Pregis MINI PAK'R V3 User manual

MINI PAK`R®V3 air cushion system

USER MANUAL V1.1 (Original Manual)

Pregis LLC

www.pregis.com

Heerlen, The Netherlands

Deerfield, Illinios USA

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 2 of 21

This product is compliant with Directive 2012/65/EC, Restriction of Hazardous

Substances.

Disposal: Power tools, accessories and packaging should be sorted for

environmental-friendly recycling.

Only for EC countries: Do not dispose of power tools into household waste!

According to the European Directive 2002/96/EC on waste electrical and

electronic equipment and

It`s incorporation into national law, products that are no longer suitable for use

must be separately collected and sent for recovery in an environmentally-friendly

manner.

Official agency certifications, declaration documents, and RoHS position statements are

available upon request or by visiting our website at www.pregis.com.

Table of content:

Box Contents ............................................................................................................................. 3

Technical Data........................................................................................................................... 4

Safety instructions...................................................................................................................... 4

Machine Parts............................................................................................................................ 5

Film roll ...................................................................................................................................... 5

Loading a film roll....................................................................................................................... 6

Connecting power .................................................................................................................. 6

Film loading............................................................................................................................ 6

Threading the Film.................................................................................................................. 7

Advance film........................................................................................................................... 7

Rotating control panel ................................................................................................................ 8

Disconnect power................................................................................................................... 8

Open cover............................................................................................................................. 8

Basic operation .........................................................................................................................12

Start production.........................................................................................................................12

Sleep mode...............................................................................................................................13

Machine settings .......................................................................................................................13

Changing Machine Settings...................................................................................................13

Length control........................................................................................................................13

Continuous Mode ..................................................................................................................13

Number of Cushions..............................................................................................................13

Air control ..............................................................................................................................14

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 3 of 21

Seal temperature control .......................................................................................................14

Maintaining MINI PAK’R V3 ......................................................................................................15

Risk of Burn!..........................................................................................................................15

Improving slit performance ....................................................................................................15

Display codes ...................................................................................................................... - 17 -

Error codes .......................................................................................................................... - 17 -

Electrical Schematic............................................................................................................. - 19 -

CE Declaration..................................................................................................................... - 21 -

Box Contents

As you unpack the box, you will find the following:

•MINI PAK’R V3®air cushion system

•Power Cord

•User Manual or USB Stick with documentation

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 4 of 21

Technical Data

The MINI PAK’R V3 air cushion system (“the machine” or “the system”) creates air cushions on-

demand for use as cushioning, protective wrap, and general transport packaging. Strict

compliance with the safety instructions are required to ensure personal safety. (See Safety

Instructions in this manual)

Specification

Film roll product

Preconfigured MINI PAK’R V3 film

Production Rate

12 meters per minute (40ft./minute)

Power Rating

Model # MM2I2IN230 – 230V, 2.5A

Mode l# MM212IN115 – 115V. 5.0A

Machine Dimensions

37cm (14.6”) wide X 36cm (14”) long X 30cm (11.8”) tall

Recommended Power Fuse

5mm X 20mm, Slow-Blow: 250V 2.5A (230V System)

5mm X 20mm, Slow-Blow: 250V 5.0A (115V System)

Machine Weight

8 kg (17.6 lbs.)

Sound pressure

< 70dbA

Safety instructions

To ensure the personal safety of operating personnel and/or users of this machine, the

instructions below must be followed at all times.

1. The machine may only be used in industrial applications. Usage in a home or office

environment is excluded.

2. The machine shall be used in a facility that is correctly ventilated for air renewal.

3. Avoid all contact with internal electrical components.

4. In case of emergency, switch off the machine and disconnect power.

5. If the machine is not used for any length of time, the Power Switch must be turned OFF

at the rear of the machine.

6. During Installation and Maintenance, the Power Switch must be in the OFF position, with

the Power Cord disconnected.

7. All safety and protection measures must be fitted and adequately maintained in

accordance with Iocal regulations.

8. Only trained and qualified service personnel may maintain any electrical and or

mechanical part of the machine.

9. During machine operation, NEVER touch the film at its point of entry into the machine.

Do not attempt to guide the film into the machine. Injury may result.

10. Under no circumstances may any installed safety feature be overridden.

11. After loading the Film Roll, the machine will automatically adjust to the right seal

temperature for the film. Any contact with the heating element must be avoided

(or any part in direct contact with the heating element), since it may remain hot for

several minutes after the machine has been switched OFF.

