ALLOMATIC SW-300DC User manual

Table of contents

Other ALLOMATIC Gate Opener manuals

ALLOMATIC

ALLOMATIC SL-90DC User manual

ALLOMATIC

ALLOMATIC SL-45 DC User manual

ALLOMATIC

ALLOMATIC OH-200DC User manual

ALLOMATIC

ALLOMATIC DC Series User manual

ALLOMATIC

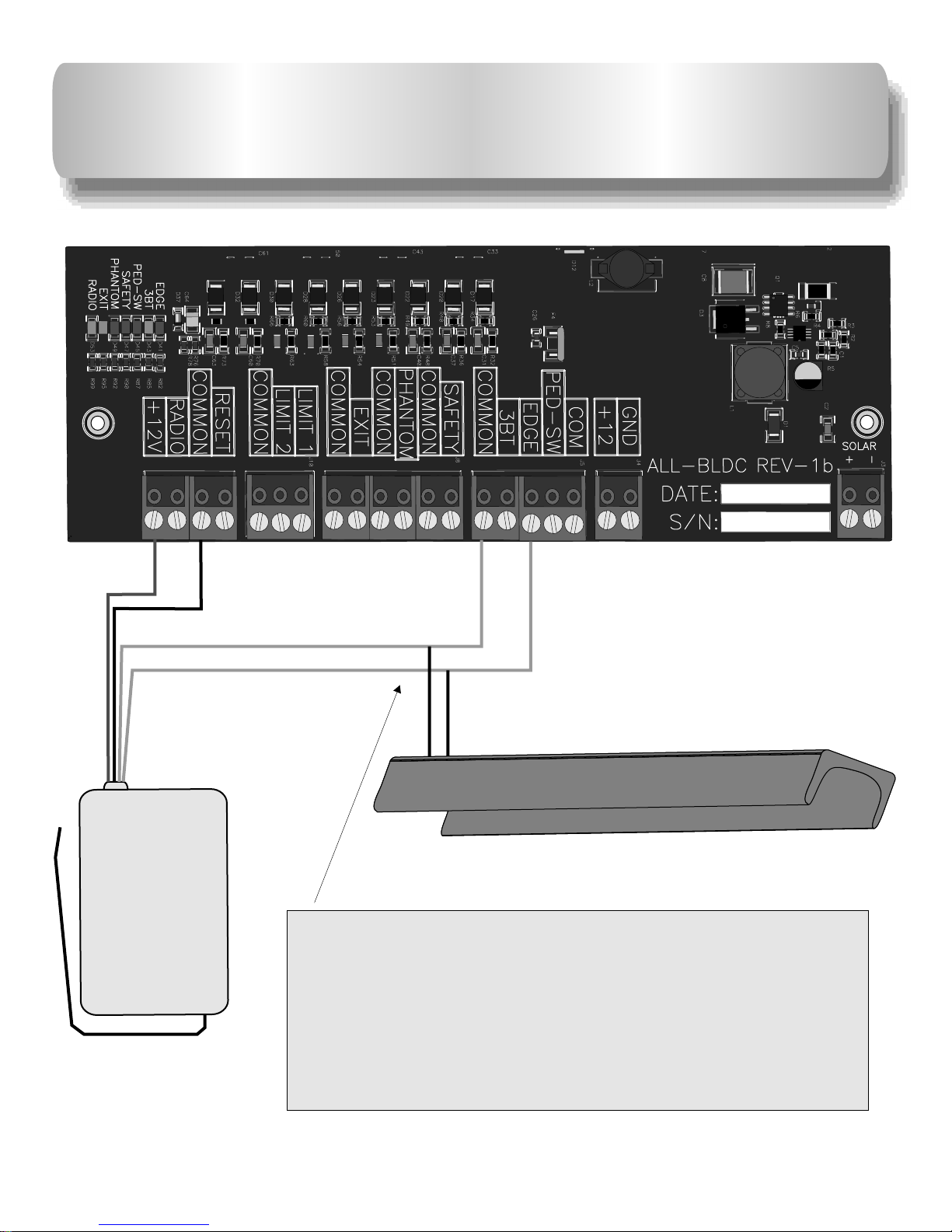

ALLOMATIC TORO 24 PRIME User manual

ALLOMATIC

ALLOMATIC TORO 24 User manual

ALLOMATIC

ALLOMATIC SL-100 AC User manual

ALLOMATIC

ALLOMATIC SL-45DC User manual

ALLOMATIC

ALLOMATIC SL-100AC User manual

ALLOMATIC

ALLOMATIC SL-175 User manual

Popular Gate Opener manuals by other brands

Merlin

Merlin Swing L300 Installation and operating instructions

SOMFY

SOMFY Elixo 500 3S RTS installation instructions

SOMFY

SOMFY Ixengo L installation manual

SEA

SEA MINI TANK installation manual

WORKMASTER

WORKMASTER GO-A8-FW Maintenance & parts manual

Beninca

Beninca DU.50V Operating instructions and spare parts catalogue