Pregis AirSpeed SMART V3 User manual

Air Cushion Technology

V2

AirSpeed™ SMART V3

Technical Manual

ii

Revision History

Rev

Date

Description

-

04/15/13

Original

1

05/02/13

Added detail in Section 4.2 on Bin Sensors

2

07/22/13

Updated advanced menu to match version 2 software

iii

TABLE OF CONTENTS

SECTION 1 –Overview ............................................................................................1

1.1 Introduction....................................................................................................1

1.2 Sensors..........................................................................................................1

1.2.1 Jaw Sensor ...............................................................................................1

1.2.2 Lost Film Sensor .......................................................................................2

SECTION 2 –Operation............................................................................................3

2.1 General Operation Screen.................................................................................3

2.1.1 Special operation for a run length of 0:00 ....................................................3

2.2 Setting Screens...............................................................................................3

2.2.1 Temperature Setting Screen .......................................................................4

2.2.1.1 Temperature Setting Timeout ...............................................................4

2.2.1.2 Temperature Test Mode .......................................................................4

2.2.2 Inflation Setting Screen .............................................................................4

2.2.2.1 Inflation Setting Timeout......................................................................5

SECTION 3 –Advanced Setup ...................................................................................6

3.1 Password Screen .............................................................................................6

3.1.1 Password Entry Timeout.............................................................................6

3.1.2 Special Processing after entering a valid password.........................................6

3.2 Advanced Setup Screen ...................................................................................6

3.2.1 Exiting Advanced Setup..............................................................................8

3.2.2 Individual Parameters ................................................................................8

3.2.2.1 Version ..............................................................................................8

3.2.2.2 Belt Odo ............................................................................................8

3.2.2.3 Test Mode ..........................................................................................8

3.2.2.4 Temp Low & Temp High .......................................................................8

3.2.2.5 Air Low & Air High ...............................................................................9

3.2.2.6 Speed ................................................................................................9

3.2.2.7 Start Delay.........................................................................................9

3.2.2.8 Air Offset ...........................................................................................9

3.2.2.9 Bin Sensor ....................................................................................... 10

3.2.2.10 Sensor Delay .................................................................................. 10

3.2.2.11 Units.............................................................................................. 10

3.2.2.12 Language ....................................................................................... 10

SECTION 4 –Optional Accessories........................................................................... 11

4.1 Foot Pedal .................................................................................................... 11

4.2 Bin Sensor.................................................................................................... 11

4.2.1 Infrared Sensor....................................................................................... 11

4.2.2 Ultasonic Sensor .................................................................................. 12

SECTION 5 –Unit Burn IN ......................................................................................13

5.1 Introduction.................................................................................................. 13

5.2 Operational State .......................................................................................... 13

5.3 Burn-in State ................................................................................................ 13

5.3.1 Overview................................................................................................ 13

5.3.2 Selecting between Bin Sensors.................................................................. 14

iv

5.3.3 Initial Change from Idle to Run .................................................................14

5.3.4 Stopping Unit.......................................................................................... 14

5.3.5 Sample Display –Idle .............................................................................. 14

5.3.6 Sample Display –Run .............................................................................. 15

5.4 Selecting between „Operational‟ and „Burn-in‟ Modes.......................................... 15

SECTION 6 –Loading New Software ........................................................................16

6.1 Introduction.................................................................................................. 16

6.2 Procedure..................................................................................................... 16

1

SECTION 1 –OVERVIEW

1.1 Introduction

This document describes how to operate the new Pregis AirSpeed™ SMART

unit, commonly referred to as Version 3. The document is written for Pregis

Systems field technicians, therefore, familiarity with the original SMART unit

is assumed.

The new Pregis AirSpeed™ SMART operator‟s interface consists of a

membrane keypad and a two line LCD display. Optionally, there is a foot

switch and a bin sensor.

