6/20

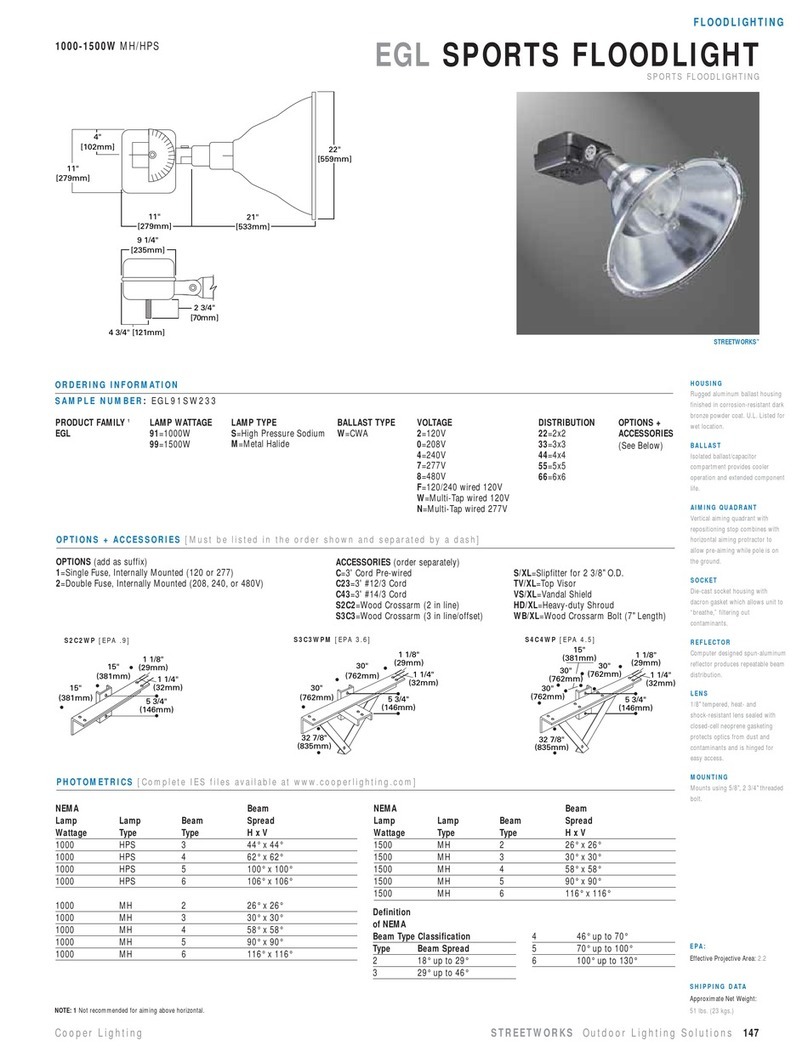

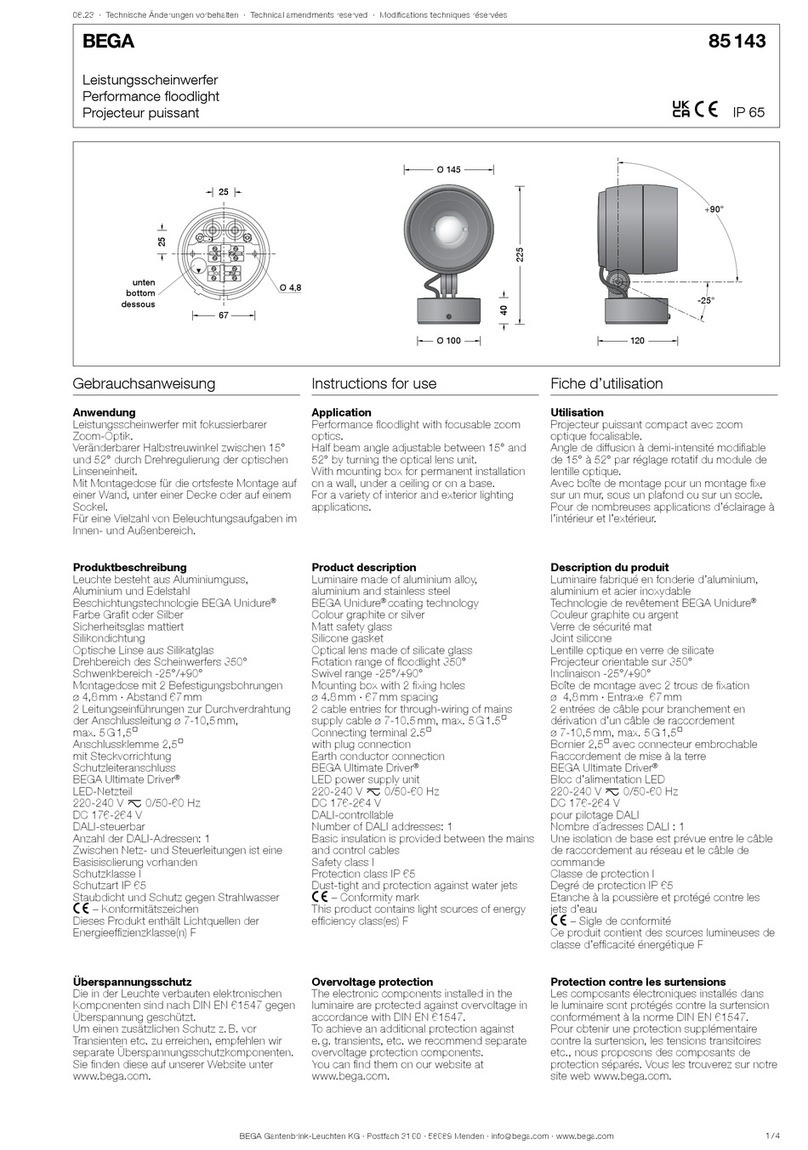

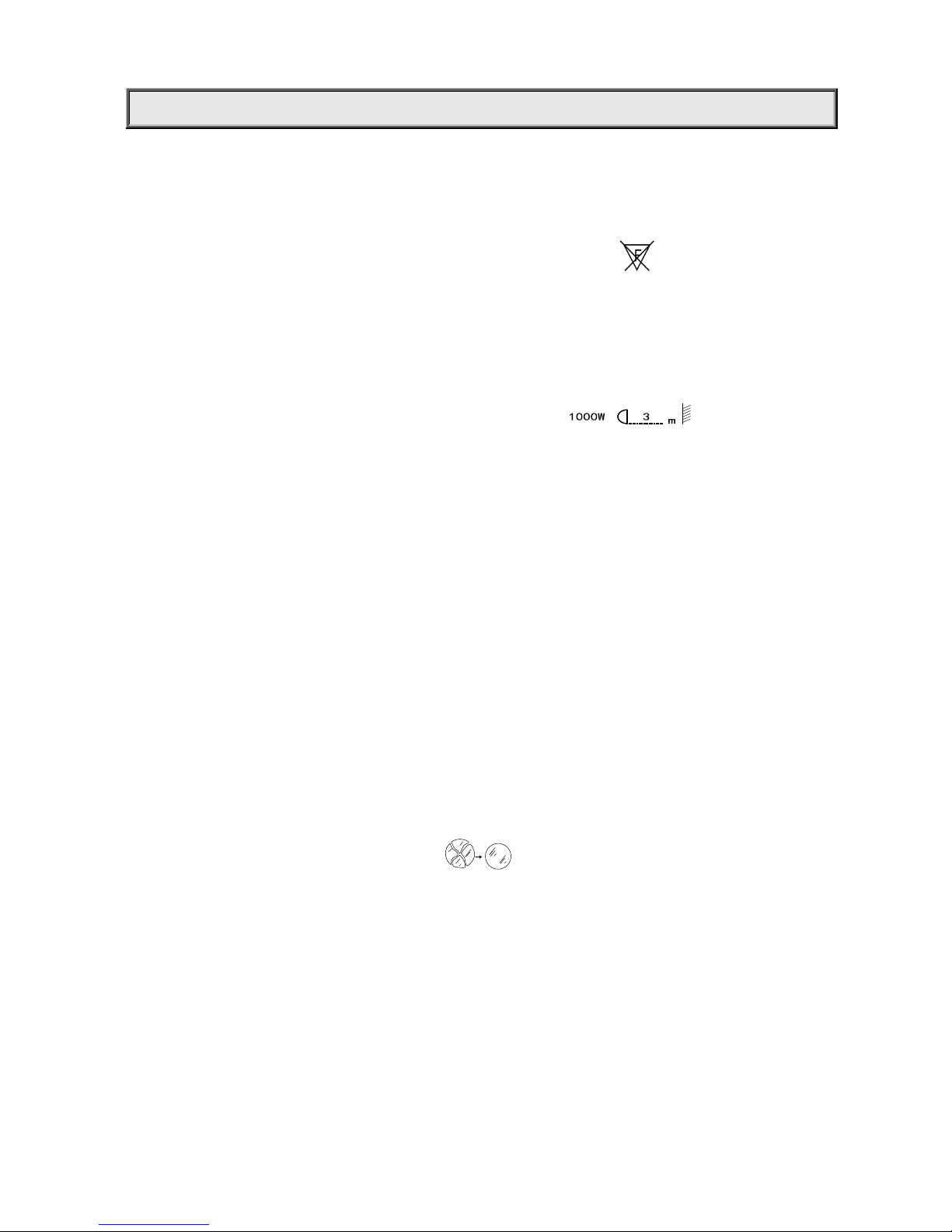

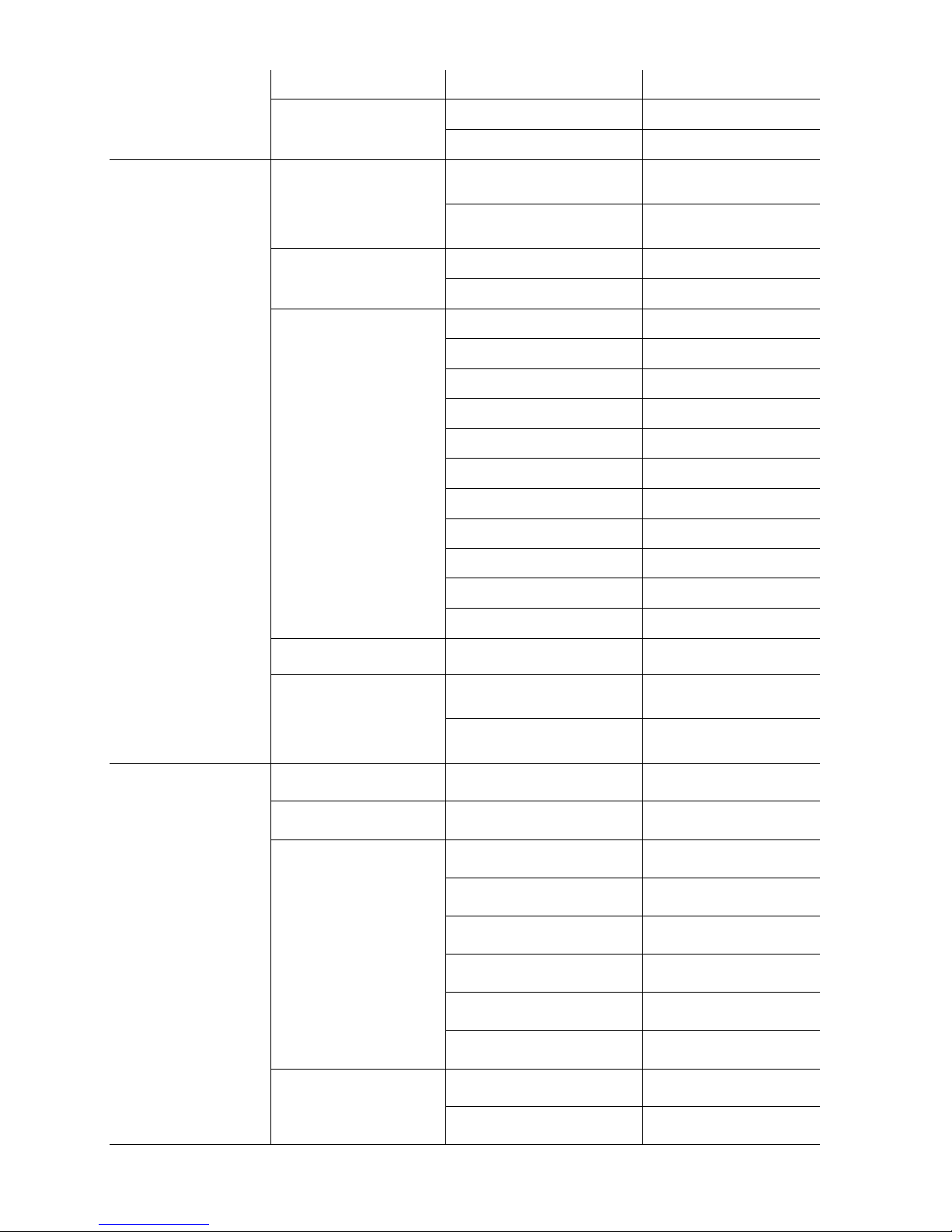

DMX TERMINATOR

In the Controller mode, at the last fixture in the chain, the DMX output has to be connected with a DMX terminator. This prevents

electrical noise from disturbing and corrupting the DMX control signals.

The DMX terminator is simply an XLR connector with a 120 (ohm) resistor connected across pins 2 and 3, which is then plugged

into the output socket on the last projector in the chain. The connections are illustrated below.

21

3

120

DMX TERMINATOR

CONNECTION

Connect a 120 (OHM) resistor

across pins 2 and 3 in an XLR plug

and insert into the DMX out socket

on the last unit in the chain.

