2

Table of Contents

Equipment Protection Quick Facts ........................................................................................................................................ 1

TABLE OF CONTENTS................................................................................................................................................2

ABOUT YOUR PRESSURE WASHER.........................................................................................................................4

SPECIFICATIONS ........................................................................................................................................................5

COMPONENT IDENTIFICATION..................................................................................................................................6

SAFETY ........................................................................................................................................................................7

Hazard Signal Word Definitions ............................................................................................................................................ 7

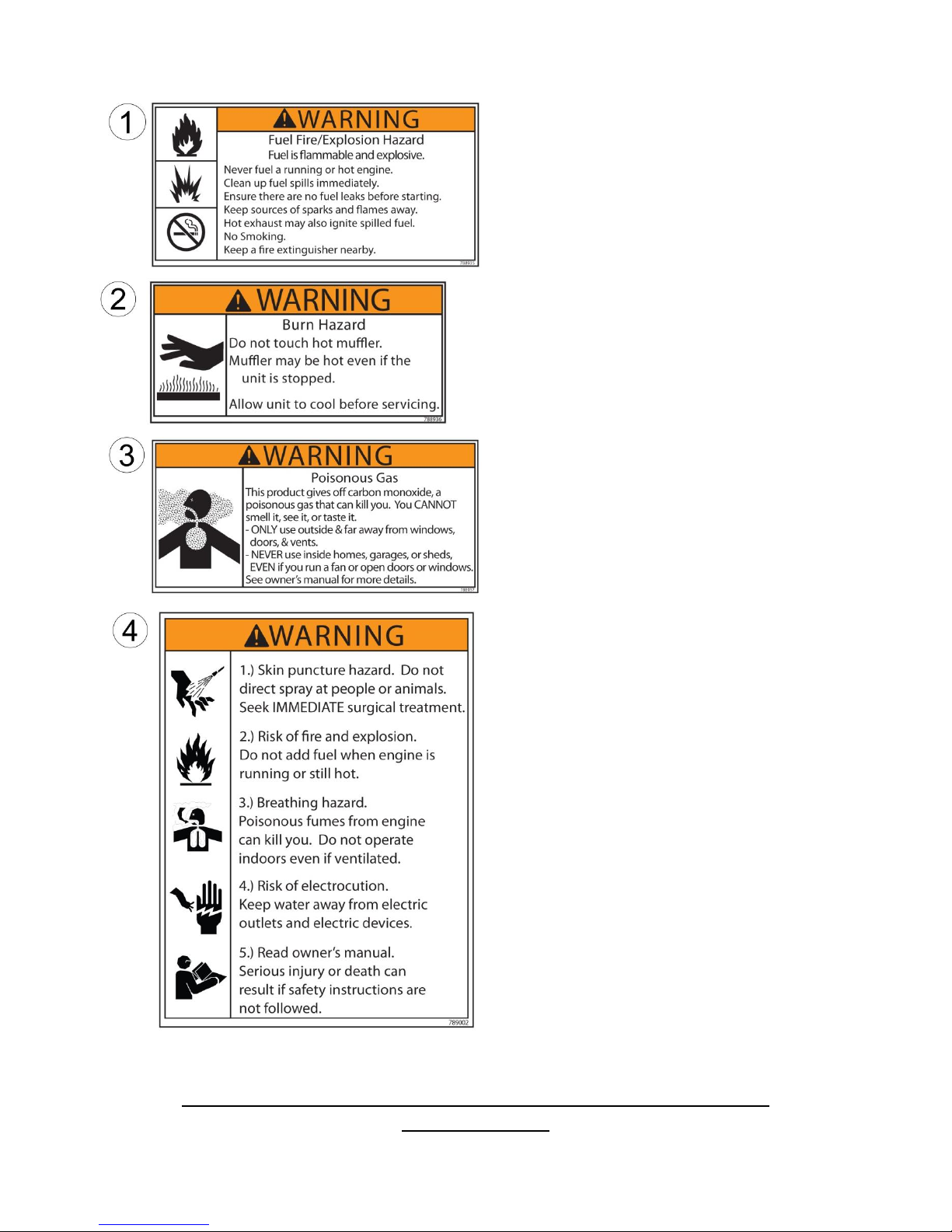

SAFETY LABELING.....................................................................................................................................................8

Safety Decal Locations ......................................................................................................................................................... 8

Safety Decals........................................................................................................................................................................ 9

