PM-932 Manual 2014 v9.docx 9

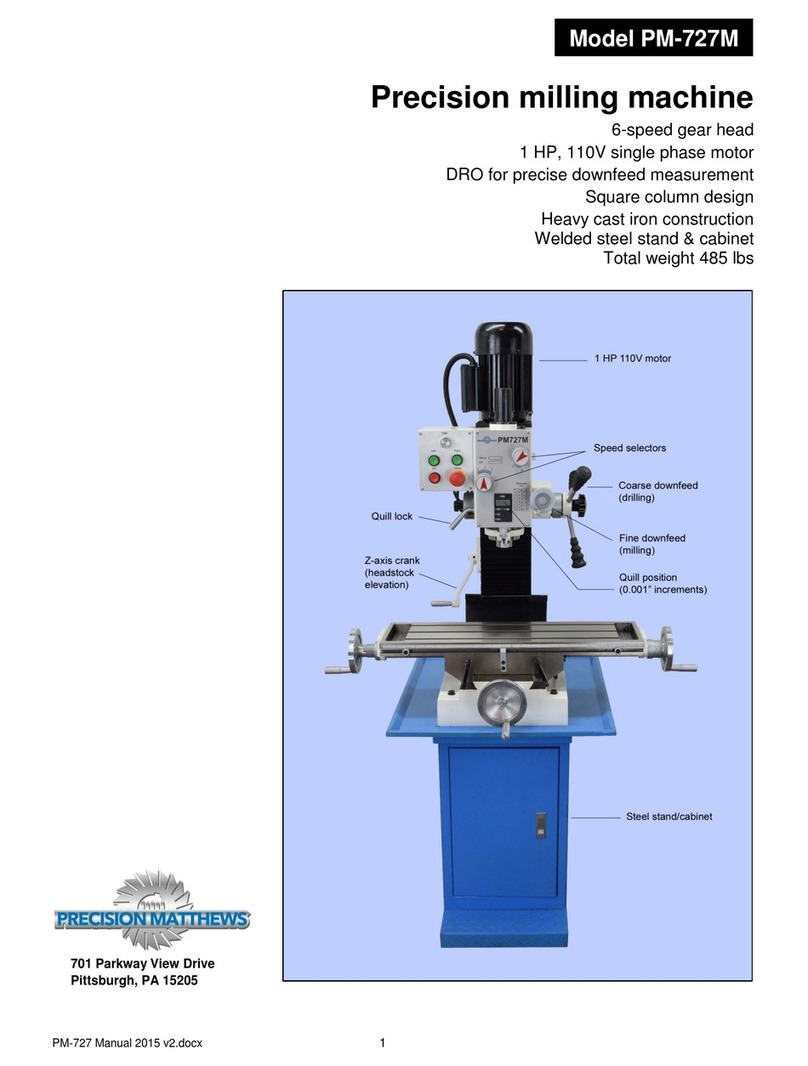

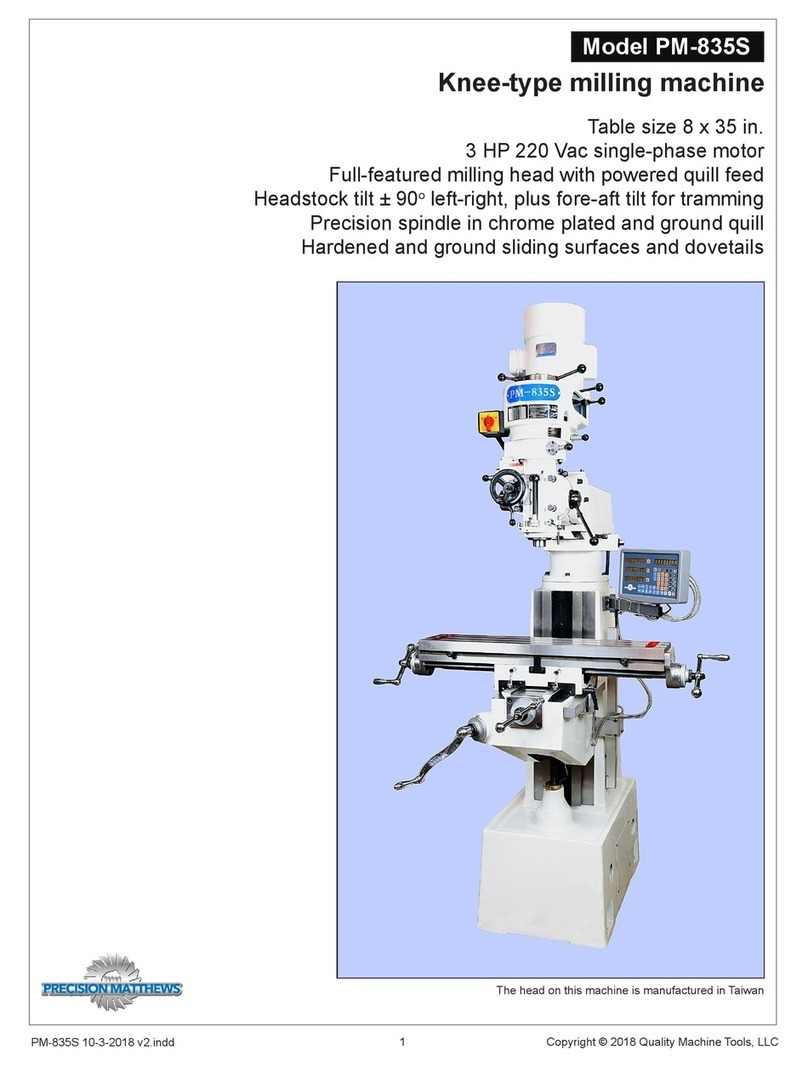

Figure 2-6 Quill downfeed controls

The lever hub (1) is full-time connected to the quill pinion. The fine

control knob (2) is connected by a worm gear to the sleeve (3),

and is free to rotate –doing nothing to the quill –if not meshed

with lever hub (1).

