue backup” or “meltback” accidentally occur (when molten adhesive becomes

visible at the point where the glue stick enters the heater tube), switch off the tool and allow

the adhesive to cool. Gently pull away this excess adhesive, reconnect the power, and allow

the tool to warm up again. Now squeeze the trigger two or three times to advance the glue

stick then use the tool as normal.

SERVICE AND REPAIRS

Except for the replacement of the nozzle, the TEC 250 contains no user-serviceable parts.

GUARANTEE

This TEC 250 is guaranteed against faulty workmanship and materials for a period of 12

months from the date of purchase. Within this warranty period the manufacturers undertake, at

their discretion, to either repair or replace any tool proved to be defective (proof of purchase will

be required for verification). This guarantee is invalidated if the tool is opened, or modified in any

way, or if adhesive formulations other than those supplied by the tool’s manufacturer are used.

Warranty claims attributable to improper, or careless, use or handling, and to normal wear, are

excluded from this guarantee.

The supplier’s and manufacturer’s only obligation shall be to replace such tools that are proved

to be defective. Neither supplier nor manufacturer shall be liable for any injury, loss or damage,

direct or consequential, arising out of the use, or the inability to use, this tool. The user shall

determine the suitability of this product for its intended use, and the user assumes all risks and

liability whatsoever in connection therewith.

The manufacturer reserves the right to improve or modify this product without prior notice.

BOND • SEAL • ASSEMBLE • INSULATE • REINFORCE • ENCAPSULATE • REPAIR • FILL – INSTANTLY

Suitable for use with most materials. Just apply TEC-BOND®hotmelt to one surface then press

parts together and the bond is made. Can be used for bonding: Wood, Paper, Cardboard, Foam,

Chipboard, Hardboard, some Plastics, Rubber, Glass, thin Metals, Ceramics, Leather, Fabrics

and many more.