INITIAL SET-UP..........................................................................................................................................................10

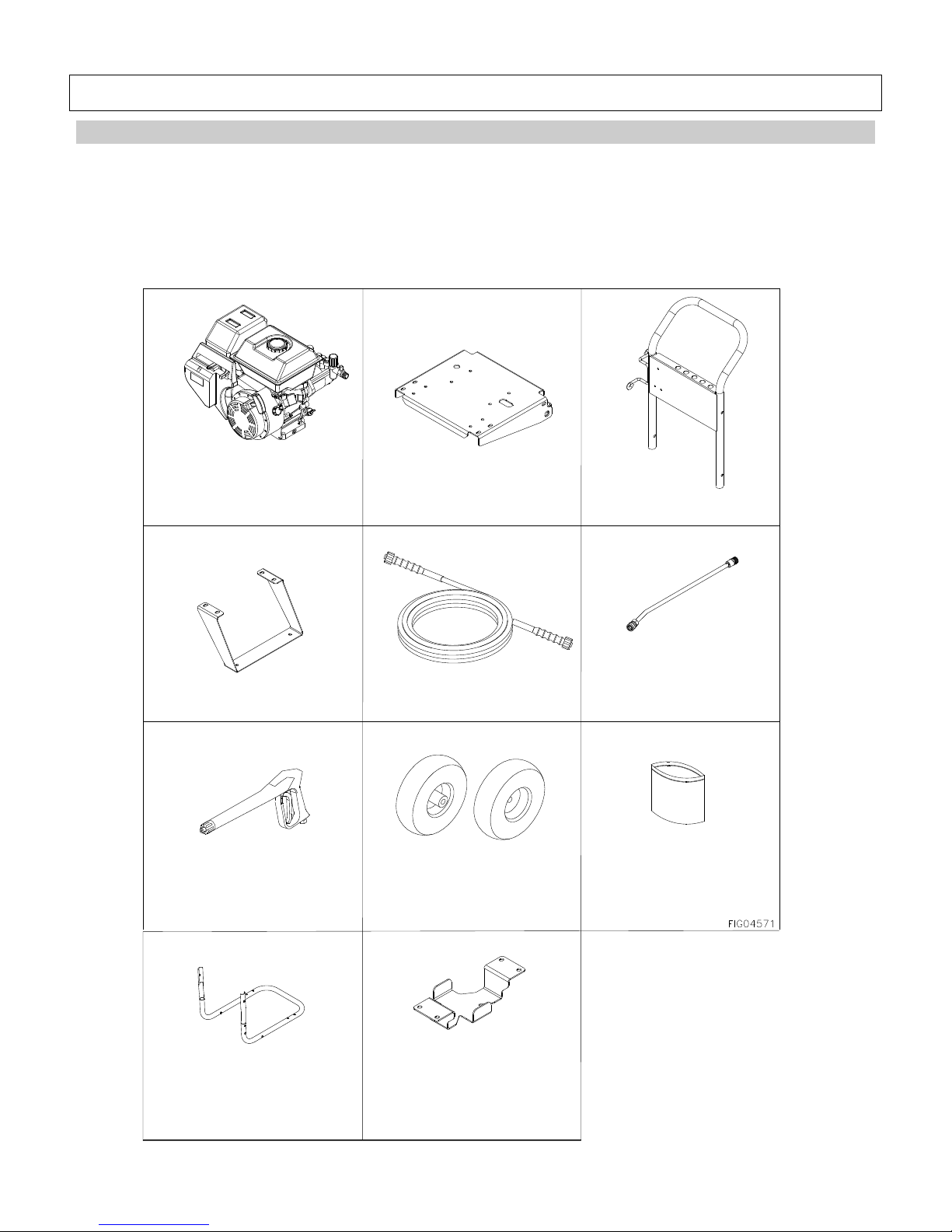

Step 1. Inspect & Unpack...................................................................................................................................................... 10

