Manual_MC2_DE_EN_V2.docx Page 2 of 44

CertoClav Sterilizer GmbH

Georg Grinninger-Str. 37

A-4050 Traun / Austria

www.certoclav.com support@certoclav.com

Contents

Introduction ..................................................................................................................................................... 3

Declaration of conformity MultiControl 2 ........................................................................................................ 4

Controller MultiControl 2 ................................................................................................................................. 5

Safety remarks .................................................................................................................................................... 5

Controller - technical data .................................................................................................................................. 6

Overview ........................................................................................................................................................ 6

Stickers ........................................................................................................................................................... 6

Controller - list of items ...................................................................................................................................... 7

Controller - connections...................................................................................................................................... 8

Controller - installation ....................................................................................................................................... 8

Controller - user interface ................................................................................................................................... 9

Controller - operation ......................................................................................................................................... 9

Screens ........................................................................................................................................................... 9

Troubleshooting ........................................................................................................................................... 11

Controller - usage of protocol printer ............................................................................................................... 12

Controller –cleaning and maintenance............................................................................................................ 12

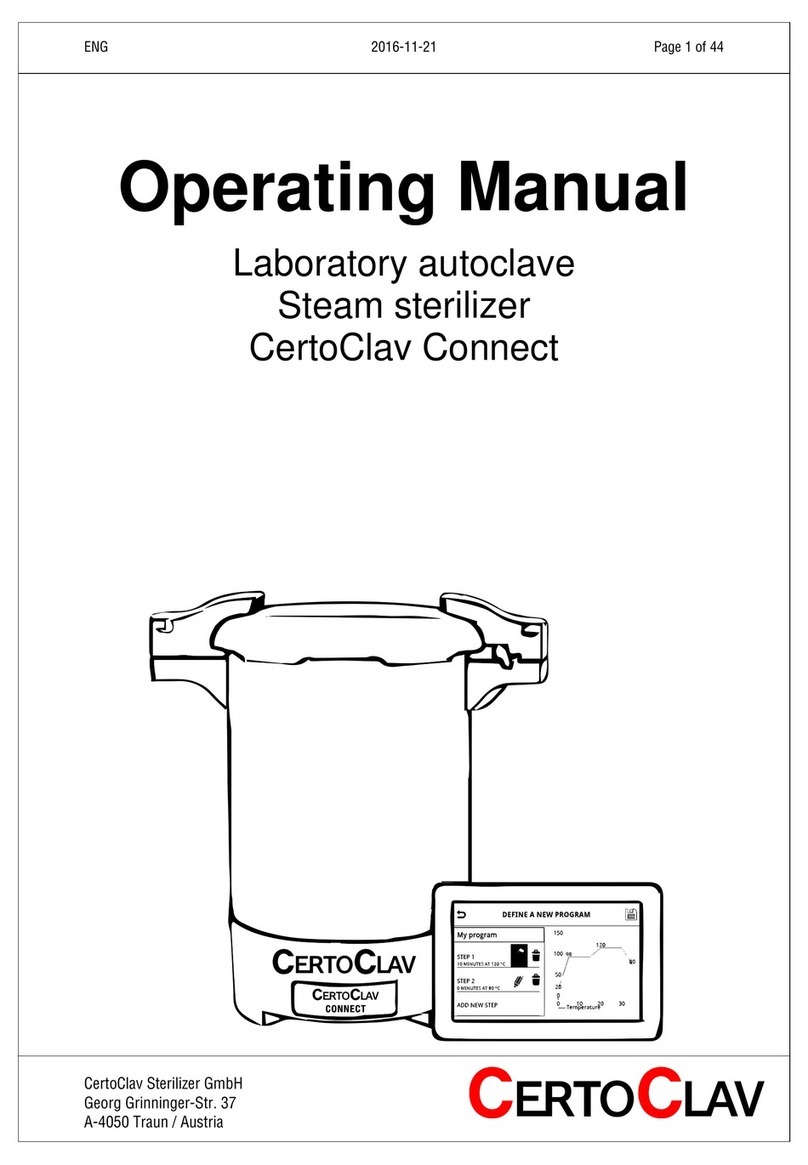

Autoclave CertoClav MultiControl 2 ............................................................................................................... 13

