PPI neuro 200 User manual

User Manual

neuro 200

neuro 200

User Manual

Advanced

Universal Process Indicator

User Manual

neuro 200

CONTENTS

1. FRONT PANEL LAYOUT 1

2. BASIC OPERATION 3

3. SET-UP MODE ACCESS AND OPERATION 6

4. PAGE-10 : ALARM PARAMETERS 8

5. PAGE-11 : RETRANSMISSION PARAMETERS 10

6. PAGE-12 : INPUT CONFIGURATION 11

7. PAGE-13 : SUPERVISORY PARAMETERS 16

8. PAGE-33 : USER LINEARISATION PARAMETERS 17

9. MECHANICAL INSTALLATION 18

10. ELECTRICAL CONNECTIONS 20

APPENDIX-A : DC LINEAR SIGNAL INTERFACE 24

1

User Manual

neuro 200

The indicator front panel comprises of digital readouts, LED indicators and membrane keys as shown in Figure 1.1 below.

FRONT PANEL LAYOUT

Figure 1.1

READOUTS

The Upper Readout is a 4 digit, 7-segment bright green LED display and usually displays the PV (Process Value).In Set-up

Mode, the Upper Readout displays parameter values/options.

The Lower Readout is a 4 digit, 7-segment bright green LED display and usually displays Process Value Units. In case of any

active Alarm(s), the Lower Readout flashes Alarm Status information. In Set-up Mode, the Lower Readout displays the names

(identifier tags) for the parameters.

INDICATORS

The front panel comprises 5 LED indicators that show Alarm status. Refer Table 1.1 below for details.

Table 1.1

Section 1

A1H

A1L

A2H

A2L

neuro 200

L1 L2

L3COM

ACK

Upper Readout

Lower Readout

ENTER / Alarm ACK Key

UP Key

DOWN Key

PAGE Key

Serial Comm. Indicator

Alarm-1 High / Low

Status Indicator

{

Alarm-2 High / Low

Status Indicator

{

Indicator Function

Flashes when Alarm-1 high limit is crossed.

A1H

A1L

COM

Flashes when Alarm-1 low limit is crossed.

Serial Communication Status. Flashes when data is being exchanged

with Master Device.

Flashes when Alarm-2 high limit is crossed.

A2H

A2L Flashes when Alarm-2 low limit is crossed.

L1, L2, L3 Unused

2

User Manual

neuro 200

Table 1.2

Symbol Key Function

Press to enter or exit set-up mode.

PAGE

DOWN

UP

ENTER /

ACK

Set up Mode : Press to store the set parameter value and to scroll

to the next parameter on the PAGE.

Run Mode : Press to acknowledge any pending Alarm(s). This

also turns off the Alarm relay.

Press to increase the parameter value. Pressing once increases the

value by one count; keeping pressed speeds up the change.

Press to decrease the parameter value. Pressing once decreases

the value by one count; keeping pressed speeds up the change.

KEYS

There are four tactile keys provided on the front panel for configuring the indicator, setting-up the parameter values. Refer

Table 1.2 below.

3

User Manual

neuro 200

PV Error Indications

The PV Error type is flashed on the Upper Readout. For different errors and the causes, refer Table 2.1 below.

Table 2.1

PV above Max. Range

PV below Min. Range

Message Error Type Cause

Thermocouple / RTD broken

Sensor Open

Under-range

Over-range

BASIC OPERATION

ALARM STATUS UNDER PV ERROR CONDITIONS

For Alarm activation, the under-range condition is treated as minimum PV, whereas the over-range and open conditions are

treated as maximum PV. Thus, Process High alarm activates under Over-range / Open error. Similarly, Process Low alarm

activates under Under-range error.

OPERATOR PAGE AND PARAMETERS

The parameters that require frequent settings are organized on a separate page, called the Operator Page. The availability of

operator parameters is controlled at supervisory level and the parameter setting cannot be locked by the Master Lock.

Section 2

POWER-UP

Upon power-up the controller executes the following sequence of operations.

