18

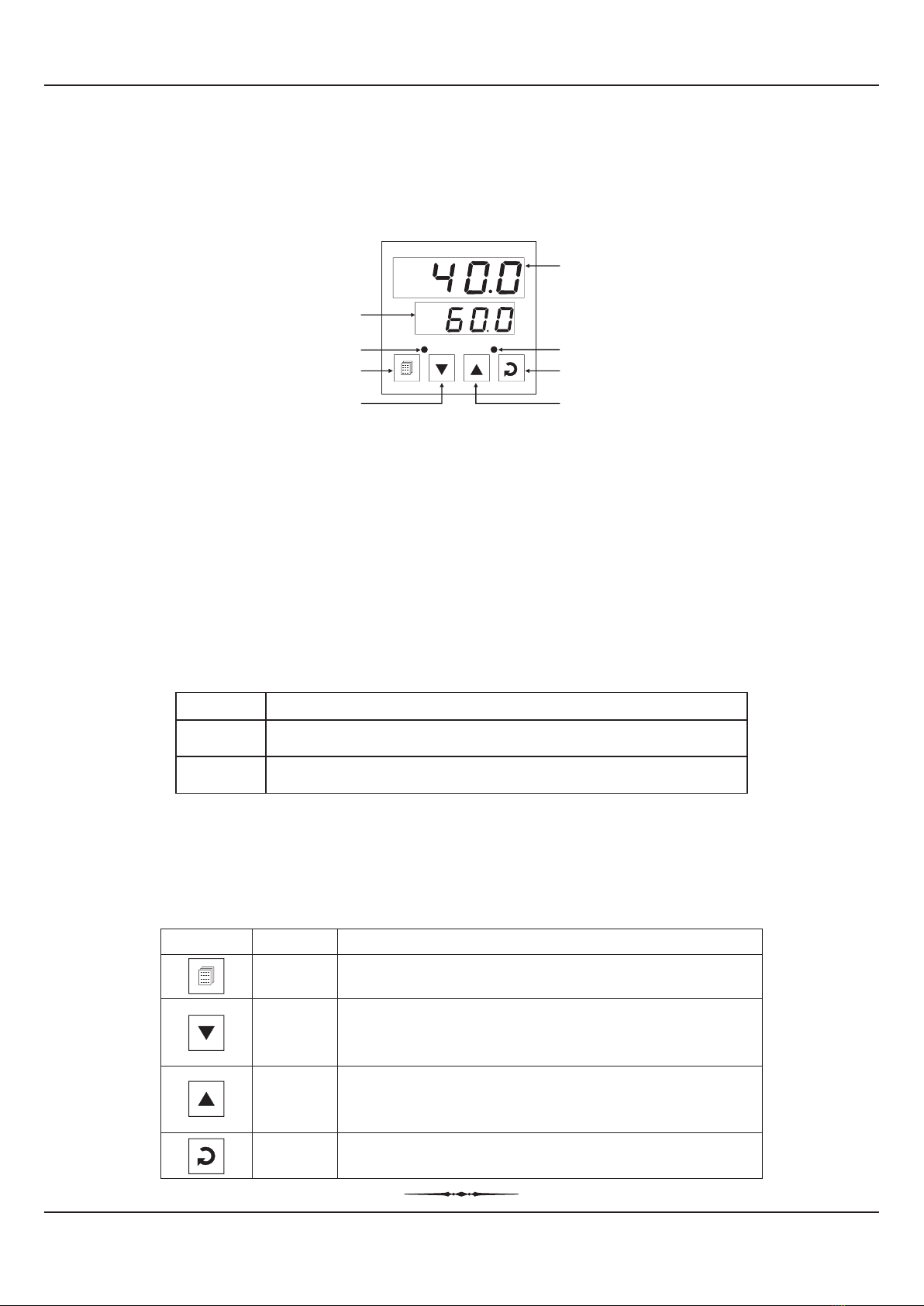

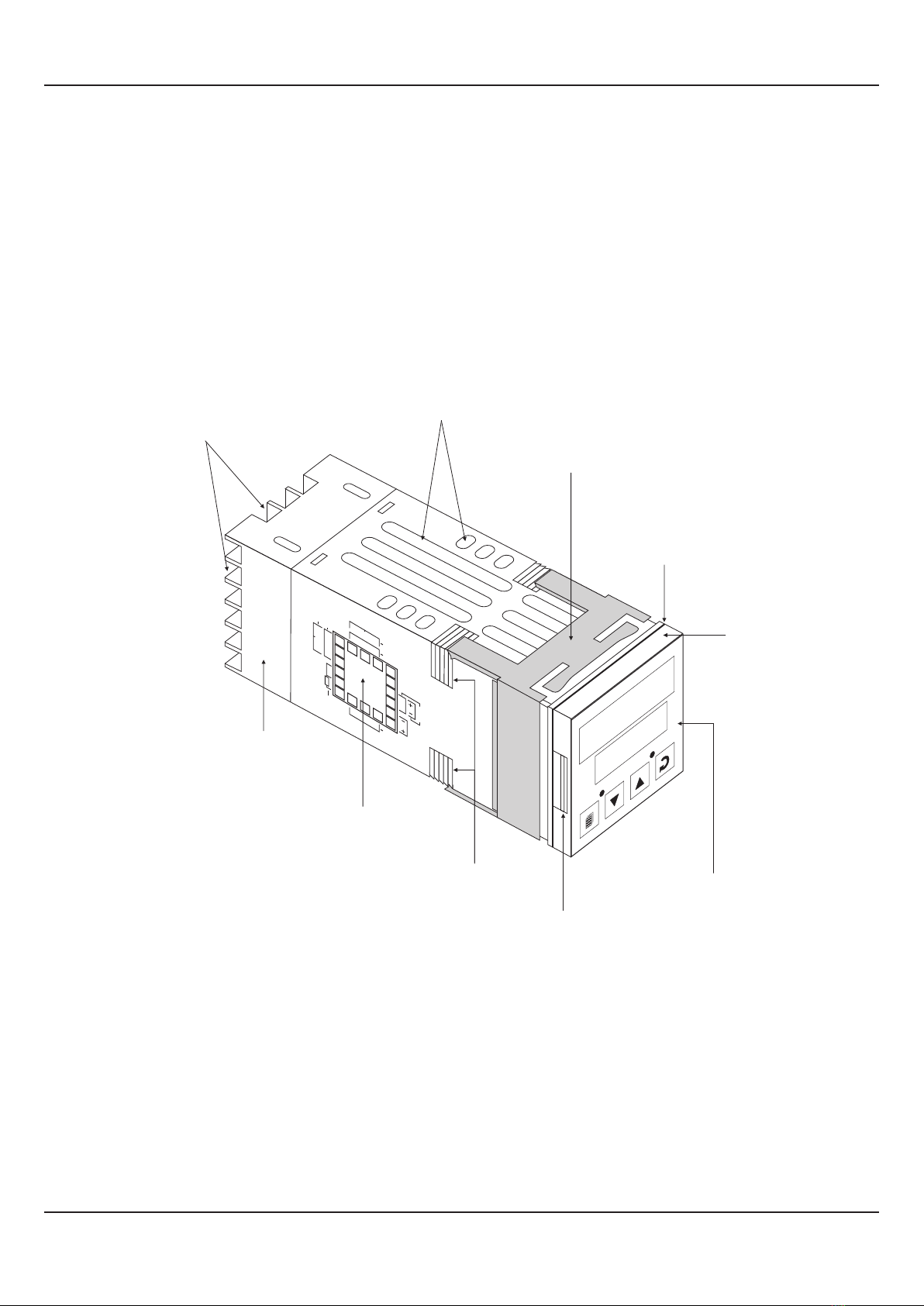

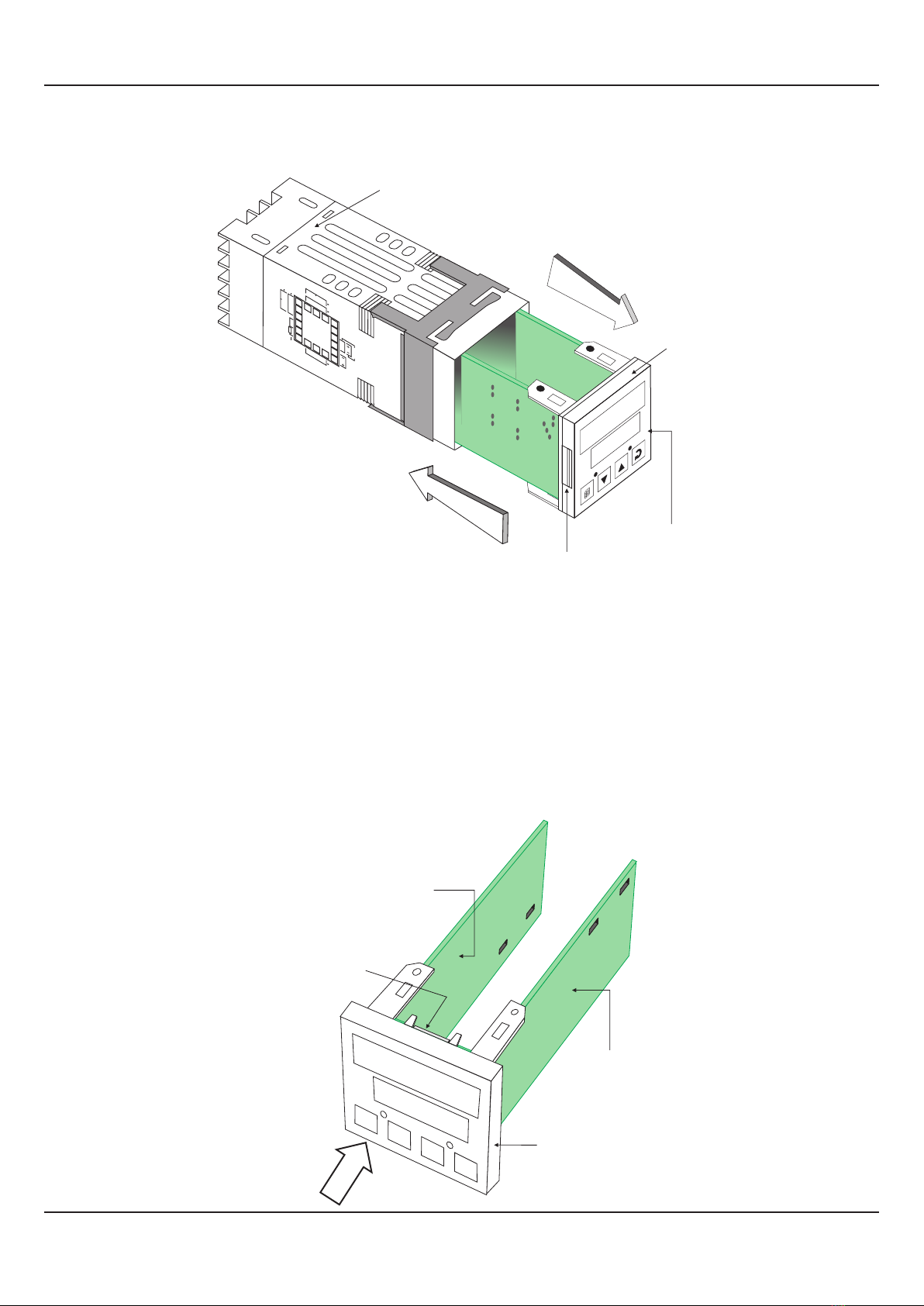

DESCRIPTIONS

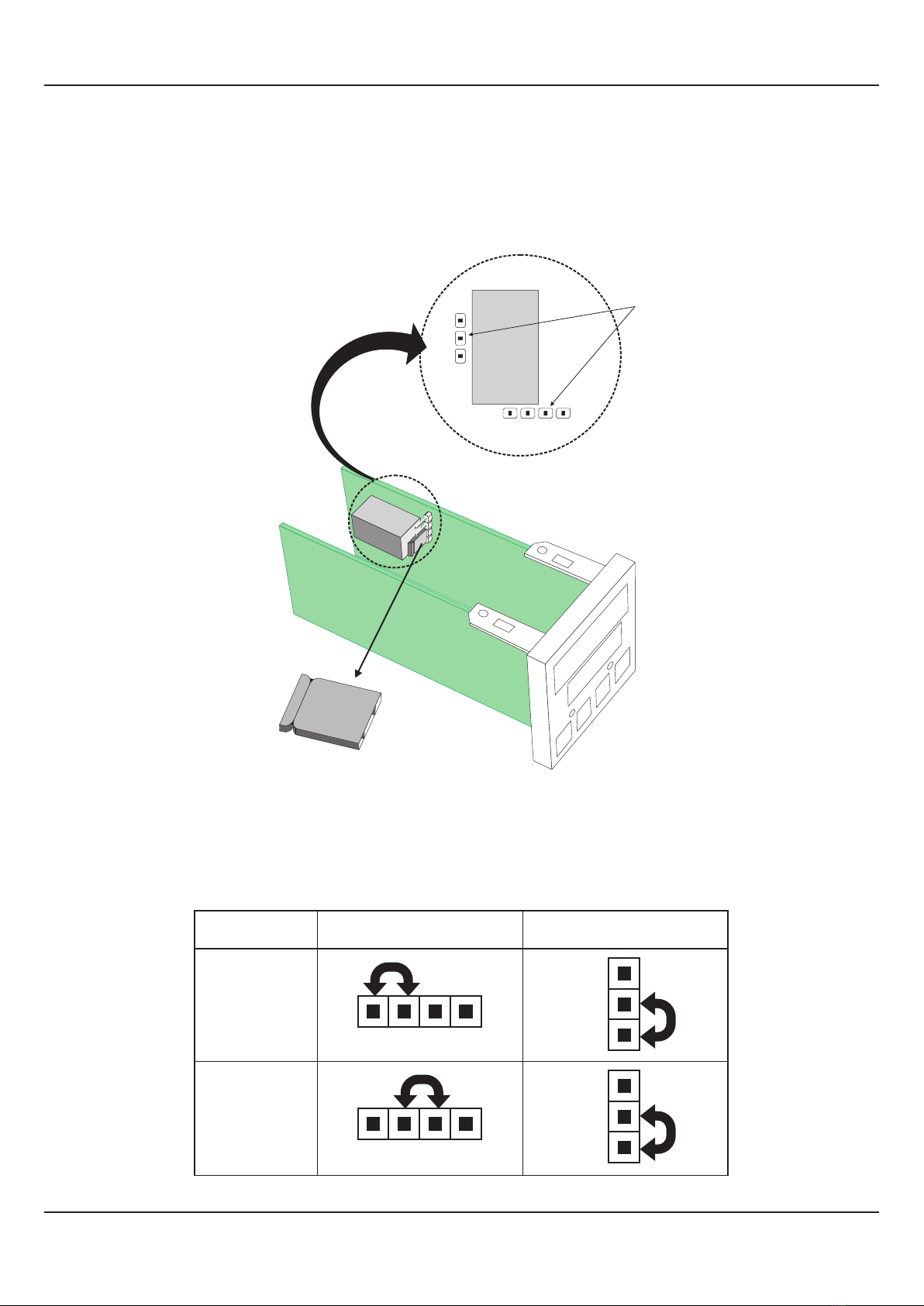

INPUT-1 : RTD Pt100, 3-Wire (Terminals 1, 2 and 3)

The indicator accepts 3-wire RTD Pt100 as input for measuring Dry Bulb Temperature Value.

Connect single leaded end of RTD bulb to terminal 1 and the double leaded ends to terminal 2 and 3

(interchangeable) as shown in Figure 10.2 (a). Use copper conductor leads of very low resistance

for RTD connections. Ensure that all 3 leads are of the same gauge and length. Use single run

cables avoiding any intermediate joints.

Figure 10.2 (a)

