Tradingate TILT User manual

TILT

ORIGINAL OPERATING INSTRUCTIONS

DEAR CUSTOMER,

Thank you for purchasing this product. Pl as r ad all th instructions in this manual

car fully, b for you ass mbl or us th product. Should you pass on this product to third

parti s, pl as hand ov r th instruction manual along with it.

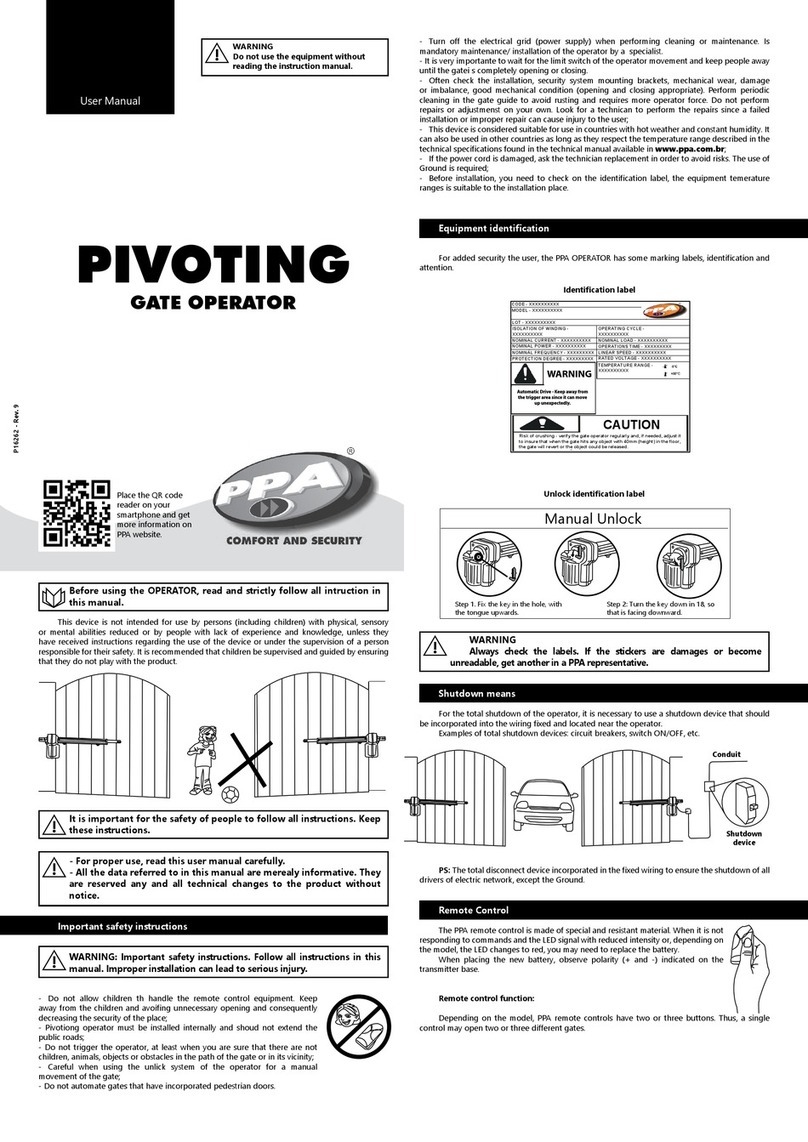

1. IMPORTANT SAFETY INFORMATION

Make sure the power supply (AC110V or AC220V) of the gate operator is

suitable for the power supply of the electrical outlet you are using.

Do not allow chil ren to play with fixe controls. Keep remote controls away from

chil ren.

Remote control is single button control; it means that one button control ON,

STOP, OFF mol , when press button for each mol , the in icator lighte . In

a tion to the remote control operating mol , manually free the key can be use to

liberating the motor an oor, the oor can be runne manually, pull own the

relief han le 90 egrees into horizontal position for relief, relief the han le an

close for locking. See the instructions 9.

When operating a biase -off switch, make sure that other persons are kept away.