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 5 of 21

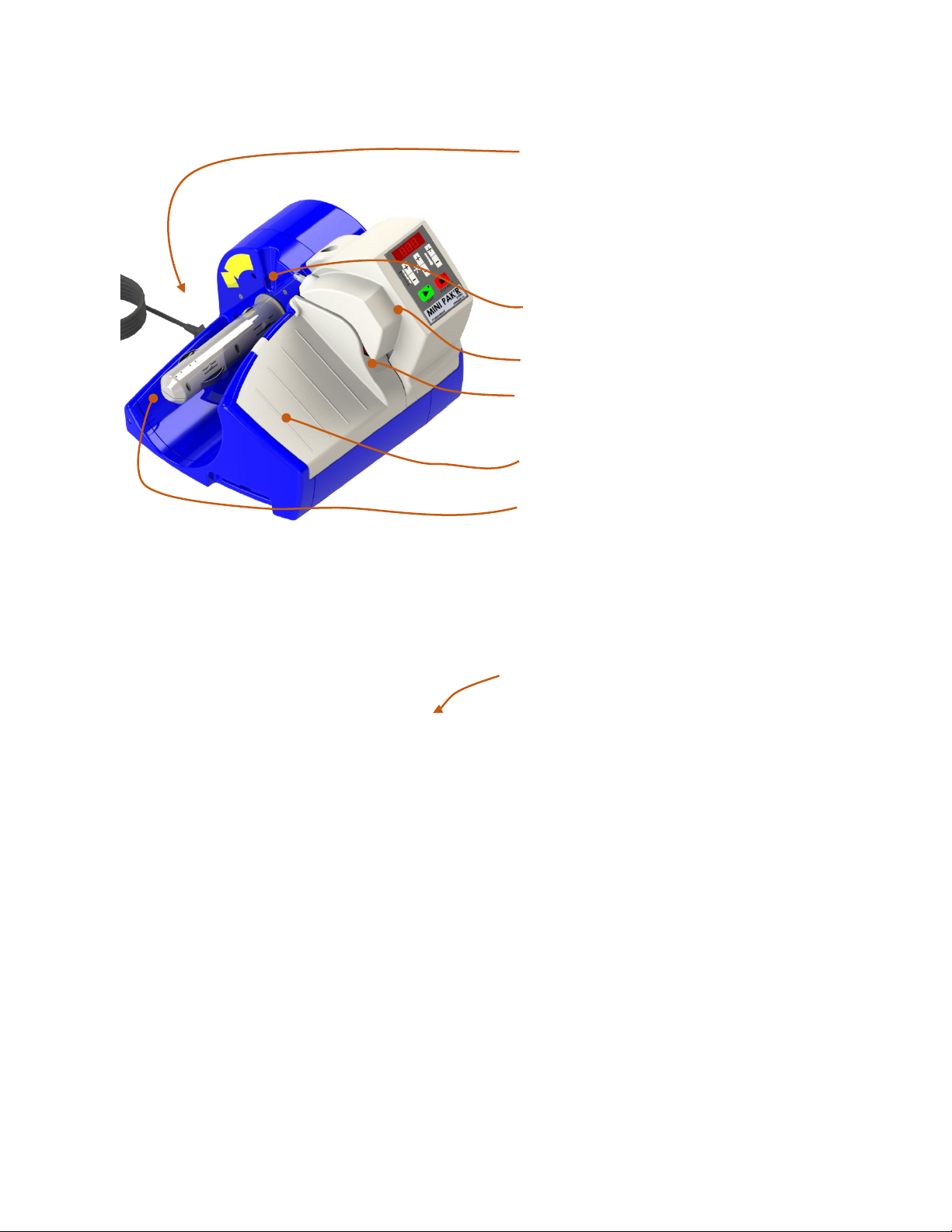

Machine Parts

1. Power cord, power switch,

fuse

2. Air filling tube

3. Control Panel

4. Upper seal cover

5. Lower seal cover

6. Film roll holder

Film roll

1. Film

2. Opened air channel

3. Film core

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 6 of 21

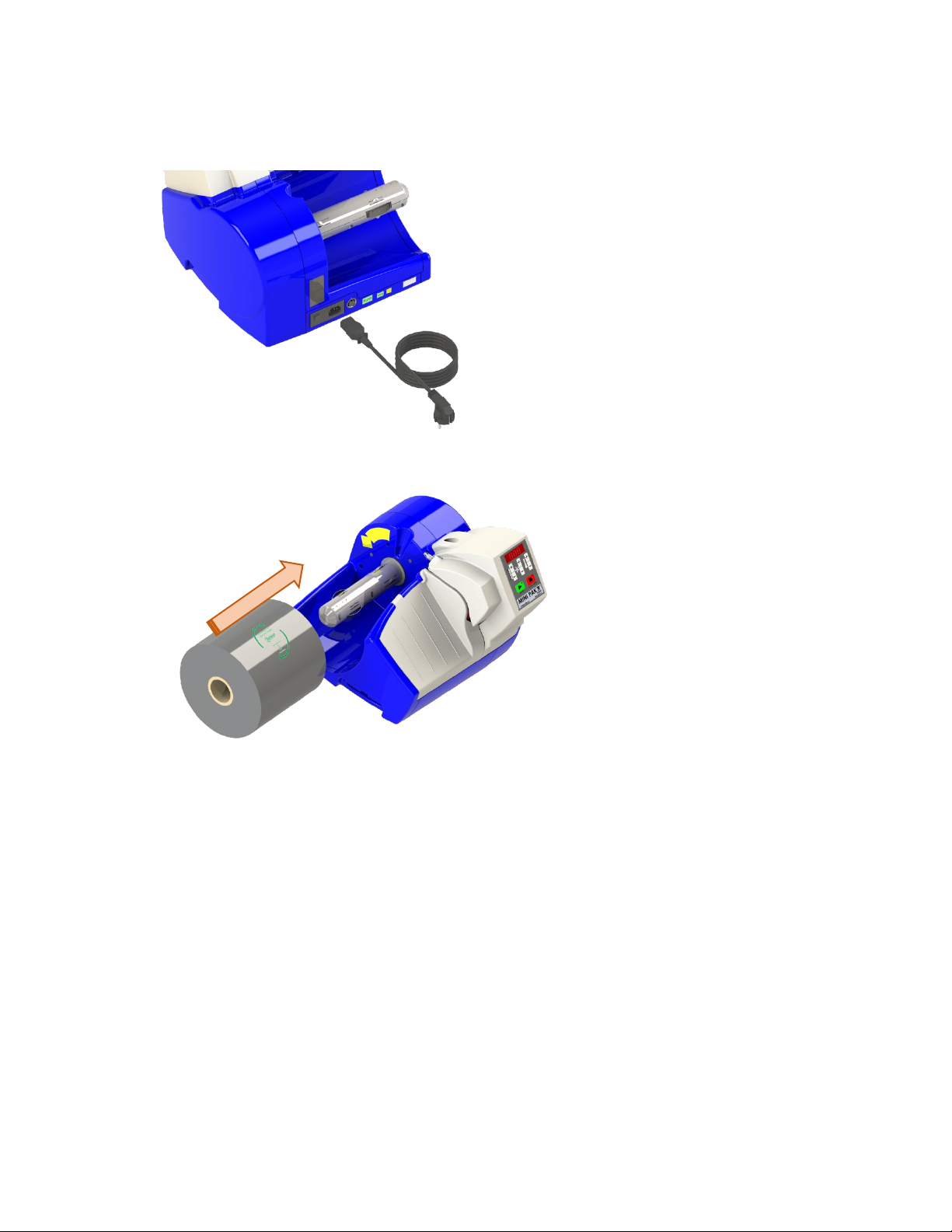

Loading a film roll

Step1:

Connecting power

1. Insert provided Power Cord

into the rear of the

machine.