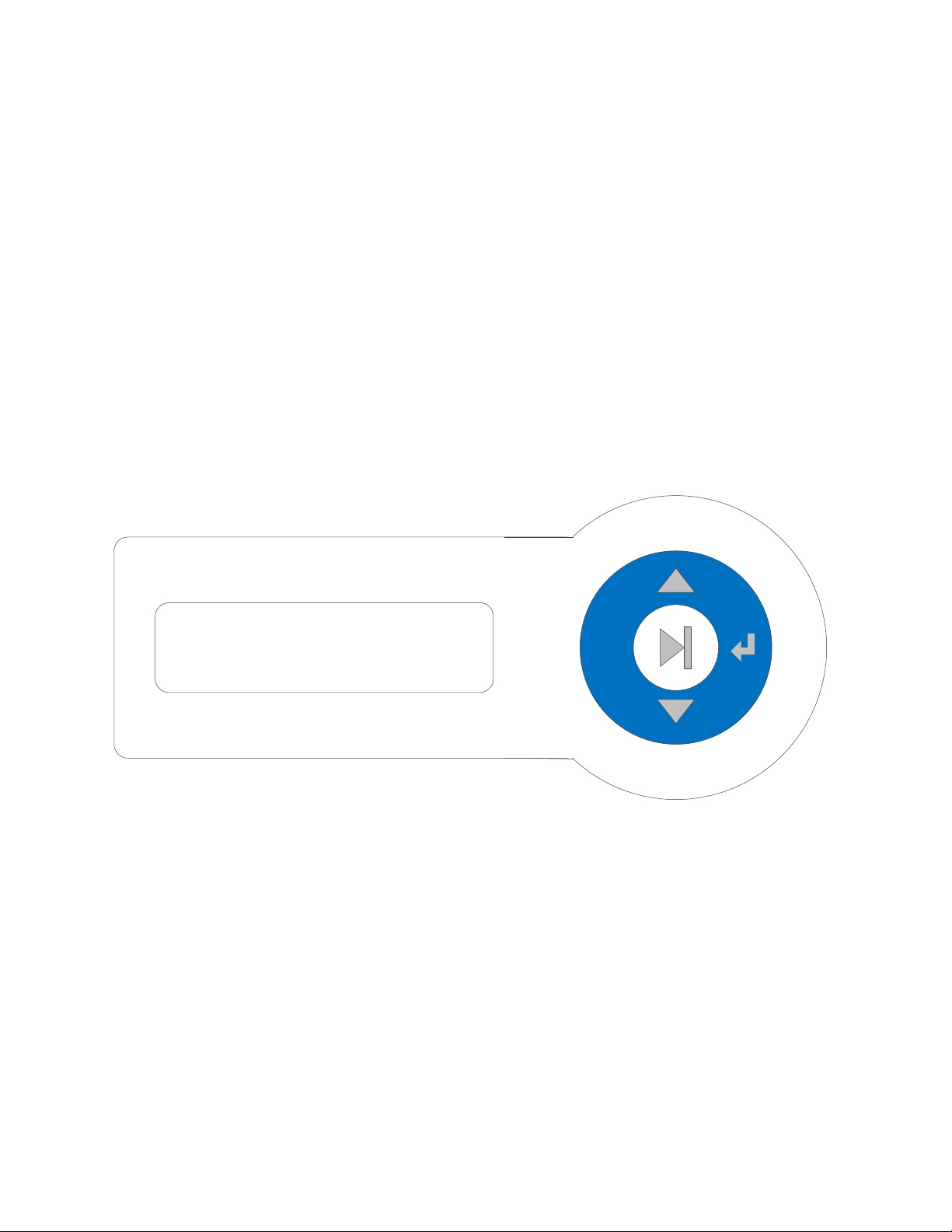

Figure 1

shows the front panel with the membrane

keypad and display.

Menu

Figure 1 Front Panel

1.2 Sensors

The unit has two standard sensors that provide feedback on the unit‟s

status.

1.2.1 Jaw Sensor

The jaws must be closed for the unit to start. If the unit is running and the

jaws are opened, the unit stops.

2

1.2.2 Lost Film Sensor

The lost film sensor monitors the rotation of the film roller. If the rotation

stops for more than three seconds, film is assumed to have been exhausted

or jammed; the unit immediately stops. The lost film sensor can be ignored

by setting „test mode‟ in the advanced settings, see Section 3.

3

SECTION 2 –OPERATION

2.1 General Operation Screen

The unit powers on with the last setting for run

length displayed. Run length is in time

(minutes:seconds) where the arrow keys are used to increase or decrease1.

Pressing Play starts the unit. While running, the timer counts down to

0:00 then stops. When stopped the display returns to the previously

entered run length. Pressing Play, while running, stops the unit and causes

it to return to the entered run length.

Pressing Up or Down arrow keys, increment or decrement the run time,

respectively.

Pressing Enter has no effect

Pressing Menu takes you to the Air Adjustment Screen (or the Temperature

Setting screen and then the Air Adjustment Screen if the Advanced Setup is

active see Section 3).