Frequently examine the installation for imbalance an signs of wear or amage to

cables, springs an mounting. Do not use if repair or a justment is necessary.

This equipment is not suit for persons with re uce physical or sensory, mental

capabilities, lack of experience or knowle ge (inclu ing chil ren). Unless they

have been given supervision by a professional person.

Repairs may only be carrie out by professionals with the appropriate knowle ge

about the evice.

2. PART LIST

3. TECHNICAL INFORMATION

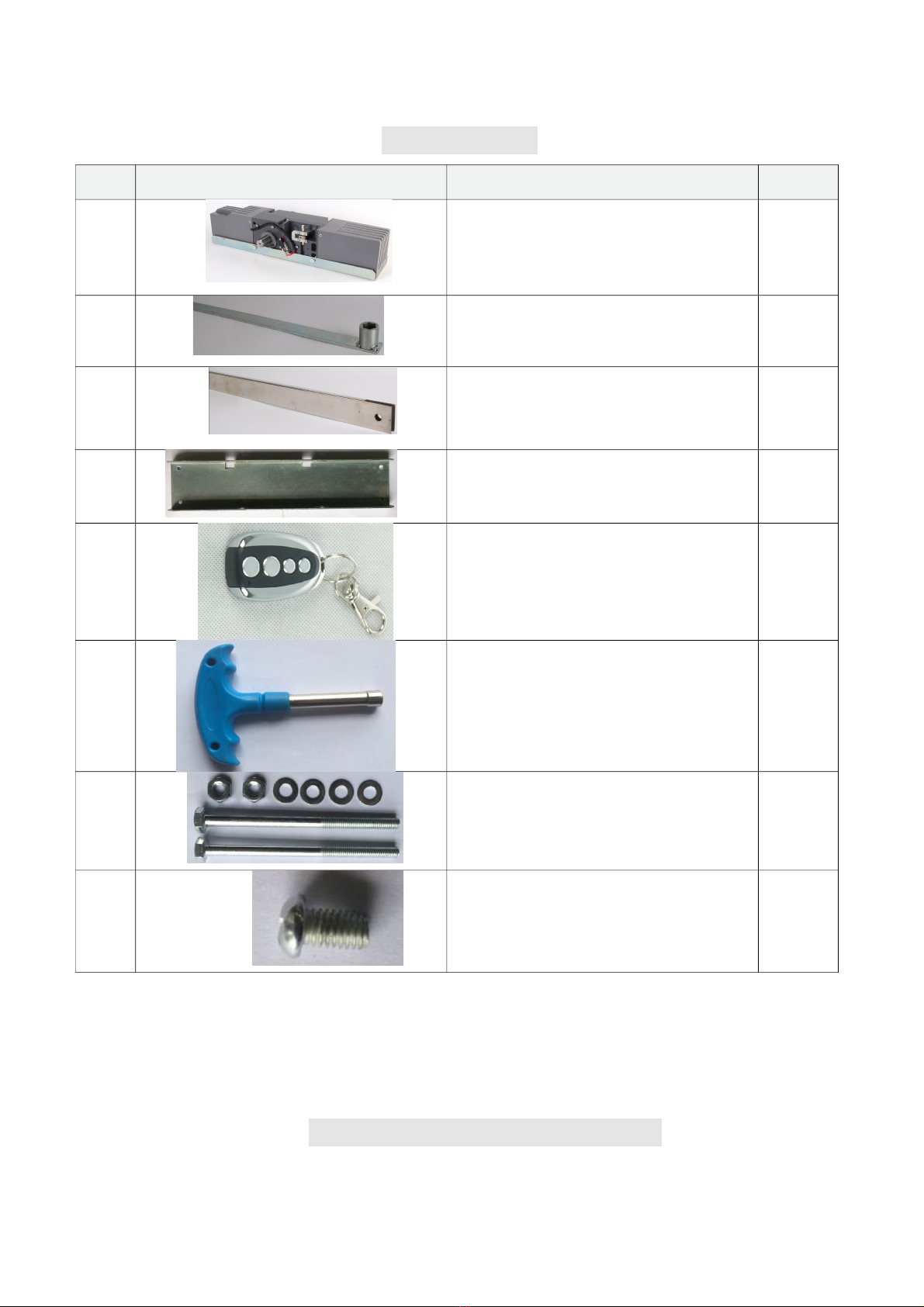

No. Image Description Qty.

