Precision Biosystems BlotCycler User manual

1

USER MANUAL

BlotCycler™automated western blot processor.

Revision 10.0.2., 02-2014 software ver 3.1

2

Table of Contents

Specifications and Safety…………………………………………………………………3

Unpacking and Testing..............................................................................................5

Overview .....................................................................................................................7

Programming ..............................................................................................................8

Instrument Set up and Operation…………..............................................................11

Appendix....................................................................................................................16

Troubleshooting ......................................................................17

Fuse replacement........................................... ..........................18

Packing Instruction............................................. .....................19

Accessory Products............................................. ......................21

Technical Support.....................................................................23

3

Specifications and Safety.

Please read this manual thoroughly before operating the BlotCycler.

We suggest that you keep this manual, as you may need to refer to it.

The BlotCycler complies with the European Community Safety requirements. Operation of the

BlotCycler is subject to the conditions described in this manual. The protection provided may be

impaired, if the equipment is used in a manner not specified by Precision Biosystems.

NOTE:

Notes will be used throughout the manual to inform on important points and provide useful hints.

CAUTION:

Cautions will be used to inform the reader of action that may have the potential to either harm the

instrumentation or affect the quality of the data.

WARNING:

Warnings are used to provide special notice of actions that have the potential to cause harm to the operator.

For technical assistance, call, write, fax, or email.

Call: 888-490-4443 x 2

Fax: 617-812-2672

Email: customersupport@precisionbiosystems.com

Write : Customer Support

Precision Biosystems

241 Francis Avenue

Mansfield, MA 02048

Specifications:

Input voltage: 110VAC

Voltage variation : +/-10%

Phase: Single phase

Power frequency: 50Hz or 60Hz (check unit label)

Rated Input current: 5.0A max

Overvoltage category: Transient overvoltage category II

Rated pollution applied: Pollution Degree 2

The device must be connected to a mains socket outlet with protective earthing connections.

- Japan

Use the cable that comes with the product.

- North America

Use the cable that comes with the product.

- Other countries

AC power cable is not attached to the product. Use a power cable that conforms to the regulations in the country where

the product is to be used.

Blot Processing Polyurethane Trays and Tank.

Mini 8–25 ml per chamber, 9 x 7.5 cm

Midi 12–40 ml per chamber, 9.5 x 15 cm

Dimensions (h × w × d) 35 × 34 × 42 cm (with Mini tray)

Weight 12.0 kg

4

Safety certifications: CE directive 2006/95/EC and 2004/108/EC, standard used EN61010-1, IEC61010-1, EN 61326-

1:2006, IEC 61326-1:2005

Installation location conditions

Operation site: Indoors

Maximum operating altitude: 2500 m or lower

Operating temperature 3ºC to 42ºC

WARNING:

(1) Do not operate the instrument under voltage fluctuations exceeding 10% of the recommended line voltage. Large

fluctuations may cause the instrument to fail. Use a three-pronged electrical outlet with a ground.

(2) Instrument can be used in the temperature range 3°C - 42°C, avoid freezing. Do not install the equipment at a place

where the temperature changed frequently.

Instrument can be used under a humidity range of 30 - 80% (RH). Relative humidity less than 80% from 3ºC to 30ºC,

decreasing linearly to 50% from 31ºC to 42 ºC

(3) Do not install the equipment near a heating element.

(4) Do not install the equipment at a place where it may be exposed to corrosive gas.

(5) Do not install the instrument in a location where it may be exposed to dust, especially in locations exposed to outside

air or ventilation outlets that discharge dust particles.

(6) Do not install the equipment at a place constantly or excessively exposed to oscillations or impacts.

(7) Do not install the instrument in a location where it may be exposed to direct sunlight.

(8) Avoid strong magnetic fields and sources of high-frequency waves. The instrument may not function properly near

strong magnetic fields or high frequency wave sources.

The WEEE (Waste Electrical and Electronic Equipment) symbol indicates that this product should not be

disposed of in unsorted municipal waste. Follow local municipal waste ordinances for proper disposal

provisions to reduce the environmental impact of WEEE.

5

Unpacking the BlotCycler.

When you receive the BlotCycler, carefully inspect the shipping box for any damages, which may have

occurred in shipping. Any damage to the container may indicate damage to its contents.

Open the box and take out the enclosed flat box with tray and tank covers and tray plugs. Remove all solutions

and accessories parts from the box.

Using the upper part of the green Styrofoam as a handle, pull BlotCycler out of the box and put it on a flat

surface. Gently remove front and back of the protective Styrofoam; it is a good idea that you have a lab

colleague help with the system removal from the box. Remove the bag. Put the instrument on a solid and

leveled surface, and inspect for any damage.

Examine the unit carefully for any damage incurred during transit. If you suspect damage to the contents may

have occurred, immediately file a claim with the carrier in accordance with their instruction before contacting

Precision Biosystems. The warranty does not cover in-transit damage. Notify Precision Biosystems

([email protected]) of any claim filed.