Pressing Play toggles the running state of the unit and returns to the General

Operation screen

2.1.1 Special operation for a run length of 0:00

A setting of 0:00 causes the unit to run continuously. The unit will start and

run until the stop button is pressed.

2.2 Setting Screens

Two settings, seal wire temperature (Temperature) and air inflation (Air

Adjustment), can be changed while the unit is running or stopped. The seal

wire temperature can be changed only by factory or field service personnel

while air inflation can also be changed by users.

1Maximum is 20:00.

TIMER ADJUSTMENT

3:00

4

2.2.1 Temperature Setting Screen

The Temperature Setting screen is available only

after the entry of a valid password, see section

3.1 . While in the General Operation screen,

pressing the Menu button brings you to the Temperature Setting screen2.

Use the arrow keys to increase or decrease the temperature of the seal wire.

The value is a percentage of the allowed temperature range that is set using

the Advanced Setup screen. Temperature Setting screen can be entered

while the unit is running and any changes take effect immediately.

Pressing Up or Down arrow keys, increment or decrement the temperature,

respectively.

Pressing Enter returns to General Operation screen

Pressing Menu takes you to the Inflation Setting screen

Pressing Play toggles the running state of the unit and remains at the

Temperature Setting screen

2.2.1.1 Temperature Setting Timeout

If you don‟t press a key for 60 seconds, Temperature Setting screen times-

out and the unit returns to the General Operation screen.

2.2.1.2 Temperature Test Mode

When test mode is enabled, see 3.2.2.3 Viewing the

Temperature Setting Screen will display the Set

Temperature percentage and the actual temperature of the thin film heater.

2.2.2 Inflation Setting Screen

If the Advanced Setup is not activated then the

Menu button will bring you to the Inflation Setting

screen directly from the General Operation Screen.

When Advanced Setup is activated pressing the Menu button while in the

2If a valid password has not been entered you are taken to the Inflation Setting screen,

section 2.2.2

TEMPERATURE

50

AIR ADJUSTMENT

50

SET TEMP 50

ACTUAL 122 F

5

Temperature Setting screen, brings you to the Inflation Setting screen. Use

the arrow keys to increase or decrease the air inflation setting. The value is

a percentage of the allowed inflation range that is set on the Advanced

Setup screen. The Inflation Setting screen can be entered while the unit is

running and any changes take effect immediately.

Pressing Up or Down arrow keys, increment or decrement the setting,

respectively.

Pressing Enter returns to the General Operation screen

Pressing Menu returns to the General Operation screen

Pressing Play toggles the running state of the unit then either remains in the

Inflation Setting screen or returns to the General Operation screen

depending on valid password entered or not entered, respectively.

2.2.2.1 Inflation Setting Timeout

If you don‟t press a key for 60 seconds, the Inflation Setting screen times-

out and the unit returns to the General Operation screen

6

SECTION 3 –ADVANCED SETUP

Advanced setup is available to factory or field personnel by entering a

password.

3.1 Password Screen

While in the General Operation screen and while the

unit is not running, you can bring up the password

screen which, in turn, allows entry to the advanced

setup. First press (and hold) the Enter key, then press (and hold) the menu

key for five seconds. Use the arrow keys to enter a three digit code (for

quicker entry hold down an arrow key), then press Enter. A successful

password brings you to the Advanced Setup screen. If unsuccessful, you

can try again.

Pressing Menu returns to the General Operation screen

Pressing Play starts the unit and returns to the General Operation screen

3.1.1 Password Entry Timeout

If you don‟t press a key for 30 seconds, the Password screen times-out and

the unit returns to the General Operation screen.

3.1.2 Special Processing after entering a valid password

Once you have entered a valid password, you don‟t need to enter it again for

fifteen minutes. That is, when in the General Operation screen and you go

to the Password screen, password entry is skipped and you immediately go

to the Advanced Setup screen. The Advanced Setup and Temperature

Setting screen will be available for fifteen minutes or until power is cycled to

the machine.

3.2 Advanced Setup Screen

The Advanced Setup is used view and change

parameters that are not available to users. Since

the unit has a two line display, you need to scroll

PASSWORD

***

VERSION 2.01

BELT ODO

7

through the parameters using the arrow keys. Pressing the down arrow

scrolls to the next parameter in the list. Some parameters you can change;

others are view only. When a changeable parameter is at the top of the

screen, it is identified by an underline immediately to the right of its value.