1 Gate Operator 1x

2

Ro 1x

3 Sli ing ro 1x

Mounting base plate 1x

4 Remote Control 2x

5 Key (for Manual Operation) 1x

6 Nut (M8) for Gate Operator 2x

7 Retainer bolt M6X10 1x

Type TILT

Power supply 230V 50Hz

Rated output power of motor 200W

Output torque 350N·m

Speed 1.75rpm

Door max. surface 9㎡

Remote control operating distance 30m (Frequency:433.92mHz)

Remote control mode Single button

Limit switch Spring limit switch

Noise ≤58dB

Duty cycle S2 15 minutes

Extra remote control 20

Environmental temperature -20°C ~ +70°C

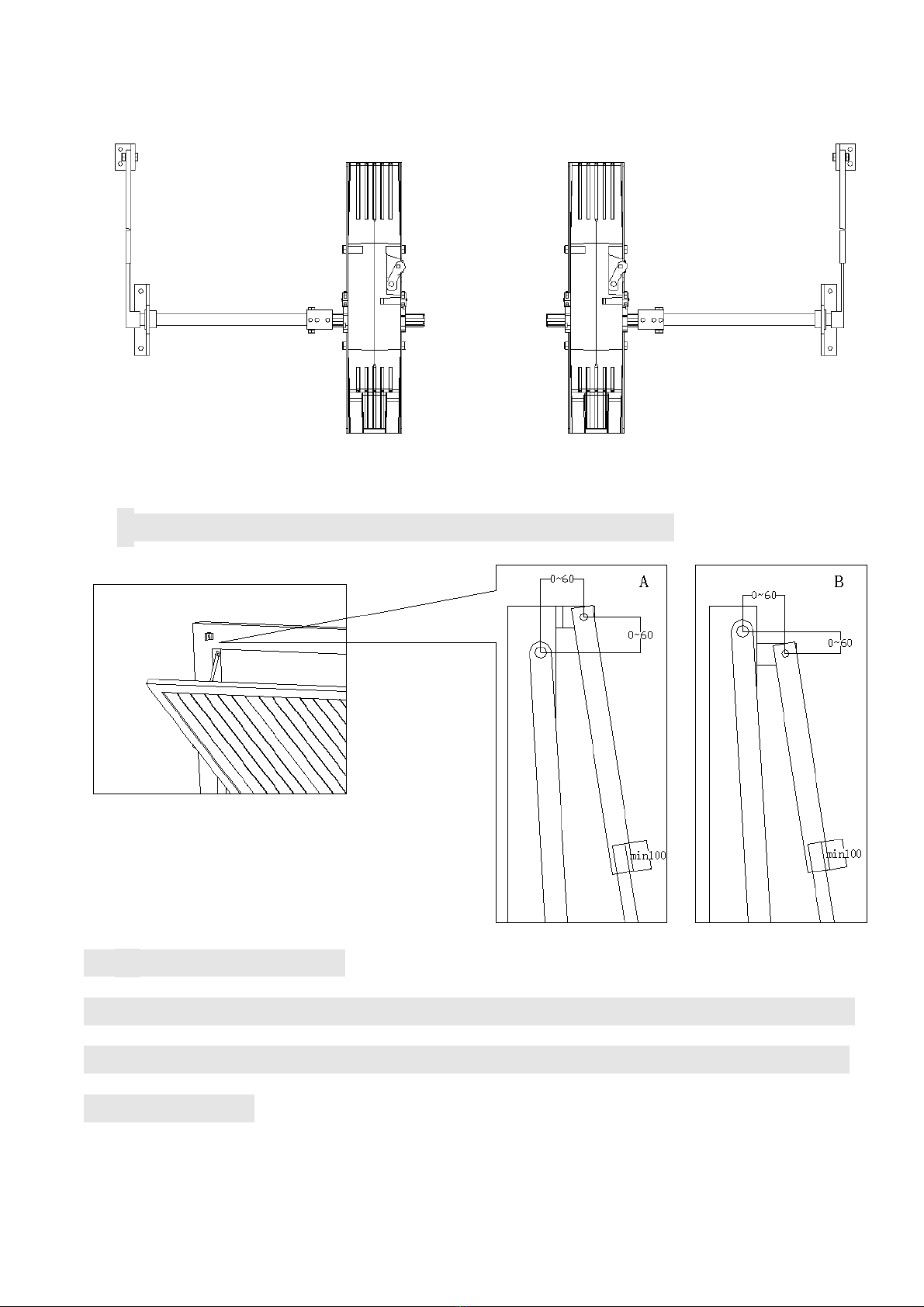

4. INSTALLATION

4.1 Installation diagram

1 Door

2 Rod & sliding rod

3 TILT motor

4 Remote control

5 Wireless keypad (optional)

Alarm lamp (optional)

4.2 Dimension

4.3 Installation

A、Overall flip up type

B、Overall slide down type

C、Folding type

4.4、Installation of link

A、Unilateral single rod type

B、Unilateral double rods type

C、Intermediate double rod type

D、Installation of two motors

* The relative mounting size of the rod and link

4.5、Manual operation

In case of power failure fit the supplied key in the unlock rod (as

shown below) turn it clockwise 180° then can open or close the

gate manually.