2. Plug Power Cord into a

dedicated, grounded outlet.

3. Switch machine power ON

(I).

Step 2:

Film loading

Push Film Roll onto the Roll

Holder (with the film feeding off

the top of the roll as shown)

until it seats firmly.

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 7 of 21

Step 3:

Threading the Film

Open the Air Channel at the

right side of the Film Roll.

Slip the Air Channel over

the end of the Air fill tube.

Step 4:

Advance film

1. Advance film up to

bend

2. Push play and hold

3. Guide film through

the MINI PAK`R V3

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 8 of 21

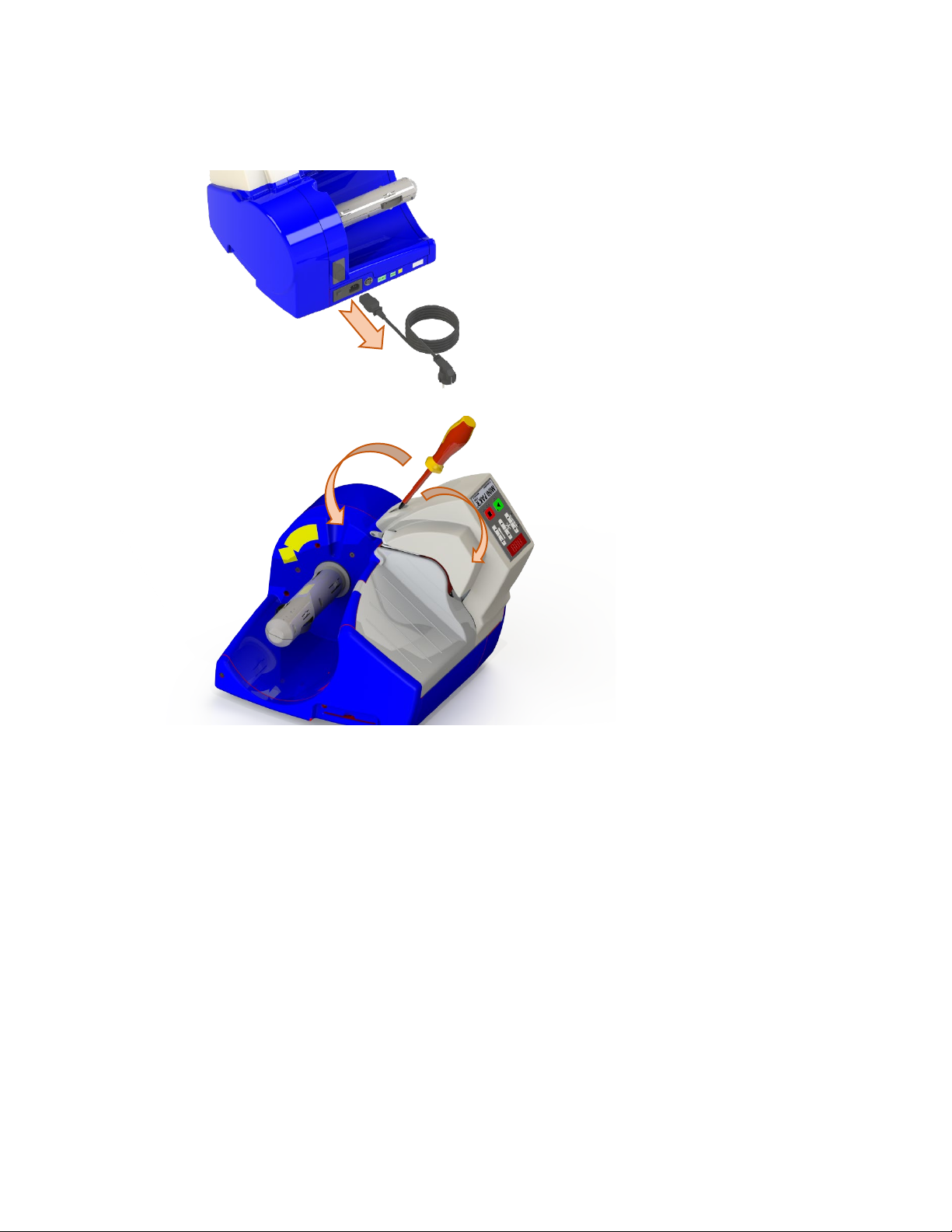

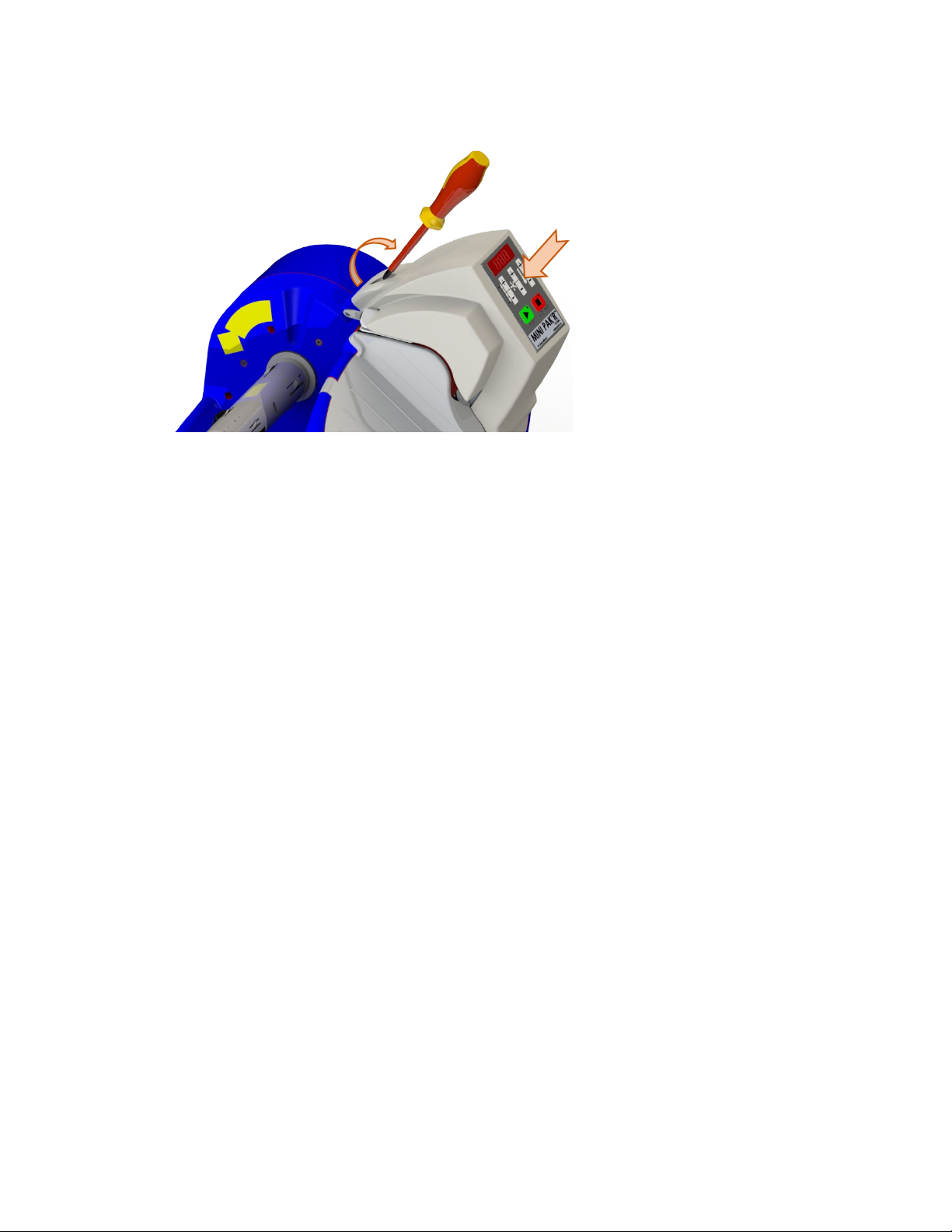

Rotating control panel

Step1:

Disconnect power

1. Switch machine power OFF

(0)

2. Remove power cable

Step 2:

Open cover

1. Unscrew cover lock with

screwdriver

2. Open top cover

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 9 of 21

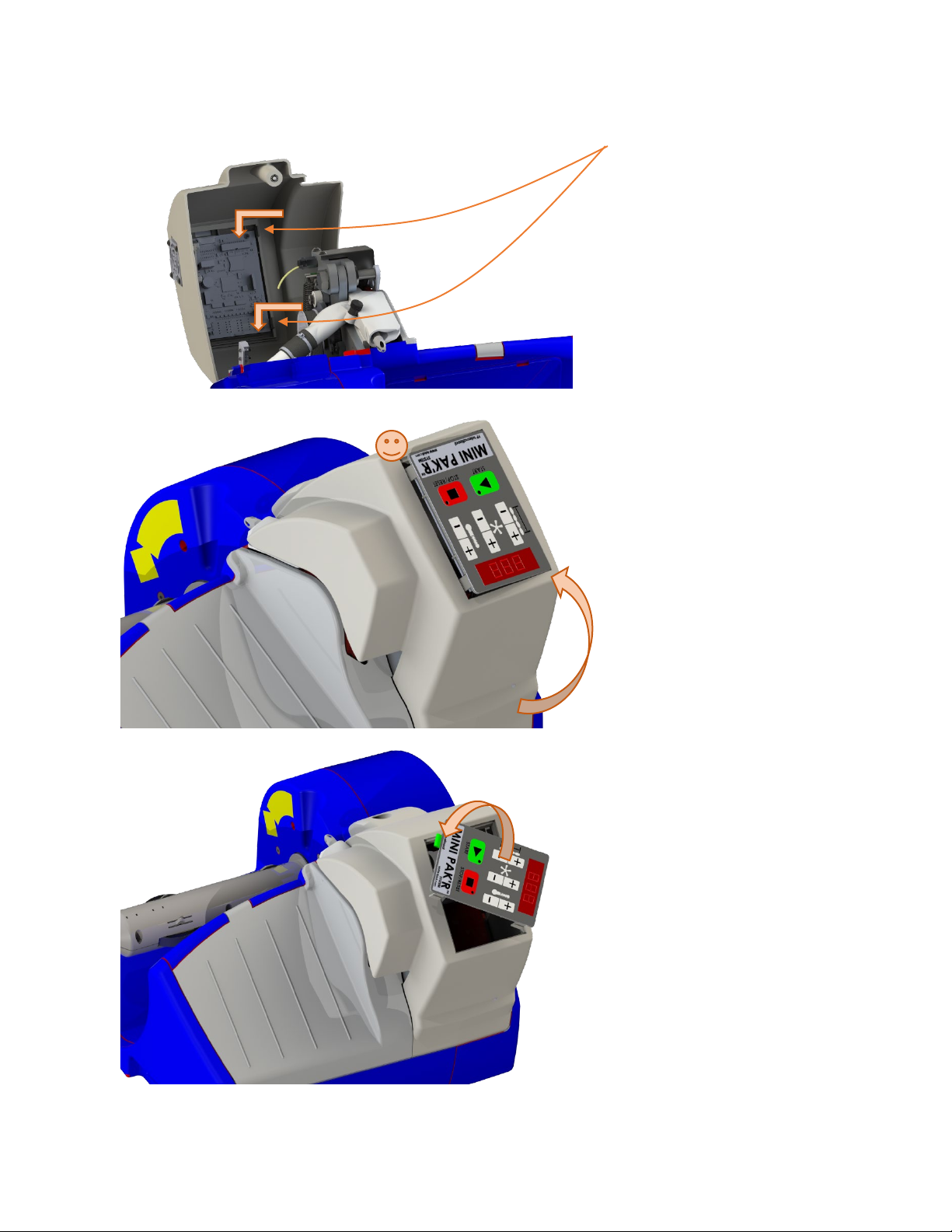

Step 3:

Unclick control panel

Push lips to the left and push

down to move the panel out of the

top cover

Step 4:

Close top cover

1. Close the top cover

2. Check if control panel can

be grabbed from the

outsize

Step 5:

Rotate control panel

1. Gently take the display

out of the top cover

2. Do not pull or remove any

cables

3. Rotate panel counter

clockwise

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 10 of 21

Step 6:

Reposition panel

1. Reposition the control

panel down into the cover

2. Guide the green flat cable

into the cover

Step 7:

Check green flat cable

Check if the green flat cable is

inside of the top cover

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 11 of 21

Step 8:

Click control panel in place

1. Click control panel back

into the top cover

2. Lock top cover with

screwdriver

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 12 of 21

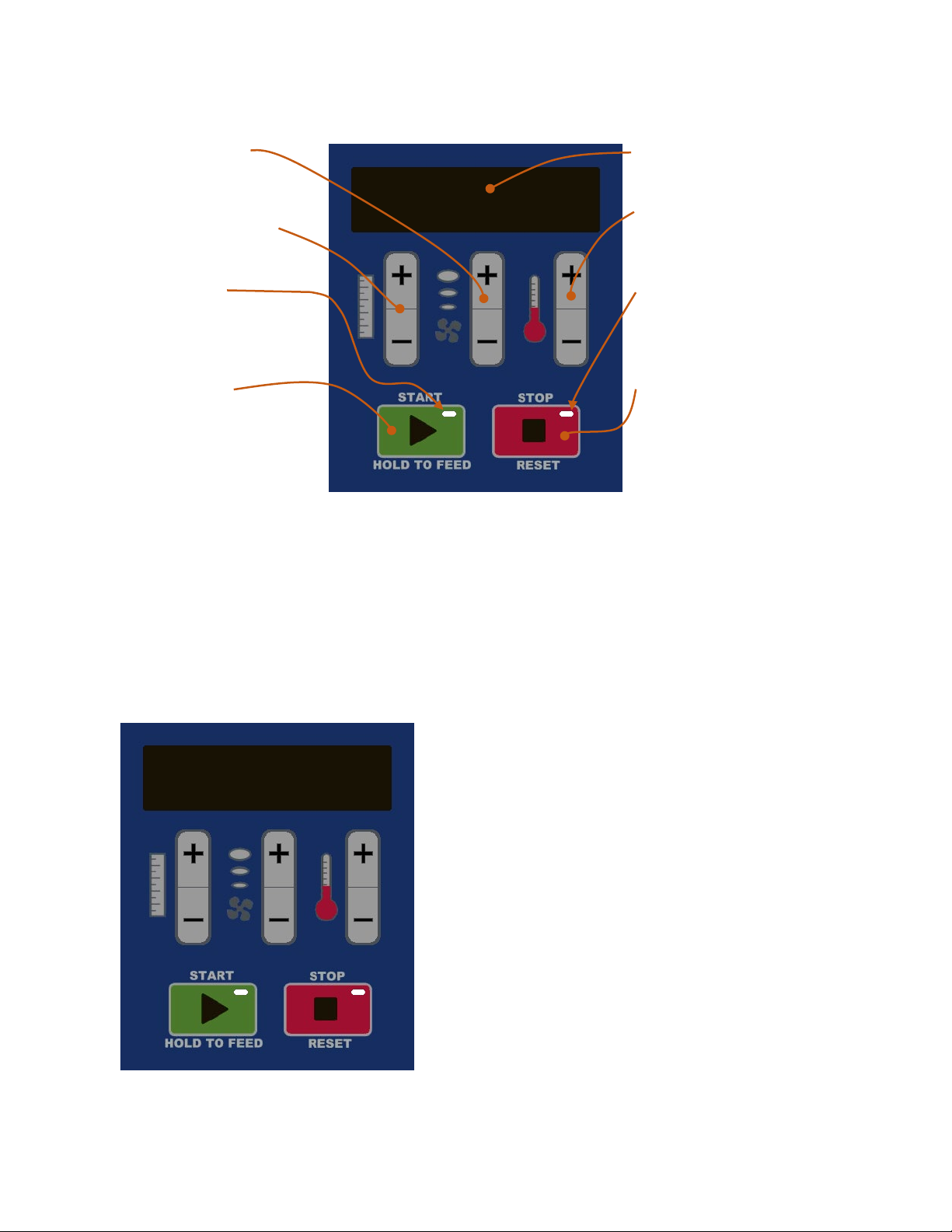

Basic operation

Set air fill level

Set number of cushions

to produce

Green LED

•Blinks while warming up

•Solid when ready

Start button

•Warm up the machine

•Start production of Air

Cushions

Display

Set seal temperature

Red LED

Stop button

•Stop production

•Reset MINI PAK’R

Industrial after error is

corrected

Initially, the display will show “SLP” (Sleep). Once film is loaded, the machine will detect the roll.

The green LED on the Start Button will begin flashing. A flashing green LED indicates that the

machine is warming to the correct seal temperature. The Control Panel will display seal

temperature while adjusting.

When the correct temperature is reached, the green LED will remain solid green. The display

will show “RDY” (Ready). The machine is ready for production. Press the Start Button to begin

making Air Cushions.