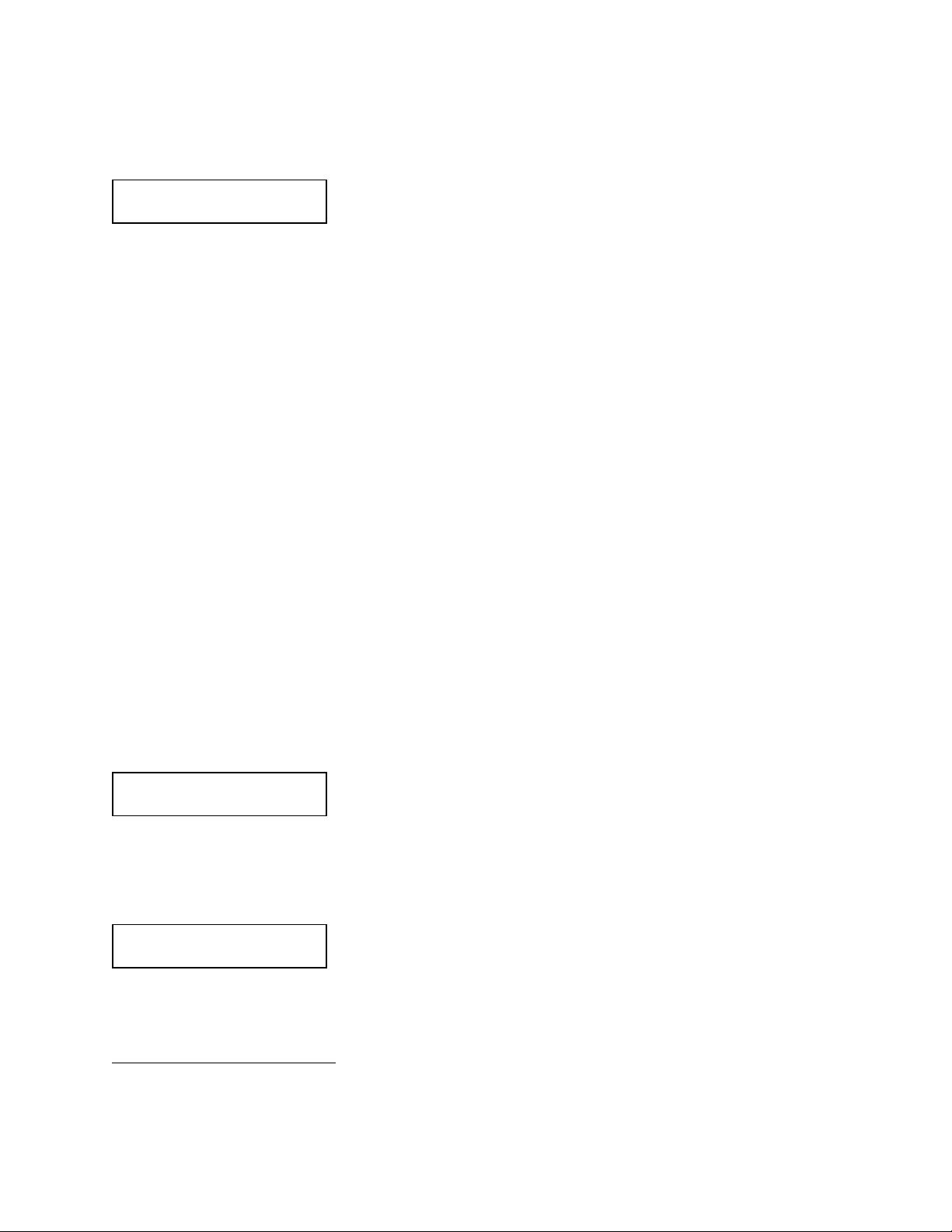

Figure 2

shows example.

Figure 2 Underline shows editable field

To change a parameter press the Enter key, the underline changes to a

block. You then use the arrow keys to adjust the parameter.

Figure 3 Up and down arrows change value

After changes, press the Enter key which returns you to the scroll mode.

Figure 4 Display shows window into parameters

While in scroll mode pressing the Menu key returns you to the General

Operation screen. Pressing the Play key starts the unit and returns you to

the General Operation screen.

TEMP LOW 10_

TEMP HIGH 90

Underline after value

denotes an editable

value

TEMP LOW 10

TEMP HIGH 90

Solid block after value

shows up and down

arrow can change value

VERSION 2.01

BELT ODO

3777 FT

TEMP LOW 0

TEMP HIGH 100

AIR LOW 20

AIR HIGH 100

SPEED 100

START DELAY 55

AIR OFFSET 100 MS

BIN SENSOR OFF

SENSOR DELAY 1 S

UNITS ENGLISH

LANGUAGE ENGLISH

Display shows two lines.