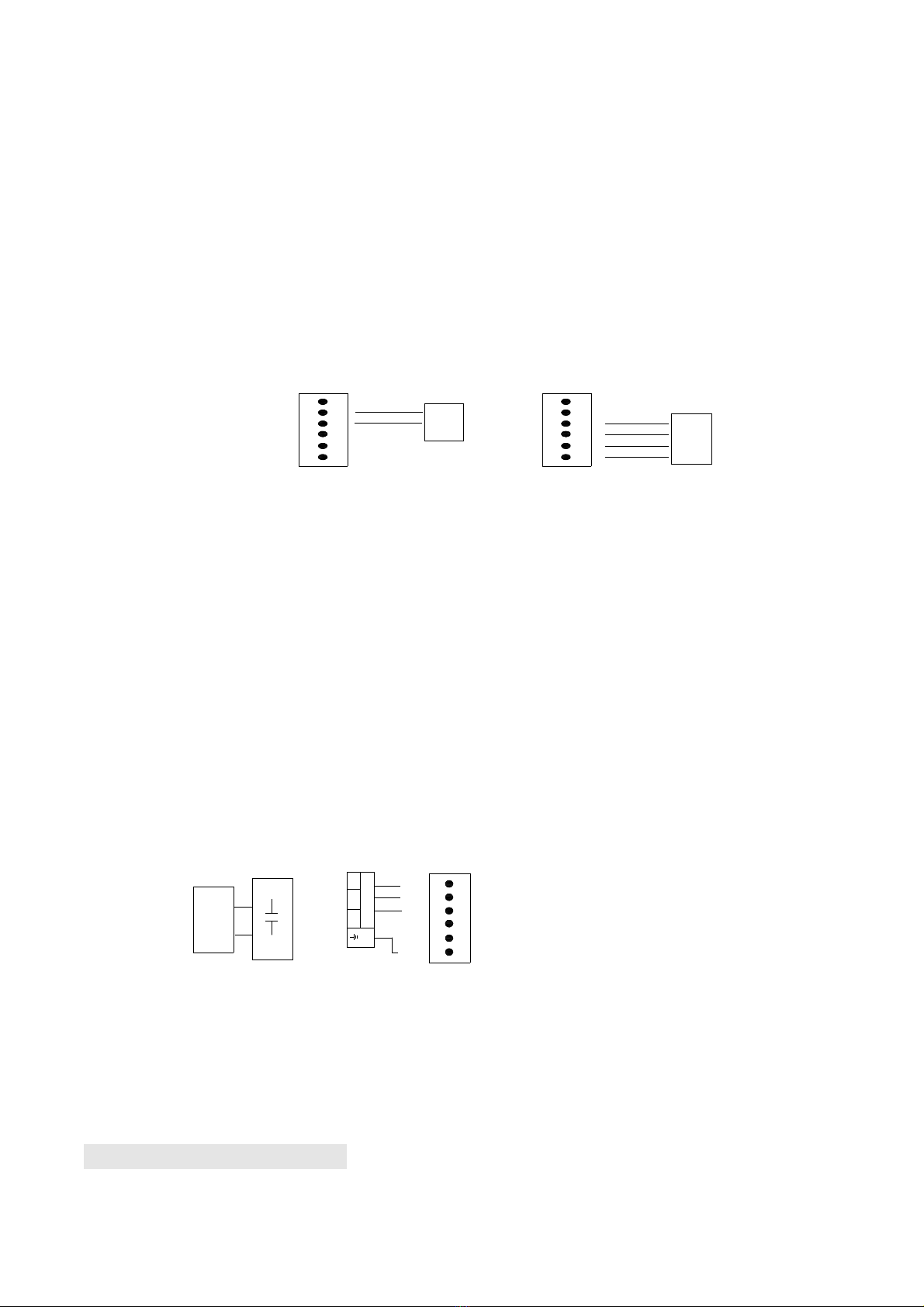

5. WIRE CONNECTION

Fig.1

5.1 Wiring notes of control board

a. Power Input (terminal J3): PE (Earth),L (Live),N (Neutral).

b. Caution light: connect caution light wire to L an N of LAMP(terminal J4)

c. Limit switch: Open limit(13 of J5) ,Com(12 of J5) ,Close limit(11 of J5)

d. Three-button mo e external button switch:Open(2 of J2),Close(1 of J2),Stop

(3 of J2),Com(4 of J2)

e. Single-button mo e external button switch: Single-button(5 of J2),Com(4 of J2)

f.Output power supply: 12VDC(7 of J5), COM (9 of J5), I.R. (8 of J5 is N.C

Infrare )

If the infrare beam is interrupte uring closing, the gate will reverse an open

imme iately. The pro uct is not factory equippe with an infrare evice; the

infrare out put signal must be N.C.

From four-terminal

to the receiver

COM

OUT

RX Receiver connecting

JUMP

NC OR NO

NC

NO

Form two-terminal to the emitter

12--24V AC/ DC

TX Emitter connecting

power supply

7

9

8

Control boar

Terminal J5

Fig.2 infrared Schematic iagram

g. Three-button switch / single-button switch (keypa ): The TILT is equippe with

