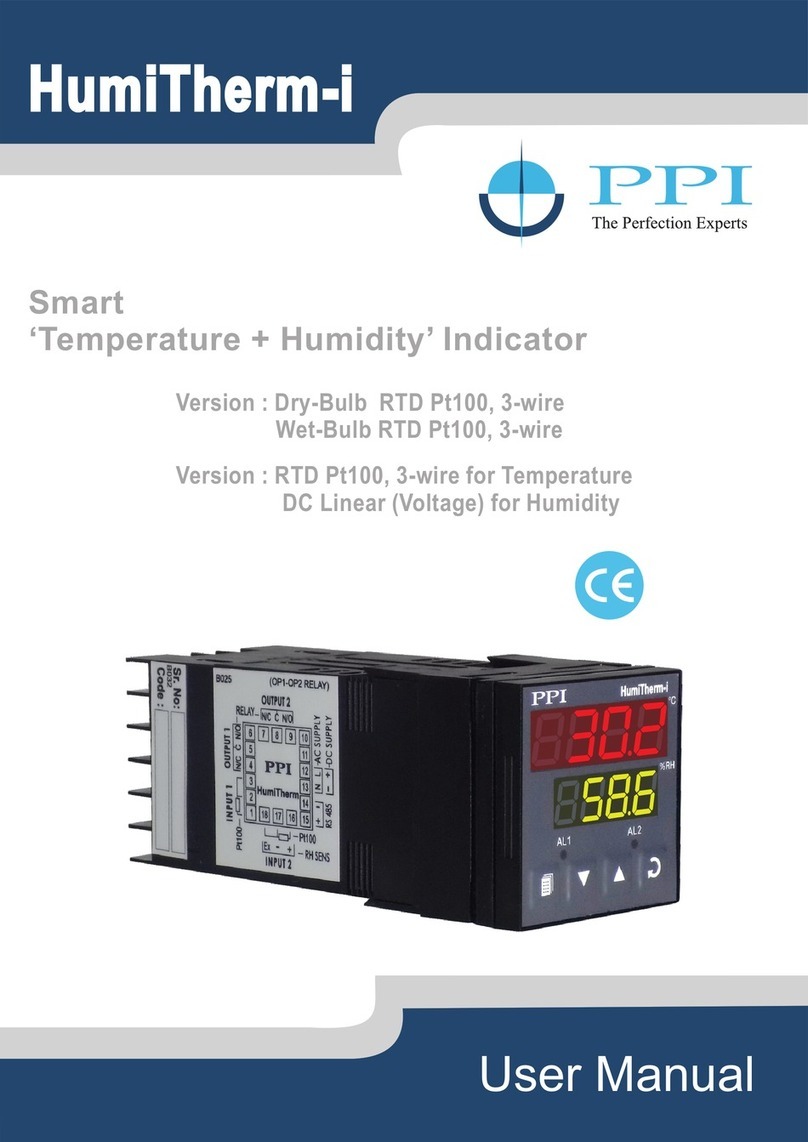

PPI HumiTherm-i Pro User manual

User Manual

HumiTherm-i Pro

Enhanced

‘Temperature + Humidity’ Indicator

(with Dry/Wet RTD Input Selection)

User Manual

HumiTherm-i Pro

User Manual

HumiTherm-i Pro

CONTENTS

1. FRONT PANEL LAYOUT 1

2. BASIC OPERATION 3

3. SETUP MODE : ACCESS AND OPERATION 6

4. PAGE-10 : TEMPERATURE - ALARM PARAMETERS 8

5. PAGE-11 : RELATIVE HUMIDITY - ALARM PARAMETERS 9

6. PAGE-12 : INPUT CHANNEL CONFIGURATION PARAMETERS 10

7. PAGE-13 : SUPERVISORY PARAMETERS 13

8. PAGE-14 : DE-HUMIDIFIER CONTROL PARAMETER 14

9. MECHANICAL INSTALLATION 15

10. ELECTRICAL CONNECTIONS 17

User Manual

HumiTherm-i Pro

1

Section 1

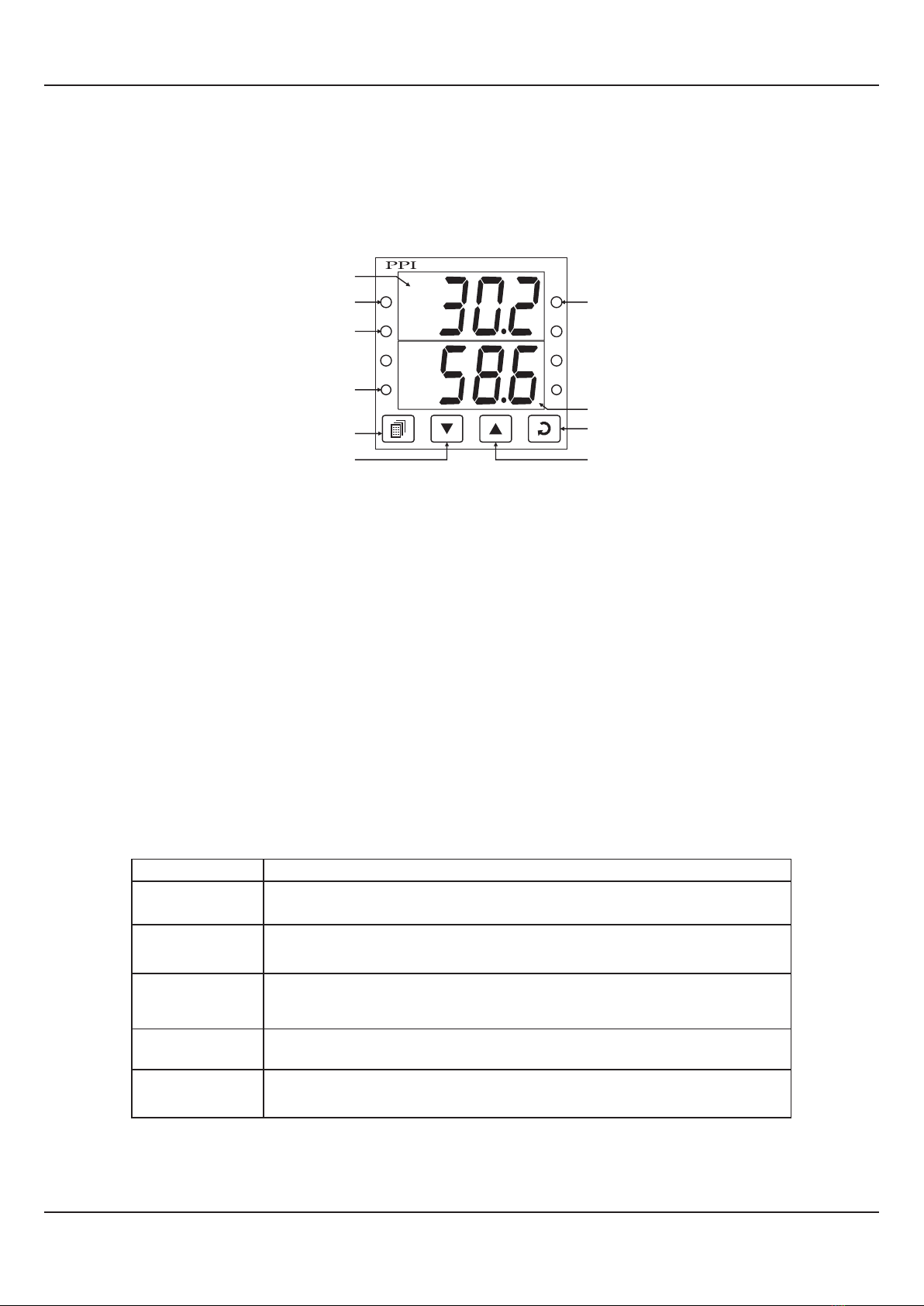

The indicator front panel comprises of digital readouts, LED indicators and membrane keys as shown in Figure 1.1 below.