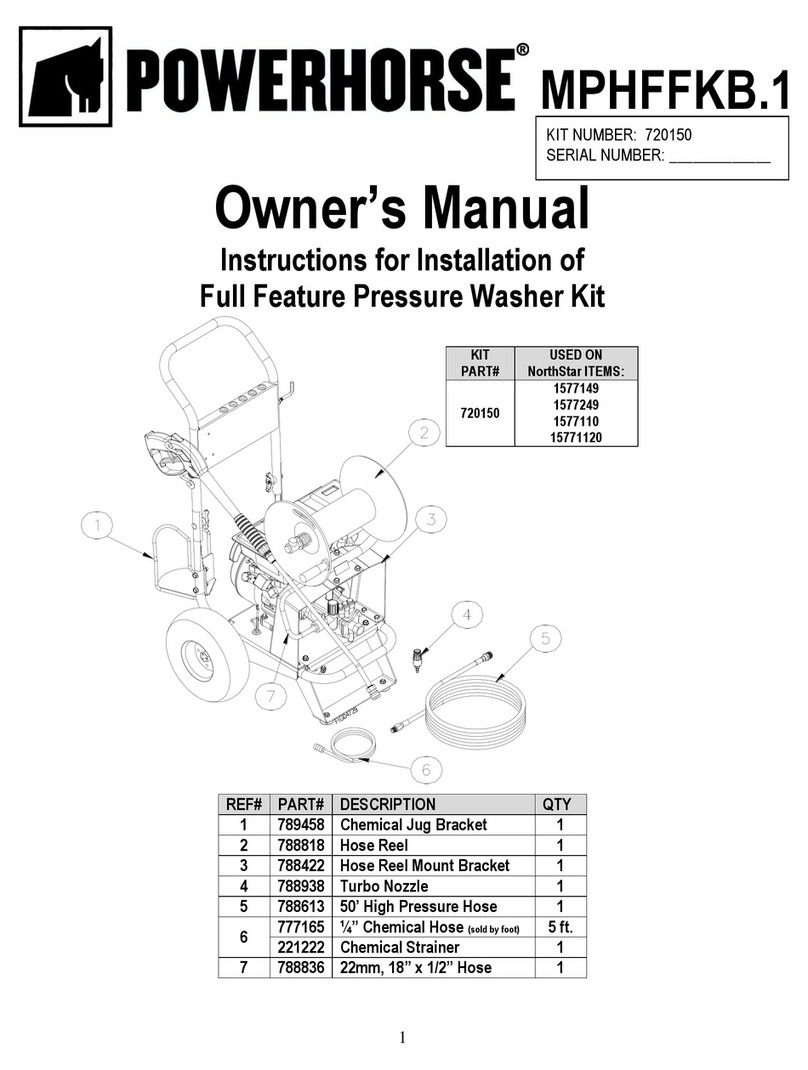

Step 2. Assembly................................................................................................................................................................... 12

Base Assembly ................................................................................................................................................................... 12

Install Battery (1577249 Only)............................................................................................................................................. 14

Step 3. Select Suitable Location........................................................................................................................................... 15

Moving and Handling .......................................................................................................................................................... 15

Outdoor Use Only ............................................................................................................................................................... 15

Install Spark Arrestor (if Required)...................................................................................................................................... 16

OPERATION ...............................................................................................................................................................17

Follow Safety Rules for Operation ....................................................................................................................................... 17

Preparing for Operation ........................................................................................................................................................ 18

Check/Add Oil to Pump....................................................................................................................................................... 18

Check/Add Engine Oil......................................................................................................................................................... 19

Inspect Fuel System/Check for Leaks................................................................................................................................. 20

Connect Hoses, Water Supply, and Spray Nozzle .............................................................................................................. 20

Prime the Water Supply......................................................................................................................................................... 22

Set Up for Chemical Spray (if desired)................................................................................................................................. 22

Start-Up Procedures.............................................................................................................................................................. 23

Start the Engine to Power the Pump................................................................................................................................... 23

Apply Cleaning Chemical (If Desired) ................................................................................................................................. 23

Begin High Pressure Spray................................................................................................................................................. 24

Shutdown ............................................................................................................................................................................... 25

STORAGE...................................................................................................................................................................26

Between-Use Storage............................................................................................................................................................ 26

Prepare Pressure Washer for Freezing Conditions............................................................................................................ 26

Prepare Engine for Long Term Storage............................................................................................................................... 27

Prepare Pressure Washer for Storage ................................................................................................................................. 27

MAINTENANCE & REPAIR........................................................................................................................................28

MAINTENANCE SCHEDULE SUMMARY..................................................................................................................28

DETAILED INSTRUCTIONS –MAINTENANCE & REPAIR ......................................................................................28

Follow Safety Rules ............................................................................................................................................................ 28

Keep Pressure Washer Clean............................................................................................................................................. 28