Pregis AirSpeed Ascent User manual

AirSpeed®Ascent

Air Cushion Machine

Operator Manual

Safety and Operation

Revision 4

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation ii

All Rights Reserved

CONTENTS

1SPECIFICATIONS...............................................................................................................................1

1.1 Sound Test Declaration.................................................................................................................1

2OPERATING SAFETY........................................................................................................................2

2.1 Safety ............................................................................................................................................2

2.2 Warning Labels.............................................................................................................................3

3SCOPE AND LIMITS..........................................................................................................................4

3.1 Introduction...................................................................................................................................4

3.2 Inputs and Outputs........................................................................................................................5

3.2.1 Compatible Accessories........................................................................................................5

3.3 Dismantling...................................................................................................................................5

4GENERAL OPERATION ....................................................................................................................6

4.1 Setting up the Machine .................................................................................................................6

4.1.1 Mounting Options.................................................................................................................6

4.1.2 Installing Feet and Mounting Hardware ...............................................................................6

4.1.3 Installing Air Pump...............................................................................................................7

4.1.4 Power On ..............................................................................................................................7

4.2 Changing Film ..............................................................................................................................8

4.2.1 Loading Film.........................................................................................................................8

4.2.2 Removing Film .....................................................................................................................9

4.3 Starting the Machine.....................................................................................................................9

4.3.1 Initial Startup ........................................................................................................................9

4.3.2 Running Film ........................................................................................................................9

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation iii

All Rights Reserved

5ADVANCED OPERATION...............................................................................................................10

5.1 Home Screen...............................................................................................................................10

5.1.1 RFID Recipe Overview.......................................................................................................10

5.2 Table of Symbols........................................................................................................................11

5.3 Fill Mode Adjustments ...............................................................................................................13

5.4 Air Level and Temperature Adjustments....................................................................................13

6TROUBLESHOOTING......................................................................................................................14

6.1 Error Codes.................................................................................................................................14

6.1.1 Resolving Errors .................................................................................................................14

6.2 Clearing Jams..............................................................................................................................15

6.3 Other Items..................................................................................................................................15

6.3.1 Wrinkled Seal......................................................................................................................15

6.3.2 Jamming at Startup..............................................................................................................15

6.3.3 Popping Seal Section ..........................................................................................................15

6.3.4 Pillow Pops Off Air Tube ...................................................................................................15

6.3.5 Flat Pillows .........................................................................................................................16

6.3.6 Tearing at Seal ....................................................................................................................16

6.3.7 Perforation Failure ..............................................................................................................16

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation iv

All Rights Reserved

Property of the Pregis Corporation

1650 Lake Cook Road

Suite 400

Deerfield, IL 60015

United States of America

Authorized CE Representative

ACC –Services Contact

1877 Kirby Lane

Kyle, Texas 78640

United States of America

AirSpeed®Ascent

120/230 VAC, 6.6/3.3 A, 60/50 Hz

Weight (without air pump): 31 lbs / 14.1 kg

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation v

All Rights Reserved

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation vi

All Rights Reserved

LANGUAGES OF OPERATION DISCLAIMER

It is illegal to operate this machine in an EU member state if this (or any other related) manual is not

written in that State’s language. If a translated version is needed, contact Pregis to order the manual.

The original version of this manual is in English and denoted “Original Instructions” in the top right

corner. All translated versions are denoted “Translation of Original Instructions” in the same