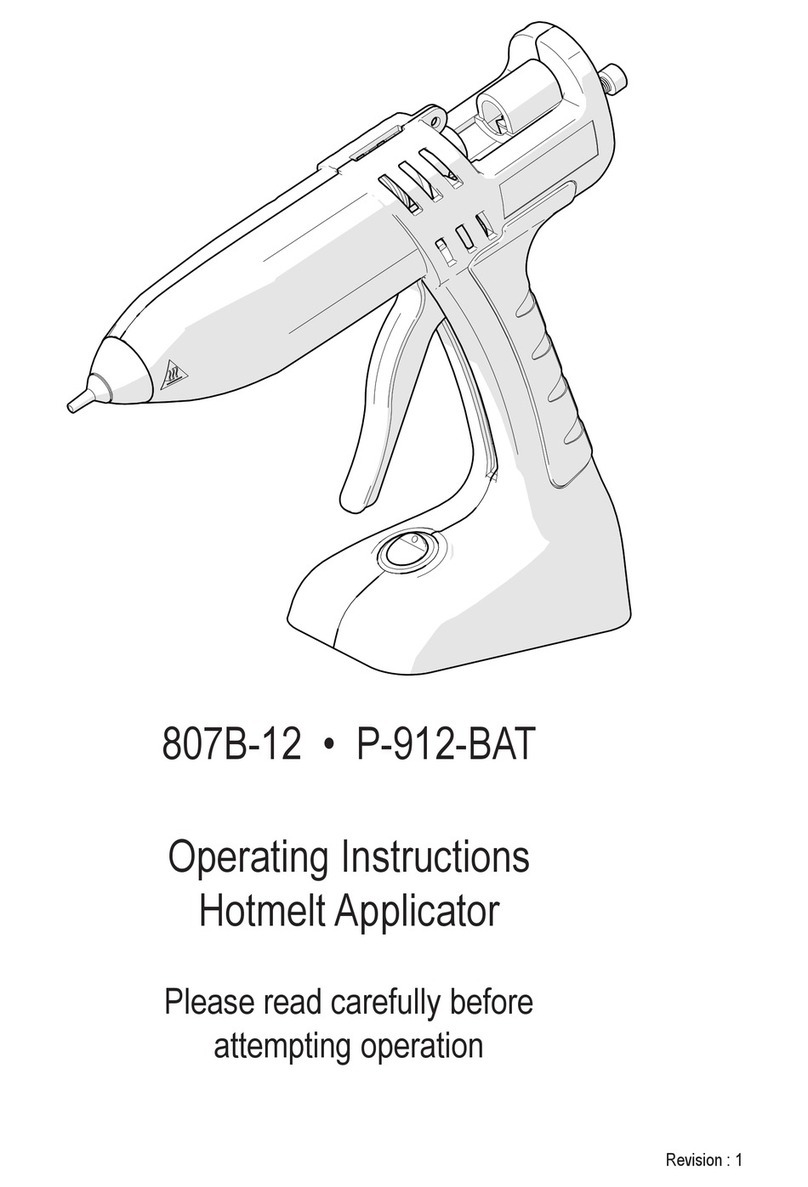

The TEC 250 is simplicity itself, to operate just plug into any power supply (100 - 240 VAC) and

the gun will be ready for use in just 7 minutes. Glue sticks can be fed continuously through the

back of the gun. Use only genuine TEC-BOND®high performance glue sticks.

Technical data

Dimensions (L x H x W): approx. 175 x 165 x 38 mm

Total weight: approx. 370 g

Connection cable with mains plug: 1.8 m long

Operating voltage: 100 to 240 VAC 50/60Hz

(electronic voltage control)

Heating up time: 5 - 7 min.

Operating temperature: approx. 200° C

Diameter of adhesive inlet: 11 - 12 mm

(use only genuine TEC-BOND®adhesive sticks)

Power consumption

Heating up phase: approx. 500 W

Rest period: approx. 20 W

Operating phase: approx.45 W

Extension cable: max. 20 m long

Wire cross section: at least 1.5 mm2

Declaration of conformity

We declare under our sole responsibility that this product is in conformity with the following standards or

standardisation documents:

EN 55014-1: 1997; EN 61000-3-2: 1995; EN 61000-3-3: 1995; EN 55014-2: 1997; EN 60335-2-45:

1990 according to the provisions of the regulations 73/23/EEC, 89/336/EEC (and amendments).