Remove the protection styrofoam insert between the black pumps inside tank. Put all parts back into the box

and save them in case you need to send instrument back for service.

Packing List:

BlotCycler with six trays

Waste tubing attached to unit

Power cord

Tray lids, 2

Tank lid, 1

Tray plugs, 4

Transformer 220-240 V /110V (optional)

Installation.

Take the power cord from the box, connect it to the back of instrument and plug into 110 V output of the

transformer. Choose the correct input voltage for transformer (use transformer instruction) and plug the

transformer into the correct outlet. Use plug adapter if required.

Place the waste tubing on the back of the instrument into a waste container (not provided) or directly into the

sink.

Make sure the longer tubing under the trays (see picture) is inserted into the

small holes in the waste collectors on the left and right sides of the

instrument.

Remove protective paper from the covers of the trays and tank.

Warning: For personal safety the BlotCycler must be properly grounded. The user should have the wall receptacle and circuit checked by a qualified

electrician to be assured that the receptacle is properly grounded. Where a two-prong receptacle is encountered, it is the responsibility of the user to

replace it with a properly grounded three-prong wall receptacle. Do not under any circumstances, cut or remove the third ground prong from the power

cord. Do not use a two-prong adapter plug.

Warning: Do not operate around flammable liquids or gases.

6

Test run

Turn on the instrument using the switch on the back of the unit. The display should light up and you should see

the first screen with information about different functions:

Check that the silicone plug is inserted in the tank between the black pumps. Make sure that the waste tubing is

going down and is not bent (Remember there is no pump in BlotCycler the solution moves under gravity). It is

important for solution removal that the waste tubing is not bent allowing the solutions to drain properly,

also the outlet of the tubing should not be immersed in the waste solution.

Left side cleaning:

Fill water 3-4 cm above minimal level (about 2 L); make sure water is not leaking.

Press button and then press button, select left side. Now you started the cleaning cycle

on the left side. Make sure that solution is going into the trays and out of the trays. You may stop the cleaning

cycle at any time as soon you verified that everything on the left side is working.

Right Side cleaning:

Repeat the same procedure for the right side, adding more solution if needed. Press button and

select right side. The cleaning of the right side should start. The solution should be coming out from all three

tubes in each tray.

Now the instrument is ready for use. Read the following instructions to program and start using the BlotCycler.