READOUTS

The Upper Readout is a 4 digit, 7-segment bright green LED display and usually displays the Temperature Value in °C or °F

(depending upon the Unit selected). In Program Mode, the Upper Readout displays parameter values.

The Lower Readout is a 4 digit, 7-segment bright green LED display and usually displays Relative Humidity (RH) Value in %.

For Dry/Wet Configuration, upon holding the UP or DOWN key pressed, the Lower Readout shows the Wet-Bulb Temperature

in °C or °F. In Program Mode, the Lower Readout displays prompts for the parameters.

Table 1.2

Figure 1.1

FRONT PANEL LAYOUT

°CA

RHA

DHO

L2

HumiTherm-i Pro

L1 L3

L4COM

Upper Readout

Lower Readout

ENTER Key

UP Key

DOWN Key

PAGE Key

Serial Comm. Indicator

Temperature Alarm

Indicator

%RH Alarm Indicator

De-Humidifier

Output Indicator

Indicator Function

Temperature Alarm Status. Flashes when temperature alarm is active.

°CA

RHA %RH Alarm Status. Flashes when %RH alarm is active.

DHO

L1, L2,

L3, L4

Shows On/Off Status of de-humidifier control output.

Unused

COM Serial Communication Status. Flashes when data is being exchanged

with Master Device.

INDICATORS

There are 8 front panel red LED indicators (4 are unused). These indicator show various statuses. The Table 1.1 below lists

each LED indicator (identified by the front panel legend) and the associated status it indicates.

User Manual

HumiTherm-i Pro

2

KEYS

There are four tactile keys provided on the front panel for configuring the controller and setting-up the parameter values. The

Table 1.2 below lists each key (identified by the front panel symbol) and the associated function.

Table 1.2

Symbol Key Function

Press to enter or exit set-up mode.

DOWN

UP

ENTER Press to store the set parameter value and to scroll to the

next parameter on the PAGE.

Press to increase the parameter value. Pressing once

increases the value by one count; keeping pressed speeds

up the change.

Press to decrease the parameter value. Pressing once

decreases the value by one count; keeping pressed speeds

up the change.

PAGE

User Manual

HumiTherm-i Pro

3

BASIC OPERATIONS

POWER-UP

Upon power-up, all displays and indicators are lit on for approximately 3 seconds. This is followed by the indication of the

indicator model name (HUm.i) on the Upper Readout and the loaded firmware version on the Lower Readout, for

approximately 1 second.

MAIN DISPLAY MODE

After the Power-up display sequence, the Upper and Lower Readout start showing the measured Temperature Value in °C or

°F and the Relative Humidity in %RH, respectively. If the Indicator is configured for Dry/Wet assembly, the Wet Bulb

Temperature (in °C) can be viewed by holding the UP or DOWN key depressed. This is called the MAIN Display Mode and this

is the one that shall be used most often.

Section 2

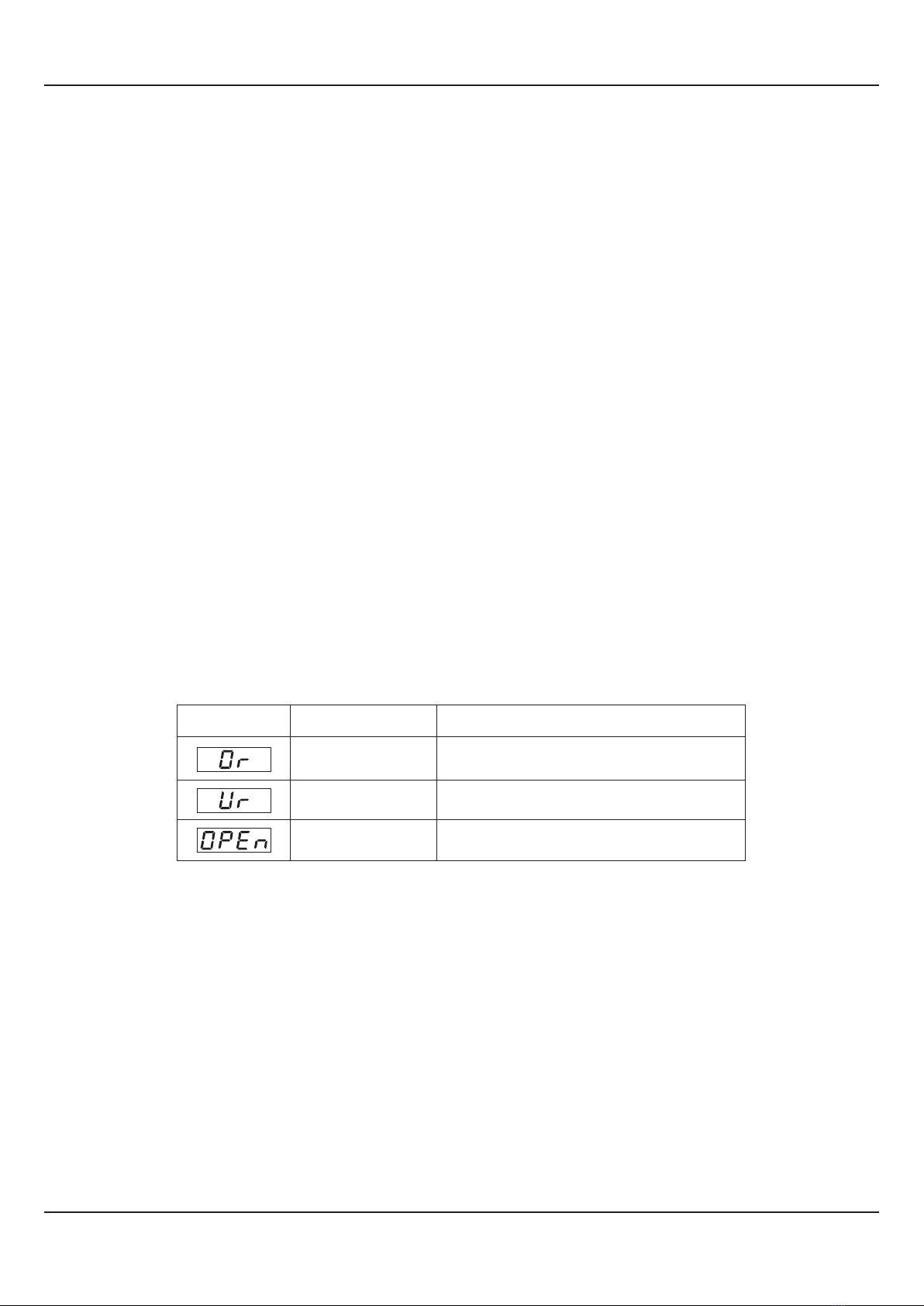

PV ERROR INDICATIONS

The indicator flashes the PV error messages for Temperature and RH Values on Upper and Lower Readout, respectively.

