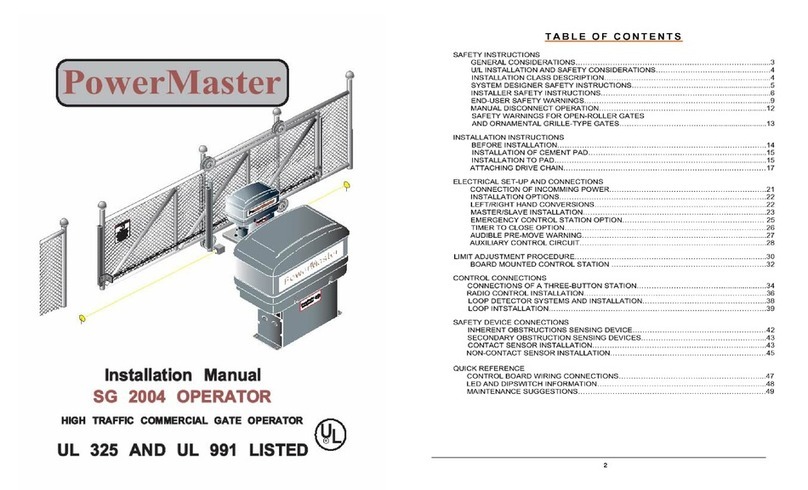

Power Master SG 2004 Installation instructions

Other manuals for SG 2004

1

Table of contents

Other Power Master Gate Opener manuals

Power Master

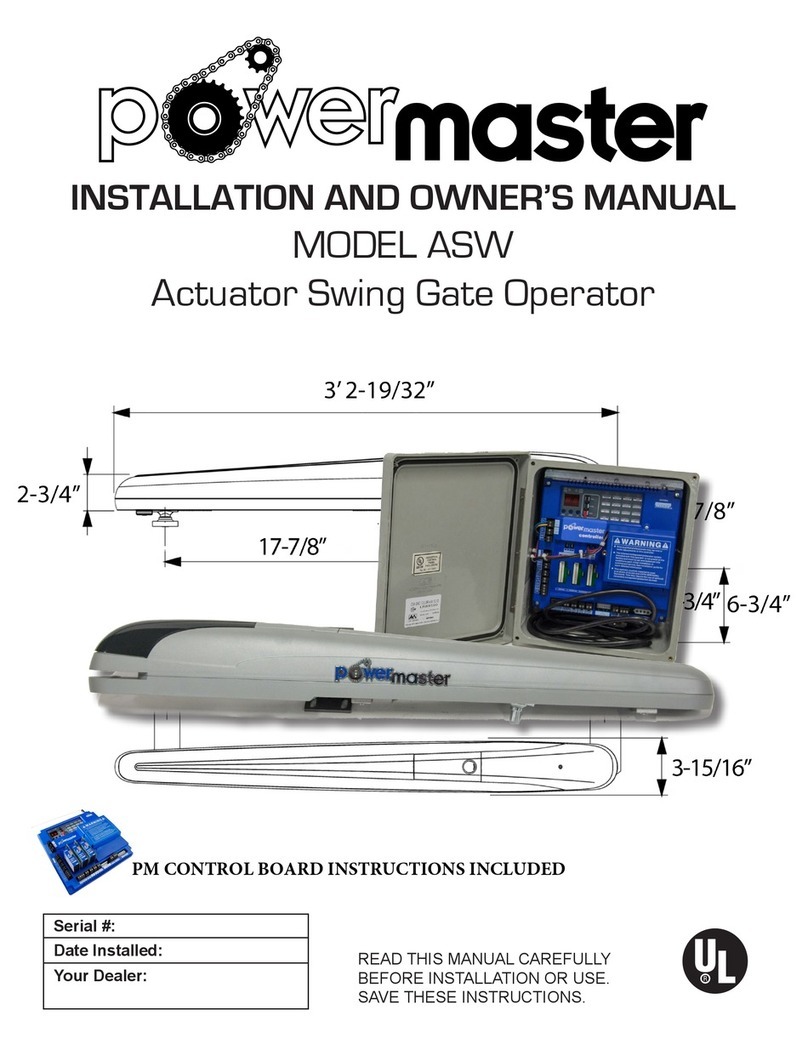

Power Master ASW Installation instructions

