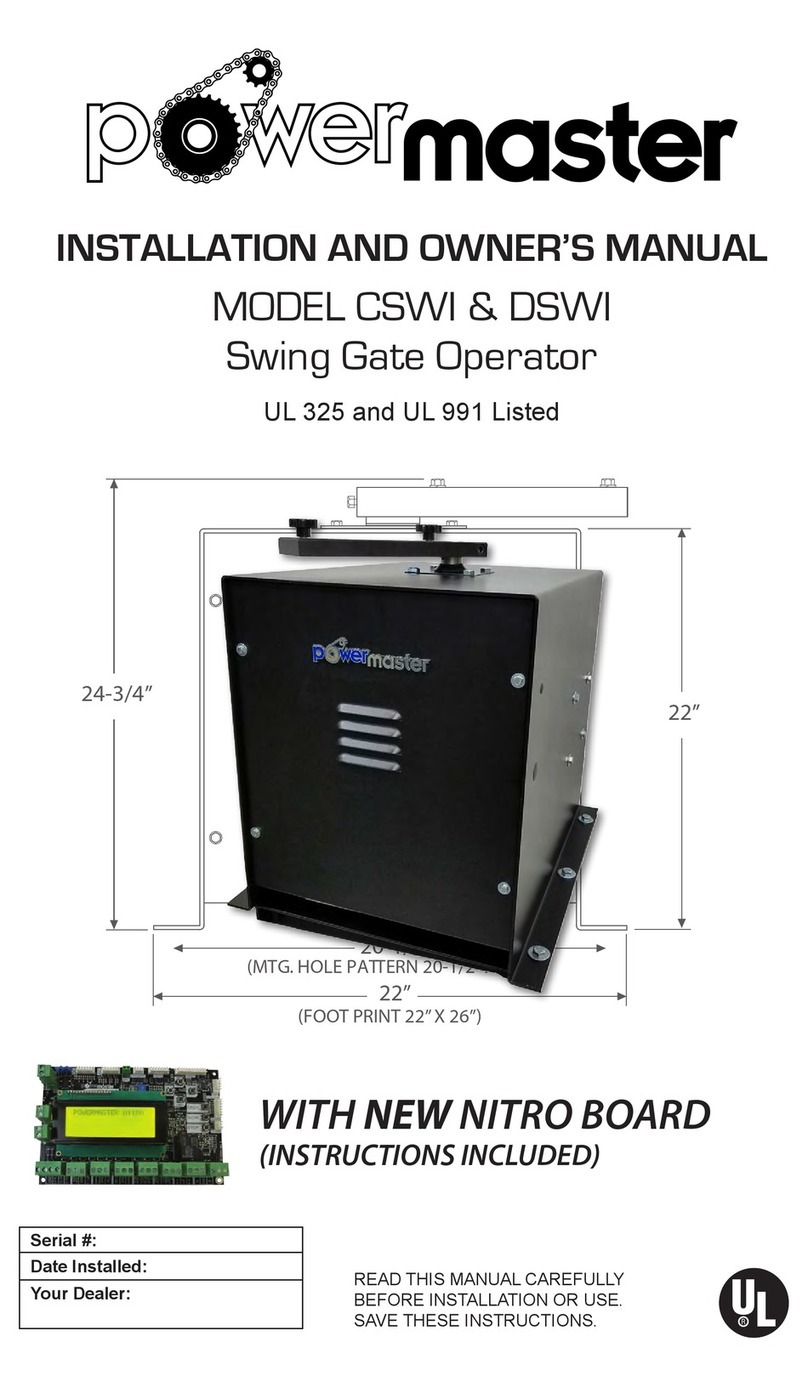

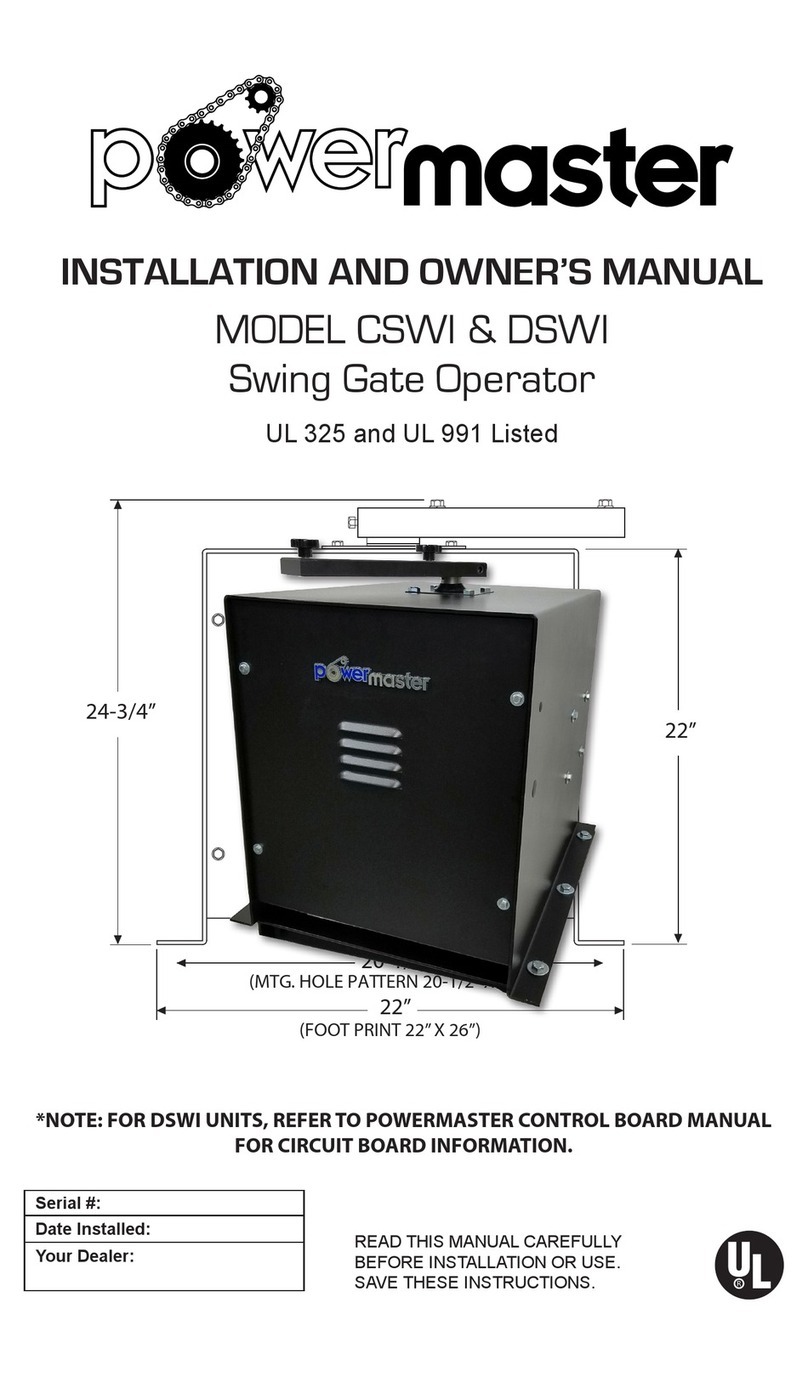

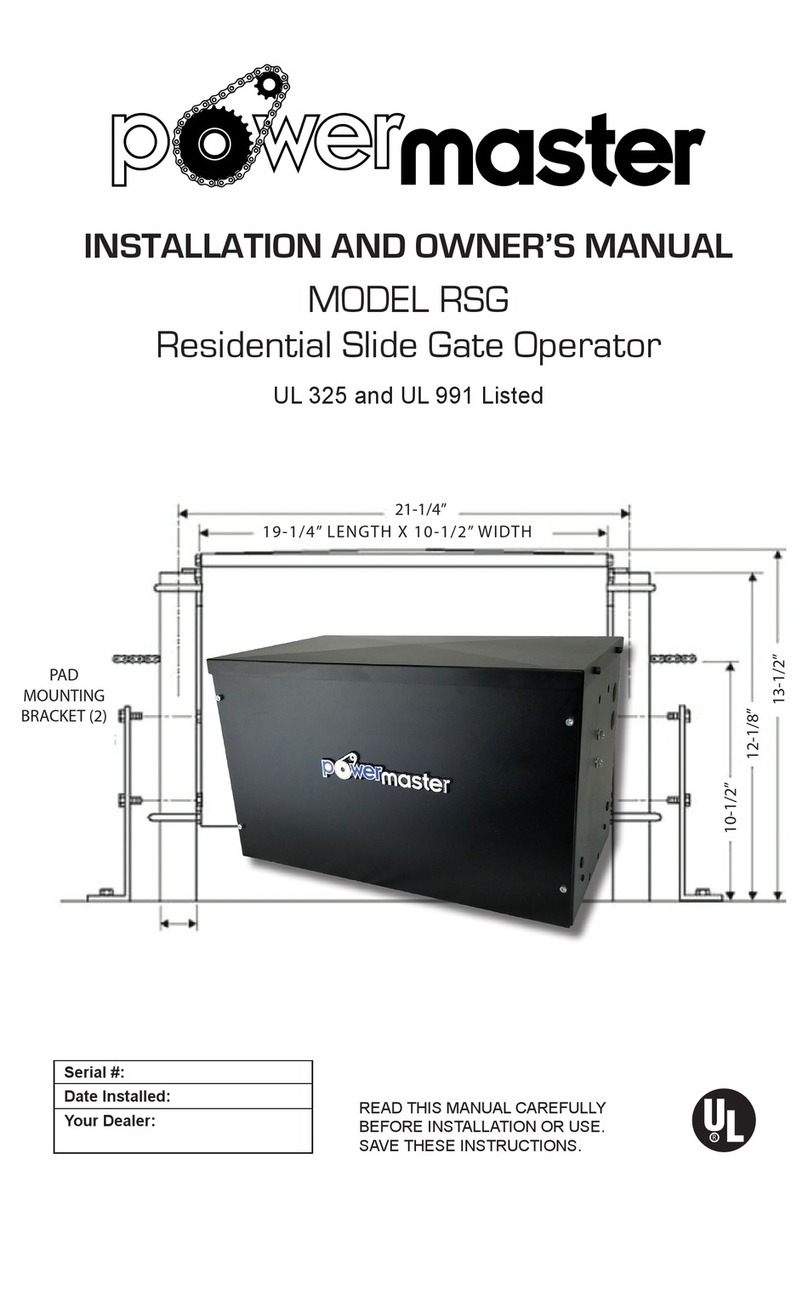

Power Master rsw Installation instructions

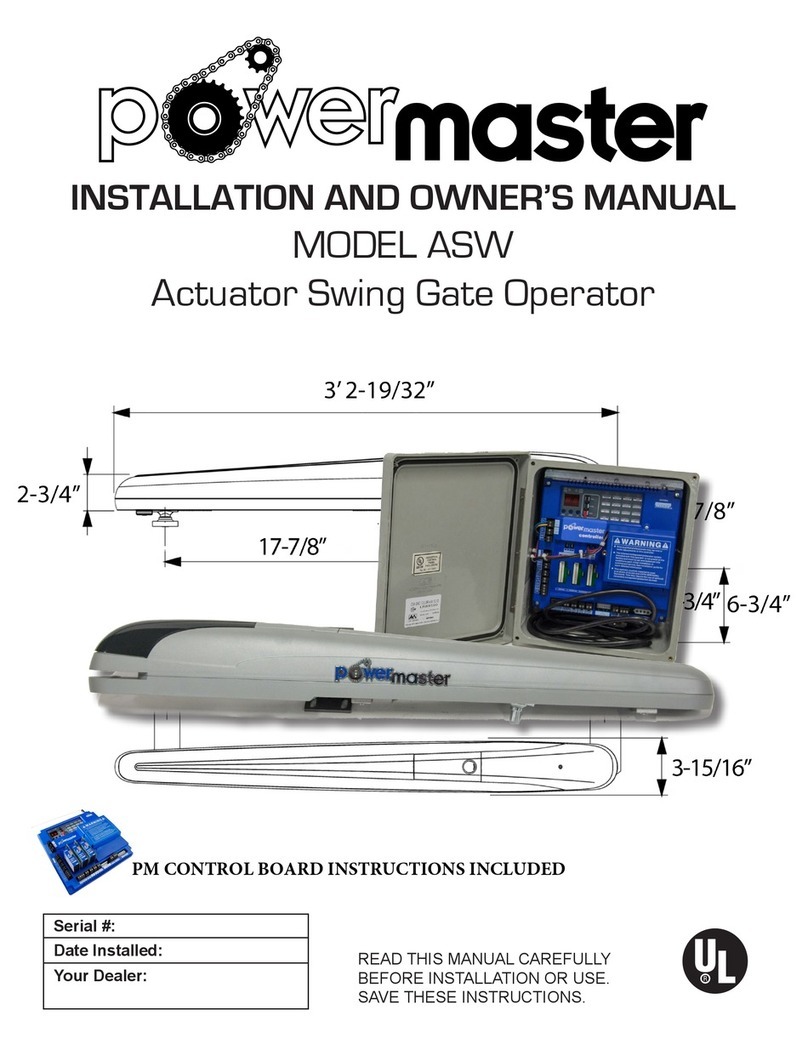

21 1/2"

14 5/ 8''

12 1/ 8''

16 1/ 4''

19 1/ 4'' LENGTH X 10 1/ 2'' WIDTH 2'' O.D. PIPE

( BY OTHERS )

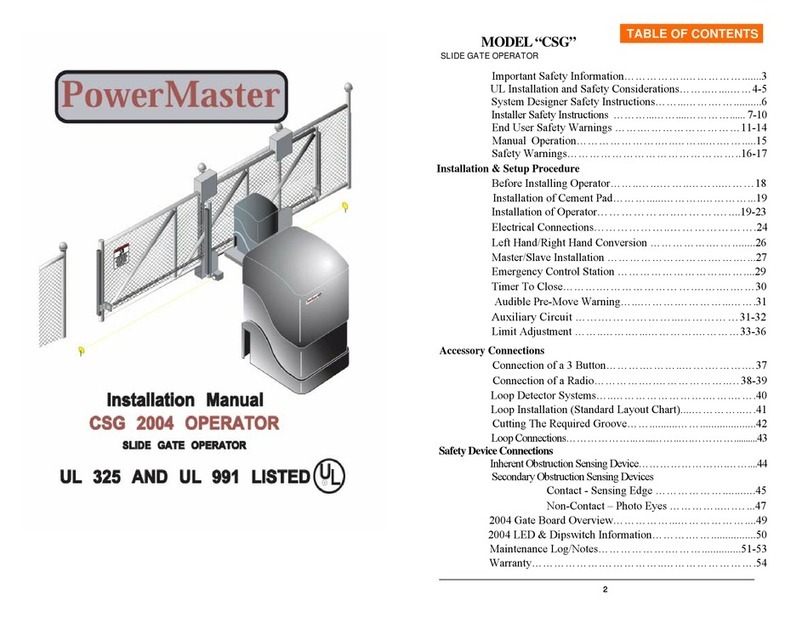

INSTALLATION AND OWNER’S MANUAL

MODEL RSW

Swing Gate Operator

UL 325 and UL 991 Listed

READ THIS MANUAL CAREFULLY

BEFORE INSTALLATION OR USE.

SAVE THESE INSTRUCTIONS.

Serial #:

Date Installed:

Your Dealer:

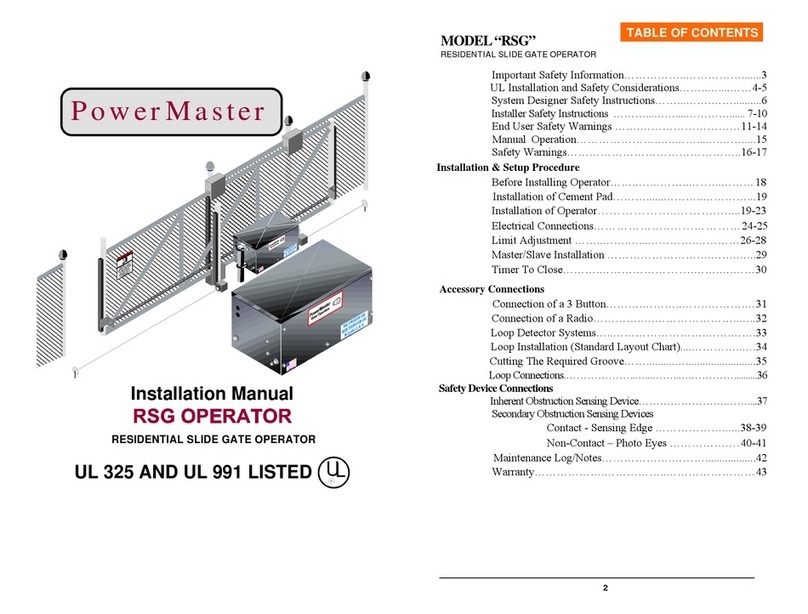

Important Safety Information ..................................................................................3

Important Notice for Gate Operators Manufactured after 1/11/16 ..........................4

UL Installation and Safety Considerations..............................................................5

System Designer Safety Instructions......................................................................6

Installer Safety Instructions ................................................................................ 7-8

End User Safety Warnings ............................................................................... 9-10

Manual Operation.................................................................................................11

Installation & Setup Procedure

Before Installing Operator.................................................................................11

Installation Layout.............................................................................................12

Installation of Operator ............................................................................... 13-14

Electrical Connections ......................................................................................15

Left Hand/Right Hand Conversion ....................................................................16

Connection of a 3-Button Station......................................................................16

Limit Adjustment ...............................................................................................17

Master/Slave Installation...................................................................................18

Timer to Close...................................................................................................18

Accessory Connections

Connection of a Radio ......................................................................................18

Loop Detector Systems .............................................................................. 18-21

Loop Installation (Standard Layout Chart) ........................................................19

Cutting the Required Groove ............................................................................19