· Checks for Sensor Fault. If the connected sensor type is RTD Pt100 and the selected sensor type is any of thermocouples

or vice-a-versa; the controller displays sensor fault massage (S.FLt) on upper readout. The user is advised to take

necessary corrective action and press Enter key to acknowledge the fault.

· All displays and indicators are lit on for approximately 3 seconds to check any display segment failure.

· Displays controller model name on the Upper Readout and the firmware version on the Lower Readout, for approximately 1

second. This helps user to verify features and refer to the correct documents versions.

MAIN DISPLAY MODE

After the Power-up display sequence, the Upper Readout starts showing the measured PV (Process Value) and the Lower

Readout displays the user set Units for Process Value. This is the MAIN Display Mode that shall be used most often.

Alarm Status Information

In case of any Alarm (or Alarms) becoming active, the Lower Readout flashes the related Alarm details in the format ‘Ax.YY’,

where x is the Alarm Number (1 or 2) and YY is the Alarm Type (Lo or Hi). For example; if Alarm -1 is active and the set Alarm

Type is Low then the Lower Readout flashes (A1.Lo). In case of multiple Alarms, each Alarm Status is flashed sequentially with

1 Seconds interval.

4

User Manual

neuro 200

Table 2.2

Parameter Description Settings

(Default Value)

View Only

(Default :NA)

(Default : No)

No

Yes

View Only

(Default :NA)

MAXIMUM PV

This indicates the highest value attained by the Process Value.

This is a read only value and is available only if Min/Max

monitoring is enabled.

MINIMUM PV

This indicates the lowest value attained by the Process Value.

This is a read only value and is available only if Min/Max

monitoring is enabled.

RESET COMMAND

Available only if Min/Max monitoring is enabled. This feature

clears the current Min/Max values and starts afresh monitoring the

PV for new highest and lowest values.

ALARM ACKNOWLEDGE

Set this parameter value to ‘Yes’ to acknowledge any pending

Alarm(s) to de-activate alarm relay(s). This parameter is available

only when any alarm(s) is active and not latched.

(Alternatively, use ENTER key to acknowledge pending Alarm(s).

(Default :No)

No

Yes

Accessing Operator Page & Adjusting Parameters

Step through the following sequence to open the operator page and to adjust the operator parameter values.

1. Press and release PAGE key. The Lower Readout shows (PAGE) and Upper Readout shows (0).

2. Press and release ENTER key. The Lower Readout shows prompt for the first available operator parameter and the Upper

Readout shows value for the parameter.

3. Use UP / DOWN keys to adjust the value and then press ENTER key to store the set value and scroll to next parameter.

The indicator automatically reverts to MAIN Display Mode upon scrolling through the last operator parameter. Alternatively,

use PAGE key to return to MAIN Display Mode.

The operator parameters are described in Table 2.2. Note that the parameters presented on Operator Page depend upon the

functions selected/enabled and supervisory level permissions. The operator parameter list mainly includes :

a) Min / Max Process Monitoring Parameters.

b) Setpoint Values for Alarm-1 and Alarm-2.

5

User Manual

neuro 200

Parameter Description Settings

(Default Value)

0 to 250

(Default :0)

Min to max Range

specified for the

selected Input Type

(Default : Min or Max Range)

RESET PASSWORD

For resetting the Min/Max values, set the reset command to ‘Yes’

and then enter the correct password.

ALARM-1 SETPOINT

The setpoint for Alarm-1. This parameter is not available if the

selected Alarm-1 type is ‘None’.

ALARM-2 SETPOINT

The setpoint for Alarm-2. This parameter is not available if the

selected Alarm-2 type is ‘None’.

Min to max Range

specified for the

selected Input Type

(Default : Min or Max Range)

6

User Manual

neuro 200

The various parameters are arranged in different groups, called PAGES, depending upon the functions they represent. Each

group is assigned a unique numeric value, called PAGE NUMBER, for its access.

The parameters are always presented in a fixed format: The Lower Readout displays the parameter prompt (Identification

Name) and the Upper Readout displays the set value. The parameters appear in the same sequence as listed in their

respective sections.

SET-UP MODE

The Set-up Mode allows the user to view and modify the parameter values. Follow the steps below for setting the parameter

values:

1. Press and release PAGE key. The Lower Readout shows PAGE and the Upper Readout shows page number 0. Refer

Figure 3.1.