Use up and down

arrows to move.

8

3.2.1 Exiting Advanced Setup

Pressing the Menu key returns you to the General Operation screen.

Pressing the Play key starts the unit and returns you to the General

Operation screen.

If you don‟t press a key for 60 seconds, the Advanced Setup screen times-

out and the unit returns to the General Operation screen.

3.2.2 Individual Parameters

The following subsections discuss each individual parameter. Some are

changeable, some are not and some are reserved for future enhancements.

3.2.2.1 Version

The version parameter displays the unit‟s software version. It is a view only

parameter.

3.2.2.2 Belt Odo

This is the belt odometer reading in feet. To reset: press (and hold) the

enter key, then press (and hold) the up key for five seconds when the

number line is selected. The odometer reading will display in meters if the

Units are changed to metric. Note: divide meters by 1000 to get kilometers.

3.2.2.3 Test Mode

The „test mode‟ parameter allows the unit to run regardless of the „lost film

sensor‟. Test mode times out after 15 minutes.

3.2.2.4 Temp Low & Temp High

These parameters form the range in which an operator can set the sealer‟s

temperature setpoint, see section 2.2.1 . Both values are expressed as a

percentage of the sealer‟s range; from „full off‟ (0) to „full on‟ (100).

Temp Low can be set from zero to Temp High minus one.

Temp High can be set from Temp Low plus one to 100.

9

3.2.2.5 Air Low & Air High

These parameters form the range in which an operator can set the inflation

value, see section 2.2.2 . Both values are expressed as a percentage of the

blowers speed; from „full off‟ (0) to „full on‟ (100).

Air Low can be set from zero to Air High minus one.

Air High can be set from Air Low plus one to 100.

3.2.2.6 Speed

The speed parameter specifies the motor speed (i.e. how fast product is feed

through the unit). It is expressed as a percentage of „full on‟. The minimum

value is 50.