Loop Connections....................................................................................... 20-21

Safety Device Connections

Inherent Obstruction Sensing Device ...............................................................21

Secondary Obstruction Sensing Devices ................................................... 22-24

Contact - Sensing Edge ...............................................................................22

Non-contact - Photo Eyes ............................................................................23

Warranty ..............................................................................................................27

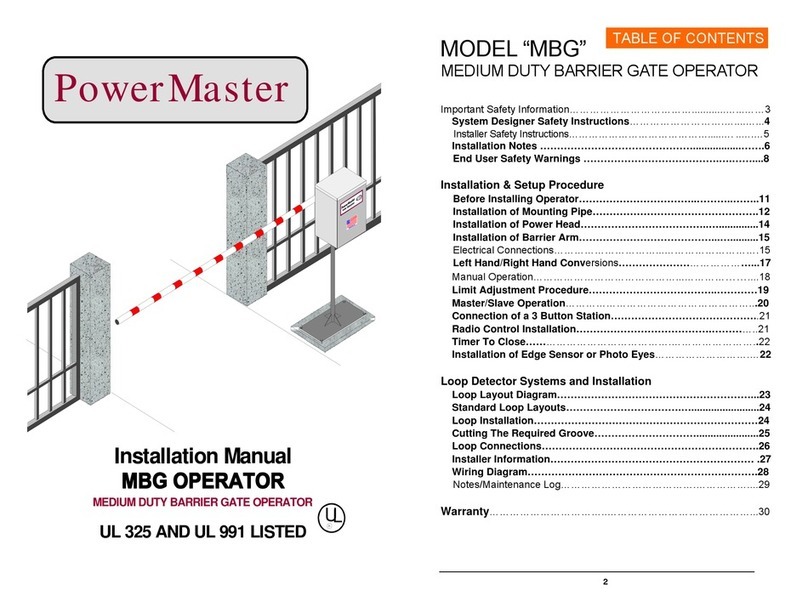

Table of Contents

Model RSW Residential Swing Gate Operator

3

Automatic gate operators provide convenience and

security to users. However, because these machines

can produce high levels of force, it is important that all

gate operator system designers, installers, and end

users be aware of the potential hazards associated

with improperly designed, installed, or maintained

systems. Keep in mind that the gate operator is a

component part of a total gate operating system.

The following information contains various safety

precautions and warnings for the system designer,

installer and end user. These instructions provide an

overview of the importance of safe design, installation,

and use.

Warnings are identied with the ▲symbol. This symbol

will identify some of the conditions that can result in

serious injury or death. Take time to carefully read

and follow these precautions and other important

information provided to help ensure safe system

design, installation and use.

▲WARNING: Gate operators are only one part of a

total gate operating system. It is the responsibility of

purchaser, designer, and installer to ensure that the

total system is safe for its intended use. All secondary

entrapment safety devices must be RECOGNIZED

by UL to ensure the safety of the complete operating

system.

IMPORTANT!

FOR SWING GATE OPERATING SYSTEMS,

SAFETY IS EVERYONE’S BUSINESS.

4

IMPORTANT NOTICE FOR GATE OPERATORS

MANUFACTURED AFTER JANUARY 11TH, 2016

All gate operators manufactured after January 11th, 2016 must have a

monitored input for each direction. In order to satisfy this requirement,

all PowerMaster gate operators with the universal board will have one

monitored input for each direction. The close photo (11) terminal will

function for the close direction and the open photo (10) will function

for the open direction. These terminals will look for, or “monitor”, the

presence of a 10k in-line resistor. If either terminal does not detect the

presence of the monitored device, the unit will function in constant

contact for this direction.

Note: The rst time a monitored device is added to the unit, the board

must “learn” what the monitored device is. To have the board learn the

monitored device, perform the following steps:

1. With the power o, hold both the open and close limit

simultaneously.

2. Power up the unit and release your ngers from the limits. The

unit has now learned the monitored device.

E.g. The operator detects there is a monitored device on the 11 terminal

but not the 10 terminal. The operator will function in momentary

contact to close and constant pressure to open.

Following are the monitored devices acceptable for use with the

GSMCB02:

Any actions taken to circumvent this monitoring are in violation of the

UL325, building code, and local laws.

Device Manufacturer Description

Prime-Guard Miller Edge Monitored Photoeye

Reecti-Guard Miller Edge Retroreective Monitored Photoeye

IRB-MON EMX Monitored Photoeye

IRB-RET EMX Retroreective Monitored Photoeye

The Solution Miller Edge Multiple Safety Devices

5

UL INSTALLATION AND SAFETY CONSIDERATIONS

INSTALLATION CLASSES

CLASS I - RESIDENTIAL VEHICULAR GATE

OPERATOR

A vehicular gate operator (or system)

intended for use in a home of one

to four single-family dwellings, or a

garage or parking area associated

therewith.

CLASS II – COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or

system) intended for use in a

commercial location or building

such as a multifamily housing unit

(ve or more single family units),

hotel, garages, retail store or other

building servicing the general

public.

CLASS III - INDUSTRIAL/LIMITED ACCESS

VEHICULAR GATE OPERATOR

A vehicular gate operator (or system)

intended for use in an industrial

location or building such as a factory

or loading dock area or other locations

not intended to service the general

public.

CLASS IV - RESTRICTED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system)

intended for use in a guarded industrial

location or building such as an airport

area or other restricted access locations

not servicing the general public, in which

unauthorized access is prevented via

supervision by security personnel.

6

1. Familiarize yourself with the precautions and warnings for the installer. Users are

relying on your design to provide a safe installation.

2. The operator is supplied with a primary obstruction sensing entrapment protection

system. The installation must also have a secondary entrapment protection system

installed, such as photoelectric sensors or an electric edge system.

3. When designing a system that will be entered from a highway or main thoroughfare,

be sure the system is placed far enough away from the road to eliminate trac

backup. Distance from the road, size of the gate, usage levels, and gate cycle/speed

must be considered to eliminate potential trac hazards.

4. Swing gates have two potential entrapment zones you must avoid. Make sure they

are protected as shown in the following diagram (Figure 1).