7

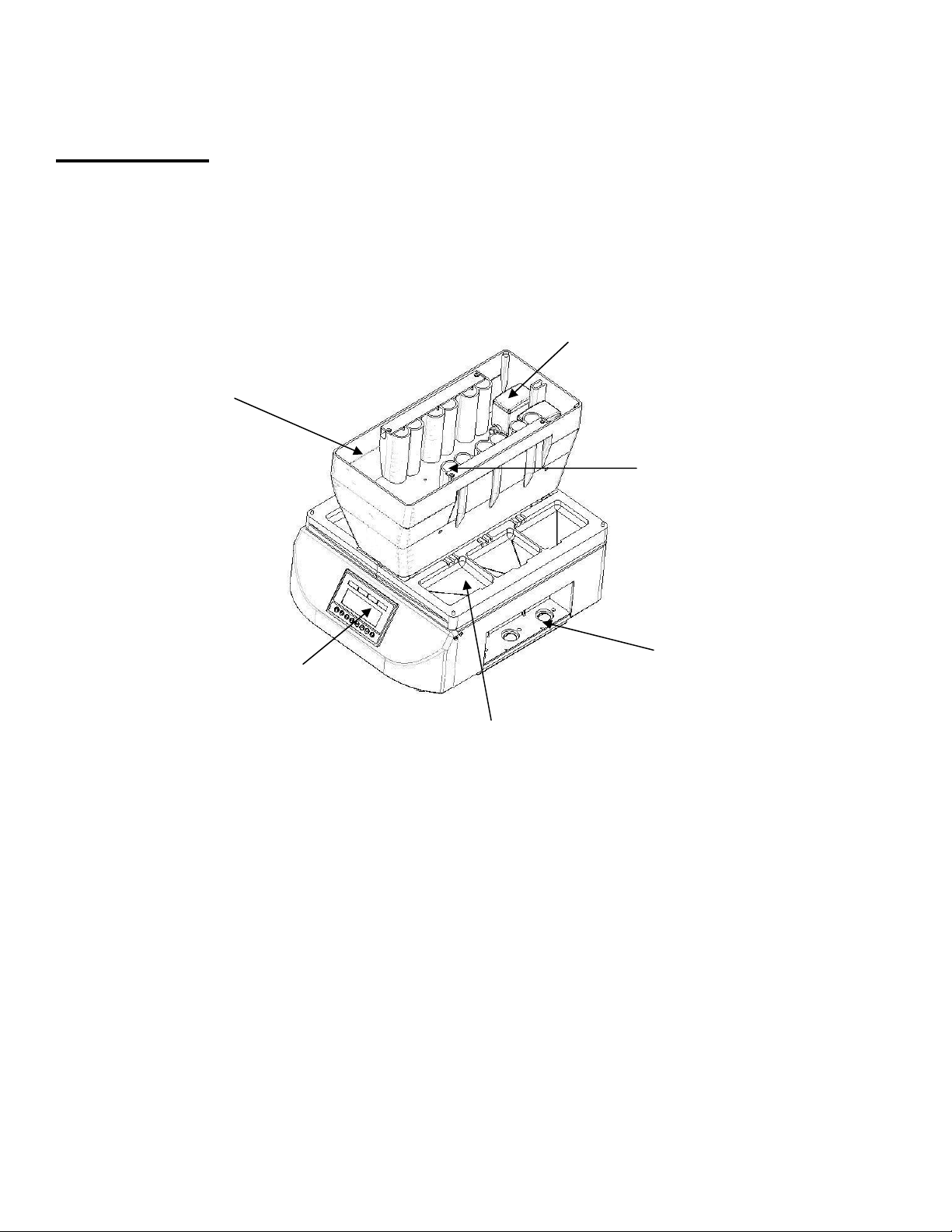

Tank

Programming

dis

p

la

y

Trays

Place for antibody

collection vials

Pump

Antibody container.

Overview

BlotCycler™ consists of programming display, four to six trays for blots (trays #1-3 on the left side and trays

#4-6 on the right side), tank with container for primary (P) and secondary (S) antibodies and pumps for

cleaning.

8

A. Programming the BlotCycler

Before starting actual western blot processing get familiar with programming interface

A1. User Interface overview

User interface contains 4 buttons:

press this button to select existing or set up a new protocol.

press this button to start a protocol

press this button to check the status of the currently running protocol and time to completion

press this button to start cleaning and perform other functions (see below)

9

A2. Protocol overview.

BlotCycler is set up to run standard protocol for western blot starting with blocking, washing after blocking, and

then primary antibody incubation, washing after primary antibodies, secondary antibodies incubation and

washing after secondary antibody incubation. Each step can be programmed independently. At the end of all

steps the trays are filled with washing solution and shaking is stopped; the antibody containers are also filled

with washing solution to facilitate cleaning.

Note:In order to skip blocking and primary antibody incubation set the Primary antibody incubation time to

zero. Protocol will start at second washing step.

