Perceuse pneumatique coudée de 3/8 po

6En cas de questions techniques, appelez le 1-800-665-8685

8011796

V 2,7

SOIN ET UTILISATION DE L’OUTIL

1. Utilisez le bon outil pour la tâche à effectuer. Ne forcez pas un outil ou un accessoire pour

effectuer le travail d’un outil industriel plus gros. Maximisez la performance de l’outil et la

sécurité en utilisant l’outil pour des travaux pour lesquels il a été conçu.

2. Cet outil a été conçu pour une utilisation spécifique. Évitez de modifier ou d’altérer cet outil ou

de l’utiliser à une fin autre que celle pour laquelle il a été conçu.

3. Tenez cet outil solidement des deux mains. L’utilisation de l’outil d’une seule main peut causer

une perte de maîtrise.

4. Entretenez les outils avec soin (consultez la section Entretien).

5. Avant de mettre l’outil en marche, retirez les clés et les clavettes de réglage, s’il y a lieu.

Toute clé ou clavette qu’on laisse attachée à une pièce rotative de l’outil pose un risque de

blessures corporelles.

6. Évitez les mises en marche involontaires. Assurez-vous que la gâchette est en position neutre

ou ARRÊT lorsque l’outil n’est pas utilisé et avant de le brancher à une source d’air.

7. Ne transportez pas l’outil avec les doigts sur la gâchette ou à proximité de ceux-ci.

INSTALLATION DE LA SOURCE D’AIR

AVERTISSEMENT ! N’utilisez jamais d’oxygène pur, de dioxyde de carbone, de gaz combustibles ou

de gaz en bouteille comme source d’air pour un outil. De tels gaz peuvent causer une explosion et des

blessures graves.

1. Réglez le régulateur de pression d’air sur le compresseur d’air à la pression (lb/po carré)

recommandée pour l’outil (voir Spécifications). Ne dépassez pas la pression d’air recommandée

de l’outil. Une pression excessive pourrait endommager l’outil ou votre pièce à travailler, ou

vous causer de sérieuses blessures.

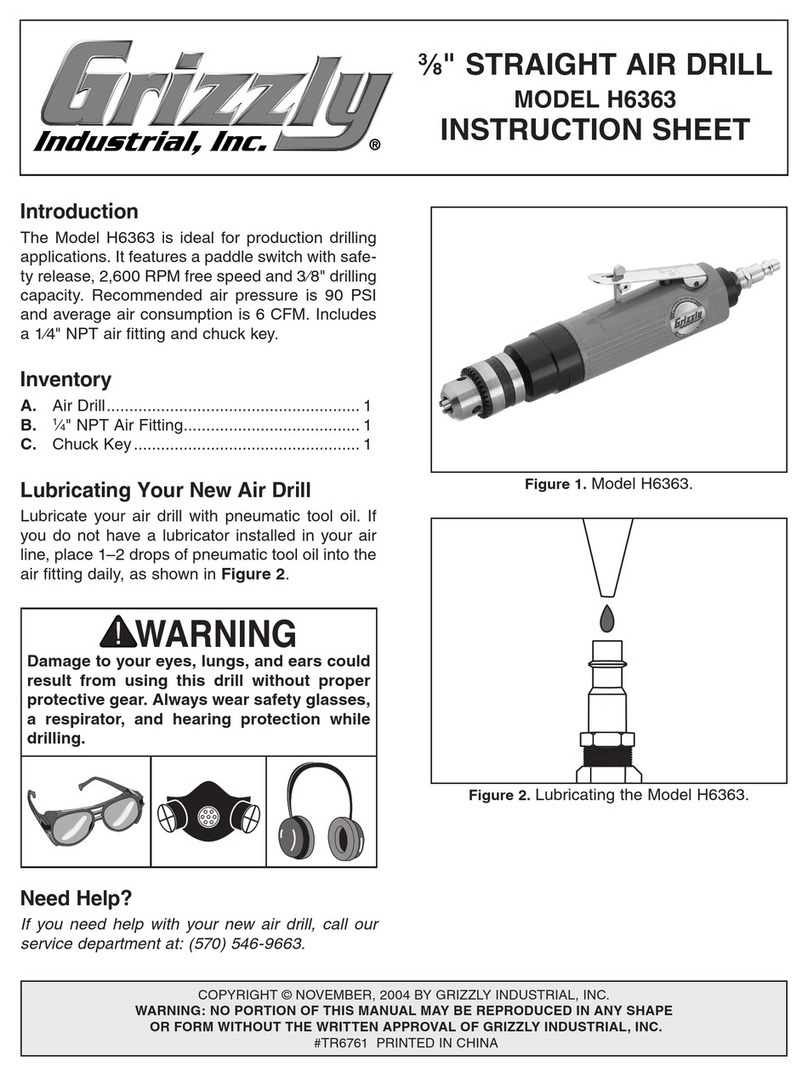

2. Préparez un raccord pneumatique standard de 1/4 po convenant à votre outil. Enveloppez la

partie filetée du raccord pneumatique à l’aide d’un ruban d’étanchéité pour filetage. Enveloppez

en sens horaire de façon qu’il ne se déroule pas lors du raccordement à un raccord rapide.

Attachez le raccord à l’entrée d’air de l’outil et serrez.

3. Raccordez le tuyau de la source d’air à un raccord rapide standard. Raccordez le tuyau à air au

raccord pneumatique de l’outil.

4. Vérifiez s’il y a des fuites dans le circuit d’air et les connections. N’utilisez pas l’outil avant

d’avoir réparé toutes les fuites d’air.

DÉCONNEXION DE LA SOURCE D’AIR

AVERTISSEMENT ! Le non-respect de cet avertissement pourrait entraîner des blessures graves ou

des dommages à l’outil ou au matériel.

Déconnectez l’outil de la source d’air avant le nettoyage, l’entretien ou le remplacement de pièces ou

d’accessoires et lorsqu’il n’est pas utilisé.

1. Amenez le régulateur pneumatique à la position ARRÊT ou L.

2. Éteignez le compresseur d’air.

3. Déconnectez le tuyau pneumatique.