Power Master

Power Master SG Operating instructions

Power Master

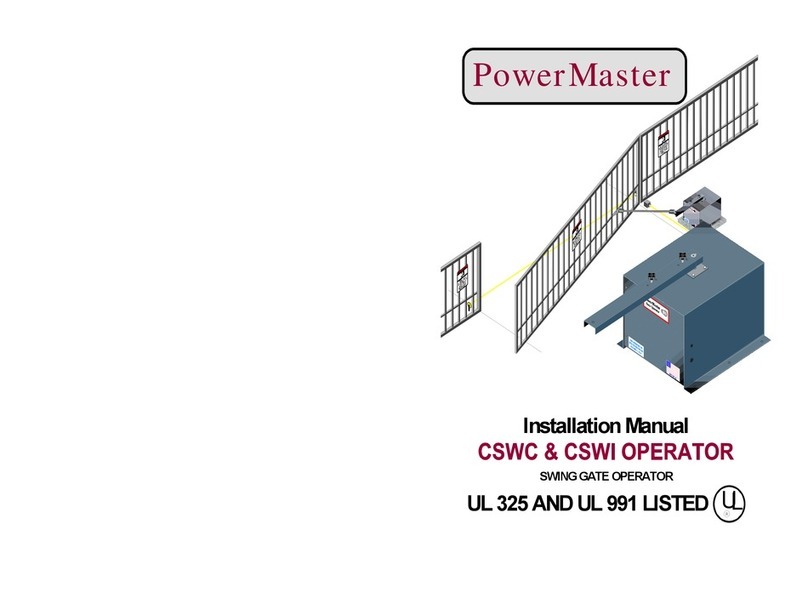

Power Master CSWC User manual

Power Master

Power Master CSG 2004 User manual

Power Master

Power Master MBG User manual

Power Master

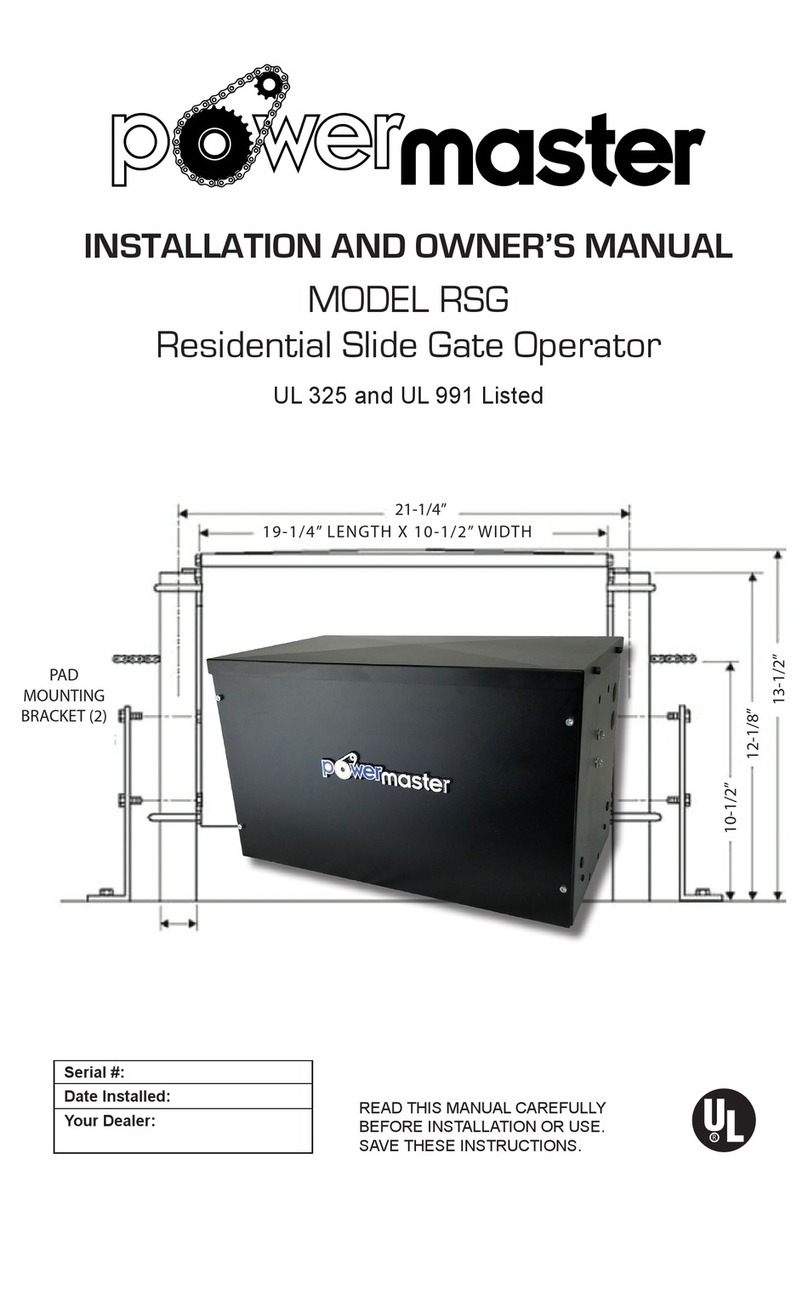

