When unpacking and before disposing of the carton check there is no transportation

damagebefore using the projector. Keep the carton well for future possible transportation.

Should there be any damage caused by transportation, consult your dealer and do not use

the unit.

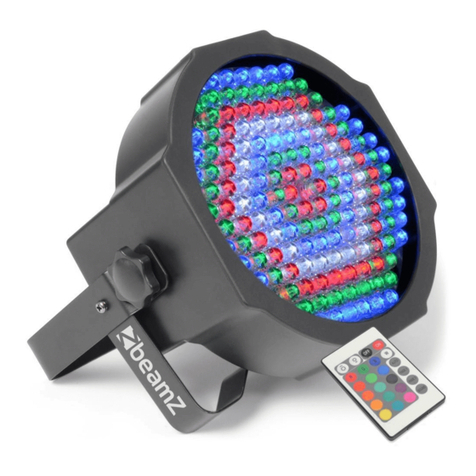

The projector is for Indoor use only, IP20. Use only in dry locations. Keep this device away

from rain and moisture, excessive heat, humidity and dust. Do not allow contact with water

or any other fluids, or metallic objects.

The projector is not designed or intended to be mounted on to inflammable surfaces.

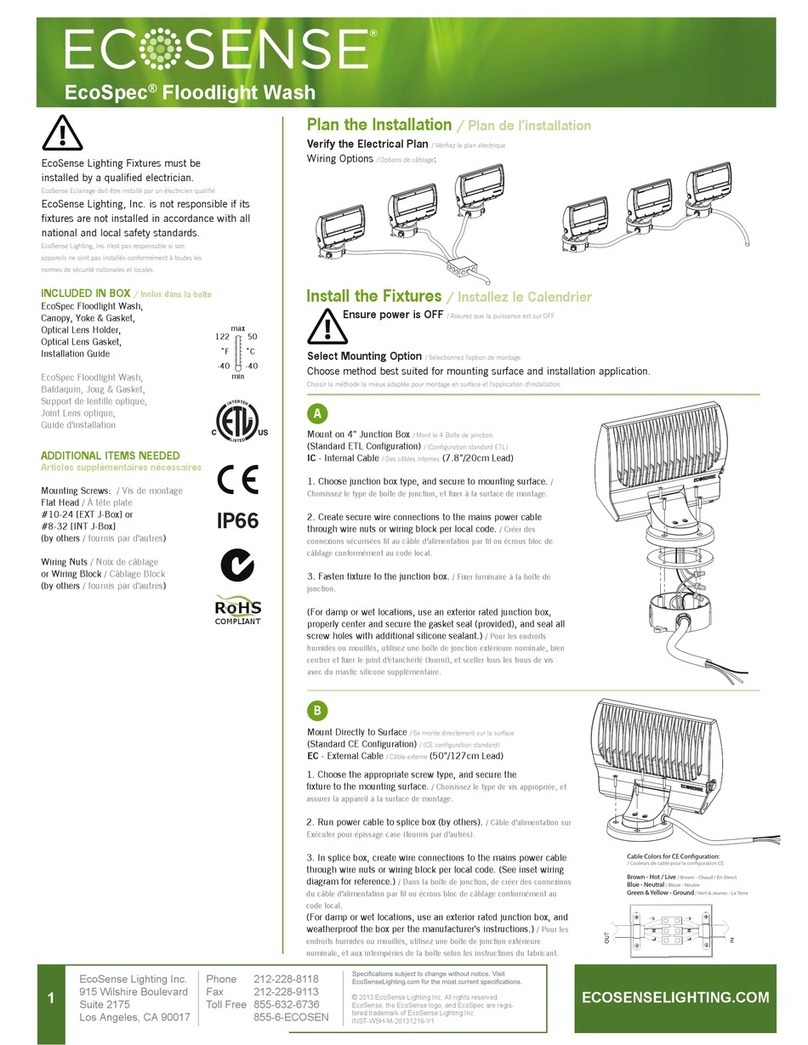

The projector is only intended for installation, operation and maintenance by qualified

personnel.

The projector must be installed in a location with adequate ventilation, at least 50cm from

adjacent surfaces. Be sure that no ventilation slots are blocked.

Do not project the beam onto inflammable surfaces, minimum distance is 3m. 3m

Avoid direct exposure to the light from the lamp. The light is harmful to the eye.

Do not attempt to dismantle and/or modify the projector in any way.

Electrical connection must only be carried out by qualified personnel.

Before installation, ensure that the voltage and frequency of power supply match the power

requirements of the projector.

It is essential that each projector is correctly earthed and that electrical installation

conforms to all relevant standards.

Do not connect this device to any dimmer pack.

Make sure that the power-cord is never crimped or damaged by sharp edges. Never let the

power-cord come into contact with other cables. Only handle the power-cord by the plug.

Never pull out the plug by tugging the power-cord.

Keep the lamp clean. Do not touch the lamp glass with bare hands.

The projector should always be installed with a secondary safety fixing. A safety cord is

supplied for this, it should be attached as shown in “installing the projector” section.

The lamp used in this projector is an MSD 250W discharge lamp. After being switched off

don’t attempt to restart the projector until lamp has cooled, this will require approx 15

minutes. Switching the lamp on and off at short intervals will reduce the life of both the lamp

and the projector. But occasional breaks in operation will prolong the life of the lamp and

the projector.

Never run the projector without a lamp.

There are no user serviceable parts inside the projector, do not open the housing and never

operate the projector with the covers removed.

Always disconnect from the mains, when the device is not in use or before

cleaning it or before attempting any maintenance work.

If you have any questions, don’t hesitate to consult your dealer or manufacturer.

SAFE USAGE OF THE PROJECTOR