location.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 1

All Rights Reserved

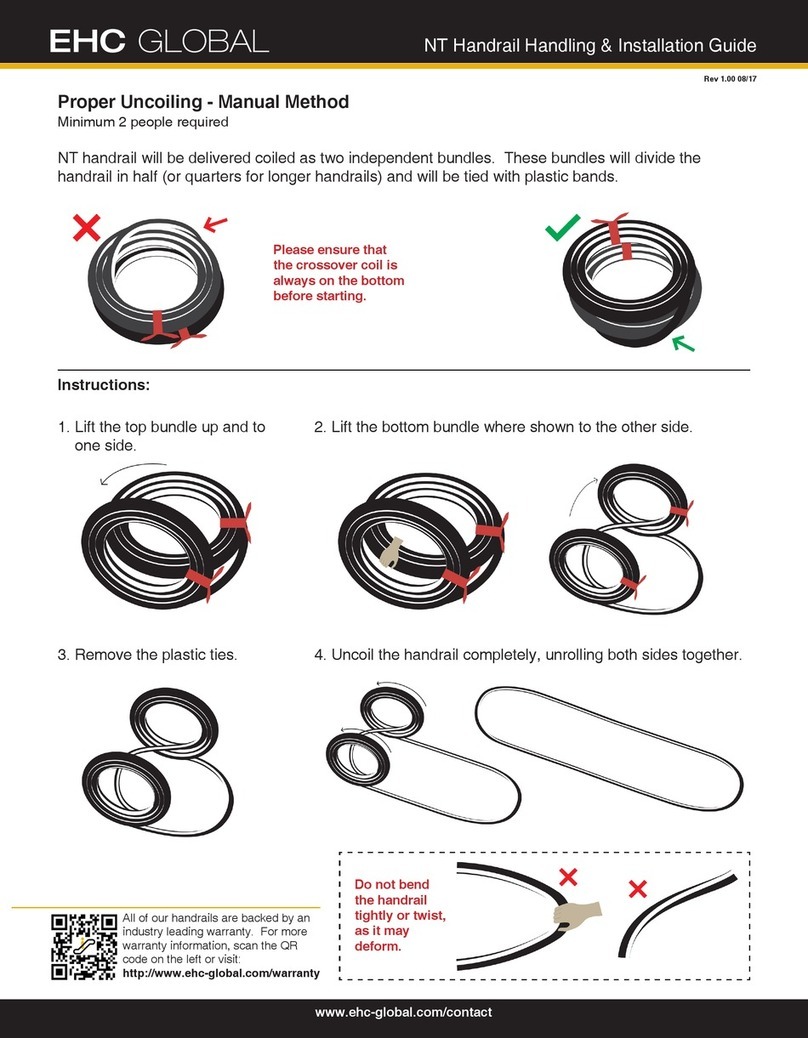

1SPECIFICATIONS

Machine

Weight (without the air pump): 31 lbs / 14.1 kg

Overall Size (L x W x H): 19.0 x 22.5 x 17.2 in / 482 x 570 x 438 mm

Power: 120/230 VAC, 6.6/3.3 A, 60/50 Hz

Production Speed: 100 feet per minute / 30.5 meters per minute

Air Pump

Weight: 28 lbs / 12.8 kg

Size (L x W x H): 10.7 x 8.9 x 9.7 in / 272 x 226 x 247 mm

1.1 Sound Test Declaration

The equivalent sound pressure level Leq at the operator station is 74 dB(A).

Figure 1. Machine dimensions.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 2

All Rights Reserved

2OPERATING SAFETY

AirSpeed®Ascent

Air Cushion Machine

Operator safety and the safety of others in the work area depend on the operator using common sense,

good judgment and reasonable care while operating the machine. The Safety, Operation and

Maintenance manual, and warning labels affixed to the machine, provide notification of specific

potential hazards.

2.1 Safety

The following instructions are only a guideline and should be considered a supplement to your plant's

comprehensive safety program. Your company’s policy supersedes these guidelines if at any time

the two contradict each other.

1. Read and understand the manual. If after reading the manual you have questions, get answers

before working with the machine.

2. Read and understand all the danger, warning, and caution statements in the manual and on the

signs attached to the equipment.

3. Never deface or remove factory installed warning decals. If a decal ever becomes lost,

damaged, or illegible, report this condition to a supervisor and obtain a replacement decal.

4. Keep the work area clean and uncluttered. Walking surfaces should always be free of packing

material and debris to prevent a slipping or tripping hazard.

5. Ensure that all covers, guards, and other safety devices are in place. Never remove a safety

device for any reason.

6. Follow the manufacturer's recommended startup procedure.

7. Never leave the equipment unattended while operating. Shut the machine off if you must leave

the work area.

8. Keep body parts and clothing away from moving components. Ties, scarves, long hair, and

gloves are especially dangerous.