Power Master RSG User manual

Power Master

Power Master RSG 2000 User manual

Power Master

Power Master SG 2004 User manual

Power Master

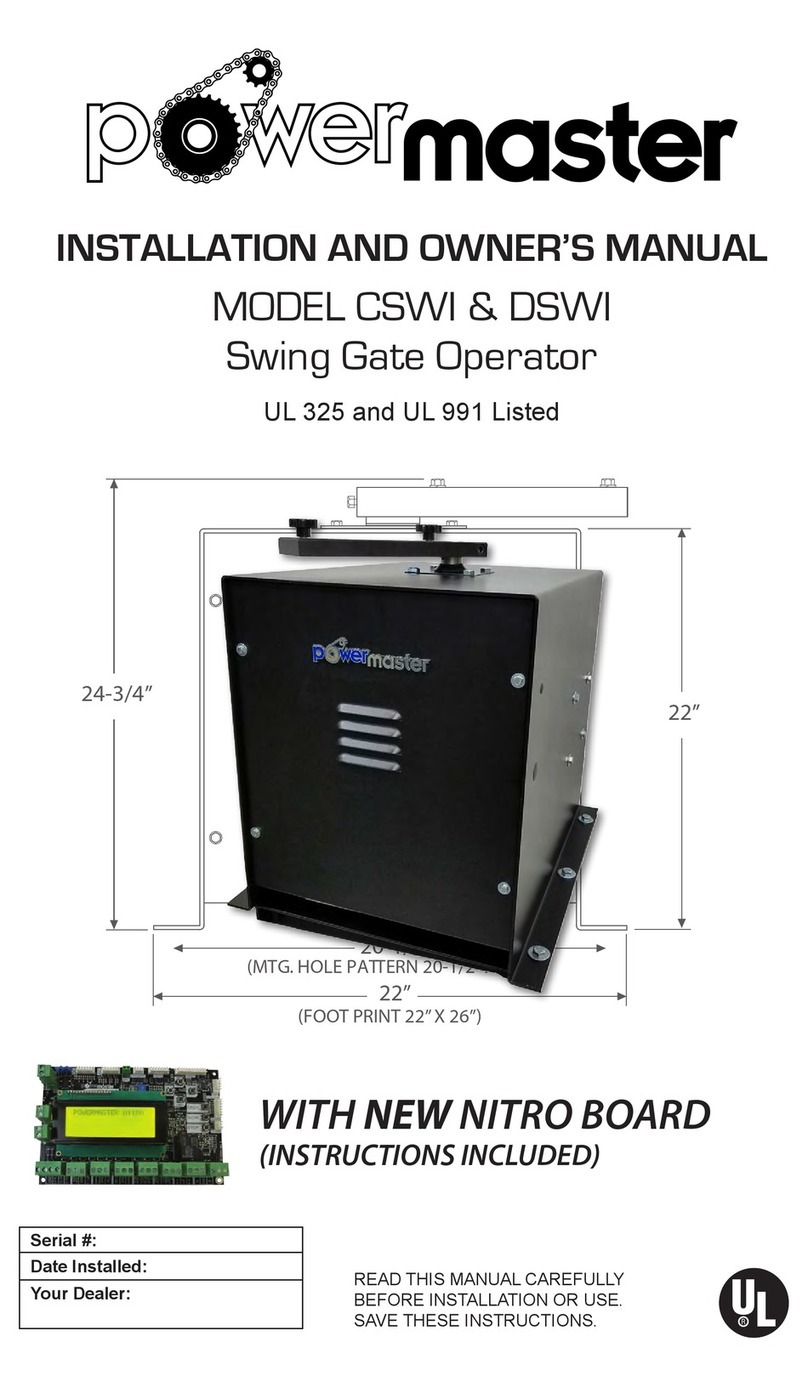

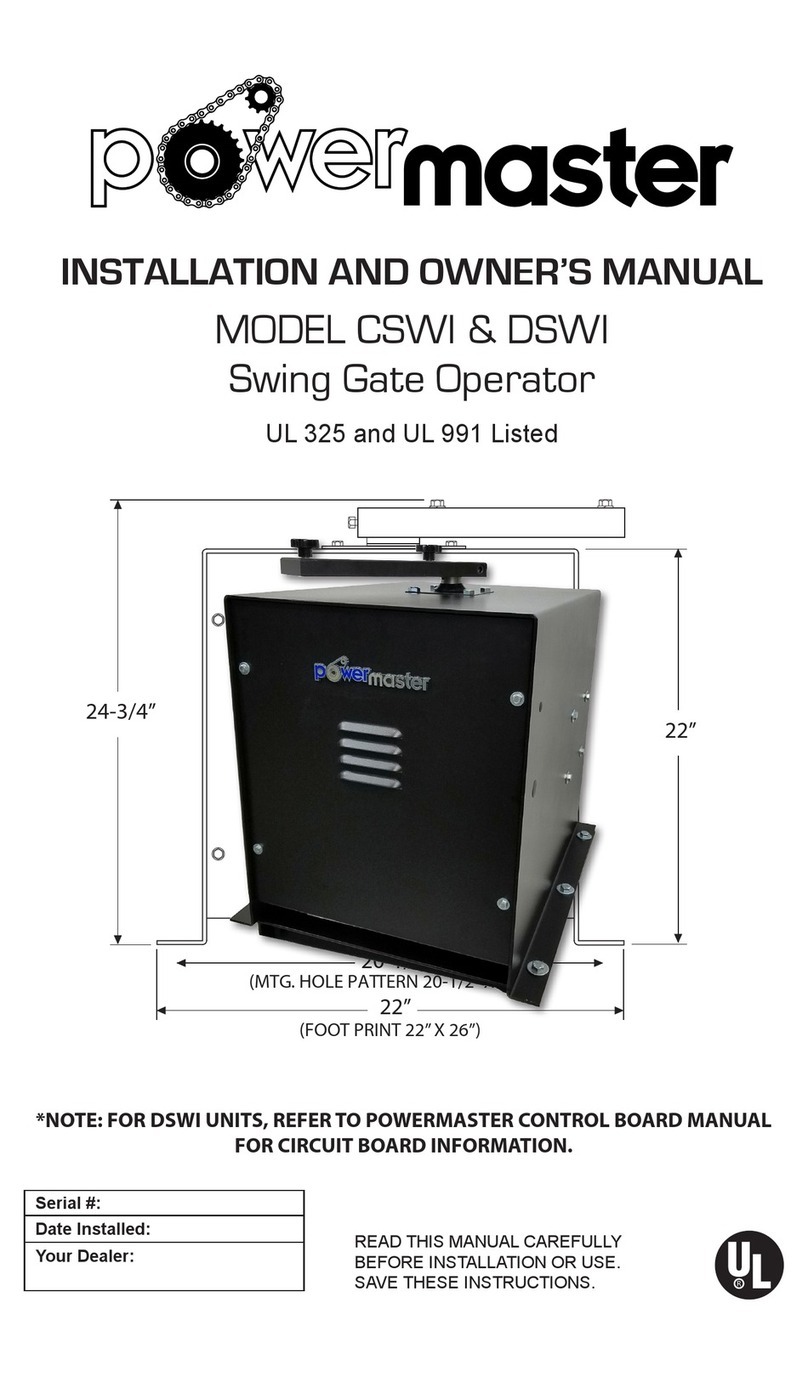

Power Master DSWI Installation instructions

Power Master

