2223V102-UK 5

Safety instructions

Definitions

Hazardous voltages have been defined as the ranges: 75 to 1500 Volt DC, and 50 to 1000 Volt AC.

Technicians are qualified persons educated or trained to mount, operate, and also trouble-shoot technically correct and in

accordance with safety regulations.

Operators, being familiar with the contents of this manual, adjust and operate the knobs or potentiometers during normal

operation.

Receipt and unpacking

Unpack the device without damaging it and check whether the device type corresponds to the one ordered. The packing

should always follow the device until this has been permanently mounted.

Environment

Avoid direct sun light, dust, high temperatures, mechanical vibrations and shock, and rain and heavy moisture. If necessary,

heating in excess of the stated limits for ambient temperatures should be avoided by way of ventilation.

The device must be installed in pollution degree 2 or better.

The device is designed to be safe up to an altitude of 2 000 m.

The device is designed for indoor use.

Mounting

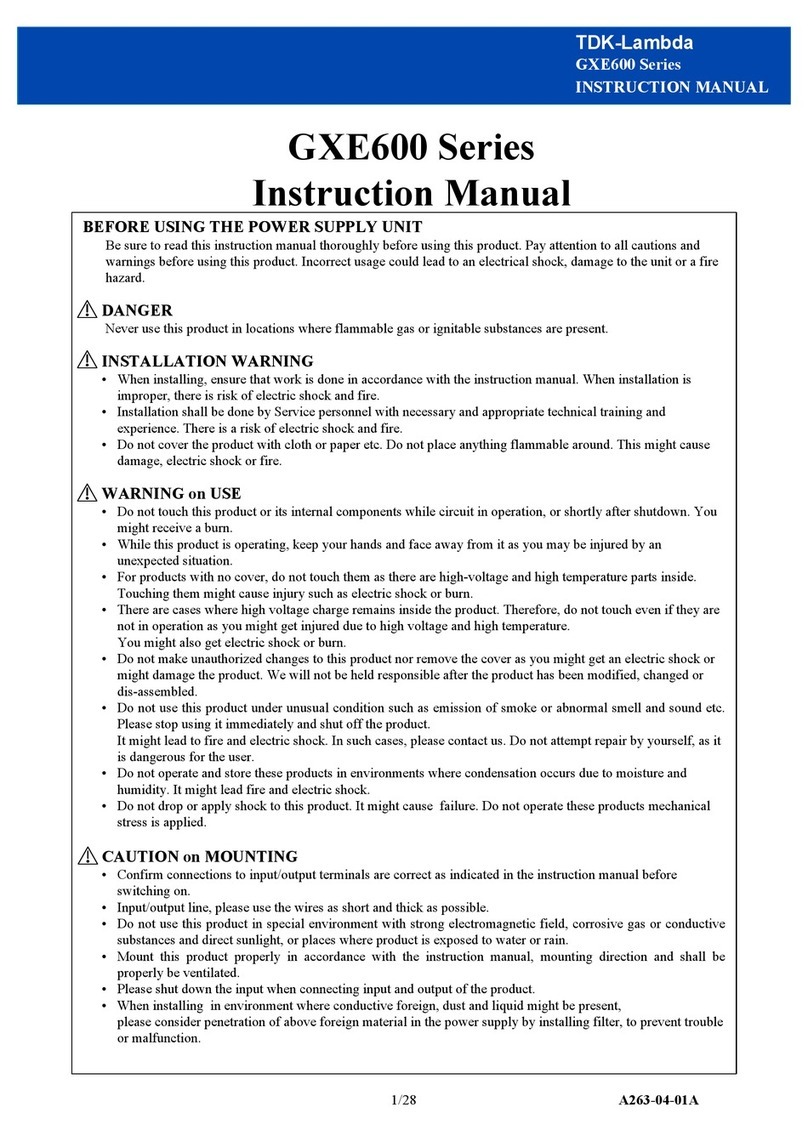

Only technicians, who are familiar with the technical terms, warnings, and instructions in the manual and who are able to

follow these, should connect the device. Should there be any doubt as to the correct handling of the device, please contact

your local distributor or, alternatively,

PR electronics A/S

www.prelectronics.com

Mounting and connection of the device should comply with national legislation for mounting of electric materials, i.e. wire

cross section, protective fuse, and location.