PIN 3

PIN 2

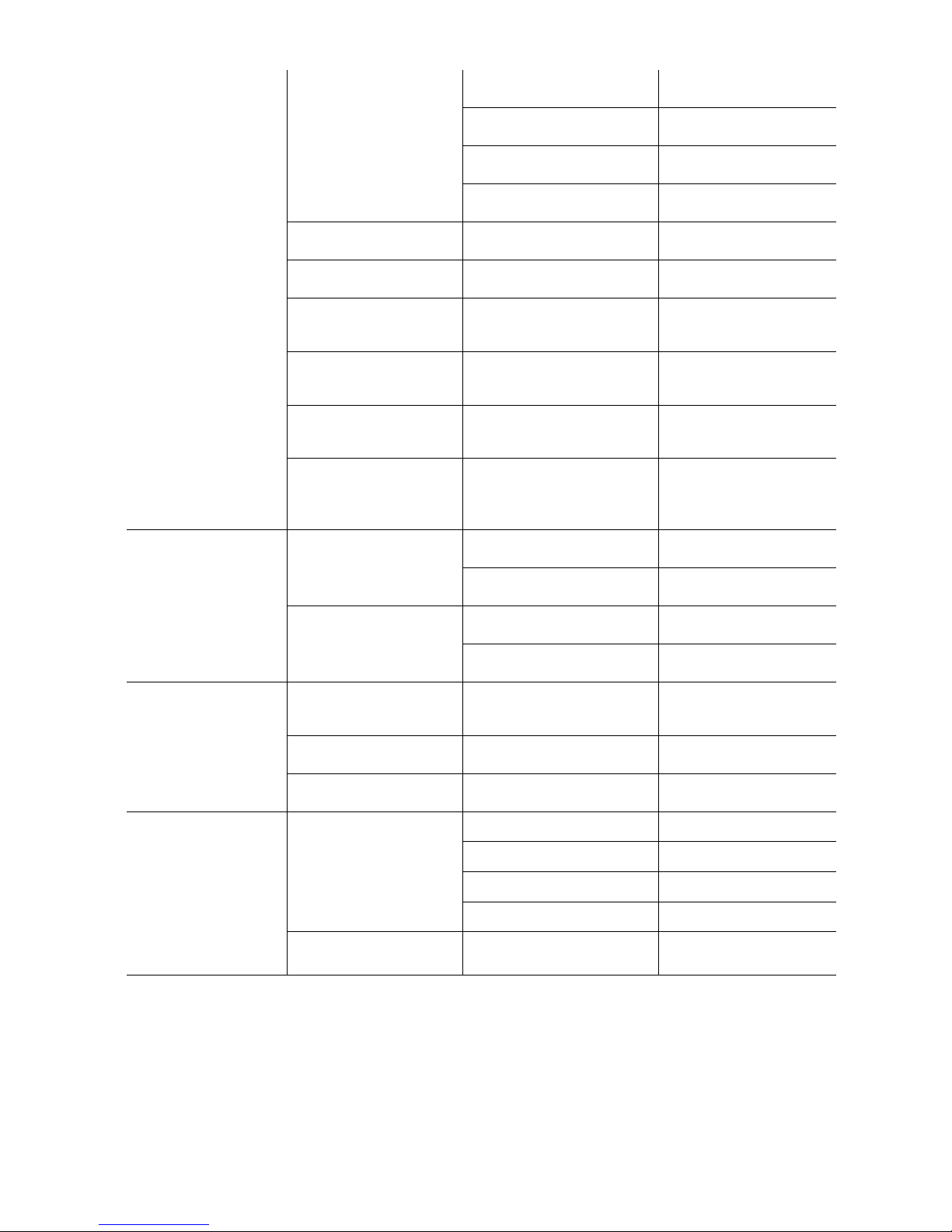

SETUP OPTIONS-PROJECTOR CONFIGURATION

Projector configuration can be set conveniently via push button and LCD display.

Launch the projector and press button ENTER for more than 5 seconds to unlock the panel, the LCD will show the function menu of

the projector, each main menu has its submenus and each submenu has a specific function. For details, please see the

“OPERATION MENU” section.

Press button UP or DOWN if you want to browse through the various Setup Options.

Press button ENTER to save your settings or enter the submenu.

Press button UP or DOWN to change values(plus or minus)

Press button FUNC, it will return to the upper menu. If button FUNC not pressed, the default will show display status automatically.

TO SET THE DMX START ADDRESS

Each XR 1000 Beam must be given a DMX start address so that the correct projector responds to the correct control signals. This

DMX start address is the channel number from which the projector starts to “listen” to the digital control information being sent out

from the controller. The XR 1000 Beam has 3 DMX modes. There are standard mode ,short mode and extended mode. For

example standard mode has 26channels, so set the No. 1 projector’s address 001, No. 2 projector’s address 027, No. 3 projector’s

address 057, No. 4 projector’s address 079, and so on.

Launch the projector. Press button ENTER more than 5 seconds to unlock panel.

Press button ENTER to display DMX address;

Press button UP and DOWN, you can set the address;

Press button ENTER to confirm; after powered on next time, the default will be last value saved

Press button FUNC, it will return to the upper menu.