Made in England

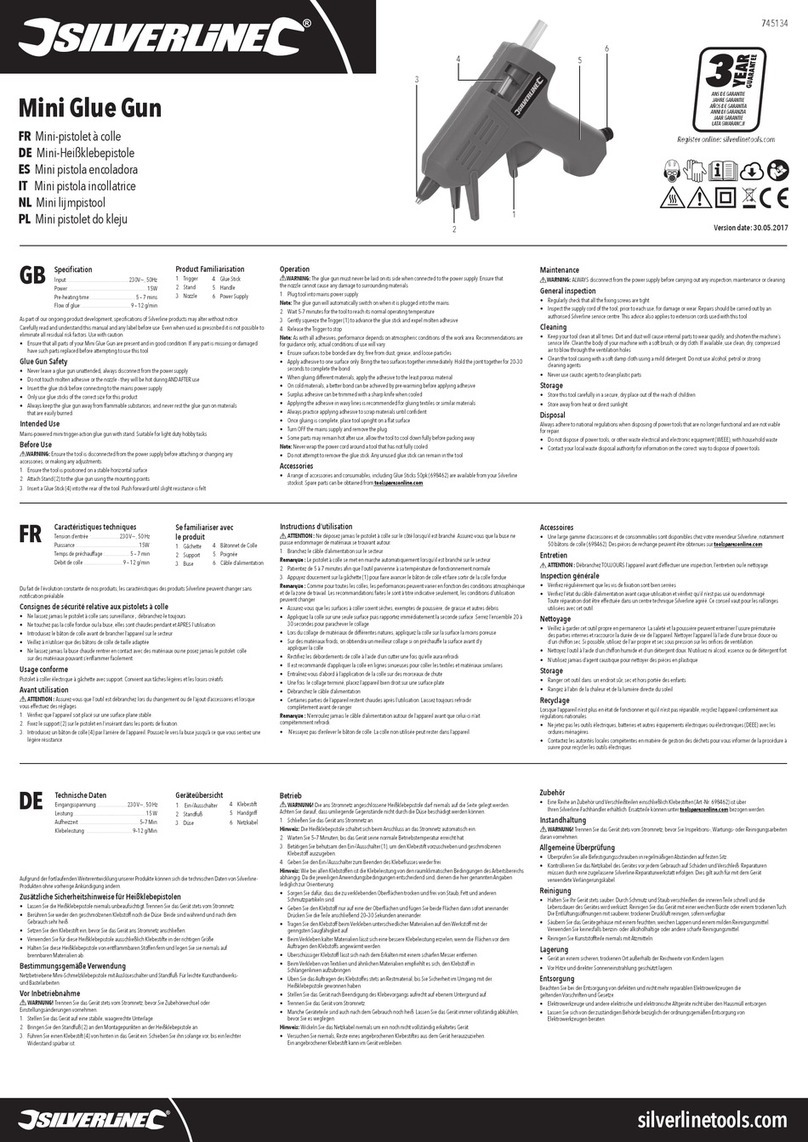

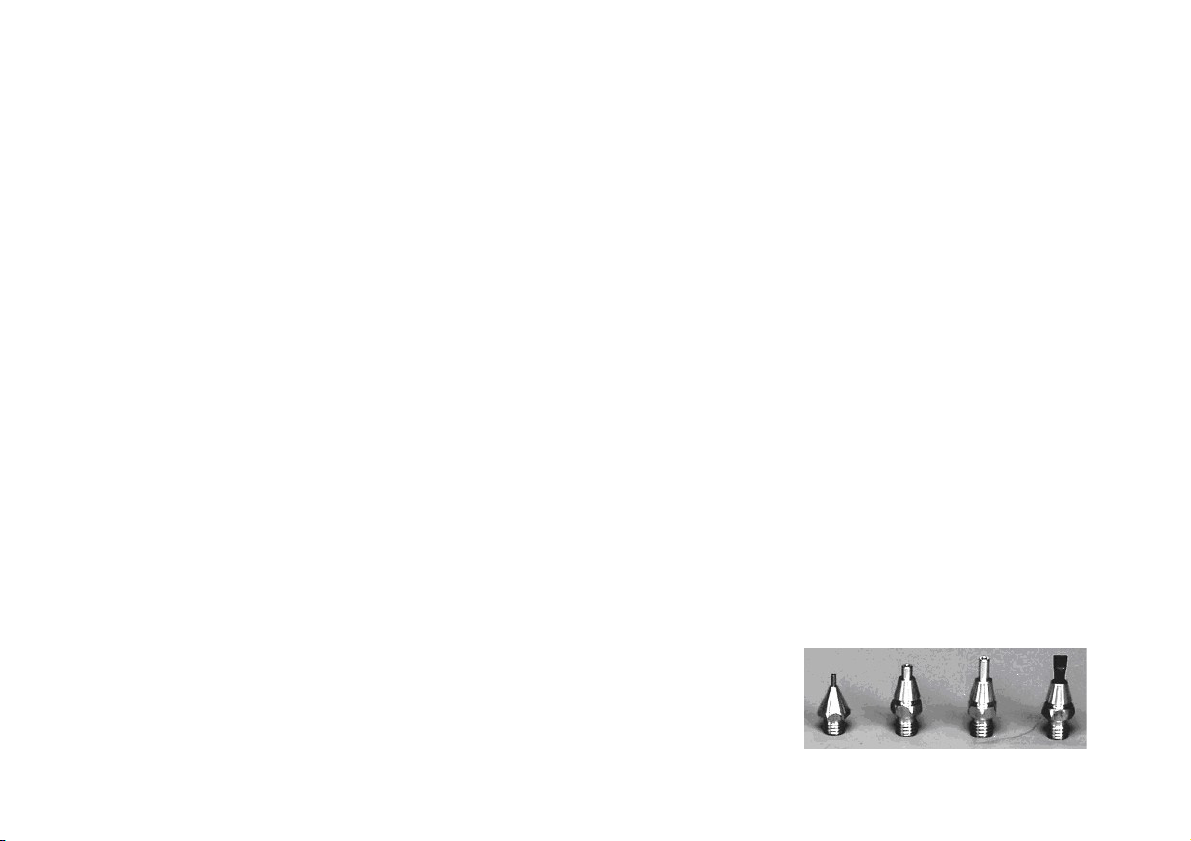

OPTIONAL NOZZLES:

MDJ004 Extension nozzle

MDJ005 Spreader nozzle

MDJ006 Pencil-point nozzle

MDJ008 Precision nozzle

MDJ008 MDJ006 MDJ004 MDJ005