5. Design the gate system so a person

cannot reach over, under, around,

or through the gate to operate any

controls. Never place controls on the

gate operator itself.

THIS GATE SYSTEM IS FOR VEHICULAR TRAFFIC ONLY. A

SEPARATE PEDESTRIAN ENTRANCE MUST BE PROVIDED.

WARNING

SYSTEM DESIGNER SAFETY INSTRUCTIONS

• Pedestrians should

keep clear of path

of gate, particularly

in the area before

fully closed.

• The area of the gate

arm and linkage

must be avoided

as it can create an

entrapment.

ENTRAPMENT ZONE

ENTRAPMENT ZONE

HORIZONTAL ELECTRIC EDGE, ON BOTTOM

OUTSIDE EDGE OF GATE. WIRED TO REVERSE

WHILE CLOSING (REQUIRED).

ELECTRIC EDGE, ON VERTICAL OUTSIDE

EDGE OF GATE. WIRED TO REVERSE

WHILE CLOSING (RECOMMENDED).

HORIZONTAL ELECTRIC EDGE, ON INSIDE

BOTTOM OF GATE. WIRED TO REVERSE WHILE

OPENING (RECOMMENDED).

1

2

FIGURE 1

▲

▲

▲

▲

▲

The illustrations and descriptive captions

provide precautions to help eliminate

injuries or fatalities. Familiarize yourself

with them when designing the total system.

7

INSTALLER SAFETY INSTRUCTIONS

BEFORE INSTALLATION

1. Check to see that the operator is proper for this type and size of gate and its frequency

of use. If you are not sure, consult factory.

2. Check to see that there are no structures adjacent to the area, which may pose a risk

of entrapment when gate is opening or closing.

3. You must ensure that the gate has been properly installed and works freely in

both directions. Replace or service any worn or damaged gate hardware prior to

installation. A freely moving gate will require less force to operate and enhance the

performance of the operator as well as the safety devices used within the system.

4. Install the gate operator on the inside of the property and/or fence line. DO NOT

install an operator on the public side of the gate.

5. Severe injury or death can result from entrapment by a gate. The operator is supplied

with an obstruction sensing primary entrapment protection system. Additional safety

equipment such as electric edges or photocell sensors must be installed to provide

the required secondary entrapment protection system. For assistance in selecting the

correct type of safety equipment, consult the factory.

6. Review the operation of the unit and become familiar with the manual operation

procedure and safety features of the system.

7. You must install a pushbutton control or key switch to allow for normal operation of

the gate if the automatic controls do not work. Locate the push button or key switch

and small warning placard within sight of the gate in a secured area at least 10 feet or

more from any moving parts of the gate or operator.

8. Outdoor or easily accessed gate controls should be of the security type to prohibit

unauthorized use. Please consult your local distributor concerning the types and

specications of available controls.

DURING INSTALLATION

1. Be aware of all moving parts and avoid close proximity to any pinch points.

2. Disconnect power at the control panel before making any electric service connections.

Connection location for controls and safety equipment can be found on the wiring

diagram, and in this manual.

3. Know the procedure for disengaging and manually operating the unit.

4. Adjust the open and close force adjustment on the control board, in each direction,

to the minimum force required to operate the gate smoothly. DO NOT increase the

force adjustment setting to make up for rough spots in gate travel - FIX THE GATE

INSTEAD!

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

8

5. Locate the controls

at least 10 feet from

the moving gate so

that the user can

observe the gate

operation, but is

not able to come

in contact with the

gate while operating

the controls.

6. Attach large warning

signs provided to

each side of the gate

or fence in the most

conspicuous place.

Mount control station

and smaller warning

placard together

within sight of the

gate opening.

AFTER INSTALLATION

You are responsible for ensuring that the end user understands the basic operations

and safety systems of the unit, INCLUDING THE MANUAL OPERATION PROCEDURE.

Point out that the safety instructions in brochure are the responsibility of the end user,

and then LEAVE THIS MANUAL WITH THE END USER.

Control

Station

10 feet

▲

▲

▲

▲

Moving Gate Can Cause

Serious Injury or Death.

KEEP CLEAR! Gate May Move

at Any Time. Children

Should Not Operate Gate.

Operate Gate Only When

Area is in Sight and Free of

People and Obstructions.

9

END USER SAFETY WARNINGS

The manufacturer of the gate operator does not know what type of gate you have, or what

type of automatic system is installed on your gate. Be sure you’ve been fully instructed

on the sequence of operation for your specic gate system(s). Keep the gate properly

maintained and have a qualied service person make repairs.

1. Be sure the following safety instructions

are distributed to all persons authorized

to use your gate.

2. KEEP GATEWAY CLEAR (Front and

Back) AT ALL TIMES. Your automatic

gate is not for pedestrian use. No

one should ever cross the path of the

moving gate.

3. DO NOT allow children to play near your

gate, or to operate the gate.

4. DO NOT operate your gate system

unless you can see it when the gate

moves.

5. Be sure a pushbutton or key switch

has been installed for manual electric

operation in the event your radio or

card key does not work. Any mounted

control station should be located a

minimum of 10 feet from the gate so

the gate cannot be reached through or

touched. Any pushbutton located in a

building should be installed within sight

of the gate.

6. DO NOT operate any controls without

watching the movement of the gate.

7. Your gate system is required to have a

primary and a secondary entrapment

safety system installed and maintained.

8. If your gate closes automatically, loop

detectors should be installed to detect

the presence of a vehicle.

▲

▲

▲

▲

▲

▲

▲

▲

10

9. DO NOT increase force adjustment to compensate for a damaged gate. The

gate should always be maintained to operate manually as easily as possible to

provide maximum protection.

10. Check all safety systems at least once per month for the correct force, speed

and sensitivity. Gate must reverse when hitting a rigid object, or when a

non-contact sensor is activated. If these functions are observed to operate

improperly, discontinue use and have it serviced immediately!

11. You are responsible for ensuring that warning signs are installed and

maintained on both sides of your gate.

12. To ensure safe operation of this equipment, you must read this safety manual

and keep it for reference.