interfaces for three-button switch an single-button switch (keypa ).

To install the keypa attach one lea of your keypa to ‘5’ of terminal J2 an the

other to the ‘4(COM)’. The keypa will function in single channel mo e.

h. For three-button switch installation, use the terminals for multi-channel mo e.

Connect open wire of external button switch to ‘1 (OPEN)’ of terminal J2,

connect close wire of switch to ‘2 (CLOSE)’, connect stop wire of switch to

‘3(STOP)’, connect common wire of switch to ‘4(COM)’.

Com

Stop

Close

Open

Three-button

switch

terminal J2

Keypa

4

5

Control boar

terminal block

Control boar

terminal block

Single-button

switch

or keypa

6

1

2

3

terminal J2

4

5

6

1

2

3

Fig.3

i. Motor an capacitor (Terminal J2, J4): MOT COM (com), MOT1 (Positive

irection), MOT2 (Opposite irection), PE (Protect Earth), C an C (capacitor)

Motor

Mot1

Mot2

Mot

COM

PE

W

UV

Control

boar

Terminal J6

Capacitor

Control boar

terminal block

terminal J4

Fig.4

5.2. Tuning and operation

a. Adjust the Adjustable resistance (see Fig.1)

VR1: For slow stop wi th a justment after touch the open limit switch.