§Error Indications for Dry-Bulb Temperature

In case of Dry-Bulb Temperature exceeding the specified Minimum or Maximum Range or in case of input sensor (RTD

Pt100) open / broken; the Upper Readout flashes the Error Messages as listed in Table 2.1 below.

Table 2.1

Message Error Type Cause

Sensor Open

Under-range

Over-range Dry Bulb Temperature above Max. Range

Dry Bulb Temperature below Min. Range

Dry Bulb Sensor (RTD) Broken / Open

§ Error Indication for Relative Humidity (RH)

If RH transmitter is connected for direct %RH measurement, the signal output is either DC Voltage (e.g. 0 - 5 V, 0 - 10 V,

etc.) or DC Current (e.g. 4 - 20 mA). Thus, an open or broken sensor means either 0 V or 0 mA output. In this case the

indicator reads the %RH that corresponds to this signal output. For example, consider 0-5V signal scaled to display 0.0 to

100.0 %RH. The Upper Readout then shows approximately 0.0 %RH (corresponding to 0 V) upon sensor open / broken.

If Dry/Wet assembly is used for RH measurement and if either Wet-Bulb RTD is open / broken or there is an error condition

while computing %RH value, the Lower Readout flashes the Error Messages as listed in Table 2.2 below.

User Manual

HumiTherm-i Pro

4

Table 2.2

Note:

For both Dry and Wet Bulb, 3-wire RTD sensor input, if the compensating lead is not connected or gets open, the indicator does not indicate

PV error but the measured value is not compensated for the lead resistance.

Message Error Type Cause

Sensor Open

Under-range

Over-range Wet Bulb Temperature above Max. Range

Wet Bulb Temperature below Min. Range

Wet Bulb Sensor (RTD) Broken / Open

RH Error

Display Freezes

To 100.0%

This error is indicated in the following cases :

• Wet-Bulb Temperature exceeds Dry-Bulb Temperature.

• Computed % RH above 100.0%.

Display Freezes

To 0.0% Computed % RH is below 0.0%.

This error is indicated in the following cases :

• Dry Bulb Temperature above 102.0°C.

• Dry Bulb Temperature below -20.0°C.

• Wet Bulb depression beyond:

50.0°C for Dry Bulb Temperature above 0°C

5.6°C for Dry Bulb Temperature below 0°C

OPERATOR PAGE AND PARAMETERS

The indicator provides a separate page, called Operator Page, for the purpose of viewing and / or resetting the stored Min. /

Max. values for Dry- Bulb Temperature and %RH. The parameters on this page are available only if the Min. / Max. feature is

Enabled in Page -13 parameter list.

Accessing Operator Page

Step through the following sequence to open the operator page and to adjust the operator parameter values.

1. Press and release PAGE key. The Lower Readout shows (PAGE) and Upper Readout shows (0).

2. Press ENTER key. The Lower Readout shows prompt for the first available operator parameter and the Upper Readout

shows value for the parameter.

3. Use UP / DOWN keys to adjust the value and then press ENTER key to store the set value and scroll to next parameter.

The indicator automatically reverts to MAIN Display Mode upon scrolling through the last operator parameter. Alternatively,

use PAGE key to return to MAIN Display Mode.

The operator parameters are described in Table 2.3. Note that the parameters are presented only if ‘Min / Max Monitoring’

feature is enabled.

User Manual

HumiTherm-i Pro

5

Table 2.3

Parameter Description Settings

(Default Value)

View Only

MAXIMUM DRY BULB

TEMPERATURE VALUE

This parameter indicates the Maximum value attained by the Dry-

Bulb Temperature. This is a read only value.

View Only

MINIMUM DRY - BULB

TEMPERATURE VALUE

This parameter indicates the Minimum value attained by the Dry-

Bulb Temperature. This is a read only value.

View Only

MAXIMUM %RH VALUE

This parameter indicates the Maximum value attained by the

Relative Humidity. This is a read only value.

View Only

MINIMUM %RH VALUE

This parameter indicates the Minimum value attained by the

Relative Humidity. This is a read only value.

0 to 250

(Default : 0)

RESET PASS - CODE

For Resetting the Min. / Max. values, set the reset command to

‘Yes’ and then set this parameter value to the Pass - Code value

stored at Supervisory level on Page-13.

RESET COMMAND

This feature clears the current Min. / Max. values and starts afresh

monitoring the Process Values for new Min & Max. (Default : No)

No

Yes

User Manual

HumiTherm-i Pro

6

The various parameters are arranged in different groups, called PAGES, depending upon the functions they represent. Each

group is assigned a unique numeric value, called PAGE NUMBER, for its access.

The parameters are always presented in a fixed format: The Lower Readout displays the parameter prompt (Identification

Name) and the Upper Readout displays the set value. The parameters appear in the same sequence as listed in their

respective sections.

SET-UP MODE

The Set-up Mode allows the user to view and modify the parameter values. Follow the steps below for setting the parameter

values:

1. Press and release PAGE key. The Lower Readout shows PAGE and the Upper Readout shows page number 0. Refer

Figure 3.1.

2. Use UP / DOWN keys to set the desired PAGE NUMBER.

3. Press and release ENTER key. The Lower Readout shows the prompt for the first parameter listed in the set PAGE and

the Upper Readout shows its current value. If the entered PAGE NUMBER is invalid (contains no parameter list or any

associated function), the indicator reverts to the MAIN Display Mode.

4. Press and release the ENTER key until the prompt for the required parameter appears on the Lower Readout. (The last

parameter in the list rolls back to the first parameter).

5. Use UP / DOWN keys to adjust the parameter value. (The display flashes if UP key is pressed after reaching the maximum

value or DOWN key is pressed after reaching the minimum value).

6. Press and release the ENTER key. The new value gets stored in the indicator’s non-volatile memory and the next

parameter in the list is displayed.

SET-UP MODE : ACCESS AND OPERATION

The Figure 3.1 illustrates the example of altering the value for the parameter ‘Units’ on PAGE-13.

Notes

1. Each page contains a fixed list of parameters that are presented in a pre-determined sequence. Note however that availability of a few

parameters, called Conditional Parameters, depend upon the settings for some other parameters. For example, the parameter ‘Control

Hysteresis’ for Output-1 is available only if, the set value for the parameter ‘Control Action’ is ‘On-Off’.

2. To exit the set-up mode and return to the MAIN Display Mode, press and release PAGE key.

3. If no key is pressed for approximately 30 seconds, the set-up mode times out and reverts to the MAIN Display Mode.

Figure 3.1

Section 3

Press PAGE

key to enter

Set-up Mode

Use UP/DOWN

key to set the

Page Number

Press ENTER

key to open

the Page

Use UP/DOWN

keys to change

the value

Press ENTER

key to store the value &

move to next parameter

or

Main Display

Mode

Default Page Page Number First Parameter

on Page-13

New Parameter

value

Next Parameter

on Page-13

or

User Manual

HumiTherm-i Pro

7

UnLocking

Repeat the Locking procedure twice for unlocking.