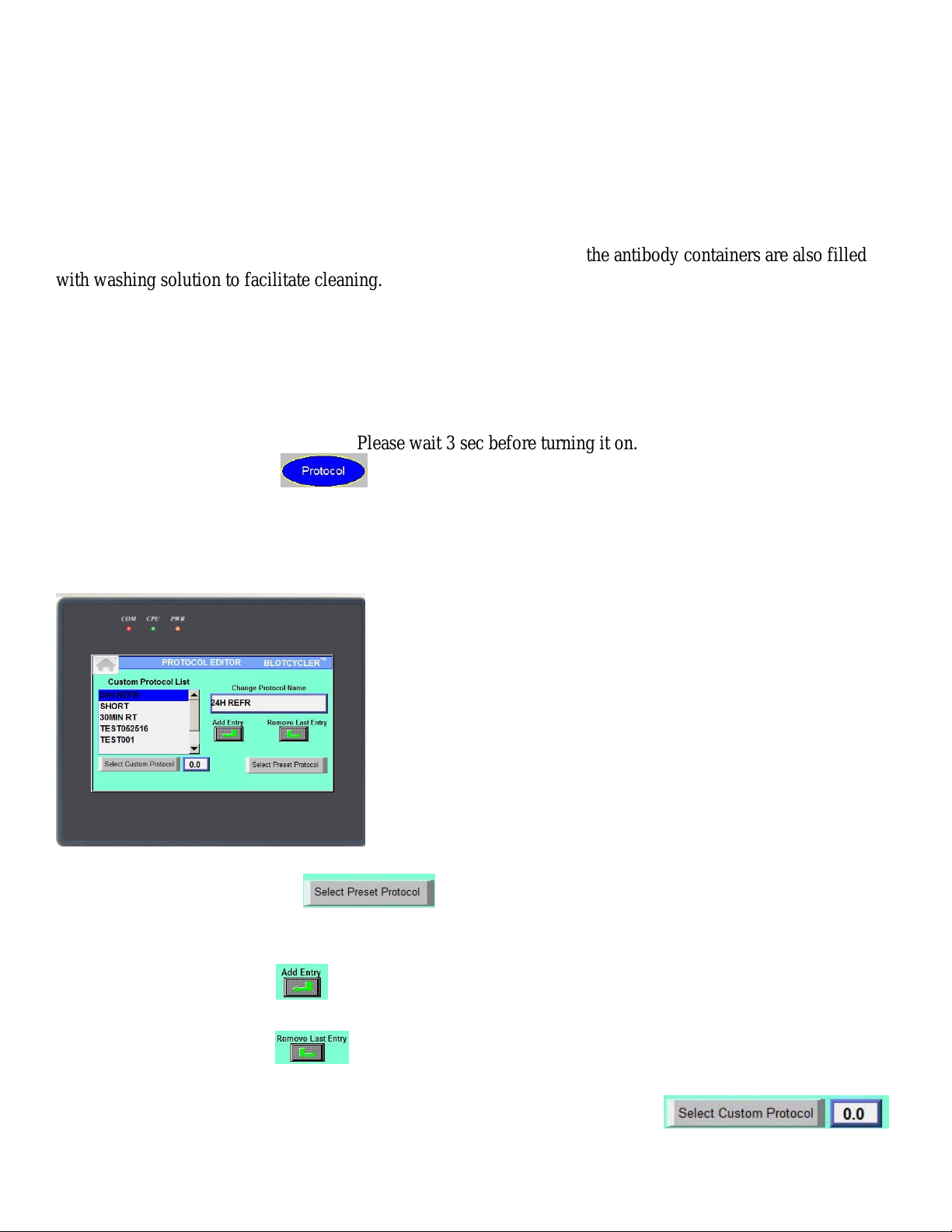

A3. Programming BlotCycler (protocol set up).

To start programming the operator needs to initialize the system by turning the system OFF and ON using the

ON/OFF switch on the back of the unit. Please wait 3 sec before turning it on.

To start protocol set up press .

On the new screen you can select existing protocols, modify existing protocol or set up a new protocol. You can

set up and save up to 20 protocols and there are 4 preset protocols that cannot be changed:

To select a preset protocol touch you will see a choice of four preset protocols, select one, and

choose on which side(right or left) to run your protocol, a new screen to start run will appear (see below)

To add a new protocol press and then touch white area under “Change Protocol Name”. Using keypad

enter new protocol name.

To delete last protocol press .

To select or modify existing protocol, highlight protocol by touching it and press .

10

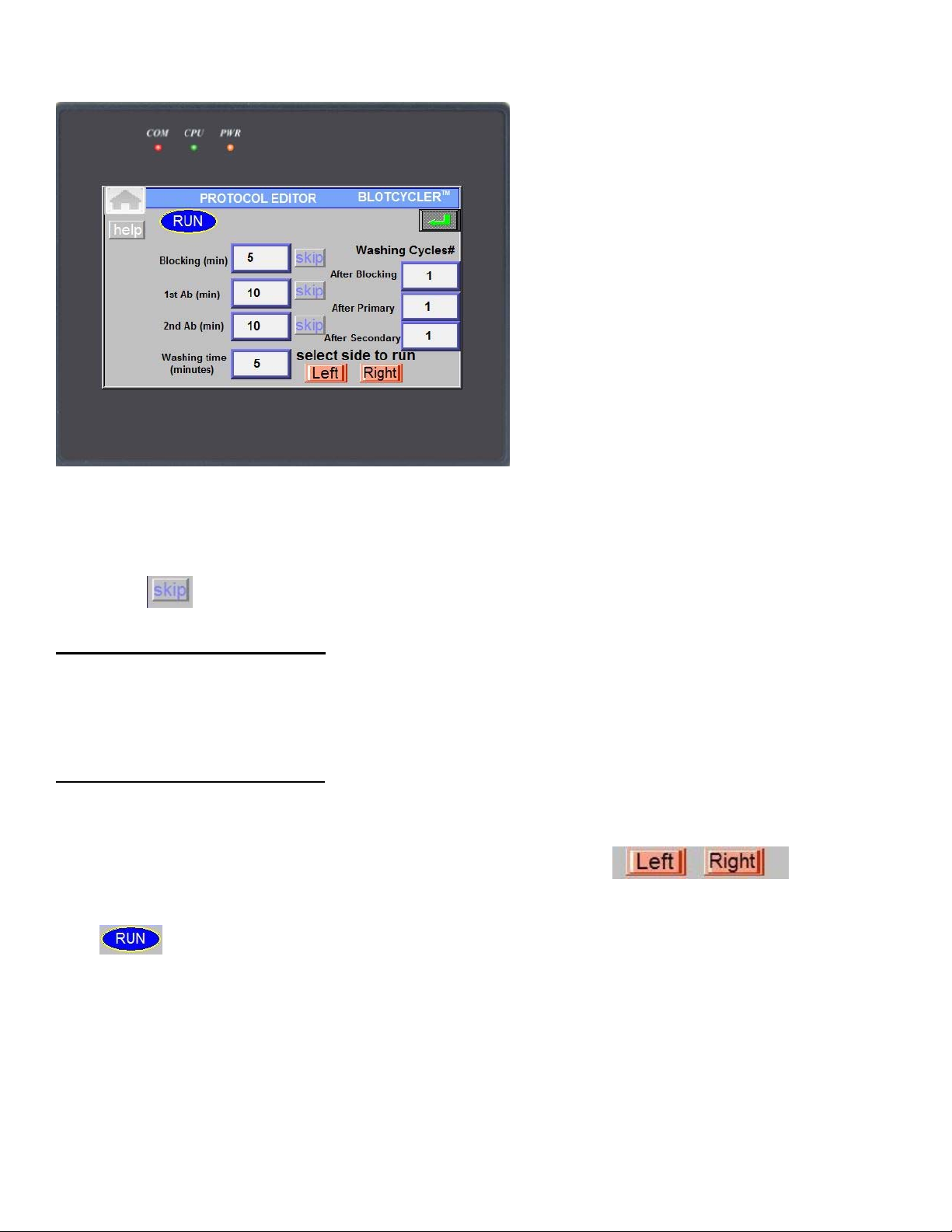

On the following screen you can change any protocol parameters:

Set the incubation time for blocking, primary (PA) and secondary (SA) incubation by touching adjacent white

area.