2. Use UP / DOWN keys to set the desired PAGE NUMBER.

3. Press and release ENTER key. The Lower Readout shows the prompt for the first parameter listed in the set PAGE and the

Upper Readout shows its current value. If the entered PAGE NUMBER is invalid (contains no parameter list or any

associated function), the reverts to the MAIN Display Mode.indicator

4. Press and release the ENTER key until the prompt for the required parameter appears on the Lower Readout. (The last

parameter in the list rolls back to the first parameter).

5. Use UP / DOWN keys to adjust the parameter value. (The display flashes if UP key is pressed after reaching the maximum

value or DOWN key is pressed after reaching the minimum value).

6. Press and release the ENTER key. The new value gets stored in the indicator’s non-volatile memory and the next

parameter in the list is displayed.

The Figure 3.1 illustrates the example of altering the value for the parameter ‘Input type’.

SET-UP MODE : ACCESS AND OPERATION

Figure 3.1

Notes

1. Each page contains a fixed list of parameters that are presented in a pre-determined sequence. Note however that availability of a few

parameters, called Conditional Parameters, depend upon the settings for some other parameters. For example, the parameter ‘Alarm

Setpoint’ is available if corresponding ‘Alarm type’ is set to other than ‘none’.

2. To exit the set-up mode and return to the MAIN Display Mode, press and release PAGE key.

3. If no key is pressed for approximately 30 seconds, the set-up mode times out and reverts to the MAIN Display Mode.

Section 3

Press PAGE

key to enter

Set-up mode

Press ENTER

key to open

the Page

Use UP/DOWN

keys to set the

Page Number

MAIN Display

Mode

Default Page Page Number

or

Use UP/DOWN

keys to change

the value

Press ENTER key

to store the value &

move to next parameter

First Parameter

on PAGE-12

Next Parameter

on PAGE-12

or

New Parameter

value

7

User Manual

neuro 200

MASTER LOCKING

The indicator facilitates locking all the PAGES (except Operator PAGE) by applying Master Lock Code. Under Locking, the

parameters are available for view only and cannot be adjusted. The Master Lock, however, does not lock the operator

parameters. This feature allows protecting the rather less frequently used parameters against any inadvertent changes while

making the frequently used operator parameters still available for any editing.

For enabling / disabling the Lock, step through the following sequence:

Locking

1. Press and release PAGE key while the indicator is in the MAIN Display Mode. The Lower Readout shows PAGE and the

Upper Readout shows 0.

2. Use UP / DOWN keys to set the Page Number to 123 on the Upper Readout.

3. Press and release ENTER key. The indicator returns to the MAIN Display Mode with the Lock enabled.

The Figure 3.2 below illustrates the Locking procedure.

Figure 3.2

UnLocking

Repeat the Locking procedure twice for unlocking.

Press PAGE

key to enter Set-up mode

Use UP/DOWN keys

to set the ‘Locking’ Code

Press ENTER key to

Lock & Return to MAIN Mode

MAIN Mode

MAIN Mode

Default Page Locking Code

or

8

User Manual

neuro 200

The parameters required for configuring Alarms are grouped on PAGE-10. The configuration includes selecting the type of

Alarm, setting the hysteresis value, enabling / disabling start-up Alarm suppression, etc. Refer Table 4.1 for parameter

description & settings.

PAGE-10 : ALARM PARAMETERS

Table:4.1

Parameter Description Settings

(Default Value)

Min. to Max. Range

specified for the

selected Input Type

(Default : Min or Max Range)

1 to 999 or

0.1 to 999.9

(Default : 2.0)

(Default : Normal)

Reverse

Normal

ALARM-1 TYPE

Select the Alarm-1 activation type. Selecting ‘None’ will disable

the alarm and suppress all the related parameters for Alarm-1.

ALARM-1 SETPOINT

Sets the Process High or Process Low limit for Alarm-1.

ALARM-1 HYSTERESIS

Sets differential (dead) band between Alarm-1 ON and OFF

states.