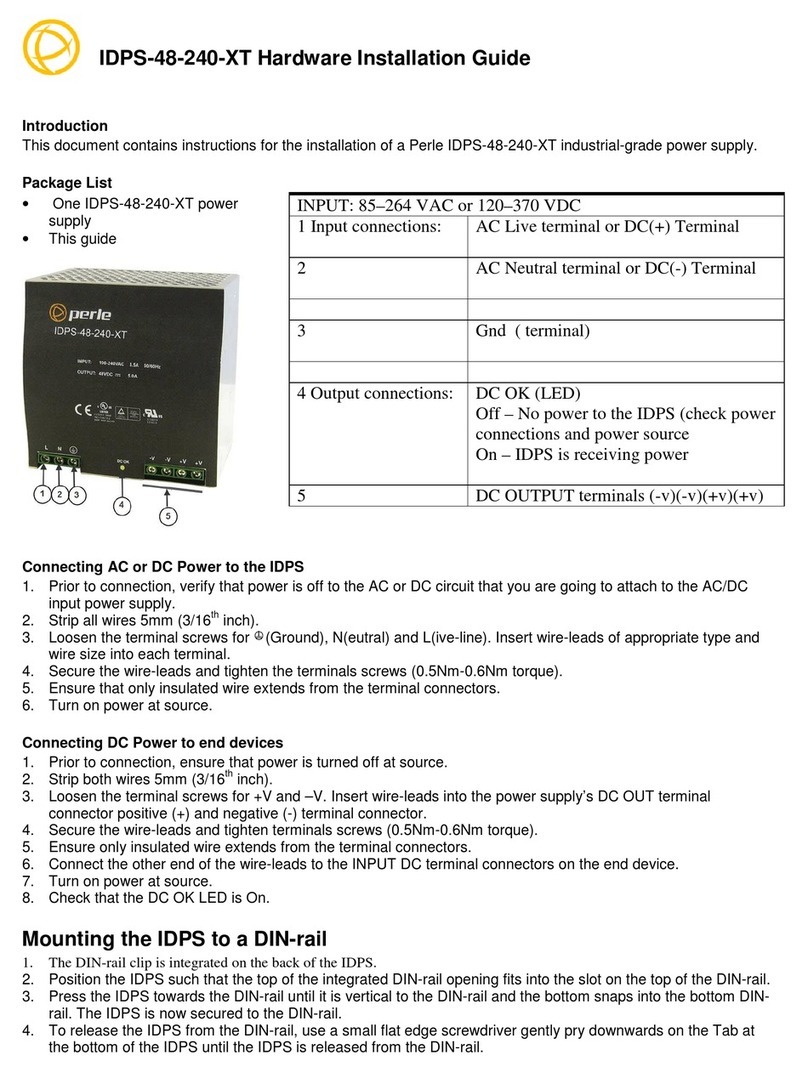

Descriptions of input / output and supply connections are shown in the block diagram and side label.

The following apply to fixed hazardous voltages-connected devices:

The max. size of the protective fuse is 10 A and, together with a power switch, it should be easily accessible and close to

the device. The power switch should be marked with a label telling it will switch off the voltage to the device.

Year of manufacture can be taken from the first two digits in the serial number.

Calibration and adjustment

During calibration and adjustment, the measuring and connection of external voltages must be carried out according to the

specifications of this manual. The technician must use tools and instruments that are safe to use.

Normal operation

Operators are only allowed to adjust and operate devices that are safely fixed in panels, etc., thus avoiding the danger of

personal injury and damage. This means there is no electrical shock hazard, and the device is easily accessible.

Cleaning

When disconnected, the device may be cleaned with a cloth moistened with distilled water.

Liability

To the extent the instructions in this manual are not strictly observed, the customer cannot advance a demand against PR

electronics A/S that would otherwise exist according to the concluded sales agreement.