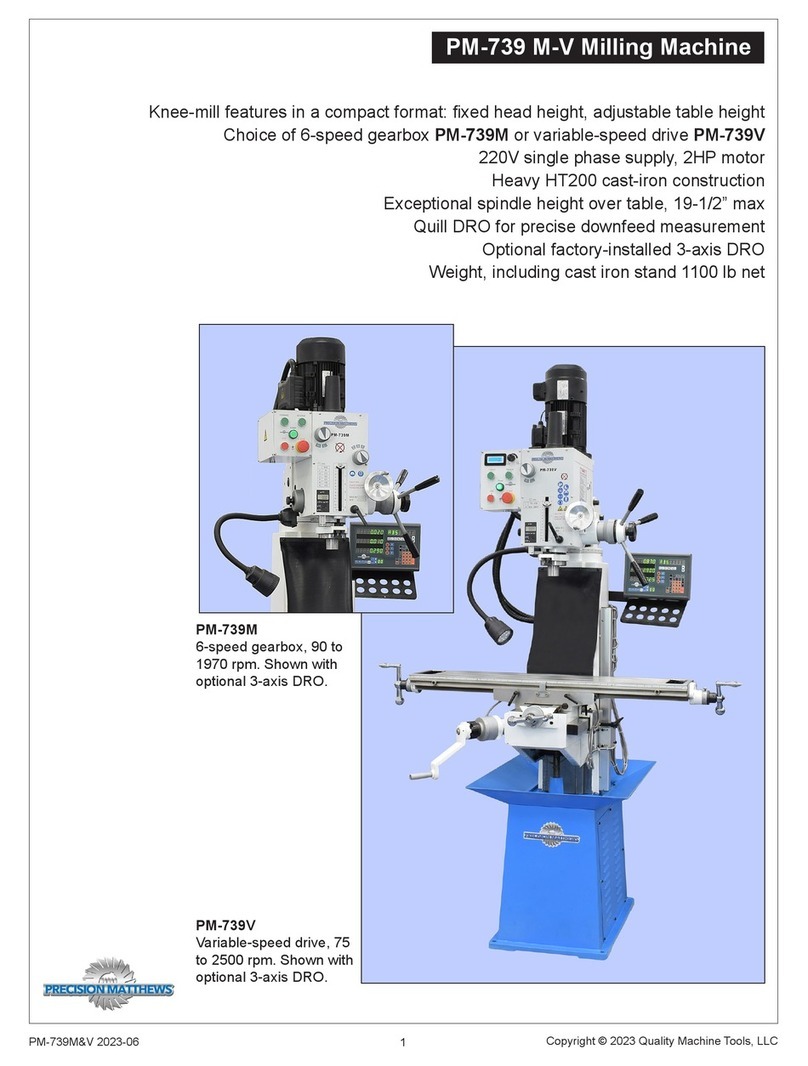

Figure 2-7 DRO, depth stop and quill locking lever

Set the depth stop by rotating the knurled knob, arrowed. For milling

operations, lock the quill before making a cut.

disconnect power. Investigate and resolve power feed problems –such as X-axis locks not free, or gears too

tightly engaged (see Section 6, Installation). Allow a cooling interval, press the reset button, then restore power.

Limit switch

Stop blocks on the front surface of the table can be independently set to limit travel to left and right, Figure 2-3

(3). To reposition a stop block, loosen its attachment screw, then tap it if needed to free the square nut in the

dovetail slot. (Slot dimensions: 10osides, 0.3" deep, width tapers from approx. 0.5" to 0.4".)

QUILL DOWNFEED

The quill is controlled in two different ways, coarse

and fine.

In the drilling mode, coarse feed , the mill functions

like a standard drill press –pull the upper lever toward

you to lower the quill. For milling operations the lever

hub is disengaged, and the quill is controlled by the

fine downfeed handwheel. The quill is locked by the

lever to the right of the depth stop, Figure 2-7.

Coarse feed (Figure 2-6)

For drilling operations, loosen knob (4), allowing the

lever hub to rotate independently of sleeve (3). If

desired, set the depth stop, Figure 2-7.

Fine feed (Figure 2-6)

For milling operations calling for precise, repeatable

control of tool depth, tighten knob (4) to engage the

tapered face of hub (1) with the internal taper on

sleeve (3). Tighten the Z-axis locks, Figure 2-8.

Rotate the fine control knob (2) to raise or lower the

quill. Before switching to fine control, it is usually a

good idea to run the depth stop up to the top. Lower

the quill by rotating the fine control knob clockwise,

positioning it precisely either by counting divisions on

the graduated dial, or by reference to the digital

readout (DRO), Figure 2-7. Use the locking lever to

hold the quill firmly in position.

If division-counting, be aware of backlash in the worm

drive. This means that the handwheel must always be

turning in the same direction throughout the entire

process, from setting a reference level to subsequent

cutting passes at specific depths –see the backlash

discussion in "Moving the table", above. Using the

DRO –which has no backlash issues –is less

laborious, but remember that the quill is spring-

loaded. This calls for care when releasing the quill

locking lever prior to repositioning the quill downward.

If the fine control knob has been allowed to

disengage (backed off counter clockwise), the quill