ALARM-1 INHIBIT

Set to Yes to suppress Alarm-1 activation upon power-up (process

start-up) condition.

ALARM-1 LOGIC

Select ‘Normal’ if Alarm-1 relay is to activate an Audio / Visual

alarm. Select ‘Reverse’ for Tripping (cut-off) the system.

ALARM LATCH

No

The Relay switches ON/OFF with Alarm switching.

Yes

The Relay Output switches (ON for Normal Logic / OFF for

Reverse Logic) upon Alarm activation. However, Alarm de-

activation does not affect the Relay status. The Relay status can

only be regained by pressing ‘Acknowledge-key’ provided the

Alarm has de-activated.

No

Yes

(Default :Yes)

No

Yes

(Default :No)

Section 4

(Default : None)

None

Process Low

Process High

9

User Manual

neuro 200

Parameter Description Settings

(Default Value)

(Default : Normal)

Reverse

Normal

Min. to Max. Range

specified for the

selected Input Type

(Default : Min/Max Range)

1 to 999 or

0.1 to 999.9

(Default : 2.0)

(Default :No)

No

Yes

Sets the Process High or Process Low limit for Alarm-2.

ALARM-2 SETPOINT

Sets differential (dead) band between Alarm-2 ON and OFF

states.

ALARM-2 HYSTERESIS

Set to Yes to suppress Alarm-2 activation upon power-up (process

start-up) condition.

ALARM-2 INHIBIT

Select ‘Normal’ if Alarm-2 relay is to activate an Audio / Visual

alarm. Select ‘Reverse’ for tripping (cut-off) the system.

ALARM-2 LOGIC

No

The Relay switches ON/OFF with Alarm switching.

Yes

The Relay Output switches (ON for Normal Logic / OFF for

Reverse Logic) upon Alarm activation. However, Alarm de-

activation does not affect the Relay status. The Relay status can

only be regained by pressing ‘Acknowledge-key’ provided the

Alarm has de-activated.

ALARM LATCH

ALARM-2 TYPE

Select the Alarm-2 activation type. Selecting ‘None’ will disable

the alarm and suppress all the related parameters for Alarm-2.

(Default :Yes)

No

Yes

(Default : None)

None

Process Low

Process High

10

User Manual

neuro 200

The parameters required for configuring are grouped on PAGE-11. The configuration includes selecting the Retransmission

Output type, Recorder Low & High settings etc. Refer Table 5.1 for parameter description & settings.

PAGE-11 : RETRANSMISSION PARAMETERS

Table 5.1

Parameter Description Settings

(Default Value)

Min. to Max. Range

specified for the

selected Input Type

(Default : -200)

Select Output Signal type in accordance with the hardware

module fitted. Select 0-20 or 4-20 mA, if Current output module is

fitted. Select 0-5 or 0-10 V, if Voltage output module is fitted.

RECORDER OUTPUT TYPE

Set the minimum Process Value (PV) that shall correspond to the

minimum recorder output signal level (0mA or 4mA or 0V).

RECORDER LOW

Set the maximum Process Value (PV) that shall correspond to the

maximum recorder output signal level (20 mA or 10 V or 5 V).

RECORDER HIGH

(Default : 0 to 20 mA)

0 to 20 mA

4 to 20 mA

0 to 5 Volts

0 to 10 Volts

Min. to Max. Range

specified for the

selected Input Type

(Default : 1376)

Section 5

11

User Manual

neuro 200

The indicator is needs to be appropriately configured in terms of input and other features like digital filter etc. The PAGE-12

presents Input configuration parameters that are listed below in Table 6.1 .

PAGE-12 : INPUT CONFIGURATION PARAMETERS

Table 6.1

Parameter Description Settings

(Default Value)

Refer Table 6.3

(Default : Type K)

Refer Table 6.3

(Default : 1)

Refer Table 6.2

(Default : ºC)

(Not Available for Thermocouple Inputs)

Set the process value indication resolution (decimal point). All the

resolution based parameters (hysteresis, alarm setpoints etc.)

then follow this resolution setting.

RESOLUTION

Select Temperature units in ºC or ºF for Thermocouple or Pt100

sensor.