3

2

1

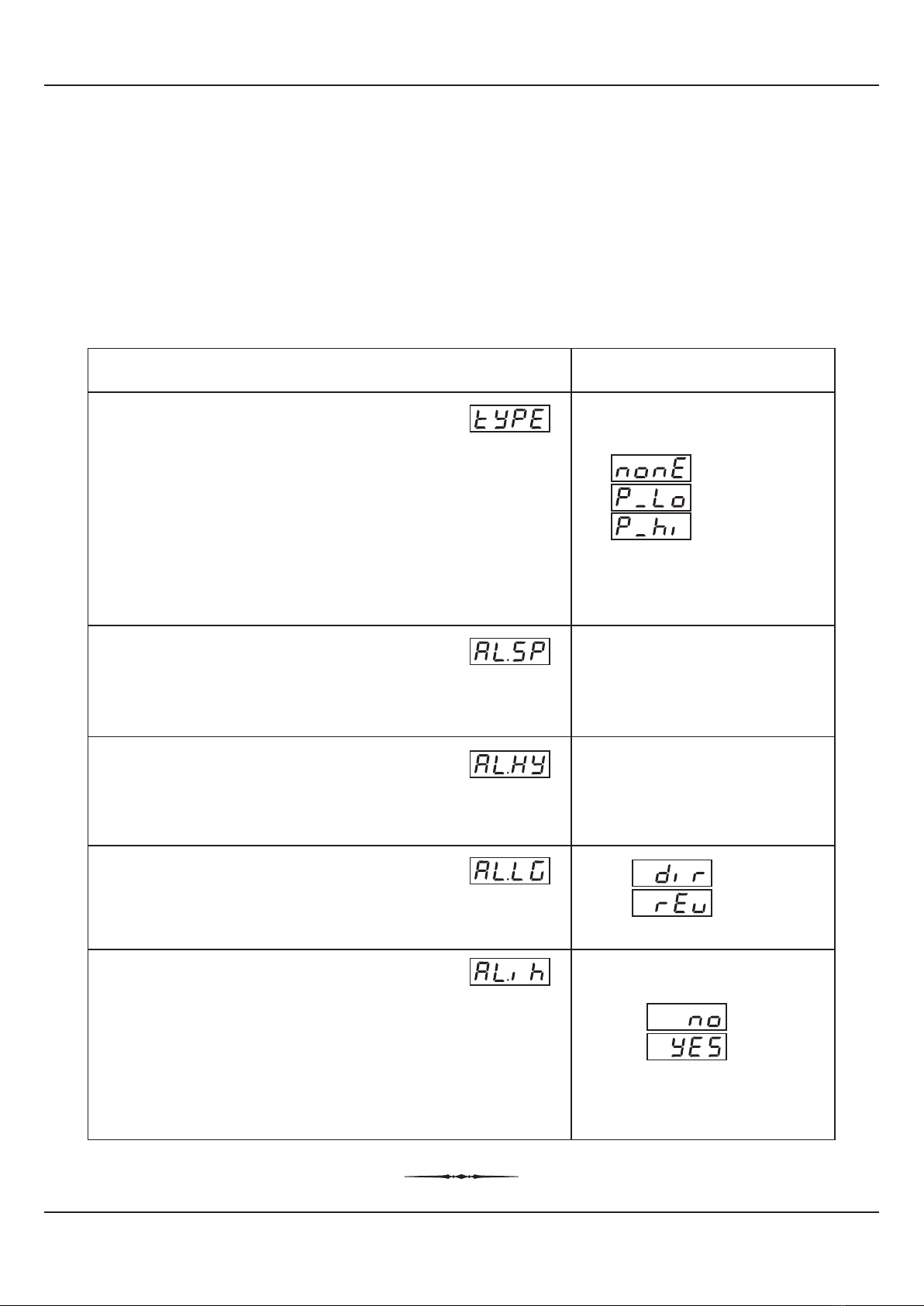

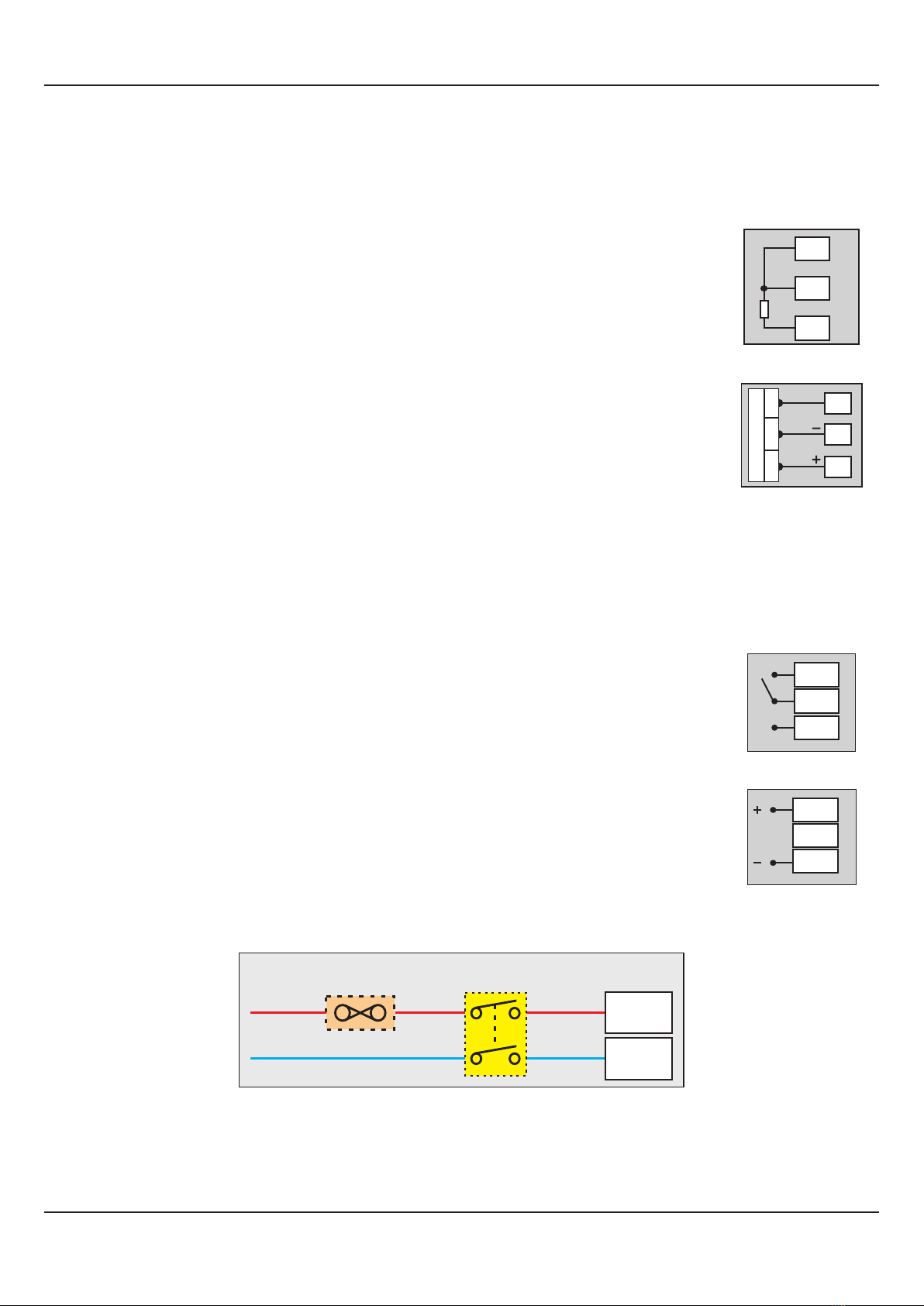

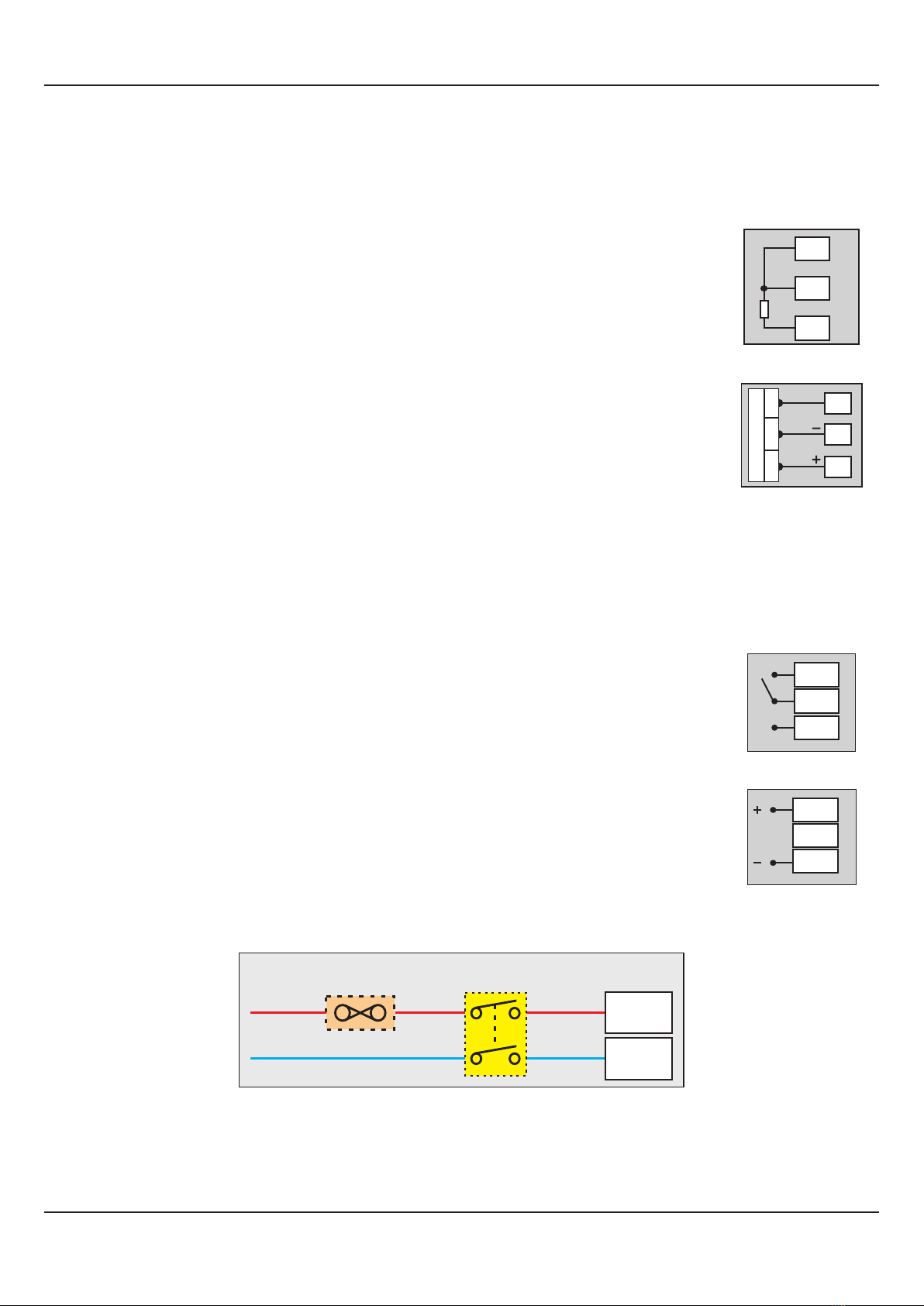

OUTPUT-1 (ALARM-1) & OUTPUT-2 (ALARM-2)

The Output-1 and Output-2 (if fitted) can be configured as either Relay or SSR Drive Output. The configuration is through

hardware jumper settings as described in Section 8: Hardware Assembly & Configurations. The terminals for Relay or SSR

Drive are as shown in Figure 10.3 (a) & 10.3 (b), respectively. The numbers in brackets indicates the terminal numbers for

Output-2 and those outside brackets indicates the terminal numbers for Output-1.

Drive for SSR

DC Voltage level is generated for switching the external SSR (Solid State Relay) which in turn

switches the load. Connect (+) and (-) terminals of SSR to indicator terminals 6 and 4, respectively.

Use Zero-Crossover, 3 to 30 VDC operated SSR.