MASTER LOCKING

The indicator facilitates locking all the PAGES (except Operator PAGE) by applying Master Lock Code. Under Locking, the

parameters are available for view only and cannot be adjusted. The Master Lock, however does not lock the operator

parameters. This feature allows protecting the rather less frequently used parameters against any inadvertent changes while

making the frequently used operator parameters still available for any editing.

For enabling / disabling the Lock, step through the following sequence:

Locking

1. Press and release PAGE key while the indicator is in the MAIN Display Mode. The Lower Readout shows PAGE and the

Upper Readout shows 0.

2. Use UP / DOWN keys to set the Page Number to 123 on the Upper Readout.

3. Press and release ENTER key. The indicator returns to the MAIN Display Mode with the Lock enabled.

The Figure 3.2 below illustrates the Locking procedure.

Figure 3.2

or

MAIN Display

Mode

Default Page Locking Code MAIN Display

Mode

Press PAGE

key to enter

Set-up Mode

Use UP/DOWN

key to set the

‘Locking Code’

Press ENTER key

to Lock & Return to

Main Mode

User Manual

HumiTherm-i Pro

8

Reverse

Direct

(Default : Direct)

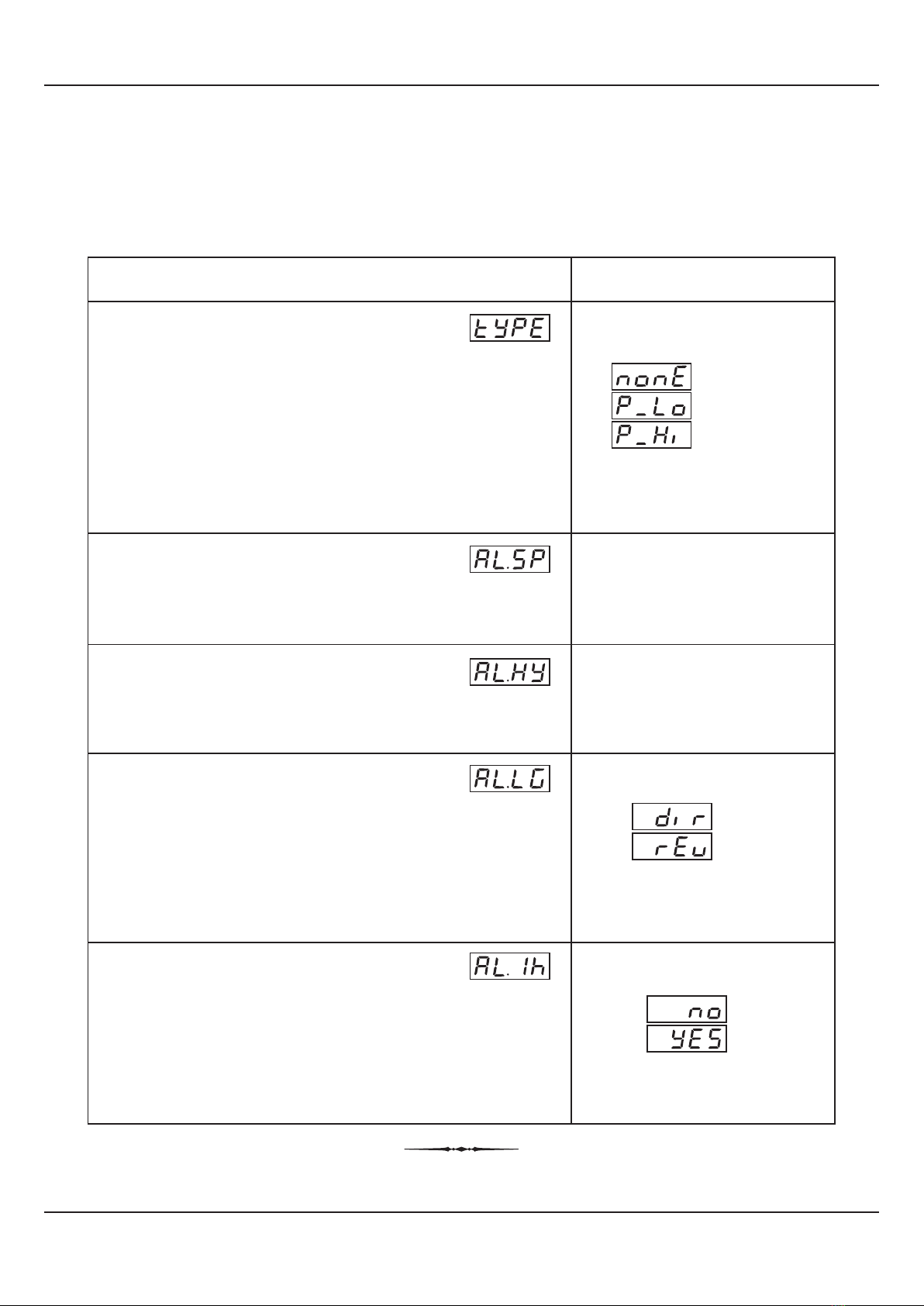

Table 4.1

PAGE-10 : TEMPERATURE - ALARM PARAMETERS

Parameter Description Settings

(Default Value)

-50.0 to 150.0°C or

-58.0 to 302.0°F

(Default :

For Process Low : -50.0

For Process High : 150.0)

(Default : 0.2)

0.1 to 25.0 °C or °F

TEMPERATURE ALARM TYPE

None

Alarm activation is disabled.

Process Low

The Alarm activates when the Temperature Value equals or falls

below the ‘Alarm Setpoint’ value.

Process High

The Alarm activates when the Temperature Value equals or

exceeds the ‘Alarm Setpoint’ value.

TEMPERATURE ALARM SETPOINT

This parameter sets the Process High or Process Low limit for

Alarm.

TEMPERATURE ALARM HYSTERESIS

This parameter sets a differential (dead) band between the ON

and OFF Alarm states. Keep it large enough to avoid frequent

switching of the Alarm relay.

(Default : Yes)

No

Yes

Section 4

TEMPERATURE ALARM INHIBIT

No

The Alarm is not suppressed during the start-up Alarm conditions.

Yes

The Alarm activation is suppressed until the Temperature Value is

within Alarm limits from the time the indicator is switched ON. This

allows suppressing the Alarm during the start-up Alarm

conditions.

(Default : None)

Process High

None

Process Low

TEMPERATURE ALARM LOGIC

Direct

Alarm Relay is energized when the alarm is active; remains de-

energized otherwise.

Reverse

Alarm Relay remains energized as long as the alarm is not active.

The relay de-energized upon alarm activation.

User Manual

HumiTherm-i Pro

9

%RH ALARM INHIBIT

No

The Alarm is not suppressed during the start-up Alarm conditions.

Yes

The Alarm activation is suppressed until the %RH Value is within

Alarm limits from the time the indicator is switched ON. This allows

suppressing the Alarm during the start-up Alarm conditions.