3.2.2.7 Start Delay

Start delay is the time between turning on the sealer‟s heater and starting of

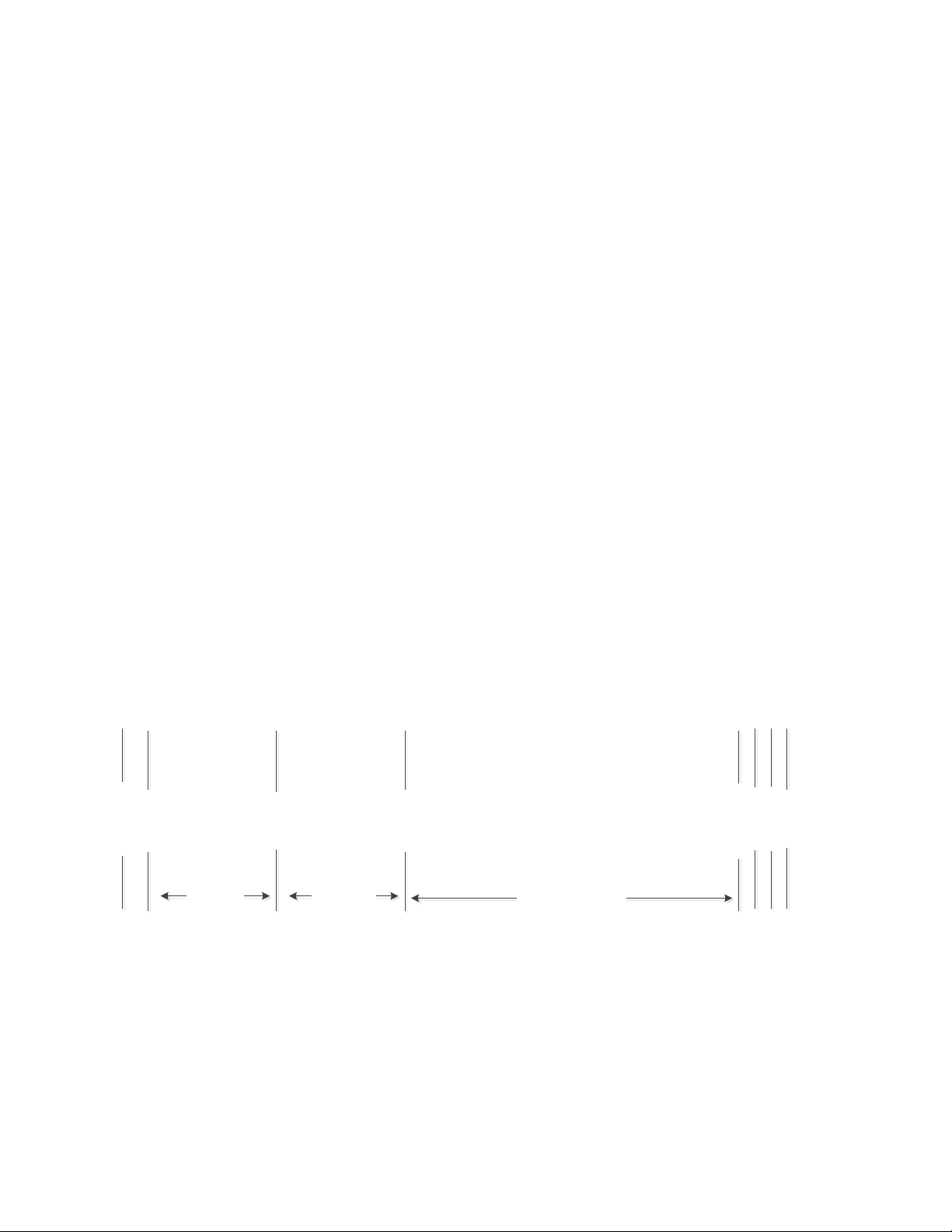

the motor, see

Figure 5

. Start delay can be 0 to 100. The Start delay is a

percentage and denotes how hot the sealer must be before turning on the

motor. Example, a Start delay of 75 means “turn the motor on when the

sealer reaches 75% of setpoint”. For sealer setpoint see section 2.2.1 .

Figure 5 Timing of „Start Delay‟ and „Air Offset‟

3.2.2.8 Air Offset

Air offset is the time between the blower starting and start of the sealer, see

Figure 5

. Air offset can be 0 to 999 milliseconds.

Blower On

Sealer On

Motor On

Start delayAir Offset

Sealer Off

Blower Off

Motor Off

Programmed Time

Time expires

Almost simultaneous

Play Pressed

10

3.2.2.9 Bin Sensor

This parameter selects the bin sensor. Set this parameter to OFF if no

sensor is present, IR if the infrared sensor is present and US if the Ultra

Sonic Bin sensor is present. See section 4.2 for a detailed explanation of

the bin sensors.

3.2.2.10 Sensor Delay

This parameter is the amount of time the bin sensor needs to be triggered

before the SMART machine will stop.

3.2.2.11 Units

This parameter changes the machine‟s units from English to Metric.

3.2.2.12 Language

This parameter is reserved for a future enhancement. Changing it has no

effect on the unit‟s operation.

11

SECTION 4 –OPTIONAL ACCESSORIES

4.1 Foot Pedal

The foot pedal operates the same as the play button. When the Time

Adjustment is set to 0:00 - pressing the foot pedal once starts the unit,

pressing a second time stops the unit. If the Time Adjustment is something

other than 0:00 then pressing the foot pedal will start the unit; the unit will

run for the given time or until the pedal is pressed again.

4.2 Bin Sensor

The bin sensor is used control the AirSpeed™ SMART as it fills an overhead

bin. The bin sensor will start the AirSpeed™ SMART when no product is

detected and will stop the SMART machine when product is detected. There

are two different sensors that work with the AirSpeed™ SMART, the flat pack

Infrared (IR) sensor and the Ultrasonic3(US) Sensor. The bin sensor is

binary. That is, the bin is either full or empty; there is no half full, quarter

full or any other indications.

When using a bin sensor the setup up of the device controls the AirSpeed™

SMART. The timer setting should be set to 0:00 for best results. A setting

other than 0:00 will lead to erratic machine cycles.

4.2.1 Infrared Sensor

The Infrared or Flatpack sensor –is the original sensor designed to work

with the AirSpeed™ SMART. The sensor has a sensitivity adjustment for fine

tuning material detection. The yellow LED will be turn ON when there is

material present and OFF when there is no material. Position the IR sensor

over the material. Follow the instructions in Section 3 for selecting the IR

sensor. Set the timer to 0:00 and press Play. When Play is pressed, if the

bin sensor shows empty the unit starts and continues until 1) play is pressed

or 2) bin sensor shows full. When the bin sensor shows empty the unit

starts again and the cycle repeats. When the play button is pressed, if the

bin sensor shows full, the unit waits until the sensor shows empty then

3At the time of writing the infrared sensor was a Carlo Gavazzi ED5506NPAP and the

ultrasonic sensor was a Pepperl & Fuchs UB1000-18GM7-75-U-V15.