Relay

Potential-free Relay changeover contacts N/O (Normally Open) and C (Common) rated 2A/240

VAC (resistive load) are provided as Relay output. Use external auxiliary device like contactor with

appropriate contact rating for driving the actual load.

6 (9)

5 (8)

4 (7)

Figure 10.3 (b)

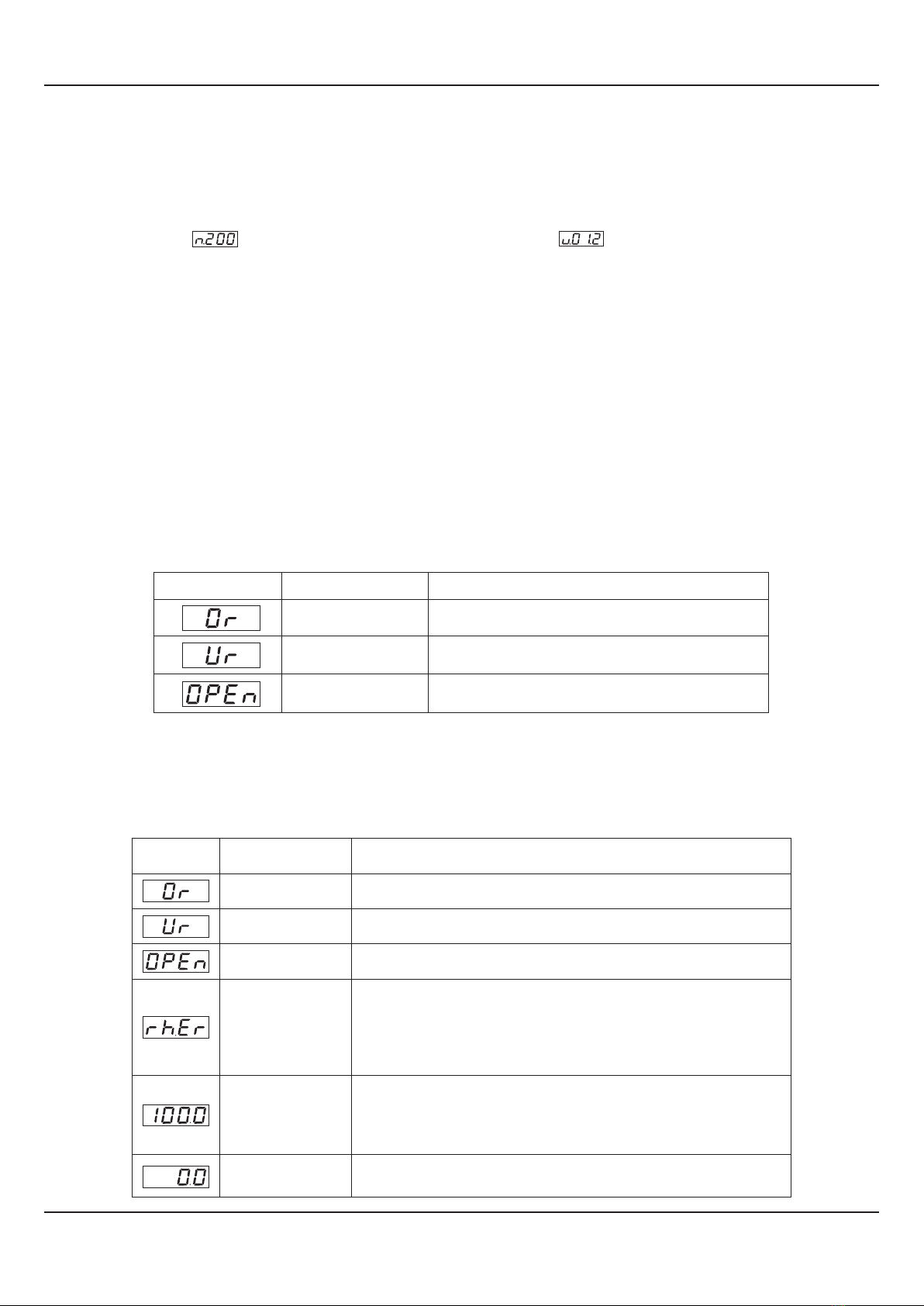

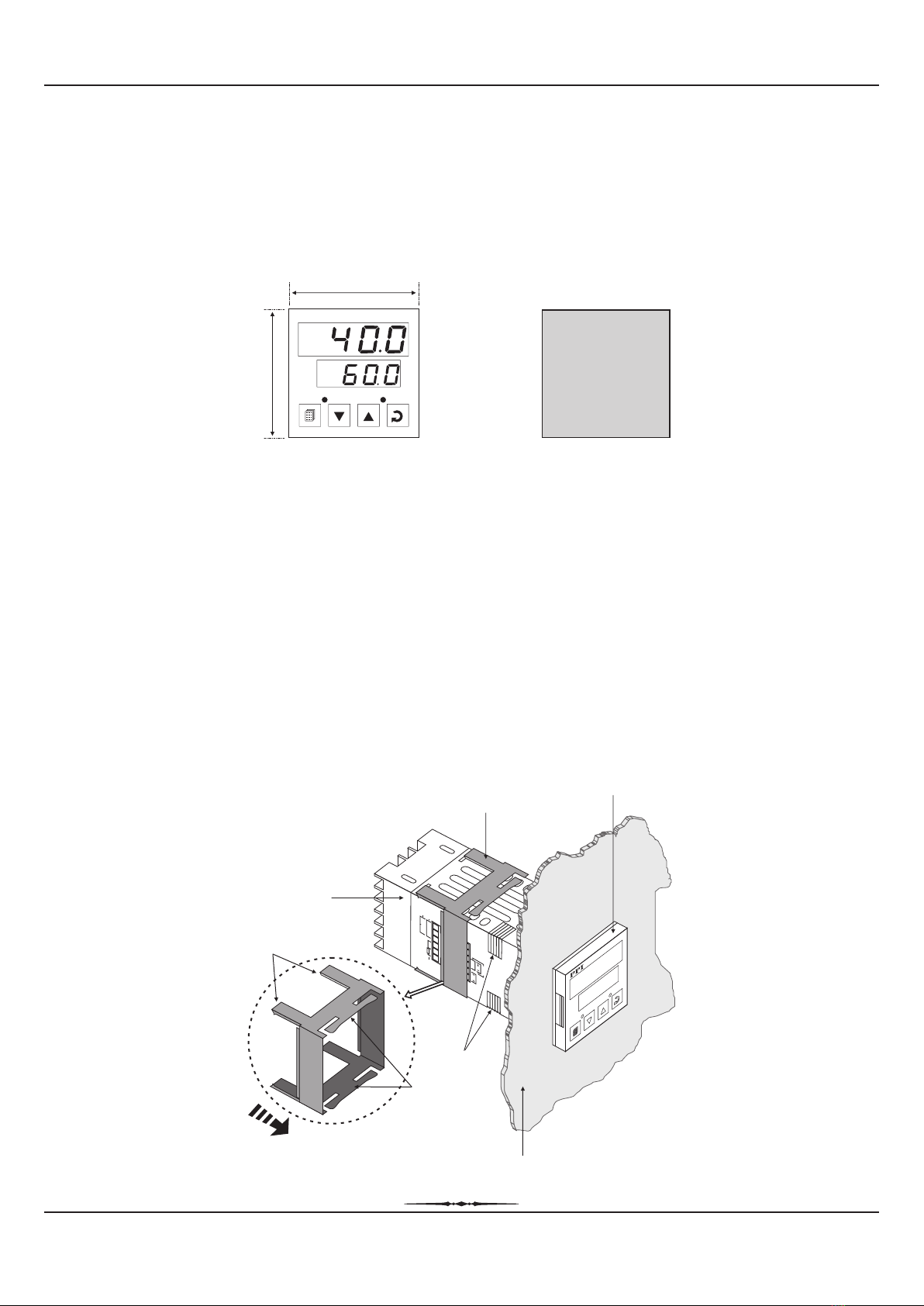

INPUT-2 : DC Linear Voltage (Terminals 16,17 & 18)

Connect Signal (OUT), Common (GND) and Supply (V+) cables from RH Sensor to terminals 16,

17 & 18, respectively as shown in Figure 10.2 (b). Terminal 18 provides +5Vdc @ 20mA excitation

supply for the Sensor. Use copper conductor leads of very low resistance for connections. Use

single run cables avoiding any intermediate joints.

Figure 10.2 (b)