Reverse

Direct

(Default : Direct)

Parameter Description Settings

(Default Value)

0.0 to 100.0%

(Default :

For Process Low : 0.0

For Process High : 100.0)

(Default : 0.2)

0.1 to 25.0%

%RH ALARM TYPE

None

Disable the Alarm.

Process Low

The Alarm activates when the %RH Value equals or falls below the

‘Alarm Setpoint’ value.

Process High

The Alarm activates when the %RH Value equals or exceeds the

‘Alarm Setpoint’ value.

%RH ALARM SETPOINT

This parameter sets the Process High or Process Low limit for

Alarm.

%RH ALARM HYSTERESIS

This parameter sets a differential (dead) band between the ON

and OFF Alarm states. Keep it large enough to avoid frequent

switching of the Alarm relay.

(Default : Yes)

No

Yes

Table 5.1

PAGE-11 : RELATIVE HUMIDITY - ALARM PARAMETERS

Section 5

(Default : None)

Process High

None

Process Low

%RH ALARM LOGIC

Direct

Alarm Relay is energized when the alarm is active; remains de-

energized otherwise.

Reverse

Alarm Relay remains energized as long as the alarm is not active.

The relay de-energized upon alarm activation.

User Manual

HumiTherm-i Pro

10

PAGE-12 : INPUT CHANNEL CONFIGURATION PARAMETERS

Table 6.1

Section 6

SIGNAL HIGH FOR TEMP SENSOR

SIGNAL LOW FOR TEMP SENSOR

Parameter Description Settings

(Default Value)

INPUT TYPE FOR TEMP SENSOR

Select Input type in accordance with the type of Temperature

sensor / transmitter connected.

(Available if temperature input type is mV/V/mA)

The transmitter output signal value corresponding to Range Low

temperature value. Refer Appendix-A : DC Linear Signal Interface

for details.

Input Type Settings Default

0 to 20 mA 0.00 to Signal High 0.00

4 to 20 mA

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

4.00 to Signal High

0.000 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

4.00

0.000

0.000

0.00

1.000

(Default : RTD)

Refer Table 6.1

TEMPERATURE RANGE LOW

(Available if temperature input type is mV/V/mA)

The temperature value corresponding to the Signal Low value

from the temperature transmitter. Refer Appendix-A : DC Linear

Signal Interface for details.

(Available if temperature input type is mV/V/mA)

The transmitter output signal value corresponding to Range High

temperature value. Refer Appendix-A : DC Linear Signal Interface

for details.

Input Type Settings Default

0 to 20 mA

4 to 20 mA

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

Signal Low to 20.00 20.00

20.00

1.250

5.000

10.00

5.000

Signal Low to 20.00

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

(Default : 0.0)

-25.0 to 25.0

(Available if temperature input type is mV/V/mA)

The temperature value corresponding to the Signal High value

from the temperature transmitter. Refer Appendix-A : DC Linear

Signal Interface for details.

TEMPERATURE RANGE HIGH

This value is algebraically added to the measured Temperature

Value to derive the final Value that is displayed and compared for

alarm / control. Use this value to nullify any known constant error.

ZERO OFFSET FOR TEMP VALUE

(Default : 100.0)

-199.9 to 999.9

(Default : 0.0)

-199.9 to 999.9

User Manual

HumiTherm-i Pro

11

Parameter Description Settings

(Default Value)

Select Input type in accordance with the type of Humidity sensor /

transmitter connected.

(Available if temperature input type is mV/V/mA)

The transmitter output signal value corresponding to Range Low

%RH value. Refer Appendix-A : DC Linear Signal Interface for

details.

(Default : 0 to 5 V)

Refer Table 6.1

(Available if temperature input type is mV/V/mA)

The transmitter output signal value corresponding to Range High

%RH value. Refer Appendix-A : DC Linear Signal Interface for

details.

SIGNAL HIGH FOR HUMIDITY SENSOR

SIGNAL LOW FOR HUMIDITY SENSOR

INPUT TYPE FOR HUMIDITY SENSOR

(Available if humidity input type is mV/V/mA)

The %RH value corresponding to the Signal Low value from the

humidity transmitter. Refer Appendix-A : DC Linear Signal

Interface for details.

%RH RANGE LOW

(Default : 0.0)

-25.0 to 25.0

(Available if humidity input type is mV/V/mA)

The %RH value corresponding to the Signal High value from the

humidity transmitter. Refer Appendix-A : DC Linear Signal

Interface for details.

%RH RANGE HIGH

(Default : 0.0)

-99.0 to 99.0

(Available for Dry/Wet RTD Assembly only)

This value is algebraically added to the Temperature Value

measured by Wet bulb RTD sensor. Use this value to nullify any

known constant error.

WET-BULB TEMPERATURE ZERO OFFSET

This value is algebraically added to the measured %RH Value to

derive the final Value that is displayed and compared for alarm /

control. Use this value to nullify any known constant error.

%RH ZERO OFFSET

Input Type Settings Default

0 to 20 mA 0.00 to Signal High 0.00

4 to 20 mA

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

4.00 to Signal High

0.000 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

4.00

0.000

0.000

0.00

1.000

Input Type Settings Default

0 to 20 mA

4 to 20 mA

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

Signal Low to 20.00 20.00

20.00

1.250

5.000

10.00

5.000

Signal Low to 20.00

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

(Default : 100.0)

-199.9 to 999.9

(Default : 0.0)

-199.9 to 999.9

User Manual

HumiTherm-i Pro

12

Table 6.2

Resolution

Range (Min. to Max.)

-199.9 to 999.9 units

-199.9 to +600.0 °C / -199.9 to 999.9 °F

0.1 °C / °F

0.1

units

Option What it means

0 to 20mA DC current

4 to 20mA DC current

0 to 1.25V DC voltage

0 to 5.0V DC voltage

0 to 10.0V DC voltage

1 to 5.0V DC voltage

3-wire, RTD Pt100

Reserved

(Don't Select)

