PrePRESS PANTHER PRO User manual

PantherPro Image Recorder TP 8250

iJune 1994 PrePRESS SOLUTIONS

Table of Contents

Section 1 General Service Information Page

1-1 Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Laser Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Regulatory Agencies Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4 Electrostatic Discharge - ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2 Overview and Specifications

2-1 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-3 Electrical Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-4 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Section 3 Theory of Operation

3-1 Panther Pro Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 High Speed Control (HSCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 CPU and Peripherals Module Overview . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-4 Page Buffer Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-5 Recorder Output Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-6 Media Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7 Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Section 4 Power Supply and Distribution

4-1 AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 DC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Section 5 Installation

5-1 Bill of Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Pre-Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-3 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-4 Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-5 System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-6 Installation Completion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

PantherPro Image Recorder

ii June 1994

TP 8250

PrePRESS SOLUTIONS

Section 6 Removal/Replacement Page

6-1 External Covers and Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 E. M. I. Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-3 Keypad/LCD Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4 Electronics Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-5 Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-6 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-7 I/O Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-8 Polygon Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-9 Laser Amplifier PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-10 Polygon Driver PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-11 Laser Diode Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-12 Second Cylinder Lens Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-13 Start Of Line Sensor PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-14 Paper Feed Gate Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-15 Gate Assembly Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-16 Metering Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-17 Drive Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6-18 Knife Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-19 Servo Leading Motor and Gearbox Assembly . . . . . . . . . . . . . . . . . . . 6-14

6-20 Servo Leading Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-21 Leading Worm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-22 Leading Spur Gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Section 7 Diagnostics

7-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 PROM Resident Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Section 8 Reference/Adjustments

8-1 Jumpers, LED’s, and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2 Laser Amp 7.5V reference Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8-3 Laser Amp Offset Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

7-2.1 Level 1 Power-up Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2.2 PROM Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7-2.3 Level 2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7-3 Disk Based Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7-3.1 HSCB_Diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7-4 Keypad Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7-4.1 Level 2 Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7-4.2 Disk Based Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7-4.3 Communications Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7-4.4 SCSI Downloader Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

PantherPro Image Recorder TP 8250

iiiJune 1994 PrePRESS SOLUTIONS

Section 9 PantherPro Parts Listing

Group 1 Case and Covers Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2,3

Group 1A Case and Covers Rear View - I/O Panel . . . . . . . . . . . . . . . . . . . . . . 9-4,5

Group 2 Front Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6,7

Group 3 Optics, Laser Diode/Amp, Polygon . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8,9

Group 4, 4A Paper Feed Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10,14

Group 4B Paper Feed Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14, 15

Group 5 Power Supply Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16, 17

Group 6 Card Cage (PCB'S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18, 19

Group 7 Take-Up Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20, 21

Group 8 Supply Cassettes, ETM Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 9-22, 23

PantherPro Image Recorder

iv June 1994

TP 8250

PrePRESS SOLUTIONS

PantherPro Image Recorder TP 8250

vJune 1994 PrePRESS SOLUTIONS

PantherPro

IMAGESETTER

TECHNICAL MANUAL

TP 8250

November 1994

PrePRESS SOLUTIONS CONFIDENTIAL

2

PantherPro Image Recorder TP 8250

1-1November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

Section 1 General Service Information

1-1 Scope of Manual

The Model PantherPro Image Recorder Service Manual is intended for the use of trained

technical representatives of PrePRESS SOLUTIONS, its subsidiaries and dealers. It is not

intended as a substitute for training. Service personnel will utilize this document as a re-

source for information concerning the following aspects of effective service:

Section 1. “General Service Information”, contains general information regarding the

service manual, laser safety information, regulatory agencies information, and

electro static discharge prevention rules.

Section 2. “Overview and Specifications”, describes the features of the PantherPro and

products specifications.

Section 3. “Theory of Operation”, describes in detail the functionality of the PantherPro.

Section 4. “Power Supply and Distribution”, contains details regarding the DC and AC

power used on the PantherPro.

Section 5. “Installation”, contains the installation instructions for the PantherPro.

Section 6. “Removal/Replacement”, contains removal/replacement procedures for items

that are normally removed for servicing.

Section 7. “Diagnostics”, contains diagnostics procedures normally performed on the

PantherPro.

Section 8. “Reference/Adjustments”, contains reference material and adjustments proce-

dures normally performed on the PantherPro.