13. Swing gates have two potential entrapment zones you must avoid. Make sure

they are protected as shown in Figure 1.

4’

MINIMUM

▲

▲

▲

▲

▲

11

INSTALLATION INSTRUCTIONS & SET-UP PROCEDURE

MANUAL OPERATION

BEFORE INSTALLING OPERATOR

IMPORTANT:Operator should always be mounted inside the gate. Determine

whether the installation is Left hand or Right hand by the direction the gate

moves in order to open, when viewed from inside the fence.

DO NOT APPLY POWER UNTIL TOLD TO DO SO! RISK

OF ELECTRICAL SHOCK OR INJURY MAY RESULT!

WARNING

Your operator is

equipped with an

emergency disconnect

for manual operation.

Be sure you know how

to properly use this

feature. To disengage

operator, follow the

procedure in Figure 2.

FIGURE 3

LEFT HAND INSTALLATION

FENCE FENCE

OPERATOR OPERATOR

HINGE HINGEGATE GATE

RIGHT HAND INSTALLATION

HAND KNOBS FOR MANUAL DISCONNECT

(USE HOLES SHOWN AS STARTING

POSITION)

CONTROL ARM

CONTROL ARM

EXTENSION

3/8” BOLT

3/8” LOCK WASHER

3/8” WASHER

1/4” DRIVE KEY

OPERATOR

DRIVE SHAFT

FIGURE 2

1. Gate must swing freely to fully opened and fully closed position.

2. The operator will be located as shown above, for left and right hand installation.

NOTE: TO DISCONNECT OPERATOR FOR

MANUAL OPERATION, REMOVE HAND

KNOBS AND SEPARATE CONTROL ARM

EXTENSION FROM CONTROL ARM

12

INSTALLATION LAYOUT

1. Layout mounting post and electrical conduit locations as shown in gures below.

Excavate required area for conduit installation and cementing of mounting posts

(Minimum of 2 feet deep. Check local codes.)

2. Set mounting post and electrical conduit in place.

3. Pour cement to secure mounting posts and let cure for two days prior to operator

installation.

Note: Distance between mounting posts and relative location to gate is very

important! Operator must be installed perpendicular to the fence.

GATE HINGE

GROUND LEVEL

17-3/8”

21-1/2”

APPROX. 16”

24” MIN.

4” MIN.

28”

18”

2” O.D. (MOUNTING POST) BY OTHERS

CENTER LINE OF FENCE

ELECTRICAL ACCESS

SIDE COVER

ELECTRICAL CONDUIT

PER LOCAL CODE

ELECTRICAL

CONTUIT

TOP MOUNTING ANGLE

2” U-BOLTS

ELECTRIAL CONDUIT PER

LOCAL CODE

APPROX. 16”

24” MIN.

4” MIN.

21-1/2”

LOWER

MOUNTING

PLATE

SWING GATE OPERATOR

2” O.D. (MOUNTING POST)

BY OTHERS

FIGURE 5

FIGURE 4

13

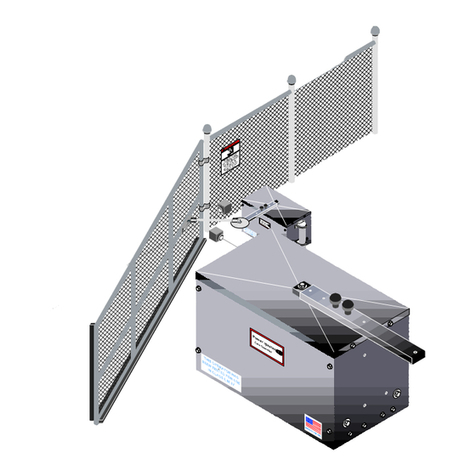

OPERATOR INSTALLATION

1. Mount operator on posts with mounting angles and mounting plates. Secure position

with 2” U-bolts and hardware provided. See Figure 5.

2. Set control arm on output shaft of operator without drive key, and install control arm

extension using hand knobs to secure position. See Figure 6.

3. Install end ttings

on connecting rod

assembly and attach one

end of assembly to end

of control arm extension.

See Figure 7.

4. Install gate bracket on

remaining end of connecting

rod (See Figures 7 & 8)

5. Locate gate bracket in position

on gate, as shown in Figure 8

and clamp in position.

6. Move control arm to its

maximum close position.

See Figure 8. Control arm

and connecting rod must be

straight in line.

FIGURE 7

FIGURE 8

NOTE: TO DISCONNECT OPERATOR FOR

MANUAL OPERATION, REMOVE

HANDKNOBS AND SEPARATE CONTROL

ARM EXTENSION FROM CONTROL ARM.

HAND KNOBS FOR MANUAL DISCONNECT

(USE HOLES SHOWN AS STARTING

POSITION FOR INITIAL SETUP)

CONTROL ARM

EXTENSION

CONTROL ARM

MOUNTING PLATE

MOUNTING ANGLE

OPERATOR

1/4” DRIVE KEY

3/8” BOLT

3/8” LOCK WASHER

3/8” WASHER

DRIVE SHAFT

FIGURE 6

GATE HINGE

36”

OPERATOR

CONTROL ARM

CONNECTING ROD ASSEMBLY

CONTROL ARM

PIVOT BOLT

GATE BRACKET

PIVOT BOLT

GATE

BRACKET

OF GATE

C

L

GATE ANGLE

(BY OTHERS) ELECTRICAL

ACCESS

SET SCREWS

3/8” PIVOT BOLT 3/8” PIVOT BOLT

3/8” HEX NUT

TUBE

SPACER

3/8” HEX NUT

FLAT WASHER

FLAT WASHER

LOCK WASHER

LOCK WASHER

SET SCREWS

ROLL

PIN (4)

SPLICE BAR

CONNECTING

ROD (2PCS)

SPACER BUSHING

END FITTING

FLAT WASHER

FLAT WASHER

FLAT WASHER

SPACER BUSHING

END FITTING

GATE BRACKET

GATE ARM

Note: Adjustment can be made in (4) locations to get desired closed position, as

described below. Always start with Option “a”.

a. Move the gate bracket to left or right of the 36 inch starting position.

b. Change length of connecting rod assembly.

c. Relocate control arm extension on control arm to a dierent hole pattern then

start position. See Figure 6.

d. Move connecting rod bolt in gate bracket to a dierent hole. See Figure 8.