User Manual

HumiTherm-i Pro

13

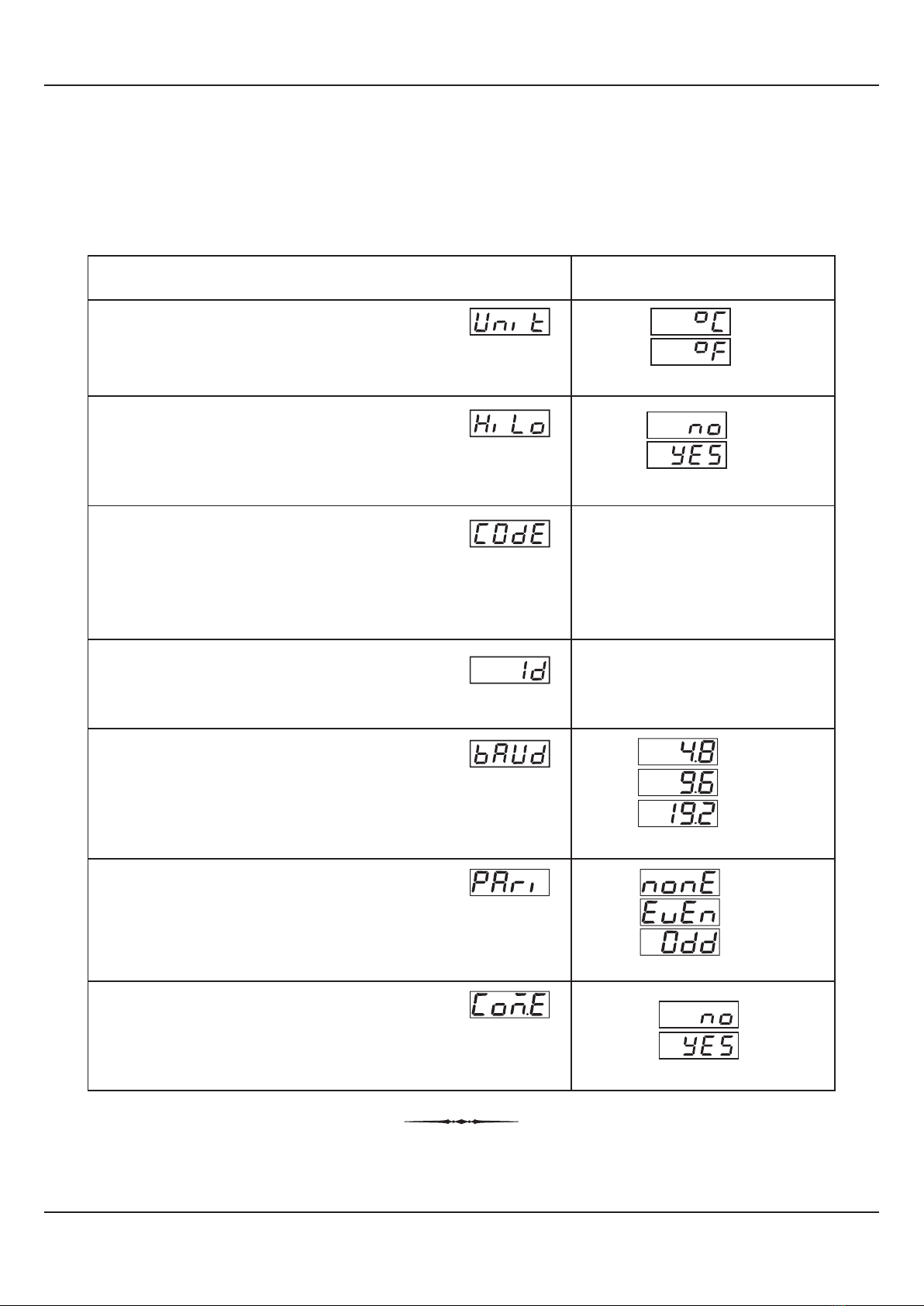

PAGE-13 : SUPERVISORY PARAMETERS

Table 7.1

PASSWORD FOR RESETTING

PV HIGH - LOW

This parameter allows protection against inadvertent resetting of

Min/Max values. That is, the reset command is executed only if the

operator sets the password that matches with this parameter

value.

Set this parameter value to ‘Yes’ for enabling the Dry-Bulb

Temperature and % RH monitoring for Min/Max values.

DRY-BULB TEMPERATURE AND

% RH MIN / MAX MONITORING

UNIT SELECTION FOR TEMPERATURE

Select Temperature Units in °C or °F.

Parameter Description Settings

(Default Value)

°C

°F

(Default : )°C

(Default : 0)

0 to 250

(Default : No)

No

Yes

Section 7

Yes

No

(Default : Yes)

BAUD RATE

Communication speed in ‘Bits per Second’. Set the value to match

with the host baud rate.

(Default : 1)

1 to 127

Communication ID used by host for serial communication.

SLAVE ID

Parity setting for serial communication protocol

PARITY

Setting to ‘No’ disallows the host to set or modify any parameter

values. The parameter values however, are still available for

reading by the host.

COMMUNICATION WRITE ENABLE

(Default : 9600)

4800

9600

19200

(Default : Even)

None

Even

Odd

User Manual

HumiTherm-i Pro

14

PAGE-14 : DE-HUMIDIFIER CONTROL PARAMETERS

Table 8.1

Parameter Description Settings

(Default Value)

Section 8

(Default : Disable)

Disable

Enable

(Default : 0)

0.0 to 100.0

(Default : 2.0)

0.1 to 99.9

DE-HUMIDIFIER CONTROL

Set this parameter to Enable if Humidifier Control is desired. If

enabled, the measured %RH value is compared with the set value

and a relay output is switched.

DE-HUMIDIFIER SETPOINT

If the measured %RH value becomes equal or exceed this

setpoint value, the de-humidifier control output relay is switched-

On.

De-humidifier ON condition :

%RH >= De-humidifier Setpoint

DE-HUMIDIFIER HYSTERESIS

If the measured %RH value becomes equal or falls below the

setpoint minus hysteresis, the de-humidifier control output relay is

switched- Off.

De-humidifier OFF condition :

%RH <= (De-humidifier Setpoint - De-humidifier Hysteresis)