9. Understand what will happen when you operate the various controls.

10. Understand the proper web path and the safe method for threading the web.

11. Learn the safe procedure for clearing the machine of web wraps or jams.

12. Exercise extreme care whenever it is required to inspect or adjust the machine while it is in

motion. NEVER reach into the machine for any reason while it is in motion.

13. Understand which adjustments are operator adjustments; only trained and qualified service

personnel may maintain/clean any electrical and or mechanical part of the machine.

14. Never operate or work around equipment if you are under the influence of alcohol, drugs or

medications that can make you less alert or affect your judgment.

15. The machine shall be used in a facility adequately ventilated for air renewal.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 3

All Rights Reserved

2.2 Warning Labels

The Operating Safety section of this manual, the Operator manual, and warning labels affixed to the

machine provide notification of specific potential hazards.

Safety signs are used to alert operating and maintenance personnel to potential hazards. The machine

manual also calls attention to potential hazards with statements describing the hazard. Warning labels

used on the machine are depicted below.

Electric Shock

Hot Surface

Refer to Instruction Manual

The meanings of the warning labels and the potential hazards they represent must be clearly

understood before attempting to operate or maintain the machine. If, at any time, a warning label on

the machine becomes lost, damaged, or illegible, contact Pregis to order replacement signs.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 4

All Rights Reserved

3SCOPE AND LIMITS

AirSpeed®Ascent

Air Cushion Machine

3.1 Introduction

The Pregis AirSpeed®Ascent produces panels of air-filled packing cushions in any quantity, as

needed. The ability to create packing cushions on demand saves storage space and reduces packaging

material waste.

Supported film rolls have a maximum size of the following:

Figure 2. Supported roll dimensions.

Use of the machine for any purpose –other than stated –may cause severe injury to the

operator and/or damage to the machine.