7. Move control arm to its open position as shown in Figure 9.

Note: Arm and connecting rod should

almost double over each other. This is

important for smooth operation and

longevity of the operator.

Note: Open position of gate may be

adjusted slightly with limit switch

adjustment, but when nished, open

position of control arm assembly should

be as close as possible to that shown in

Figure 9. If mechanical adjustments are

made to achieve desired open position

of gate, repeat Steps 6 & 7, since this will

aect the closed position.

8. When the desired open and closed gate position have been achieved, place gate in the

fully closed position and remove control arm extension from control arm. See Figure 6.

9. Remove control arm from operator drive shaft and insert drive key. See Figure 6.

10. Replace control arm on operator drive shaft with drive key and secure with 3/8 inch bolt.

See Figure 6.

11. Replace control arm extension on control arm and secure with hand knobs as shown in

Figure 6.

GATE

OPERATOR

CONNECTING

ROD ASSEMBLY

CONTROL ARM

ASSEMBLY

FIGURE 9

12. By turning the internal drive pulley by hand, move the control arm to somewhere in

its normal drive segment.

13. Control arm extension may now be attached to control arm as in Figure 6.

Note: If operator was ordered as a right or left hand unit from the factory, the control

arm position will be somewhere in its normal travel segment and the limit switches will

be set at an approximate open and close position. Final adjustments will be made later

after power is connected.

If the hand of the operator is to be changed in the eld as described in the following

section than before the control arm extension is replaced as in Step #11, proceed to

Step #12.

15

ELECTRICAL SET-UP AND CONNECTIONS

NOTE: Before connecting the operator, use a voltmeter to determine that the electrical

service is 115V. THIS OPERATOR CANNOT BE CONNECTED AT 230 VOLTS. Damage will result

which is not covered under warranty.

DO NOT APPLY POWER UNTIL TOLD TO DO SO! RISK

OF ELECTRICAL SHOCK OR INJURY MAY RESULT!

WARNING

NOTE: Wiring to operator must use watertight materials in accordance with local electric

code. See the following wire gauge/distance charts for proper sizing. Master/Slave

installations should have SEPARATE power supply wiring or length of wire runs should be

gured at half that shown on the chart. This unit must be grounded in accordance with N.E.C.

and local codes.

NOTE: In order to properly run and check the operator at various stages during the setup

procedure, it is suggested that a three button control station be connected at this time.

Hot leg (Black) to Black; Neutral (White) to White; Ground to Ground Screw.

1. Be sure the power switches at source, and at the operator are OFF.

2. Connect incoming power lines and ground wire as shown below.

LOW VOLTAGE WIRE GAUGE/ DISTANCE CHART

24 AWG: UP TO 150’

20 AWG: 150’ - 200’

18 AWG: 250’ - 1,500’

Control wiring should be run as twisted pairs. DO NOT run

control wires in the same conduit as power wires. telephone

wires, or loop detector leads.

LINE

VOLTAGE HP WIRE GAUGE

14 AWG 12 AWG 10 AWG 8 AWG 6 AWG

115VAC 1/2 150’ 250’ 400’ 500’ 650’

Inside Power Box,

Connect As Shown

Power

Switch

Incoming Power

115V - 1PH

Operator

Power Box

BLK

WHT

BLK

WHT

GND

GND

16

LEFT/RIGHT HAND CONVERSION:

Refer to Figure 3 to determine hand of

operator required for this installation. This unit

is factory setup for right hand operation.

To convert operator to left hand operation,

make certain the power switch is o, and locate

the motor capacitor (See Figure 10). Switch the

red and blue wires on the capacitor that goes

to the motor. The operator is now setup for left

hand installation.

TO MOTOR

SWITCH THE RED AND

BLUE WIRES GOING TO

THE MOTOR TO

CHANGE OPERATOR

TO LEFT HAND

OPERATION

TO CONTROL

BOARD

FIGURE 10

1. Connect a wire from the COMMON connection of the control station to Terminal #5.

2. Connect a second wire from the OPEN button of the control station to Terminal #6.

3. Connect a third wire from the CLOSE button of the control station to Terminal #7.

4. Connect a fourth wire from the STOP button of the control station to Terminal #4.

STAY CLEAR OF ALL MOVING PARTS

AND ELECTRICAL COMPONENTS OF

THE OPERATOR WHILE TESTING!

WARNING

READ ENTIRE PROCEDURE BEFORE

STARTING. TURN OFF MAIN POWER

BEFORE MAKING ANY ADJUSTMENTS!

WARNING

CONNECTION OF A 3-BUTTON STATION

A CONTROL STATION SUCH

AS A THREE BUTTON STATION

(OPEN, CLOSE, STOP) WITH ALL

NORMALLY OPEN CONTACTS IS

REQUIRED FOR THIS PROCEDURE.

SEE INSTRUCTIONS BELOW.

OPEN

CLOSE

STOP

COMMON

4567

17

NOTE: For Master/Slave installation, travel time for the Master operator must be set

longer than the Slave operator.

Drive Shaft

Open Limit

Switch

Limit Switch

Limit Cam

Close

Limit Cam

Actuating

Screw

Adjustment

Set Screw

Open

Limit Cam

Close Limit

Switch

OPEN LIMIT SWITCH ADJUSTMENT

1. Turn on power. Press OPEN button on control station. Gate should stop before full open

position is reached. If gate does not stop when open position is reached, PRESS STOP

BUTTON!

2. To adjust gate for more open travel, loosen open limit cam set screw and rotate limit

cam in the opposite direction drive shaft rotates to open gate. Re-tighten set screw after

adjustment (See Figure 11).

3. If it was necessary to stop gate, adjust open limit switch cam for less open travel by

rotating the cam in the same direction that the drive shaft rotates to open the gate.