User Manual

HumiTherm-i Pro

15

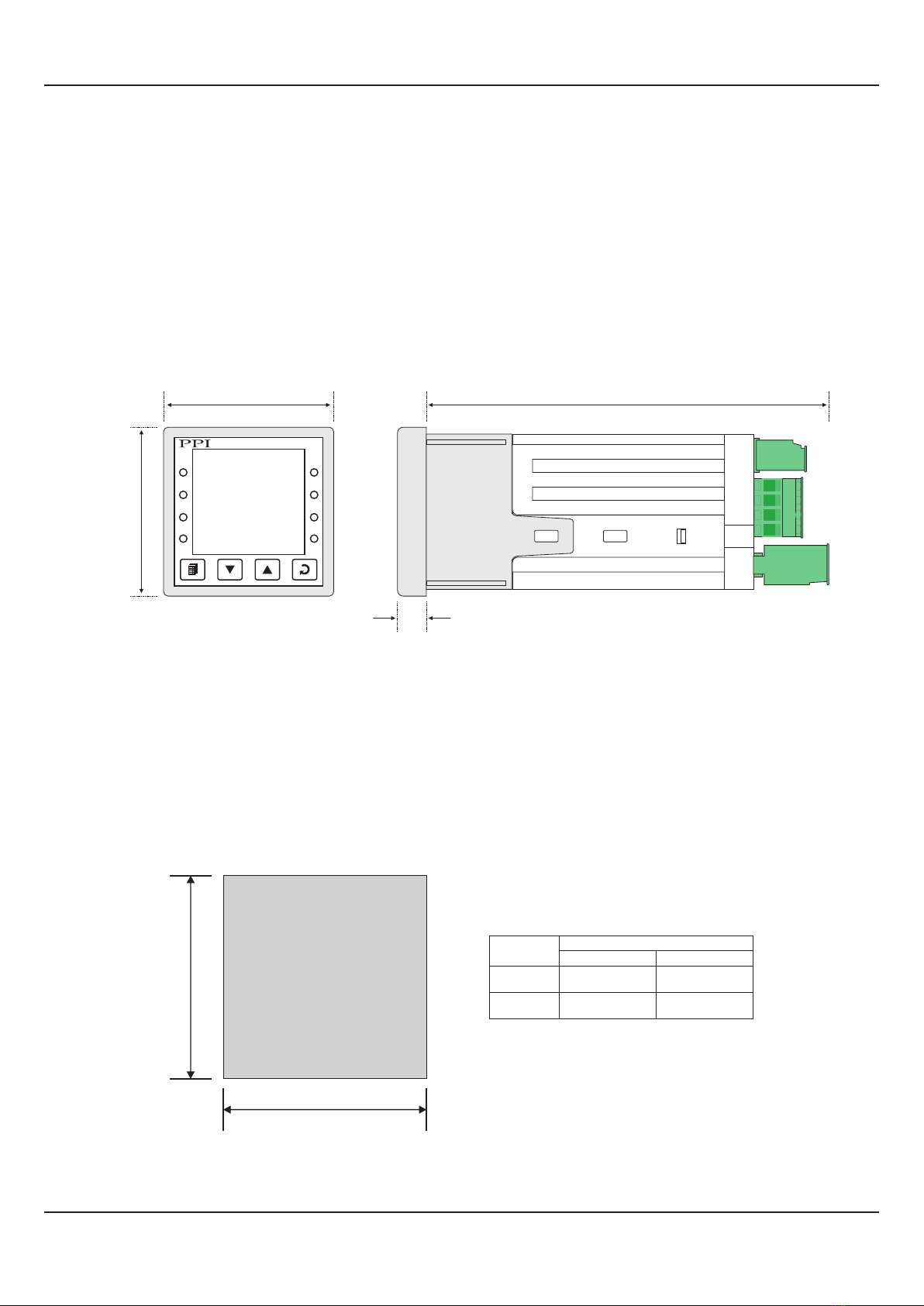

MECHANICAL INSTALLATION

Section 9

OUTER DIMENSIONS AND PANEL CUTOUT

The Figure 9.1 shows the controller outer dimensions.

Figure 9.1

Figure 9.2

94mm

(3.70in)

7mm (0.276in)

Side View

48mm

(1.89in)

48mm

(1.89in)

Front View

°CA

RHA

L1

DHO

L3

HumiTherm-i Pro

L2

COM L4

PANEL CUTOUT

The Figure 9.2 shows the panel cutout requirements for a single controller.

V

H

Parameter Dimensions

mm inches

H

V

45 (-0, +0.5)

45 (-0, +0.5)

1.77 (-0, +0.02)

1.77 (-0, +0.02)

User Manual

HumiTherm-i Pro

16

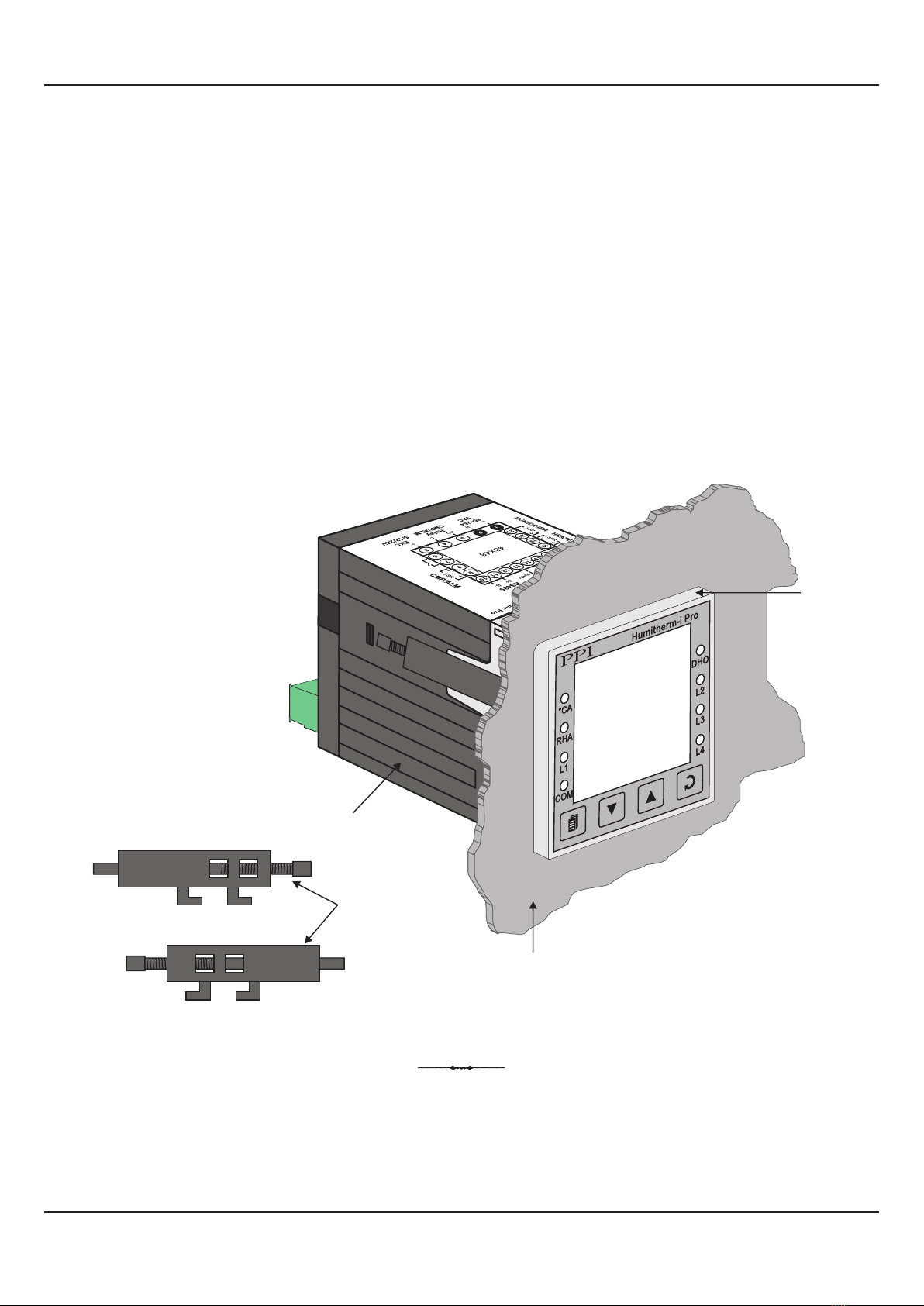

PANEL MOUNTING

Follow the steps below for mounting the controller on panel:

1. Prepare a square cutout to the size shown in Figure 9.2.

2. Remove the Panel Mounting Clamp from the controller Enclosure and insert the rear of the controller housing through the

panel cutout from the front of the mounting panel.

3. Hold the controller gently against the mounting panel such that it positions squarely against the panel wall, see Figure 9.3.

Apply pressure only on the bezel and not on the front label.

4. Insert the mounting clamps on either side of the controller in the slots provided for the purpose. Rotate the screws clock-

wise so that they move forward until they push firmly against the rear face of the mounting panel for secured mounting.

Figure 9.3

Clamps

Bezel

Controller

Mounting Panel with

Square Cutout

User Manual

HumiTherm-i Pro

17

ELECTRICAL CONNECTIONS

WARNING

MISHANDLING / NEGLIGENCE CAN

RESULT IN PERSONAL DEATH OR

SERIOUS INJURY.