Start production

When the green LED remains steady green, and the

Display reads “RDY” (Ready), press and release the

Start Button again to begin production. The Air

Pump will force air into the film, and after a few

seconds the Drive Motor will advance the inflated Air

Cushions through the Seal Bar and past the Slitting

Blade. Air Cushions will emerge at the front of the

machine.

Press the Stop Button to stop production. The

machine is factory set in continuous mode, and will

create Air Cushions until the Film Roll is empty. To

create a fixed length of Air Cushions, use the Length

Control buttons (next page).

F

rdy

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 13 of 21

Sleep mode

If the machine is not used for 30 minutes, it will enter

“Sleep” mode. The Display will read “SLP”. To

resume Air Cushion production, press the Reset

Button. The Seal Bar will begin heating. Press the

Start Button again when the green LED remains

steady green and the Display reads “rdy” to resume

Air Cushion production.

Machine settings

Changing Machine Settings

The machine automatically chooses the correct air and temperature settings for the Film Roll

you have loaded. You do not need to adjust Machine settings manually. However, if the

automatic settings are not optimal, the Control Panel allows you to change the following

settings:

•Length control

•Air – Fill level control

•Seal temperature control

Length control

Length Control sets the number of Air Cushions to be

produced each time you press the Start Button. You have

2 options:

Continuous Mode

Length Control at the factory is preset at continuous

production. Press the Start Button and the machine will

run the film until the Film Roll is empty or the Stop Button

is pressed. The Machine will display the number of Air

Cushions produced.

Number of Cushions

If you want to produce a fixed length of Air Cushions,

press the + Button until the desired number is displayed.

The machine will count down the number of Air Cushions

yet to produce.

To change from Fixed to Continuous mode, press the

- Button until the Display shows ”---”.

--

SL

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 14 of 21

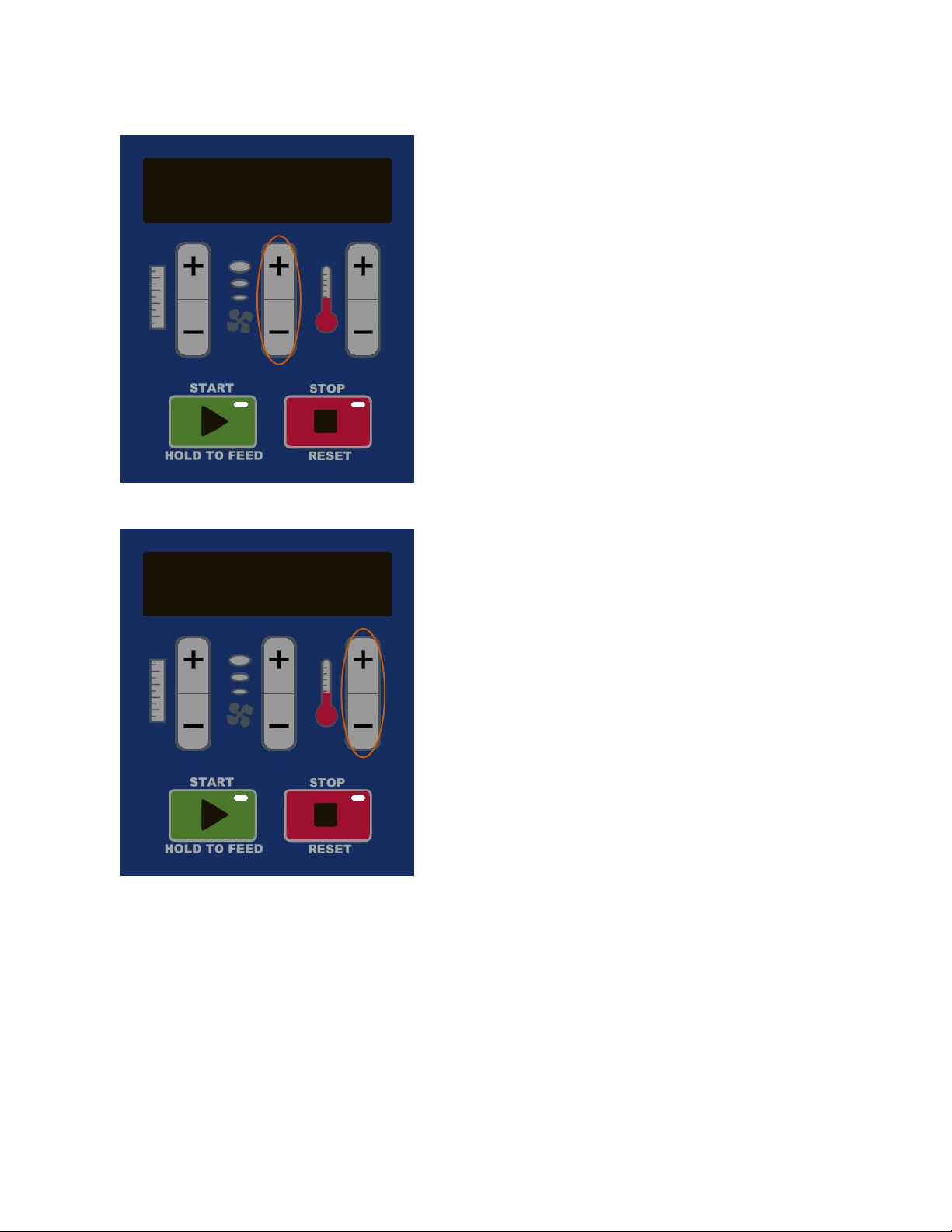

Air control

Air Control regulates the amount of air in the Air

Cushions.

If you want fuller Air Cushions, press the + Button.

If you want less full Air Cushions, press the - Button.

Seal temperature control

The Temperature Control regulates the temperature of

the Seal unit that fuses the front and back film sheets

together.

If the Air Cushions become flat, and upon inspection the

Heat Seals are leaking air, increase the Temperature

Control by pressing the + Button.