32.25" Width

9.25" Diameter

38 lbs Weight

3" Paper Core

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 5

All Rights Reserved

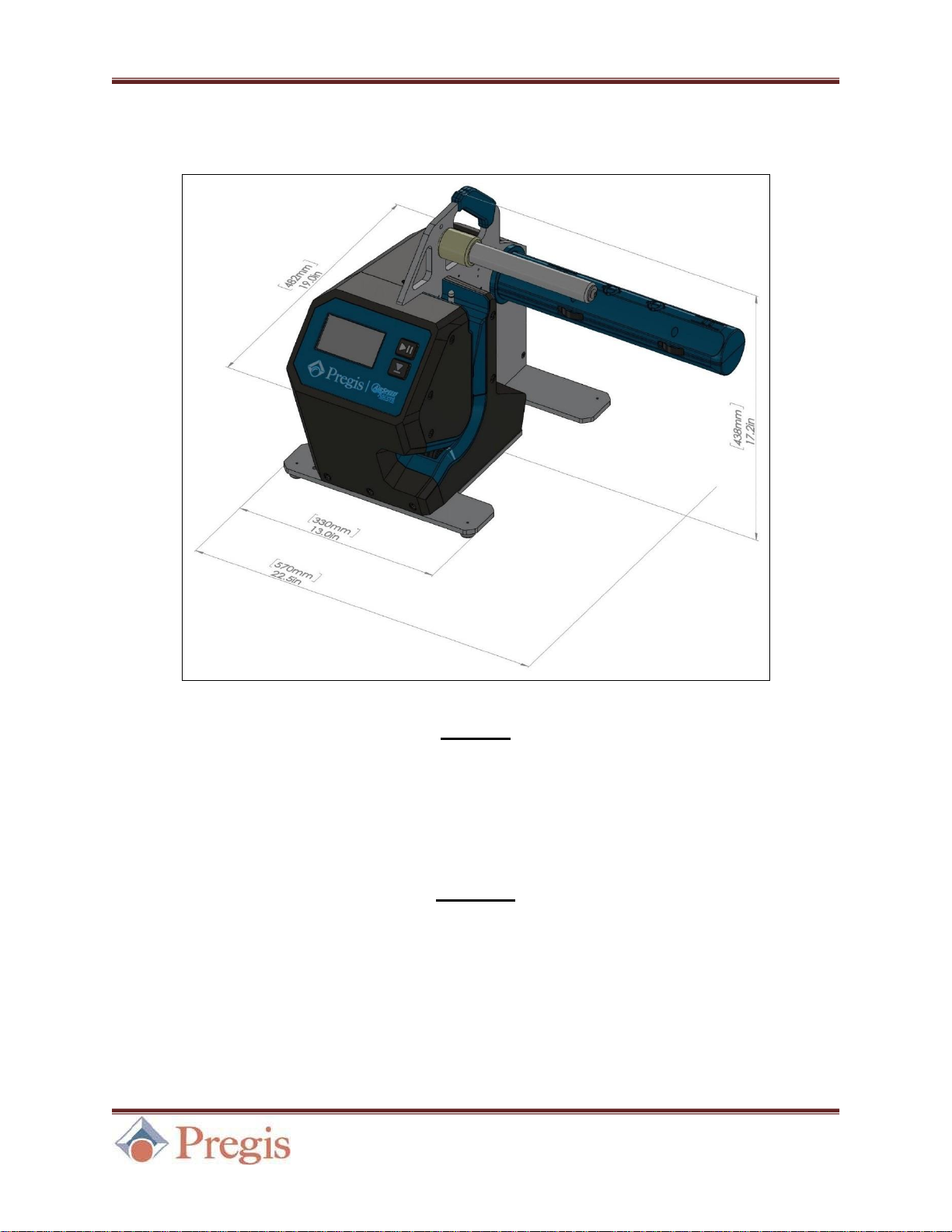

3.2 Inputs and Outputs

3.2.1 Compatible Accessories

For a list of accessories compatible with the AirSpeed®Ascent, see the Pregis Systems Catalog.

3.3 Dismantling

Upon dismantling of this system at the end of its service life, please follow the

local recycling laws and regulations in effect at that time.

Programming Port

Power Switch

Power Input

Accessory Port I/O

Power Output to

Air Pump

Air Hose Input

Figure 3. Inputs and Outputs.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 6

All Rights Reserved

4GENERAL OPERATION

4.1 Setting up the Machine

4.1.1 Mounting Options

The machine can be mounted either horizontally, vertically, or on a “C” frame. Horizontal mounting

utilizes a floor stand with casters for ease of movement. Place the machine on the stand and secure

with (4) M8 bolts (SAP# 1031638).

Optionally, the machine can be mounted vertically on a frame with an attached bin, called a “C”

frame. The “C” frame is mounted on casters for ease of movement.

Vertical mounting utilizes a baseplate to assist in mounting to a vertical plane. This configuration is

ideal for use with overhead delivery systems.

4.1.2 Installing Feet and Mounting Hardware

To install the feet (SAP# 1027857, 1027881) or mounting hardware (SAP# 1031638), reference the

figure below.

Note: If the machine is used without a stand or frame, ensure that the four rubber feet are fastened

to the base of the machine.

Figure 4. To remove or fasten the four rubber feet,

use a 3mm hex wrench. (Two out of four shown.)

Figure 5. To mount the machine to a stand or frame,

use a 6mm hex wrench.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 7

All Rights Reserved

4.1.3 Installing Air Pump

Securely attach the Air Pump to the Air Hose using a slotted screwdriver or a 1/4" hex driver. Then

attach the Air Hose and Air Pump power to the rear of the machine. See Section 3.2.

4.1.4 Power On

Plug the AC power cord into the back of the machine. Insert power cord into a suitable outlet. Power

the machine on or off using the Power Switch on the rear of the machine. See Section 3.2.

DO NOT POWER ON MACHINE UNTIL IT IS SECURED.

Figure 6. Attaching Air Hose to Air Pump.

Figure 7. Connecting Air Pump to rear of machine.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 8

All Rights Reserved

4.2 Changing Film

4.2.1 Loading Film

Figure 8. With the air channel first,

slide the film roll onto the Spindle.

Figure 9. Firmly press the roll to the end of the

Spindle, up against the flange.

Figure 10.Pull the film off the roll

and over the Guide Roller.

Figure 11.Thread the Air Tube into the air channel.

Figure 12.Pull the film forward to the Backing

Wheel (larger, red wheel).

Figure 13. While holding down the Jog button, pull

the film past the Nip Roller (lower, black wheel).