Figure 10.1

Section 10

1 2 345

21

20

19

18

10

1112

13

14

1516

17

6

7

8

9

+

-

L N

NO C

EXC

5/12/24V

85~264

VAC

Relay

DE-HUM

B+ B-

RS485

TEMP INPUT

+

RTD

RH INPUT

mA/V

-

+

RTD

TEMP. ALARM

RH ALARM

NOCNC

RLY

+

-

SSR

NOCNC

RLY

SSR

mA/V

-

+

1. The user must rigidly observe the Local Electrical Regulations.

2. Do not make any connections to the unused terminals for making a tie-point for other wires (or for any other reasons) as

they may have some internal connections. Failing to observe this may result in permanent damage to the controller.

3. Run power supply cables separated from the low-level signal cables (like RTD, DC Linear (Voltage) signals, etc.). If the

cables are run through conduits, use separate conduits for power supply cable and low-level signal cables.

4. Use appropriate fuses and switches, wherever necessary, for driving the high voltage loads to protect the controller from

any possible damage due to high voltage surges of extended duration or short-circuits on loads.

5. Take care not to over-tighten the terminal screws while making connections.

6. Make sure that the controller supply is switched-off while making/removing any connections or removing the controller

from its enclosure.

CONNECTION DIAGRAM

The Electrical Connection Diagram is shown on the top side of the enclosure. The diagram shows the terminals viewed from

the REAR SIDE with the controller label upright. The connecters provided for wiring are pluggable male-female type. The

female parts are soldered on the controller PCBs while the male parts are with screws and removable. The rear panel

electrical wiring connection diagram is shown in Figure10.1.

User Manual

HumiTherm-i Pro

18

DESCRIPTIONS

TEMP INPUT : RTD Pt100, 3-Wire / mA / V (Terminals 17, 16, 15)

RH INPUT : RTD Pt100, 3-Wire / mA / V (Terminals 14, 13, 12)

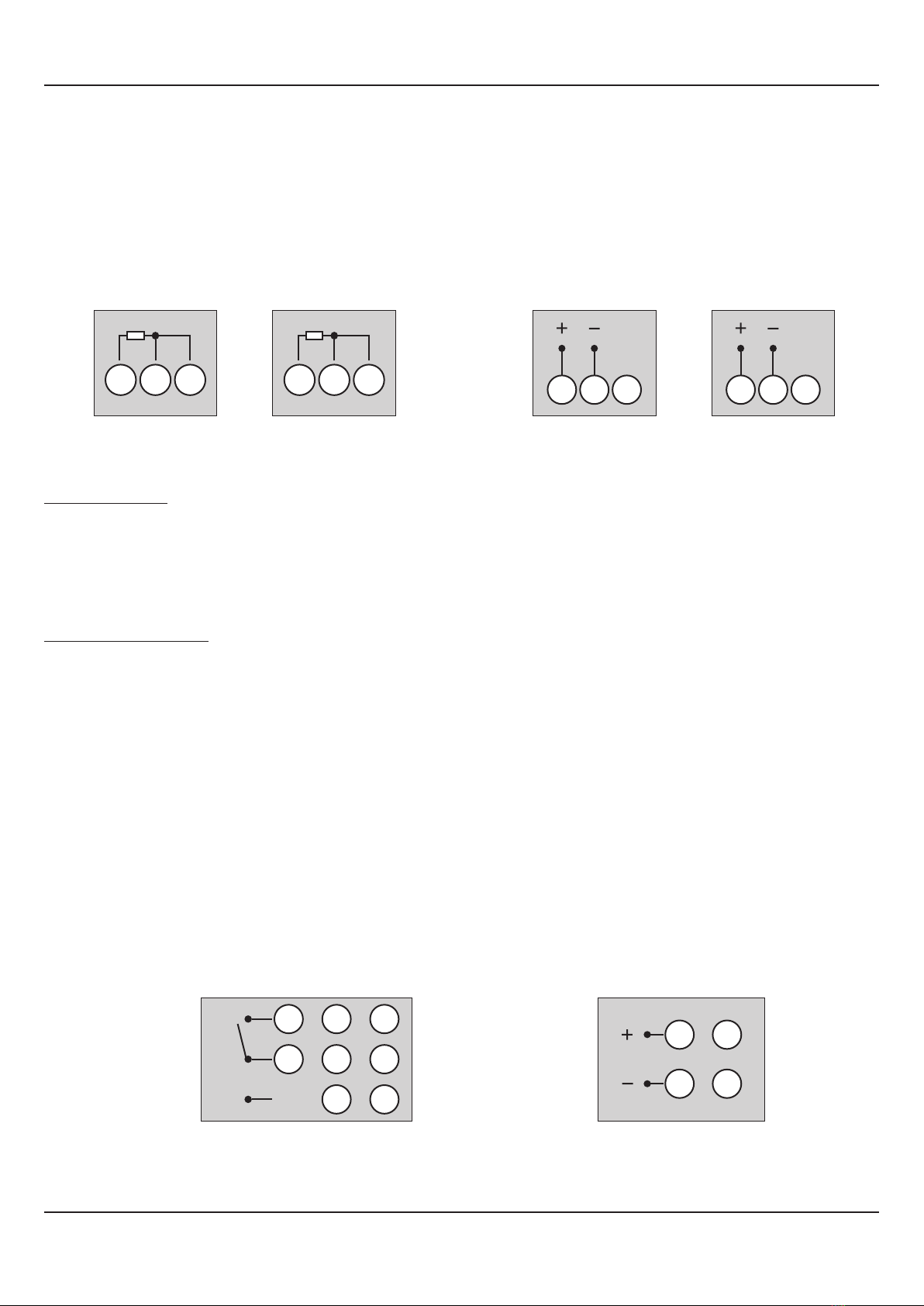

RTD Pt100, 3-wire

Connect single leaded end of RTD bulb to terminal 17 (14) and the double leaded ends to terminal 16 (13) and 15 (12),

interchangeable, as shown in Figure 10.2 (a). Use copper conductor leads of very low resistance ensuring that all 3 leads are

of the same gauge and length. Avoid joints in the cable.

DC Linear Signal (mA/V)

Use a shielded twisted pair with the shield grounded at the signal source for connecting Voltage source. Connect common (-)

to terminal 16 (13) and the signal (+) to terminal 17 (14), as shown in Figure 10.2 (b).The DC Current source (mA) is also

connected in the similar way.

TEMP. ALARM : Relay (Terminals 18, 19, 20)

TEMP. ALARM : SSR (Terminals 18, 19)

RH ALARM : Relay (Terminals 7, 8, 9)

RH ALARM : SSR (Terminals 8, 9)

DE-HUM CONTROL OUTPUT : Relay (Terminals 3, 4)

Figure 10.2 (a) : RTD Input

1516

17

Temperature Input

1213

14

Humidity Input

Figure 10.2 (b) : mA / V Input

1516

17

Temperature Input Humidity Input

1213

14

Figure 10.3

NO

C

NC

9

8

7

3

4

18

19

20

Temp. Alarm / RH Alarm / De-hum Control

Relay

9

8

18

19

Temp. Alarm / RH Alarm

SSR

Table of contents

Other PPI Measuring Instrument manuals