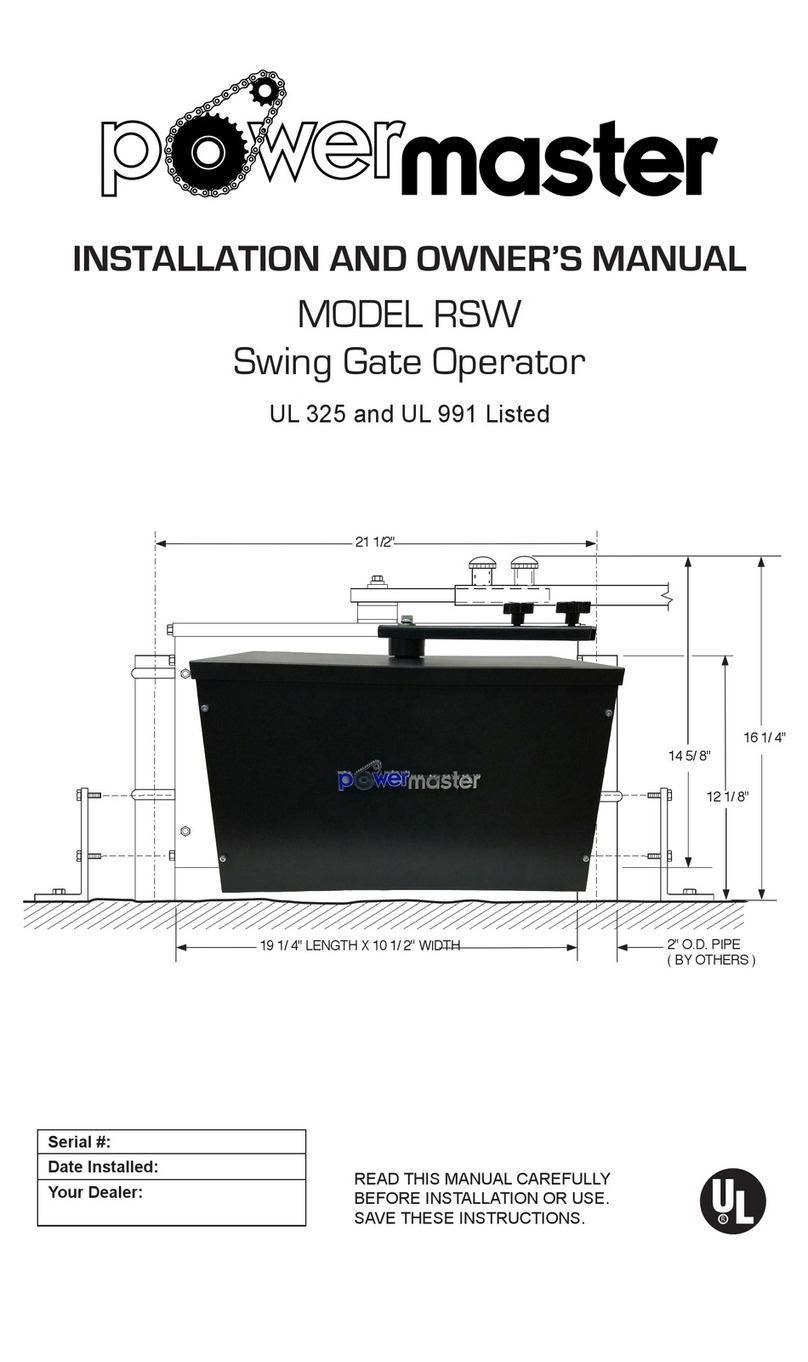

Power Master rsw Installation instructions

Popular Gate Opener manuals by other brands

Life

Life Optimo OP3 Instructions and warnings for installation, use and maintenance

Chamberlain

Chamberlain LA412PKGUL instruction manual

fadini