Note: The minimum time for blocking is 5 minutes, the minimum time for PA and SA incubation is 10

minutes.

Note: press to skip the step, zero time for blocking, PA or SA will appear.

Set the number of washing cycles:

By touching the white area on left side of the screen set the number of washing cycles after blocking,

PA(primary Ab) incubation time and SA(secondary Ab) incubation time.

Note: you can skip washing after blocking by selecting zero, but you cannot skip washing after primary and

secondary antibodies incubation.

Set the duration of washing cycle:

By touching the white area on left of “washing time” you select the duration of each washing cycle. It

can be set between 3 and 20 min.

After finishing the protocol modification select side you would like to run: .

Please note if the button is dimmed, this side is running and cannot be selected

Press button on the top of the screen and use the following screen to verify protocol selection and to

start protocol (see below).

11

B. Set up and Operation

B1. Before starting, you will need to run electrophoresis, transfer protein to membrane and prepare the

following solutions:

Blocking solution for each blot: 12-18 ml mini tray and 18-30 ml for midi tray

Primary Antibody (PA) for each mini blot 10-15 ml , for midi blot 18-25 ml

Secondary Antibody (SA) for each mini blot 12-18 ml for midi blot 18-30ml

Washing buffer up to 3.5 L (depending on the number of blots)

Note: Use 0.1% Tween 20 in the washing, blocking and antibody buffers. This will reduce the surface tension

of solutions and ensure even distribution of the antibody over the blot during incubation.

B2. Loading of the Blot Cycler

Note: If the BlotCycler has not been used for several days, run a cleaning cycle first.

Remove tray covers, place membranes in the trays

Add blocking buffers to each tray containing a membrane.

Close the trays by replacing the covers

Note: tray cover has a cut that should be on the upper side to ensure trays are covered completely.

Remove tank cover

Add Primary Antibodies (P1 – P6). Insert collection vial for primary antibody collection and re-use

Note: Make sure that primary antibody (P) and trays are matched.

(For midi size trays you can use only 1 and 3 on the left side and 4 and 6 on right side)

Add Secondary Antibodies (S1 – S6).

Note: Make sure that secondary antibody (S) and trays are matched.

(For midi size trays you can use only 1 and 3 on the left side and 4 and 6 on right side)

Fill the reservoir with washer to the appropriate level, replace the top cover.

Place a waste container, making sure it is below the instrument level and the waste tube does not touch

the waste solution.

Note: If you do not use all trays you can plug washing tubing with yellow plugs provided.

12

B3. Start Cycling

Note: you do not need to change any settings, if you are using the same protocol as before.