Safety remarks .................................................................................................................................................. 13

Autoclave - technical data ................................................................................................................................ 14

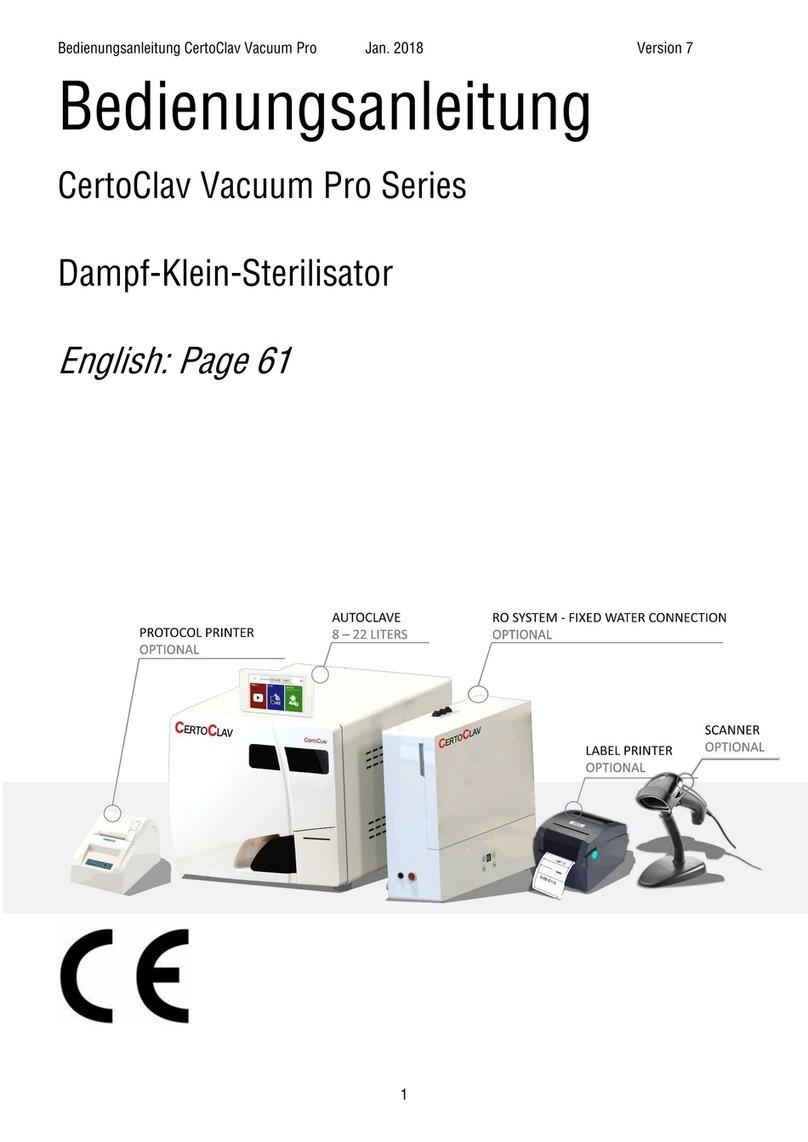

Overview ...................................................................................................................................................... 14

Directives...................................................................................................................................................... 14

Stickers ......................................................................................................................................................... 15

Autoclave –list of items ............................................................................................................................... 16

Autoclave - setup .............................................................................................................................................. 16

Autoclave - operation ....................................................................................................................................... 17

Loading the autoclave .................................................................................................................................. 17

Close and Locking ......................................................................................................................................... 17

Starting a program ....................................................................................................................................... 18

Venting ......................................................................................................................................................... 18

Sterilization / Autoclaving ............................................................................................................................ 18

Cooling down –end of cycle –acoustic signal ............................................................................................. 18

Opening ........................................................................................................................................................ 18

Autoclave - cleaning and maintenance............................................................................................................. 19

Spare parts ................................................................................................................................................... 19

Electric schematic......................................................................................................................................... 21

MULTICONTROL 2 BRIEFOPERATIONGUIDE ..................................................................................................... 22