For DC Linear input (mA/mV/V), Select appropriate Units from the

list in Table 6.2. Note however that the selected Units are for the

purpose of Lower Readout indication only.

UNITS

Section 6

SIGNAL RANGE LOW

SIGNAL RANGE HIGH

This parameter is available only if the selected input type is DC

Voltage / Current and defines the transmitter output signal value

corresponding to Range High process value.

Input Type Settings Default

0 to 20 mA

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

Signal Low to 20.00 20.00

20.00

80.00

1.250

5.000

10.00

5.000

Signal Low to 20.00

Signal Low to 80.00

Reserved 80.00

Signal Low to 80.00

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

Input Type Settings Default

0 to 20 mA 0.00 to Signal High 0.00

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

4.00 to Signal High

0.00 to Signal High

0.000 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

4.00

0.00

Reserved 0.0 to Signal High 0.0

0.000

0.000

0.00

1.000

This parameter is available only if the selected input type is DC

Voltage / Current and defines the transmitter output signal value

corresponding to Range Low process value.

Select Input type in accordance with the type of Thermocouple or

RTD sensor or transducer output connected for process value

measurement. Ensure proper hardware jumper settings, if

required.

INPUT TYPE

12

User Manual

neuro 200

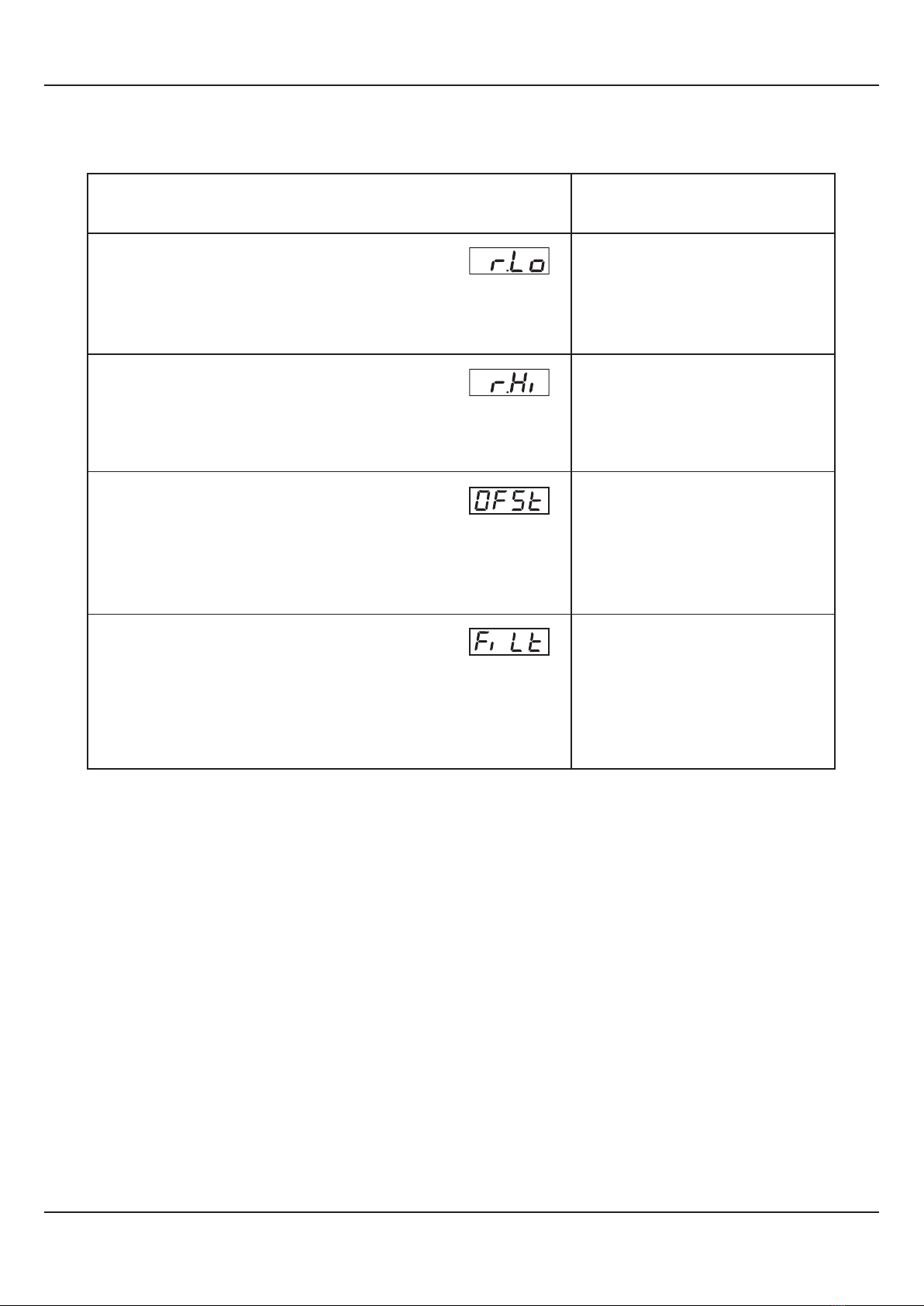

DC RANGE LOW

Parameter Description Settings

(Default Value)

-1999 to 9999

(Default : 100.0)

-1999 to 9999 or

-199.9 to 999.9

(Default : 0)

This value is algebraically added to the measured PV to derive the

final PV that is displayed and used for Alarm / Retransmission.

Final PV = Measured PV + Offset

OFFSET

FILTER

Sets the time constant, in seconds, for the low-pass digital filter

applied to the measured PV. The filter helps smoothing /

averaging the signal input and removing the undesired noise. The

higher the filter value the lower the indication response to the PV

changes and vice-a-versa.

0.5 to 60.0 Seconds

(in steps of 0.5 Seconds)

(Default : 2.0 sec.)