12

starts. If the bin sensor shows full and the unit is powered down, when the

unit‟s power is restored, the unit automatically starts when the bin sensor

shows not full.

4.2.2 Ultasonic Sensor

The Ultrasonic sensor –is the original sensor designed to work with the

A5000 System. The AirSpeed™ SMART V3 was enhanced to include the

capability to use this sensor. The sensor has a required adjustment

procedure for configuring the sensor. Please read the

20120613 US Sensor

Training

document on the Pregis Tech Portal. The sensor is designed to turn

ON when there is material present and OFF when there is no material.

Position the Ultrasonic sensor over the material. Follow the instructions in

Section 3 for selecting the US sensor. Set the timer to 0:00 and press Play.

When Play is pressed, if the bin sensor shows empty the unit starts and

continues until 1) play is pressed or 2) bin sensor shows full. When the bin

sensor shows empty the unit starts again and the cycle repeats. When the

play button is pressed, if the bin sensor shows full, the unit waits until the

sensor shows empty then starts. If the bin sensor shows full and the unit is

powered down, when the unit‟s power is restored, the unit automatically

starts when the bin sensor shows not full.

13

SECTION 5 –UNIT BURN IN

5.1 Introduction

At unit power-up the controlling software interrogates a jumper on the

processor card. If the jumper is not installed the unit enters its „operational‟

state. If the jumper is installed the unit enters its „burn-in‟ state.

5.2 Operational State

The unit‟s „operational‟ state is everything describe up to this point. That is,

section 1 through section 4.

5.3 Burn-in State

The unit‟s „burn-in‟ state allows you to exercise the unit‟s components for an

extended period without an operator.

5.3.1 Overview

The burn-in state has three modes „idle‟, „run‟ and „sealer test‟. During „idle‟

the motor, sealer and blower are off. Button presses are shown on the

display as are changes in either the „lost film‟ or „bin‟ sensor‟. When play is

pressed the unit enters „run‟ mode. While in „run‟ the unit operates the

motor, sealer and blower for about one minute and then rests for about one

minute with the motor, sealer and blower off. The unit can be loaded with

product or not as the „lost film‟ sensor is ignored. The unit remains in „run‟

state changing from „run‟ to „rest‟ and back again continuously until the unit

is stopped or is powered-down.

The „sealer test‟ state is used to run the sealer from full-off to full-on and

back to full-off. Its purpose is to verify the drivers for the sealer before

plugging in the actual sealer. The actual sealer must NOT be plugged in;

you need to use the sealer simulator. The „sealer test‟ state is entered from

the „idle‟ state by switching DIP SWITCH #1 to the ON position. As long as

the switch is on, the sealer is cycled between full-off and full-on and back to

full-off. When the switch is turned off, the sealer test exits after completing

a cycle.

14

5.3.2 Selecting between Bin Sensors

Once the unit has entered burn-in mode the jumper (JP2) is reassigned to

be a „bin sensor select‟. If the jumper is installed the burn-in software looks

for the Infrared sensor. If the jumper is not installed the burn-in software

looks for the Ultrasonic sensor.

5.3.3 Initial Change from Idle to Run

When burn-in starts, the unit is placed into „idle‟ and remains there until the

play button is pressed. At this time the unit changes to „run‟ and the

operation discussed in the section 5.3.1 commences.

5.3.4 Stopping Unit

To stop the unit from cycling between „rest‟ and „run‟ press the play button.

The unit goes „idle‟ but will not restart until the play button is pressed again.

5.3.5 Sample Display –Idle

Two sample „idle‟ displays are shown in

Figure 6

. The top display is

immediately after pressing the UP arrow button and the bottom immediately

after pressing the MENU button.

Figure 6 Last Button Pressed is Displayed

UNIT TEST V 1.51

UP

UNIT TEST V 1.51

MENU

15

5.3.6 Sample Display –Run

A sample „run‟ display is shown in

Figure 7

. The display shows the sealer

temperature and the time remaining in the „run‟ state

Figure 7 Sample Running Display

5.4 Selecting between „Operational‟ and „Burn-in‟ Modes

The jumper plug JP2 on the cpu board is used to select between

„Operational‟ and „Burn-in‟ modes. When the two pins of JP2 are shorted,

„Burn-in‟ mode is selected. When open the „Operational‟ mode is selected.

NOTE: This jumper is also utilized to select which bin sensor is active during

„Burn-in‟ mode only.