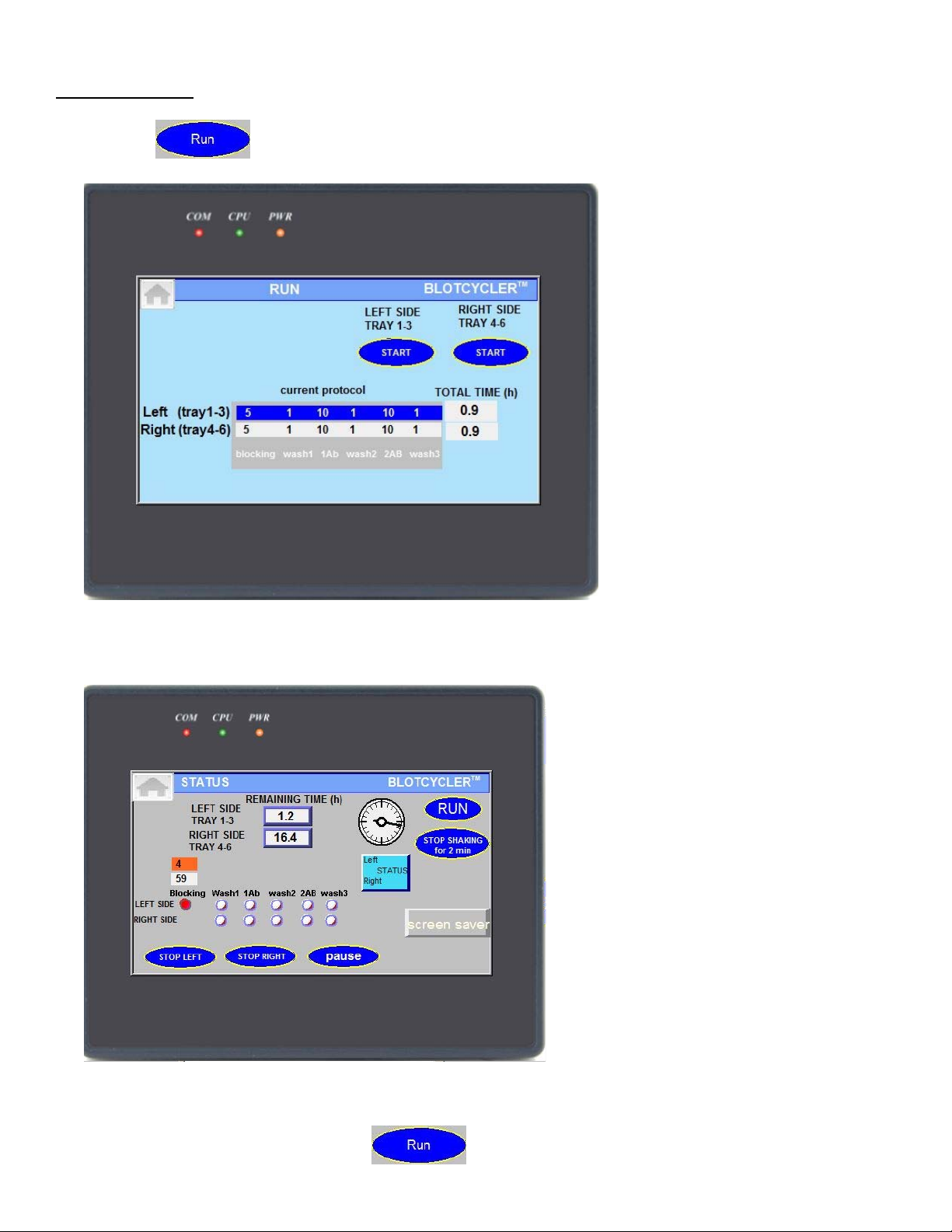

Press button to open a following screen:

Press corresponding start button to start cycling for left (Tray 1-3) or right side (Tray 4-6).

A new screen will appear that show the status of current protocol:

Red blinking dot indicates the current step, the number above it indicate the time to completion of the

current step.

In order to return to previous screen press button.

13

B4. Pause Cycling

you can pause protocol by pressing button. Shaking will not stop

To continue protocol press button for left or right side.

Note: protocol will start from next step if it was close to the end of the previous step.

Use to stop shaking while loading blot into trays. Protocol on other side will not stop, shaking

will resume in two minutes.