Jog Button

Start/Stop Button

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 9

All Rights Reserved

4.2.2 Removing Film

4.3 Starting the Machine

4.3.1 Initial Startup

Upon startup, the machine will require user interaction to warm up. Once this step is complete, the

machine will be ready to run film.

4.3.2 Running Film

To run film through the machine, first follow all prior steps outlined in Section 4. To start the

machine, press the physical or touchscreen Start/Stop button. See Section 5.2.

Figure 14.Tear the film along a perforation between

the roller and the air channel.

Figure 15.Use the Jog button to pass the remainder

of the film through the machine.

Figure 16.Wake up the machine by pressing the

Wake from Seep Button.

Figure 17.Wait for the heater to warm up. Progress

is displayed on the right side of the screen.

Jog Button

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 10

All Rights Reserved

5ADVANCED OPERATION

5.1 Home Screen

Each item displayed below is described in the Table of Symbols, located in Section 5.2.

5.1.1 RFID Recipe Overview

The recipe (preset operating parameters) for each film type is automatically loaded from the RFID

tag on the roll. Air Level and Temperature settings are adjustable within a predefined range.

See Section 5.4.

Start/Stop Button

Seal Temperature

Button

Run Time/

Length Button

Figure 18.Home Screen.

Seal Temperature

Indicator

RFID Film Type

Fill Mode Button

Air Level Button

Production

Speed Setting

Product Select

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 11

All Rights Reserved

5.2 Table of Symbols

Symbol

Name

Description

Sleep/Wake Symbol

Displayed on startup, this symbol indicates

whether the machine is in Sleep Mode. See Section 4.3.

Wake from Sleep

Button

Use this button to wake the machine from Sleep Mode.

See Section 4.3.

Progress Bar

Function progress is displayed on the right side of the

screen for various processes, including Wake from Sleep.

Start/Stop Button

Use this button to Start the machine. While the machine is

running, this turns into a Stop button able to stop the

machine if pressed. See Section 5.1.

Start/Stop Button

(Physical)

The physical Start button performs similarly to the

touchscreen button. It is located near the lower right corner

of the front panel. See Figure 13 in Section 4.2.

Jog Indicator and

Button

The Jog button is used to load film. Hold the touchscreen

Start/Stop button for 3 seconds access the Jog feature.

Alternatively, use the physical Jog button.

Jog Button (Physical)

The physical Jog button is used to load film. It is located

near the upper right corner of the front panel.

See Figure 13 in Section 4.2.

Back Button

The Back button allows the user to return to the Home

Screen.

Fill Mode Button

This button brings up the Fill Mode menu. Depending

on fill mode, length/time per run can be set be pressing the

Run Time/Length button. See Section 5.3.

Run Time/Length

Buttons

Once a mode is selected in the Fill Mode menu,

length/time per run can be set by pressing either indicator.

See Figure 20 in Section 5.3.

Run Time/Length

Indicator

Once Run Time or Length is selected in the Fill Mode

menu, the appropriate indicator will display on the Home

Screen.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 12

All Rights Reserved

Symbol

Name

Description

Seal Temperature

Indicator and Button

By selecting the Seal Temperature button, one can adjust

the sealing temperature. Once set, the Seal Temperature

Indicator will blink until the machine is ready.

Wait Symbol

The Start/Stop button will turn into a Wait symbol while

a temperature change is in progress. See Section 5.1.

Air Level Button

By selecting the Air Level Button, one can adjust the air

level. See Section 5.1.

Production Speed

Button

By selecting the Production Speed button, an authorized

user can adjust the production speed. This setting is not

customer adjustable. See Section 5.1.

RFID Film Type

Indicator

This indicates the detected RFID Film Type and is located

to the right of the Fill Mode button. See Section 5.1.

Enter/Delete Key

When changing a value via the Keypad, use the Enter Key

to save the displayed value. The Delete button can be used

to erase numbers as needed.

Keypad and

Level Visualizer

When changing a setting such as Fill Mode, Seal

Temperature, or Air Level, use the keypad to change the

value. The Level Visualizer will display the range of

acceptable values.

Bin Mode Toggle

If the machine is attached to a bin, this setting will be

enabled. This setting is not customer adjustable.