SEALER TEMP: 215.5

RUN STATE 420

16

SECTION 6 –LOADING NEW SOFTWARE

6.1 Introduction

At power-on the AirSpeed™ Smart‟s Bootloader executes. This bootloader is

used to update the unit‟s application software. If the bootloader does not

detect new software, the existing application software is started.

6.2 Procedure

1. The new software is stored on a USB memory stick.

2. Power off the unit

3. Open the unit and install the USB memory stick into the control board.

4. Install jumper JP2

5. Power on the unit.

6. After a few seconds the bootloader recognizes the USB stick and loads

the new software.

7. After software is loaded, it is started and enters the unit „burn-in‟.

8. Power off the unit

9. Remove jumper JP2

10. Remove the USB memory stick

11. Power on unit and verify that the unit is operational. That is, it is not

in unit „burn-in‟.

Notes:

You must install both the USB memory stick and JP2 as the bootloader looks

for the USB memory stick only if JP2 is installed.

Table of contents

Other Pregis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Festo

Festo CP-AM-MEAS Original operating instructions

Endress+Hauser

Endress+Hauser Liquiphant M/S FTL5 Series operating instructions

Once

Once BioShift Single Door UV-C Germicidal Chamber instruction manual

ABB

ABB A145-M65 Operation manual

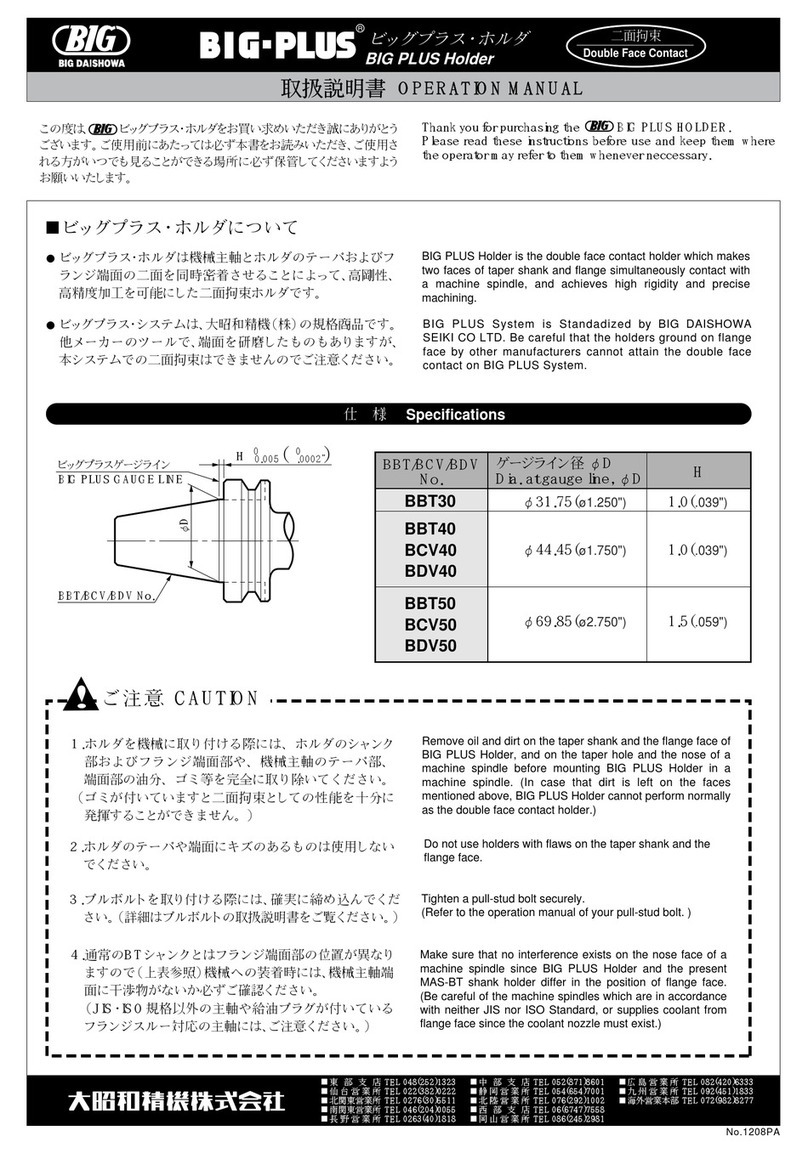

Big Daishowa

Big Daishowa BBT30 Operation manual

MG

MG M8YS1 instruction manual