To completely stop protocol use or buttons

14

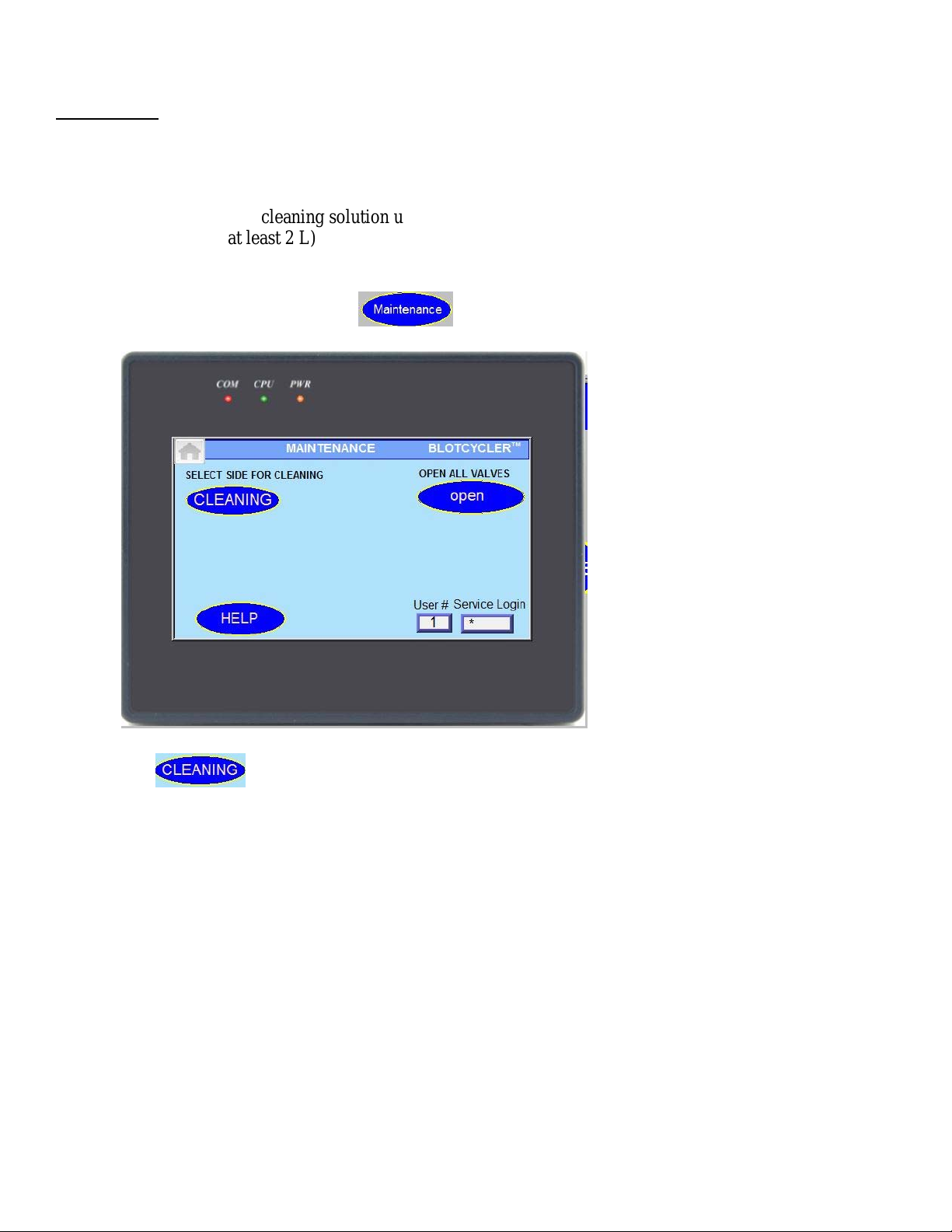

B5. Cleaning

Note: you can do a cleaning only after both sides have finished cycling.

Remove all membranes and containers for primary antibodies.

Fill the device with cleaning solution up to Max Level (if you want a shorter cleaning cycle you can add

less buffer, but at least 2 L).

Note: Make sure there is enough cleaning solution otherwise the pumps can be damaged.

Go to the home screen and press button, a new screen will appear:

.

Press and select left or right side on pop-up window.

Note: you can start another side only after cleaning on the other side is completed.

Note: to remove the excess of cleaning solution from the tank you can repeat the cleaning cycler or just

remove the plug located between the pumps.

Note: you can stop cleaning at any time but need to restart BlotCycler before starting a new protocol.

15

B6. BlotCycler Maintenance:

Run cleaning cycle every time you finished western blot processing. You can use deionized or distilled water

for cleaning. At least once in a week perform intensive cleaning with cleaning solution (cat #CL500).

If the BlotCycler is not intended to be used within next 24h, run cleaning cycle with cleaning solution and

then with deionized or distilled water and open all valves. It is a good idea to keep all valves open all the

time while BlotCycler is not in operation.

Go to home screen and press button and then button.

When all valves are open, the beep sound and the message will appear. Now you can turn BlotCycler

off.

Note: before opening valves check that there is no solution in the tank or the level close to minimal level.

Now turn BlotCycler off.

Note: after opening valve you need to restart BlotCycler using switch on the back before using it

again.

Warning: If there is a risk that a large volume of spilled liquid has penetrated the casing of

the instruments and come into contact with the electrical components, immediately switch off

the system, wipe out all spilled solution and do not operate until completely dry.

16

Appendix

Troubleshooting

Problem Possible Cause Solution

No power (the digital

display remains black

when the power is

turned on)

AC power cord is not connected.

Fuse has blown.

Check AC power cord connections at both ends.

Use the correct cords. Replace the fuse

If the problem still persists after verifying that

correct power cord is used and the fuse is

replaced, contact Technical support.

Buffers leak from the

trays and tank

immediately

Valves remain open. Turn instrument off, wait at least 5 sec and

turned instrument on. After initialization valves

will be closed.

Weak or no signal from

the blot Detection step missed or

detection reagents not working. After the blot processing is complete, perform

the detection step using your standard detection

reagents and protocol manually. Make sure the

detection reagents are functional.

Insufficient incubation with

detection reagent Remove blot from detection reagent when

signal-to-noise ratio is acceptable.

Poor or incomplete transfer Make sure transfer apparatus and membrane

sandwiches are assembled correctly. Use

appropriate transfer times. After blotting, stain

membrane to measure transfer efficiency.

Protein of interest ran off the gel Use positive control and/or molecular weight

marker to match gel separation range to size of

protein being blotted. After blotting, stain

membrane to measure transfer efficiency.

Incorrect reagents added or

incorrect containers are filled Make sure that primary and secondary antibody

are added to correct containers and number on

antibody container in the tank and tray match

each other.

Sample too dilute Load the larger amount of protein onto the gel

or increase concentration of proteins.

Poor retention of proteins or

protein weakly bound to

membrane

Use membranes with appropriate binding

capacity. Dry PVDF membrane after protein

transfer to ensure strong binding of the proteins.

Inactive or overly dilute primary

or secondary antibody Determine antibody activity by performing a

serial dilution using six trays or dot blot.

Increase antibody concentration as necessary.