-1999 to 9999

(Default : 0.0)

This parameter is available only if the selected input type is DC

Voltage / Current and defines the process value corresponding to

the Signal Low value from the transmitter.

DC RANGE HIGH

This parameter is available only if the selected input type is DC

Voltage / Current and defines the process value corresponding to

the Signal High value from the transmitter.

13

User Manual

neuro 200

Table-6.2

Lower Readout Units

°C

°F

Kelvin

Engineering Units

Percentage

Pascals

Mpascals

Kpascals

Bar

Milli bar

PSI

kg/sq cm

mm water gauge

Inches water gauge

mm mercury

Torr

Litres per hour

Litres per minute

% Relative Humidity

% O2

% CO2

% Carbon Potential

Temperature

Pressure

Flow

14

User Manual

neuro 200

Lower Readout Units

volts

Amps

Milli amps

Milli Volts

Ohms

Parts per million

Revolutions per pinute

Milli seconds

Seconds

Minutes

Hours

PH

%PH

Miles per hour

Milli grams

Grams

Kilo grams

cm (Centimeter)

mm (Millimeter)

Inch

Foot

Mile

Meter

Kilometer

Electricity

Time

Weight

Length /

Height /

Distance

15

User Manual

neuro 200

Table 6.3

Resolution

Option What it means Range (Min. to Max.)

Type J Thermocouple

Type K Thermocouple

Type T Thermocouple

0 to +960°C / +32 to +1760°F

-200 to +1376°C / -328 to +2508°F

-200 to +385°C / -328 to +725°F

Type R Thermocouple

0 to +1770°C / +32 to +3218°F

Fixed

1°C / 1°F

0 to 20mA DC current

4 to 20mA DC current

0 to 0mV DC voltage 8

Reserved

0 to 1.25V DC voltage

0 to 5.0V DC voltage

0 to 10.0V DC voltage

1 to 5.0V DC voltage

3-wire, RTD Pt100

-1999 to +9999 units

-199 to +600°C / -328 to +1112°F

-199.9 to 600.0°C / -199.9 to 999.9°F

or

User settable

1°C / 1°F

or

0.1°C / 0.1°F

User settable

1 / 0.1 / 0.01/

0.001 units

Type N Thermocouple

Type B Thermocouple

Type S Thermocouple

0 to +1300°C / +32 to +2372°F

0 to +1825°C / +32 to +3092°F

0 to +1765°C / +32 to +3209°F

Reserved for customer specific Thermocouple type not listed

above. The type shall be specified in accordance with the ordered

(optional on request) Thermocouple type.