If the Air Cushions become flat because the seals are

burned through at the seal line, as evidenced by holes in

the Air Cushions, decrease the Temperature Control by

pressing the - Button.

NOTE: After changing the Temperature Control setting,

the MINI PAK’R V3 may take a few moments to establish

the new seal temperature. During heat-up or cool down,

the green LED will flash until the correct temperature has

been achieved.

If Air Cushions continue to show poor seals and produce

flat cushions, contact Pregis for assistance.

15

.0

215

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 15 of 21

Maintaining MINI PAK’R V3

Risk of Burn!

Before opening Covers, turn Power OFF, unplug the Power Cord, and

wait 10 minutes for the machine to cool down.

Improving slit performance

The slit performance can be improved by reposition, flip or replace the slitting blade:

•If the film jams frequently

•If the blade is not cutting the film properly or is making a very rough cut

1. Turn power off, unplug power

cord, then wait 10 minutes for

the machine to cool down.

2. Loosen the integrated screw in

the top cover, with a slotted or

Philips screwdriver.

3. Open the top cover

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page 16 of 21

4. Unscrew thumbscrew to

loosen the blade

5. The slit performance can be

improved by repositioning the

blade, so that the film is again

cut by a sharp section of the

blade. This is achieved by a

number of options:

a) Reposition blade further

into the manifold

b) Flip the blade on the short

edge

c) Exchange blade if cut

edge is fully used

6. (Re-)position the blade

7. Tighten the thumb screw

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page - 17 - of 21

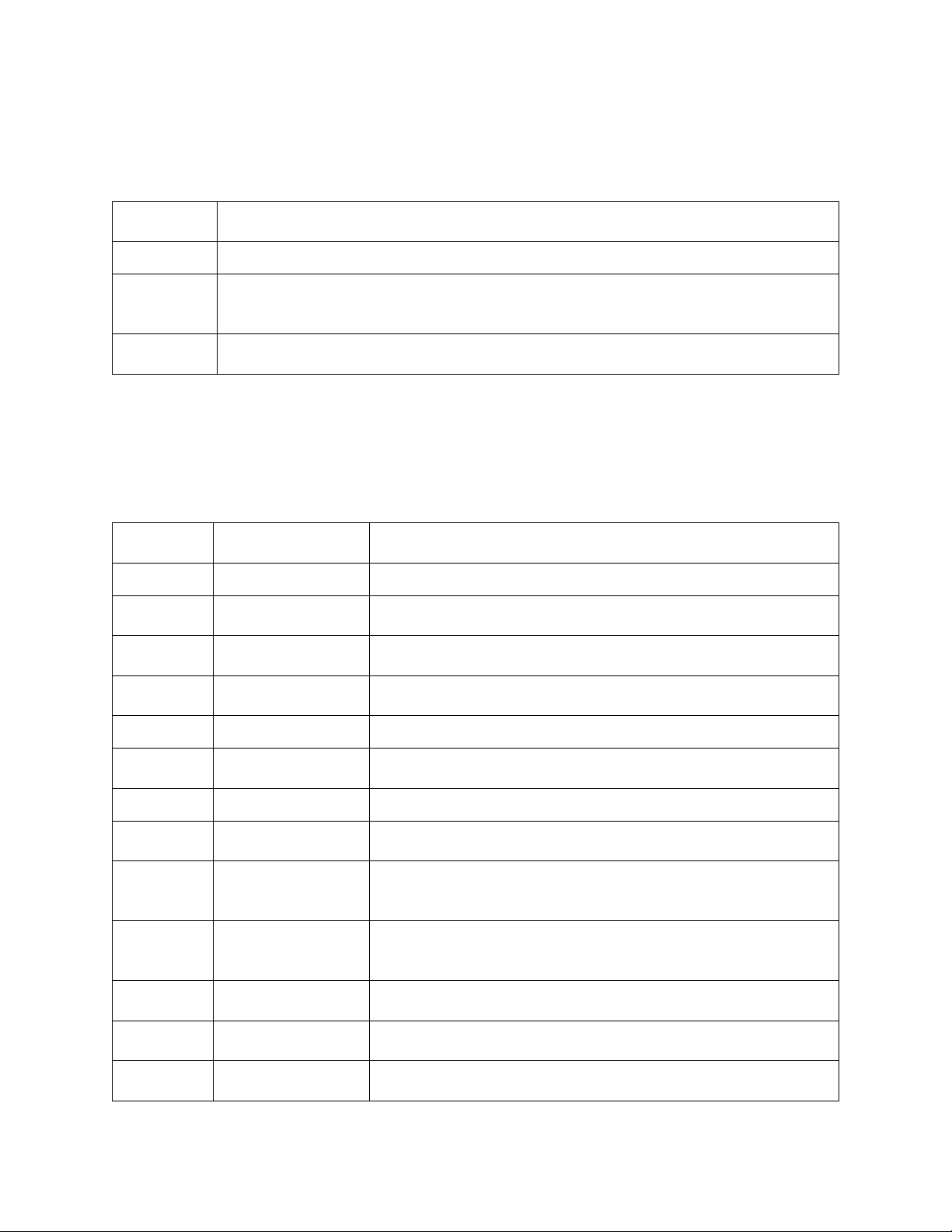

Display codes

Display

code

Explanation

RDY

The machine is ready for air cushion production.

SLP

After 90 minutes without operation the machine enters in sleep mode to safe

power.

No actions needed.

STY

Machine is in reduced temperature mode.

No actions needed.

Error codes

If the Display shows an Error Code, and the red LED flashes, consult the chart below to

determine the cause. Clear the problem as described below, then press the STOP/RESET

Button to resume normal operation.

Display

code

Error

Action

E1

Cover open

Make sure covers are closed.

E2

Jam / end of roll

In case of jam, open cover and remove jammed film

carefully.

E3

Heater high temp.

issue

Contact Pregis for assistance and swap the machine.

E4

Heater low temp.

issue

Contact Pregis for assistance and swap the machine.