fadini HINDI 880 EVO instruction manual

Beninca

Beninca DU.IT14N Operating instructions and spare parts catalogue

DKS

DKS 9210 owner's manual

Genius

Genius MISTRAL ENV manual

HySecurity

HySecurity SlideSmart DC 15 Installation and maintenance manual

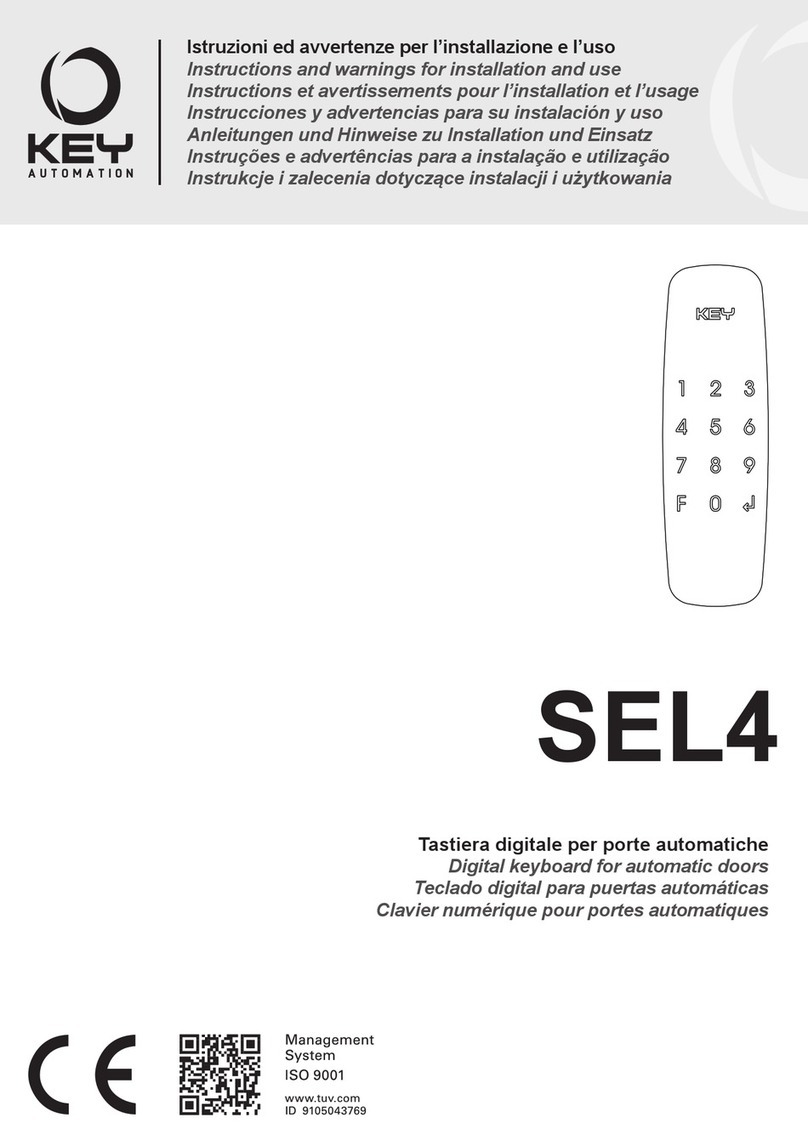

Keyautomation

Keyautomation SEL4 Instructions and warnings for installation and use

Elite

Elite Robo Slide instruction manual

GiBiDi

GiBiDi SERRA321 Instructions for installation

GiBiDi

GiBiDi PASS 600 Instructions for installation

Elite

Elite CSW200UL instruction manual