(Remark: DIP switch “3” at the position “ON”.)

Clockwise rotation to increase, counter-clockwise rotation to re uce.

The total time can be set to 0 secon s as minimum an 5 secon s as maximum.

VR2: For slow stop wi th a justment after touch the close limit switch.

(Remark: DIP switch “4” at the position “ON”.)

Clockwise rotation to increase, counter-clockwise rotation to re uce.

The total time can be set to 0 secon s as minimum an 5 secon s as maximum.

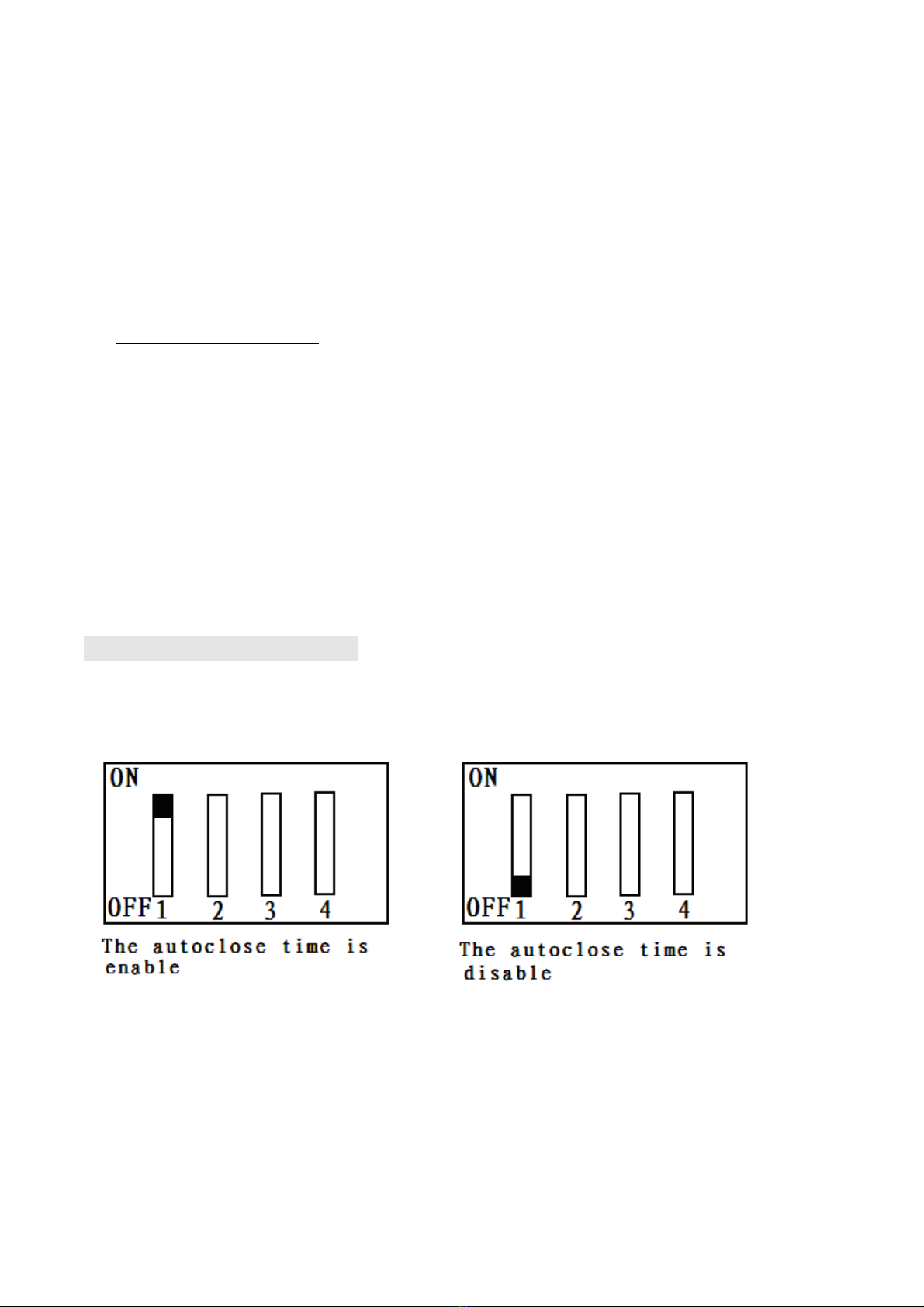

VR3:For auto-close time a justment.

(Remark: DIP switch “1” at the position “ON”.)

Clockwise rotation to increase, counter-clockwise rotation to re uce.

The total time can be set to 0 secon s as minimum an 70 secon s as

maximum.

VR4: For motor working total time a justment.

Clockwise rotation to increase, counter-clockwise rotation to re uce.

The total time can be set to 10 secon s as minimum an 60 secon s as

maximum.

Warning: Motor force can not be set too large, just rive the oor is ok.

Remote control

The remote control works in a single channel mo e. It has four buttons. See

Fig.12 Remote transmitter. The function of button 1, button 2、 button3 are the

same an button 4 is pe estrian mo e. With each press of the remote control

button (1, 2 an 3) which has been programme , the gate will close, stop, open

or stop cycle.

You can program/learn button 1, button 2, button 3 an button4 in ivi ually. If

you learn button1, the button 1 is enable, button 2, button 3 an button4 are

isable. if you learn button 2 too.

Button 1

Button 2

Button 3

Button 4

Fig.5Remote transmitter

A ing extra remote controls (Learn) : Remove the cover, press an hol the

learn button ‘S1’ (Fig.1) more than 1 secon s, then the ‘LED of LEARN’ (Fig.1)

will be on, then press the remote control button which you want to use, the

‘LED’ will turn on about 2 secon s an then turn off again. The learning

process is finishe .

Up to 25 remote controls may be use .

Erase remote controls : To erase all existing remote controls, press an hol

learn button ‘S1’, the LED of ‘LEARN’ will turns on, release the button until the

LED turns off. This in icates that all the remote controls have been erase

completely. If you change another manufactory co e transmitter must erase

first.

Verify open irection: If the gate oes not move in the esire irection, then

you will nee to reverse the motor operating irection, open the black plastic

cover, you can o this by exchanging wires ‘MOT1’ an ‘MOT2’, ‘Open limit(13

of J5)’ an ‘Close limit(11 of J5)’.

