IMPORTANT!

FORSLIDEGATEOPERATINGSYSTEMS

SAFETY IS EVERYONE’S BUSINESS

Automatic gate operators provide convenience and security to

users. However, because these machines can produce high

levels of force, it is important that all gate operator system

designers, installers, and end users be aware of the potential

hazards associated with improperly designed, installed, or

maintained systems. Keep in mind that the gate operator is a

component part of a total gate operating system.

The following information contains various safety precautions

and warnings for the system designer, installer and end user.

These instructions provide an overview of the importance of

safe design, installation, and use.

Warnings are identified with the ▲symbol. This symbol will

identify some of the conditions that can result in serious injury or

death. Take time to carefully read and follow these precautions

and other important information provided to help ensure safe

system design, installation and use.

▲WARNING:Gate operators are only one part of a

TOTAL GATE OPERATING SYSTEM. It is the

responsibility of purchaser, designer, and installer to ensure

that the total system is safe for its intended use. All

secondary entrapment safety devices must be

RECOGNIZED by U/L to ensure the safety of the complete

operating system.

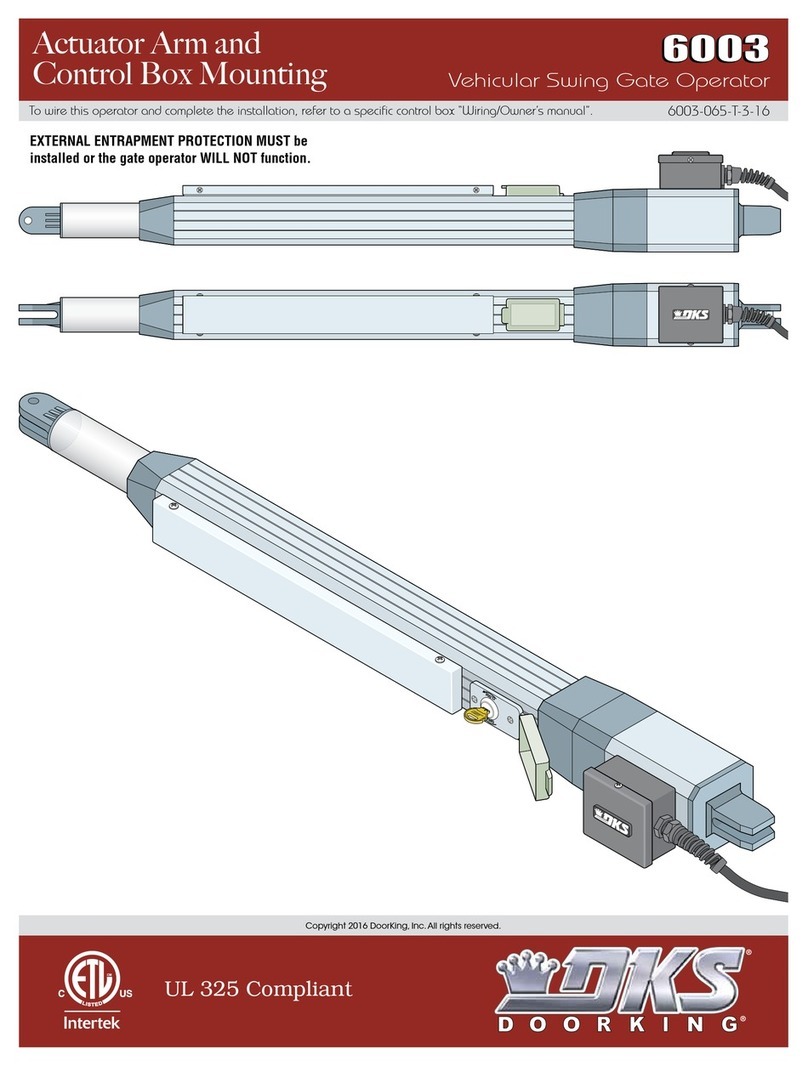

▲WARNING:This operator is only intended for installation

on gates used for vehicular traffic. A separate pedestrian

access opening shall be provided which is designed to

promote pedestrian usage and shall be located such that

persons will not come in contact with the vehicular gate

during its entire path of travel.

4

U/L INSTALLATIONAND SAFETY

CONSIDERATIONS

INSTALLATION CLASSES

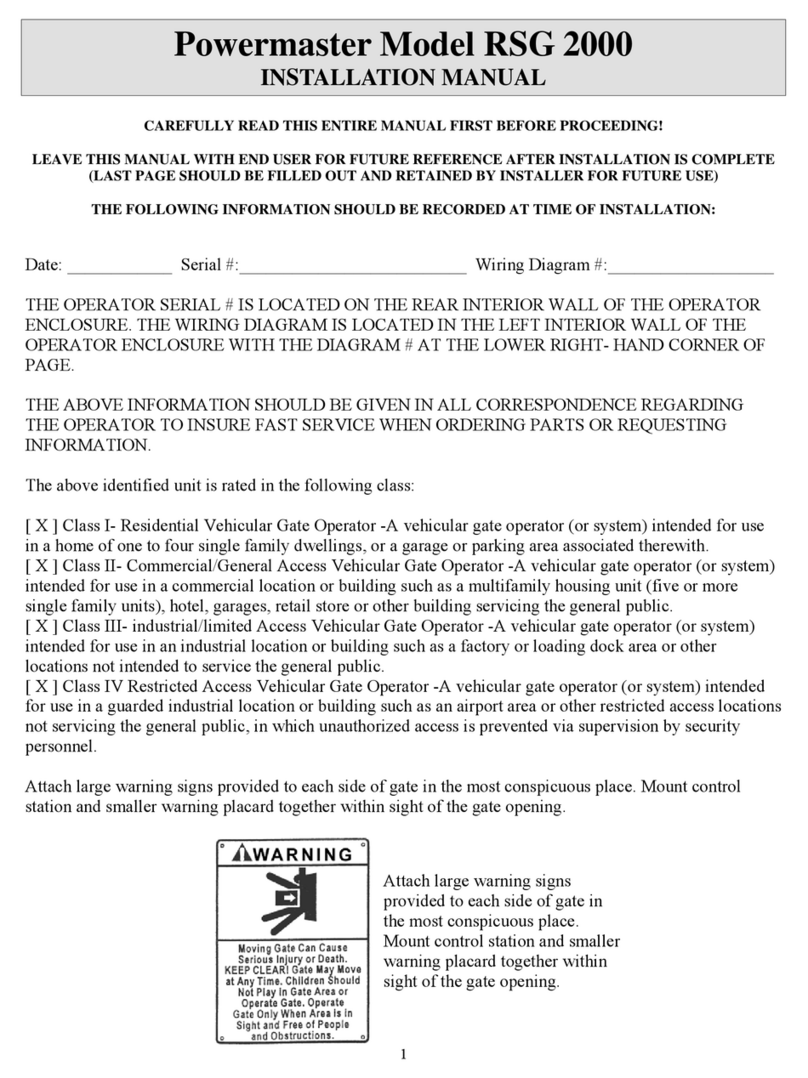

CLASS I – RESIDENTIALVEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in

a home of one to four single-family dwellings, or a garage or

parking area associated therewith.

CLASS II–COMMERCIAL/GENERAL ACCESS VEHICULAR

GATE OPERATOR

A vehicular gate operator (or system) intended for use in a

commercial location or building such as a multifamily housing

unit (five or more single family units), hotel, garages, retail store

or other building servicing the general public.