PowerPlus Energy Pty Ltd • LiFe4838P Installation and Operation Manual 19/10/2023 | V2.5 page 9 of 20

5. INSTALLATION

This section of the document provides important information

and guidance to installers to ensure a safe and trouble-free

installation process.

Installation should be carefully considered, and all aspects

of the specications should be understood to determine a

suitable location and way of installing the battery.

•The battery system could also be installed in a humidity-

and climate-controlled room (example, reverse cycle

air-conditioner cooled).

•The temperature of the cabinet should be always held

at a temperature above dew point.

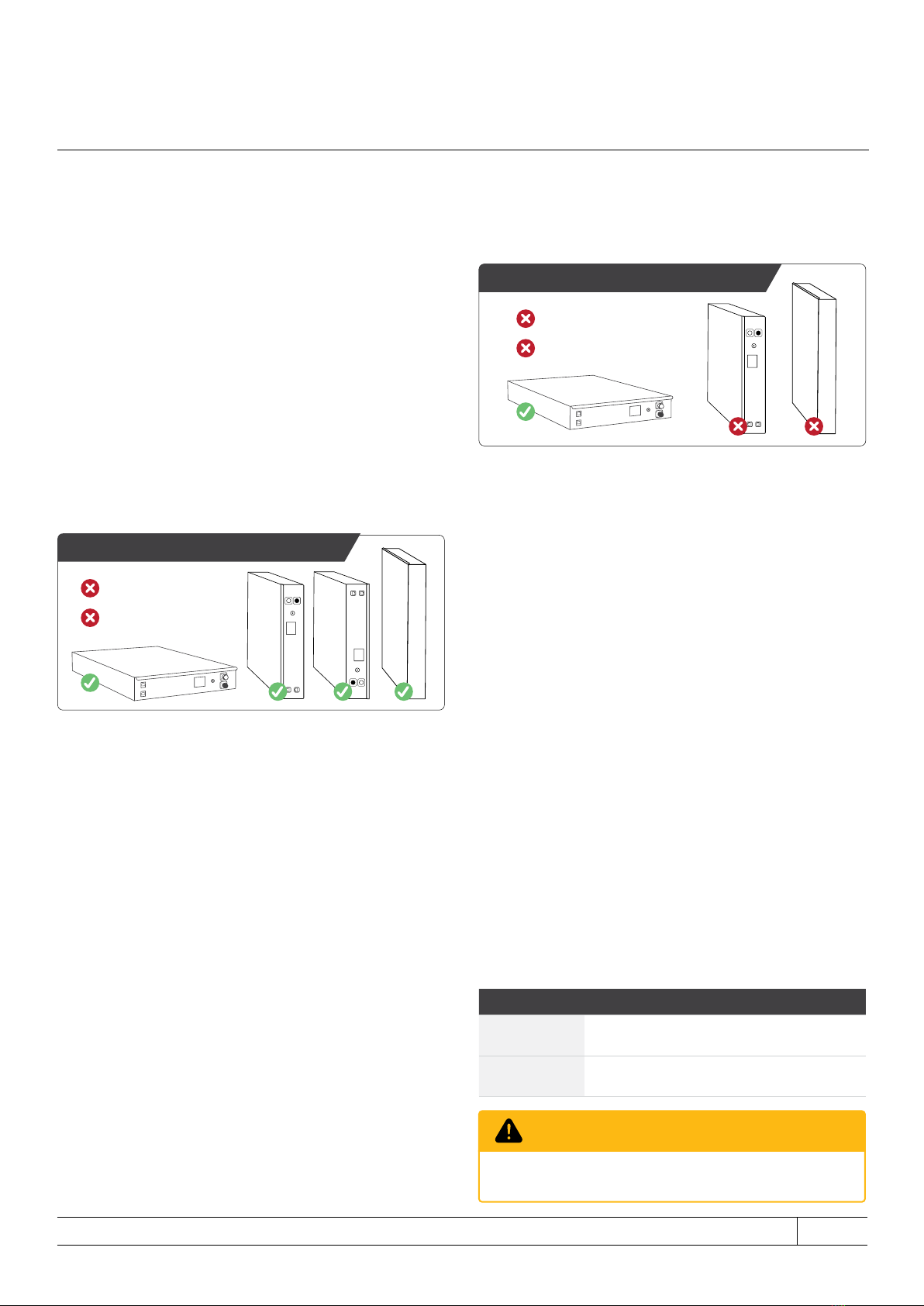

5.2 BATTERY INSTALLATION

PowerPlus Energy highly recommends their Rack Series or

Slimline Series, indoor and outdoor cabinets for containing the

batteries in a system installation. Full specication details are

available on the PowerPlus Energy website.

However, this section provides instructions which should be

followed when creating a custom enclosure or system for

containing the batteries.

5.2.1 CUSTOM CABINETS

The battery has been designed to t into a standard 800mm

deep 19-inch equipment rack.

If you are planning to design and assemble your own battery

enclosure, please carefully consider the following suggestions

and recommendations:

•If the battery is installed into enclosures without rails,

please ensure that they are securely seated to prevent

accidental damage or tampering.

•If a custom enclosure or mounting method is used, please

ensure the batteries are not stacked more than 6 high

unless battery support rails are used to distribute weight.

•Please ensure there is adequate air ow around the

battery stack within the cabinet. Except for the top and

bottom surfaces of the stack, a clearance of at least

25mm is required around the stack (4 sides of the stack).

WARNING

If the battery is not stored or operated within the

recommended temperature range specied in Section

5.1, the Battery Management System (BMS) may halt

the operation of the battery as a protective measure. It is

important to note that if the battery is subjected to extreme

temperatures frequently, there will be a negative impact to

its long-term performance and reduce its longevity.

5.1 LOCATION AND ENVIRONMENT

The location of the battery should be in accordance with

the IP rating in Table 4.4 (Physical Characteristics) and

operating temperature range specied in Table 4.3 (Operating

Conditions).

The LiFe4838P battery is designed to be installed in a 19-

inch data rack assembly or an electrical enclosure of your

choice. The external rack assembly or electrical enclosure

is considered outside the scope of the battery product

certication. If the battery is to be installed outdoors a suitable

enclosure with IP54 (or greater) rating should be used.

The location of the battery should meet the below conditions:

•Due to the risk of short circuits and rapid metal corrosion,

the battery should not be installed where direct contact

of salt air may be possible. If salt air is unavoidable,

appropriate air ltration must be employed to keep the

battery free of salt deposits. It is highly recommended that

the battery should be installed in an indoors environment,

or inside an IP66 or greater enclosure.

•The oor is level and free from obstructions.

•There are no explosive or ammable materials nearby.

•The recommended operating temperature is between

15°C and 30°C.

•The temperature and humidity should remain as constant

as possible.

•The area is of a clean environment with minimal dust.

•The area or enclosure is insect and vermin proof.

•The batteries and battery cabinets/housings are not

exposed to direct sunlight.

5.1.1 EXTREME HUMIDITY CLIMATES

When PowerPlus Energy’s LiFe4838P batteries are being

installed in elevated humidity conditions, extra precautions

should be taken:

•A humidity control agent (i.e., chemical which absorbs

humidity) may be required inside the enclosure, with

controlled airow to expel moist air.

NOTE

The battery will exhibit optimal performance and lifespan

if it is operated within its ideal temperature range.