5.3. Programming Process

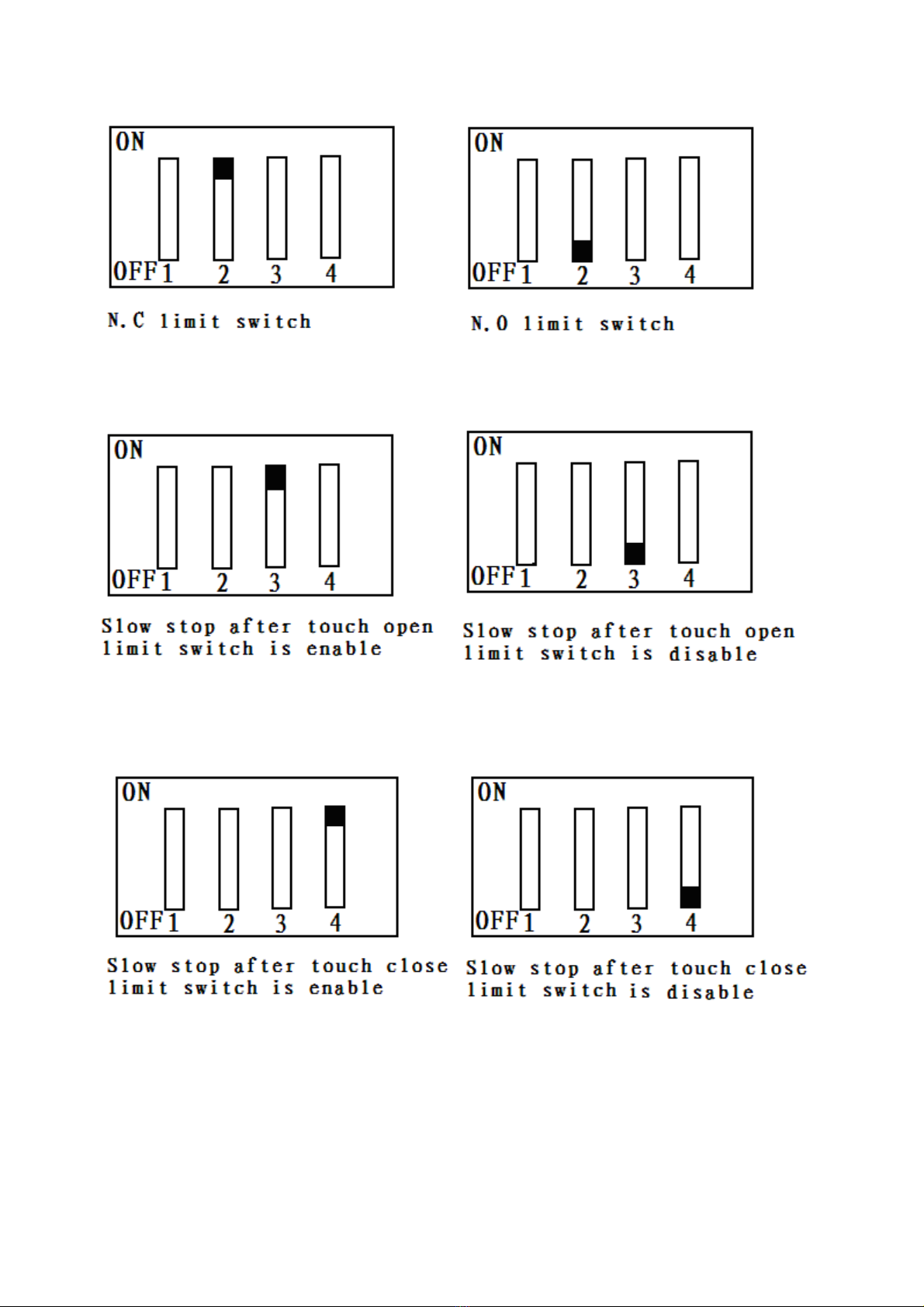

Adjust the DIP switch(see Fig6 and table 1)

Fig6A

Fig6B

Fig6C

Fig6D

Table 1: DIP switch adjust

DIP DIP-switch Function SET

1ON the Auto-close function is enable,

Rotate VR3 to a just the wi th

OFF the Auto-close function is isable

2ON N.C. limit switch(spring limit)

OFF N.O. limit switch(spring limit)

3ON Slow stop after touch open limit switch is enable

Rotate VR1 to a just the wi th

OFF Slow stop after touch open limit switch is isable

4ON Slow stop after touch close limit switch is enable

Rotate VR2 to a just the wi th

OFF Slow stop after touch close limit switch is isable

NOTE:

(1) You must follow the operating instruction as above any wrong operation

is not allowed during setting. If your device responds to your requested

function correctly you have set the function successfully otherwise

repeat the above setup instruction until your device responds to your

expected function.

(2) If the gate can not be moved please check whether the gate is obstructed

or the gate is too weight.

Table of contents

Popular Gate Opener manuals by other brands

Dea

Dea ghost 200 Operating instructions and warnings

Stanley

Stanley Dura-Max 5400 Series Installation and operation manual

Chamberlain

Chamberlain CSW200UL8 owner's manual

Chamberlain

Chamberlain TC1000 quick start guide

Comunello

Comunello CONDOR 220 Installation and user manual

Topens

Topens CK2500 user manual