High background on the

blot Film overexposed or became wet

during exposure Decrease exposure time or allow signal to

further decay. Prevent leakage of solutions by

encasing membrane in transparency film and

blotting excess substrate from edges before

exposure.

17

Short blocking time or washing

intensity Increase blocking time and the number of

washes

High concentration of primary

and/or secondary antibody Determine optimal antibody concentration by

performing dilution series using all six trays.

Decrease antibody concentration as necessary.

Protein is overloaded Reduce load or dilute concentration of sample.

Membrane, solutions, trays, or

antibody containers are

contaminated

Use clean glassware and purified water to

prepare solutions. Wear clean gloves at all

times. Use forceps when handling membranes.

Run cleaning protocol with cleaning buffer,

increase the concentration of cleaning buffer

two times

Protein is overloaded Reduce load or dilute concentration of sample.

Non-specific

binding too high Insufficient removal of SDS or

weakly bound proteins from

membrane after blotting

Follow proper protocol for membrane

preparation before immunodetection.

Short blocking time Increase blocking time.

Affinity of the primary antibody

for the protein standards Check with protein standard manufacturer for

homologies with primary antibody.

18

Replacing the Fuse

Follow the instructions below to replace the 250V, 5A rated fuse for the power socket.

1. Turn off BlotCycler using switch on the back of the instrument and detach the power cord from the rear of

the instrument.

2. Open the fuse compartment located on the power entry block using a small flat blade screwdriver or

fingernail to gently open the fuse compartment.

3. Pull the fuse holder out of the compartment and inspect the fuse. If the fuse is burned or there is a break in the

fuse element, replace the 250 V, 5 A with the identical type fuse.

4. Place the fuse holder back into the compartment and snap the cover closed.

For additional fuses, contact Customer Support.

19

Repackaging the Instrument

Find an original box; take out an insert a flat box (originally contained tray and tank covers and dummy vials).

Find a small T-bar and place between pumps into the tank.

(If you cannot find T-bar, use any appropriate material to secure pump inside tank)

There are two green Styrofoam covers: front and back (they are slightly different):

Back Front

Remove tray and cover and place them in a flat box (see below). Put on front and back sterofoam covers on the

instrument. Make someone help you to make sure that instrument is not flip over.

20

Using upper part of green Styrofoam as handles put BlotCycler in the box:

Place insert flat box over instrument (if you cannot find flat box use any soft material to fill the gap between

instrument and box top surface):

Close and tape the box.

Ship to:

Precision Biosystems

ATTN: Production Team

241 Francis Ave

Mansfield, MA 02048, U.S.A.

Table of contents

Popular Laboratory Equipment manuals by other brands

Esco

Esco Swift MiniPro SWT-MIP-0.5 Series Service manual

Parker Balston

Parker Balston NitroFlow60 Installation, operation and maintenance manual

Microm

Microm HM 355 S instruction manual

Meler

Meler Micron 5 instruction manual

Barnstead Thermolyne Corporation

Barnstead Thermolyne Corporation 494 Series Operation manual and parts list

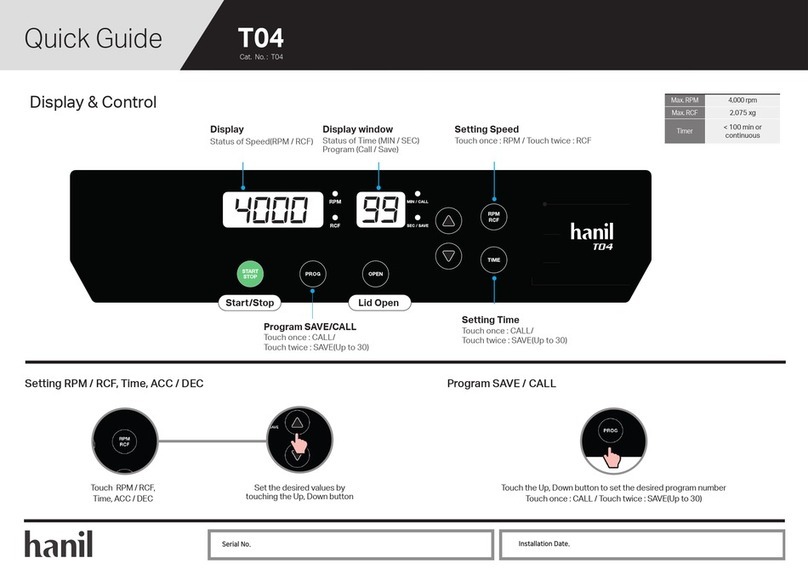

Hanil

Hanil T04 quick guide

Ocean Optics

Ocean Optics USB-ISS-UV/VIS quick start guide

Ultravation

Ultravation UVPhotoMAX GI PTXGI-1224 Installation and owner's manual

Metrohm

Metrohm Combustion-IC-System Manual - Short Instructions

FujiFilm

FujiFilm BL-7000 Operation manual

Brooks

Brooks FluidX XSD-1 user manual

BlackHawk Labs

BlackHawk Labs USB560v2 installation guide