18

17

16

Ex

RH Sensor

GNDOUT V+

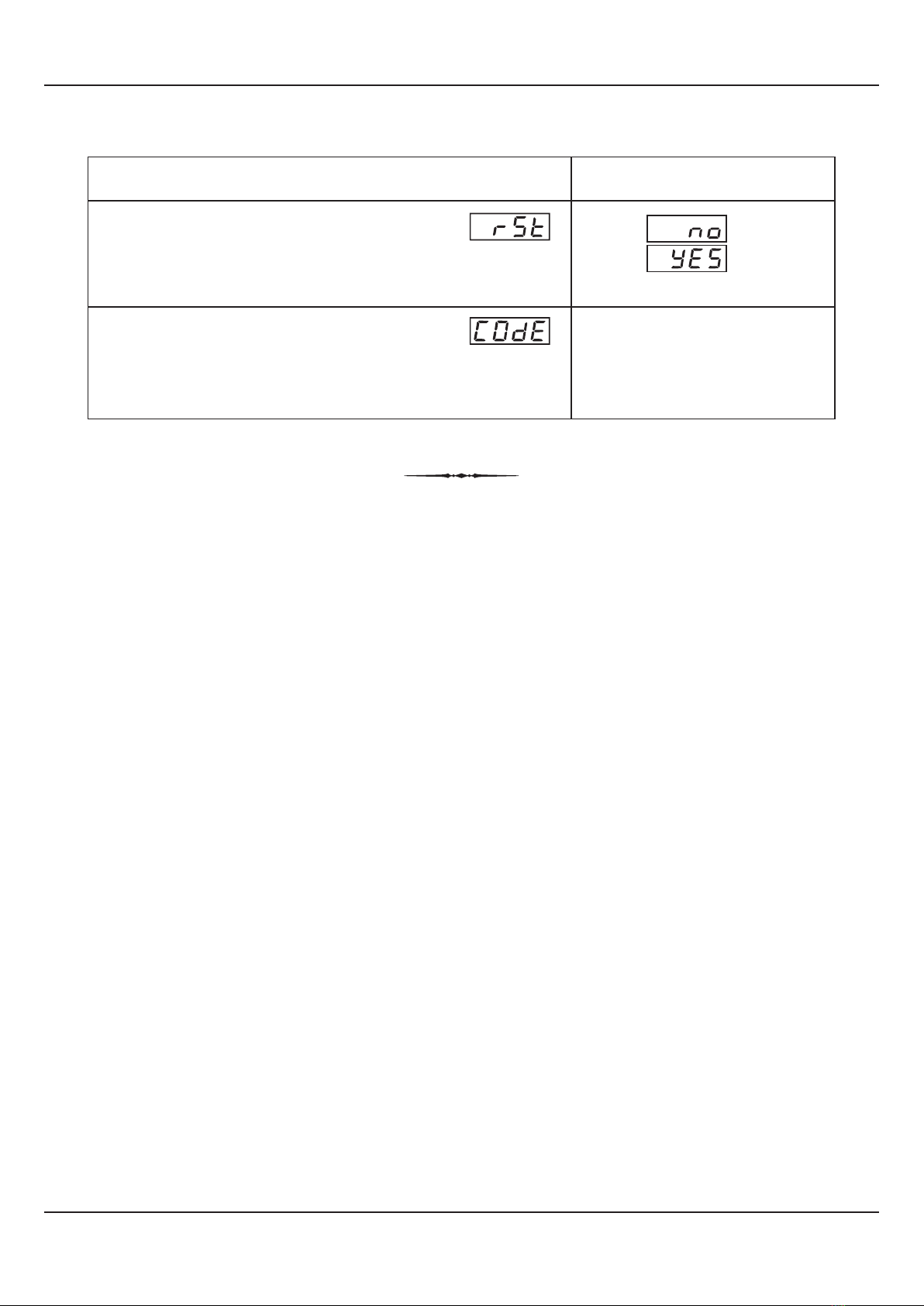

6 (9)

5 (8)

4 (7)

N/O

C

Figure 10.3 (a)

N/C

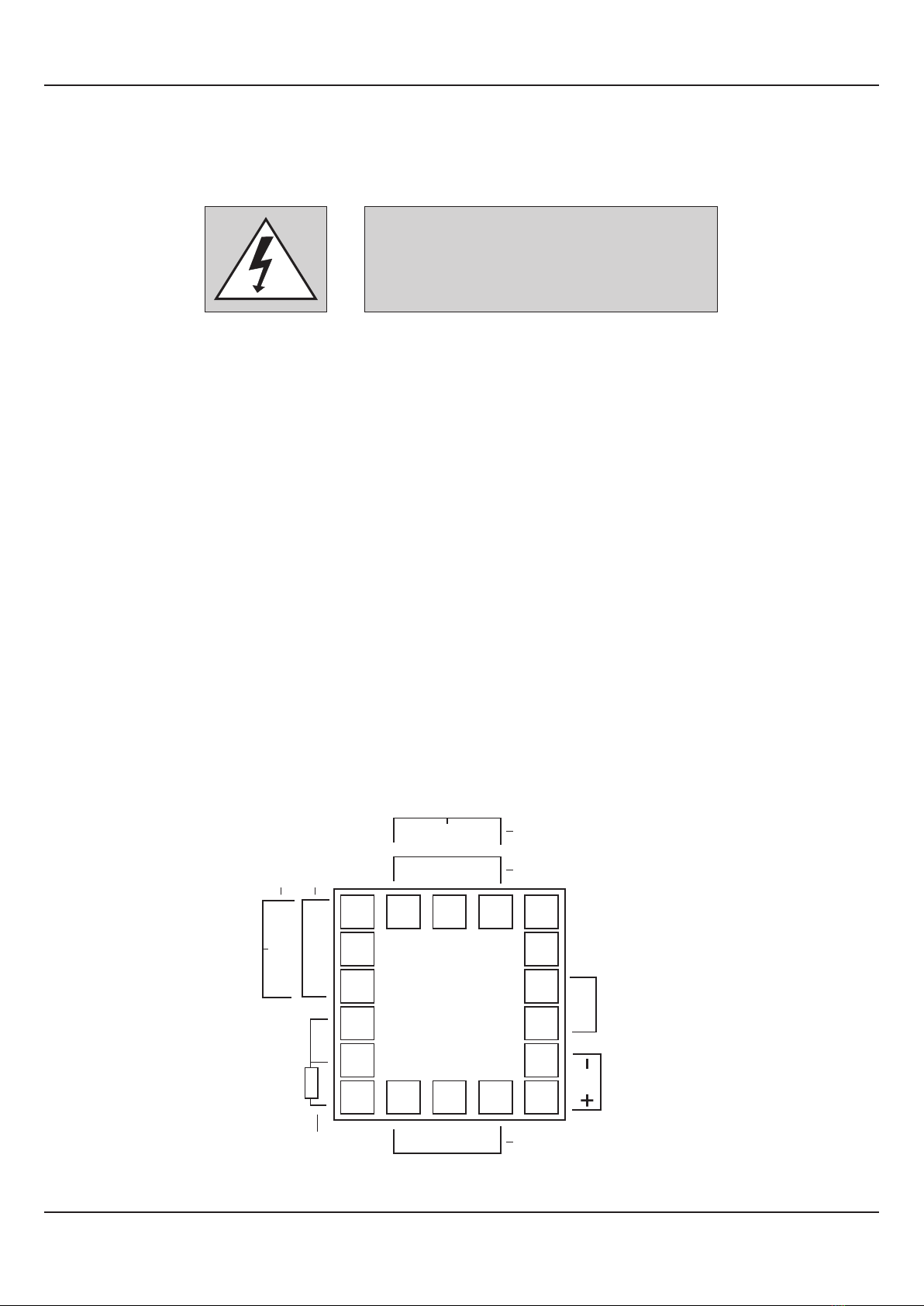

POWER SUPPLY Figure 10.4

The indicator is supplied with power connections suited for 85 to 264 VAC line supply. Use well-insulated copper conductor

2

wire of the size not smaller than 0.5mm for power supply connections. Connect Line (Phase) supply line to terminal 12 and the

Neutral (Return) supply line to terminal 13 as shown in Figure 10.4 above. The indicators is not provided with fuse and power

switch. If necessary, mount them separately. Use a time lag fuse rated 1A @ 240 VAC.

User Manual

HumiTherm-i (Dry-Wet)

Line

Neutral

12 (L)

13 (N)

2 Pole

Isolating Switch

Fuse

Power Supply

Terminal