E5

Heating fault

Contact Pregis for assistance and swap the machine.

E6

No RFID tag

detected

Swap the film roll and reset the system. If error repeats,

contact Pregis for assistance and swap the machine.

E8

Temp. read fault

Contact Pregis for assistance and swap the machine.

E9

Incompatible tag

detected

Swap roll with compatible film roll. If the error still appears,

contact Pregis for assistance and swap the machine.

E10

Temp. read fault

Clear error and allow machine to reheat. If error repeats,

cycle power. If error repeats, contact Pregis for assistance

and swap the machine.

E11

Temp. read fault

Clear error and allow machine to reheat. If error repeats,

cycle power. If error repeats, contact Pregis for assistance

and swap the machine.

E12

Thermocouple

fault

Reset power to the machine. If error persists, contact

Pregis for assistance and swap the machine.

E16

Power monitor

fault

Contact Pregis for assistance and swap the machine.

E17

Power monitor

fault

Contact Pregis for assistance and swap the machine.

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page - 18 - of 21

E18

Power monitor

fault

Contact Pregis for assistance and swap the machine.

E28

Drive motor driver

fault

Contact Pregis for assistance and swap the machine.

E31

Drive motor start

fault

Contact Pregis for assistance and swap the machine.

E32

Drive motor stop

fault

Contact Pregis for assistance and swap the machine.

E36

Blower load fault

Contact Pregis for assistance and swap the machine.

E40

Blower start fault

Contact Pregis for assistance and swap the machine.

E41

Blower stop fault

Contact Pregis for assistance and swap the machine.

E44

Seal motor driver

fault

Contact Pregis for assistance and swap the machine.

E45

Seal position fault

Power cycle the machine, if the error repeats, contact

Pregis for assistance and swap the machine.

E47

USB load fault

Remove USB device. Contact Pregis for assistance and

swap the machine.

E48

USB general fault

Contact Pregis for assistance and swap the machine.

E49

USB device not

compatible

Remove USB device. Contact Pregis for assistance and

swap the machine.

E50

Incorrect USB file

format

Format USB to FAT or FAT32, Use Pregis recommended

USB drive, not all drives are compatible.

E59

Control board

reset

Unexpected reset detected. Contact Pregis for assistance

and swap the machine.

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page - 19 - of 21

Electrical Schematic

MINI PAK’R V3 - MM2I2IN115 / MM2I2IN230 Page - 20 - of 21

Table of contents

Other Pregis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SafanDarley

SafanDarley E-Brake Premium 100-3100 instruction manual

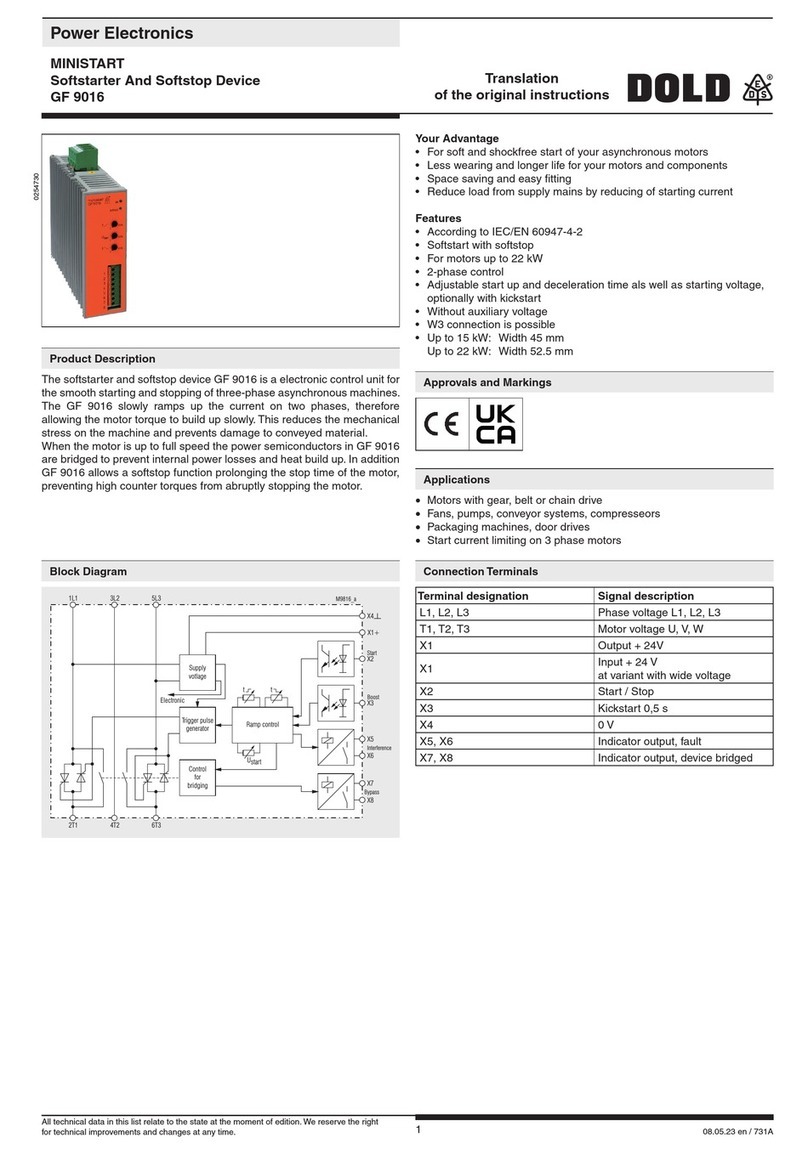

DOLD

DOLD MINISTART GF 9016 manual

DESSALATOR

DESSALATOR PRO COMPACT D300 Assembly and user's manual

SCHUNK

SCHUNK TRIBOS SVP-2D Assembly and operating manual

ABB

ABB HT846935 Operation manual

Wilo

Wilo RexaLift FIT L1 Installation and operating instructions