16

User Manual

neuro 200

The supervisory level responsibilities include exercising control over operator, making process related decisions and

controlling the availability of process data for remote use. The PAGE-13 parameters allow implementation of supervisory level

decisions. The Table 7.1 below lists supervisory parameters.

PAGE-13 : SUPERVISORY PARAMETERS

Table 7.1

Parameter Description Settings

(Default Value)

0 to 250

(Default : 0)

(Default : 9.6)

4800

9600

19200

ALARM SP ADJUSTMENT

ON OPERATOR PAGE

Supervisory permission for Alarm setpoint adjustments on

Operator Page. Set to ‘Enable’ for permission.

PROCESS VALUE HIGH-LOW MONITORING

This parameter enables or disables the PV monitoring for

Min/Max values. Set to ‘Yes’ for enabling the feature.

This parameter allows protection against inadvertent resetting of

Min/Max values. That is, the reset command is executed only if the

operator sets the password that matches with this parameter

value.

PASSWORD FOR RESETTING

PV HIGH-LOW

BAUD RATE

Communication speed in ‘Bits per Second’. Set the value to match

with the host baud rate.

PARITY

One of the communication error trapping features. Select the data

packet parity as implemented by the host protocol.

(Default : Disable)

Disable

Enable

(Default :No)

No

Yes

Section 7

1 to 127

(Default : 1)

SERIAL ID NUMBER

Unique numeric code assigned to the for identification by indicator

the host. Set the value as required by the host.

(Default : Even)

Odd

Even

None

SERIAL WRITE PERMISSION

Setting to ‘No’ disallows the host to set / modify any parameter

value. The host, however, can read the value. (Default :Yes)

No

Yes

17

User Manual

neuro 200

The parameters listed on this PAGE-33 are used to implement the linearisation curve on the process value represented by the

DC linear output of a transmitter. The parameters affect the measured PV only if the ‘User Linearisation’ feature is ‘Enabled’

and if the input type is DC Linear. That is, the PV measured using Thermocouple or RTD is not affected by the linearisation

parameters. The Table 8.1 below lists the user linearisation parameters.

PAGE-33 : USER LINEARISATION PARAMETERS

Table 8.1

Parameter Description Settings

(Default Value)

0 to 9999

(Default : 0)

2 to 32

(Default : 2)

1 to 32

(Default : 1)

-1999 to 9999

(Default : Undefined)

USER LINEARIZATION SETTING CODE

Protection password for access to the linearisation related

parameters. Set to 333 as valid password.

USER LINEARIZATION

Enable / Disable user linearisation feature.

TOTAL BREAK POINTS

Select number of segments for the purpose of input PV curve

linearisation by setting the number of total break points.

Set the actual measured (X co-ordinate) value for the selected

break point number.

ACTUAL VALUE FOR

BREAK POINT (X CO-ORD)

DERIVED VALUE FOR

BREAK POINT (Y CO-ORD)

Set the computed or derived (Y co-ordinate) value for the selected

break point number.

-1999 to 9999

(Default : Undefined)

(Default :No)

No

Yes

Section 8

BREAK POINT NUMBER

Select the break point for which the X, Y co-ordinates are to be set.

18

User Manual

neuro 200

MECHANICAL INSTALLATION

Section 9

94mm

(3.70in)

7mm (0.276in)

Side View

48mm

(1.89in)

48mm

(1.89in)

Front View

A1H

A1L

L1

A2H

L2

neuro 200

A2L

COM

ACK

L3

V

H

Parameter Dimensions

mm inches

H

V

45 (-0, +0.5)

45 (-0, +0.5)

1.77 (-0, +0.02)

1.77 (-0, +0.02)

OUTER DIMENSIONS AND PANEL CUTOUT

The Figure 9.1 shows the controller outer dimensions.

PANEL CUTOUT

The Figure 9.2 shows the panel cutout requirements for a single controller.

Figure 9.1

Figure 9.2

Table of contents

Other PPI Measuring Instrument manuals