Bin Mode Indicator

This indicates that Bin Mode is enabled when/if the

machine is attached to a bin.

Bin Empty/Full

Indicator

While in Bin Mode, indicators will activate if the bin is

empty or full.

Winder Enabled

This indicates that Winder Mode is enabled when/if the

machine is attached to a winder.

Winder Idle /

Threading Indicator

While in Winder Mode, indicators will activate if the

winder is idle or threading.

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 13

All Rights Reserved

5.3 Fill Mode Adjustments

Pressing the Fill Mode button brings up the Fill Mode Selection menu.

After desired value is entered, click the Enter key and return to the Home Screen using the Back

button. Continuous Mode can be activated by entering zero (“0”) for either setting in Time or

Length modes. In this mode, the machine will run until stopped by the user.

5.4 Air Level and Temperature Adjustments

Pressing the Air Level button and Seal Temperature button opens the Blower Setting and Seal

Drum Setting menus, respectively.

Figure 19.The Fill Mode Selection menu allows the

user to toggle between length and time per run.

Figure 20.Both length and time per run can be

adjusted by selecting the Run Time/Length

icon.

Figure 21.Length mode allows the user to select set

length of pillow whenever the

Start

button is pressed.

Figure 22.Time mode has a similar function, but

run time is determined in minutes and seconds.

Figure 23.Input the desired value, click the Enter key, return to the Home Screen using the Back button.

Back

Button

AirSpeed®Ascent Operator Manual Tech Service Hotline: 886-904-6979 Original Instructions

November 2020

Copyright Pregis Corporation 14

All Rights Reserved

6TROUBLESHOOTING

6.1 Error Codes

Code

Name

Cause

Solution

*136

CM Power

Fault <CR>

See Manual

AC Common Mode Error detected.

Latching Error

Check all AC wiring and components.

Power cycle the machine.

250

Film Jam

Error /

Film NOT

Advancing

Roll is out of film

Replace with full roll. See Section 4.2.

Material not properly threaded onto

air tube

Ensure material is properly threaded onto

air tube. See Section 4.2.

Material is jammed

Clear jam if possible. See Section 6.2.

460

RFID Error:

No Tag

No RFID tag detected

Rotate roll of material.

Verify material type.

Load an alternate roll of material.

462

RFID Error:

Invalid

Material

RFID tag detected is not for the

Ascent Machine

Verify material type.

Power cycle the machine.

Load an alternate roll of material.

464

RFID Error:

Bad Tag

Status

RFID tag detected is not readable

Rotate roll of material.

Power cycle the machine.

Load an alternate roll of material.

466

RFID Error:

Bad

Checksum

RFID tag detected has a bad

checksum

Rotate roll of material.

Power cycle the machine.

Load an alternate roll of material.

468

RFID Error:

No Recipe

RFID tag detected has no recipe on

the Ascent Machine

Load an alternate roll of material.

Load latest recipe set.

470

RFID Tag

Error:

Invalid Tag

Invalid number of Blocks on RFID

Tag, may be corrupted

Rotate roll of material.

Power cycle the machine.

Load an alternate roll of material.

*Note: Error 136 may present during power surges or lightning events. This is expected behavior.

Power cycle the machine to restore operation in this event.

6.1.1 Resolving Errors

Errors displayed that are not described above should be resolved by attempting the following steps.

(For Error 136 start with item 2.)

1. Clear the error. Remove the machine from sleep or start a cycle.

2. Locate the power switch on the rear of the machine and restart the machine. Start a cycle after

allowing the machine to heat.

3. Power off the machine and remove the power cord for 30 seconds. Plug back in the power

cord and repower the machine. Start a cycle after allowing the machine to heat.

4. If a problem persists, call Technical Services at 886-904-6979.

Table of contents

Other Pregis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

DESSALATOR

DESSALATOR PRO COMPACT D300 Assembly and user's manual

FLENDER

FLENDER FASTEX IC250 Assembly and operating instructions

Uniflex

Uniflex UA 4 Operation manual

JohnDow Industries

JohnDow Industries JDI-AF10E owner's manual

Jäger

Jäger Z33-D060.12 S15A manual

GSI Group

GSI Group SCR Series instruction manual