4. Press CLOSE button and stop gate in mid travel with STOP button.

5. Repeat procedure until desired open setting is obtained.

CLOSE LIMIT SWITCH ADJUSTMENT

1. Press CLOSE button on control station. Gate should stop before full closed position is

reached. If gate does not stop when close position is reached, PRESS STOP BUTTON!

2. To adjust gate for more close travel, loosen close limit cam set screw and rotate limit cam

in the opposite direction drive shaft rotates to close gate (See Figure 11).

3. If it is necessary to stop gate, adjust close limit switch cam for less close travel by rotating

the cam in the same direction that the drive shaft rotates to close the gate.

4. Press OPEN button and stop gate in mid travel with STOP button. Repeat procedure until

desired close setting is obtained.

NOTE: After both OPEN and CLOSE limit adjustments are complete, check that both limit

cam set screws are tight.

FIGURE 11

NOTE: Operator should be completely installed, mechanically and electrically, before

attempting to set limit switch cams (See Figure 11).

LIMIT ADJUSTMENT PROCEDURE

18

MASTER-SLAVE INSTALLATION

NOTE: A single unit is considered a

Master. In a Master/Slave installation,

one unit must be converted to LEFT

HAND operation.

1. Place jumper on the Master

operator’s control board in the

OFF position.

2. Place jumper on the Slave operator’s

control board in the ON position.

3. Connect Terminal #15 of Master unit

to Terminal #5 of Slave unit.

4. Connect Terminal #16 from the

Master unit to Terminal #6 on the

Slave unit.

5. Connect Terminal #17 from the Master unit to Terminal #7 on the Slave unit.

SLAVE POSITION

(ON)

MASTER POSITION

(OFF)

JUMPER JUMPER

ON

SLAVESLAVE

ON

FIGURE 12

MASTER

SLAVE

15

14

1312

1198

765

4

321 10 16 17 18

15

14

1312

1198

765

4

321 10 16 17 18

TIMER TO CLOSE OPTION

The operator is equipped with a timer to close option for use with control devices, such as a

radio control or card key control. The AUTO RE-CLOSE TIMER adjustment screw is located on

the printed circuit board. The operator is shipped from the factory with this timer preset to

the OFF position, fully counter-clockwise. As the timer adjustment screw is rotated clockwise,

the closing of the gate can be delayed from 2 seconds to 60 seconds.

LOCATION OF AUTO CLOSE

TIMER ADJUSTMENT

2 SEC

OFF

AUTO

CLOSE

TIMER

60 SEC

19

RADIO CONTROL INSTALLATION

A three or four wire radio control

receiver can be installed on this

operator. This radio control receiver

can only be used to open the gate,

therefore the TIMER TO CLOSE option

must be activated for closing.

ACCESSORY CONNECTIONS

NOTE: If your radio’s connecting wires are not color coded as shown, see the radio’s

installation manual to determine which wires are for the normally open contacts and which

require the 24VAC Power Supply.

GREY

BLACK

RED

24 VAC

GREY

N.O.

CONTACT

4 WIRE

RADIO

SINGLE BUTTON

COMMON

TERMINAL A

TERMINAL B

LOOP DETECTOR SYSTEMS AND INSTALLATION

The diagram on the right depicts the

typical loop options for a Swing Gate

installation.

1. The Exit Loop provides a signal

to open the gate when a vehicle

enters the loop zone.

2. The Reversing Loop protects

a vehicle in the loop zone from

being contacted with the gate by

overriding any close signal while

the gate is open, and by reversing

the gate if closing.

3. The Shadow Loop protects a

vehicle in the loop zone from

being contacted with the gate

by overriding any close signal

while the gate is in the full open

position.

4'

4'

4'

4'

4'

4'

4'

Road Surface

3/16” to 1/4”

Saw Slot

Sealant

Min 1”

Approx.

10’

Loop Wires

LOOP INSTALLATION

1. Lay out the desired loop locations per the diagram. The standard size chart on the

following page will give an approximate length of wire required for various loop

dimensions and number of turns required.

FIGURE 13

20

CAUTION: The loop wires

and lead-in wires must

be a continuous piece of

wire without splices. The

amount of lead-in wire

required must be added

to these lengths for total

wire required. Only use

wire intended for this

type of application

(Type XHHW insulation

16 AWG).

NOTE: Buried steel from

drains or other systems may

aect functioning of the

loop system. Check with the

factory for advice on any

special installations.

Call 1-800-243-4476.

LOOP SIZE # OF TURNS LOOP WIRE

LENGTH (FT)

4’ X 4’ 4 64’

4’ X 6’ 4 80’

4’ X 8’ 3 72’

4’ X 10’ 3 84’

4’ X 12’ 3 96’

4’ X 14’ 3 108’

4’ X 16’ 3 120’

4’ X 18’ 3 132’

4’ X 20’ 3 144’

4’ X 22’ 3 156’

4’ X 24’ 3 168’

4’ X 26’ 3 180’

4’ X 28’ 3 192’

4’ X 30’ 2 136’

4’ X 32’ 2 144’

4’ X 34’ 2 152’

4’ X 36’ 2 160’

4’ X 38’ 2 168’

4’ X 40’ 2 176’

STANDARD LOOP LAYOUTS

FOR APPROX. 36” HEIGHT DETECTION

Loop Wire

(See Chart)

Lead In Wire

(Twisted at 6

turns per foot)

1/2” Conduit

Conduit Cut

3/16” to 1/4”

1” to 2”

1” to 2”

2. Cut the required groove at the locations laid out in Step#1 according to the diagram

below (Figure 14).

FIGURE 14

Other manuals for rsw

1

Table of contents

Other Power Master Gate Opener manuals

Power Master

Power Master CSWI Installation instructions

Power Master

Power Master SG 2004 Installation instructions

Power Master

Power Master RSG User manual

Power Master

Power Master CSWC User manual

Power Master

Power Master rsw User manual

Power Master

Power Master CSG 2004 User manual

Power Master

Power Master DSWI Installation instructions

Power Master

Power Master MBG User manual

Power Master

Power Master RSG Installation instructions

Power Master

Power Master SG Operating instructions