Section 9. “Parts Catalog”, contains the catalog which identifies and list part numbers of

the PantherPro.

PantherPro Image Recorder

1-2 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

1-2 Laser Safety Information

CAUTION - Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Classification and Labeling of Laser Product

According to the Code of Federal Regulations, laser products are classified in Classes I

through IV. These classes are assigned according to the amount of laser radiation acces-

sible to the operator. The PantherPro Image Recorder is certified as a Class I product. The

operator is not exposed to any hazardous laser radiation during operation and mainte-

nance.

The laser itself, however, is a Class IIIb laser, and emits laser radiation which is considered

hazardous according to the Federal Code of Regulations, section 1040.10. This level of

radiation is not accessible to the operator as long as the optics cover of the PantherPro is

not removed.

The PantherPro uses a low-power, 5 milliwatts laser diode which only emits visible red

light. As with any bright source of optical energy, safety precautions should be applied. One

should not stare into the beam or any reflections from shiny sources.

Laser Warning Labels

Figure 1-1 represents the laser warning label. This label is located inside the PantherPro on

a protective panel that encloses the laser optics, on the rear panel, and the electronics

cover. (See Figure 1-2).

CAUTION - LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

ATTENTION - RAYONNEMENT LASER EN CAS

D’OUVERTURE. EXPOSITION DANGEREUSEAU FAISCEAU

Safety Label

Figure 1-1

Operator Safety

Operator access to laser radiation is not possible during operation or operator mainte-

nance. During operation the protective housing prevents access to all radiation fields. The

recorder hinged supply cassette cover may safely be opened for operator maintenance.

This maintenance includes removing and installing the photographic media supply and

take-up cassettes.

To insure safety during maintenance, redundant interlocks shut off power to the laser diode

PantherPro Image Recorder TP 8250

1-3November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

Laser Warning Labels

Laser Warning Label Locations

Figure 1-2

assembly (laser diode power up to 5 milliwatts at 670 nanometers could be accessible in

the machine interior if the interlocks are defeated). The PantherPro electronics and optics

covers should never be removed by the customer.

Servicing Safety

Service procedures include removal of the machine covers to replace or adjust compo-

nents. The inner laser assembly and other components may be replaced in the field. The

laser output and the focused beam are accessible in the interior.

The supply cassette door includes two magnetic interlock switches which are mounted and

connected in series so that if the access door is lifted, both switches open to open the

interlock circuit. When the interlock circuit is open, all power is dropped to the current

source for the laser diode.

All service procedures will be performed with the main power shut off and with the safety

interlock circuit open (no laser diode current).

When performing alignments, carefully follow the procedures documented in the technical

manual. DO NOT defeat the safety interlock switches unless specified in the procedure.

Also, NEVER override the safety interlock switches if the polygon/motor assembly is not

spinning, as this could allow the focused beam to be emitted.

PantherPro Image Recorder

1-4 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

Caution: Direct or indirect reflected eye contact with the laser beam may cause

serious eye damage.

Warning: At no time should the unit be left unattended with the interlocks defeated.

The following safety precautions should always be observed:

1. Never operate the unit with the optics cover removed.

2. Laser safety goggles must be worn when making any adjustments to the recorder with

the interlocks defeated.

3. Any adjustments that are to be made with the interlocks defeated must be made in a

secure area, with only trained personnel present.

4. Do not place screwdrivers or other shiny objects in the path of the laser beam.

5. Remove all jewelry from fingers and wrists before making any alignments.

6. Remember that the laser beam is invisible and can cause permanent damage to the

eyes.

1-3 Regulatory Agencies Information

The PantherPro is an approved product designed and manufactured in accordance with UL

(Underwriters Laboratories) and CSA (Canadian Standards Association) standards. The

product also complies with the requirements in Part 15 of FCC Rules for a Class A comput-

ing device.

This equipment complies with the requirements in part 15 of FCC Rules for a Class A

computing device. Operation of this equipment in a residential area may cause unaccept-

able interference to radio and TV reception requiring the operator to take whatever steps

are necessary to correct the interference.

The PantherPro also complies with specific European safety standards; international mod-

els are shipped with a label bearing the “CE” mark. This label demonstrates compliance

with IEC safety standards. The PantherPro also meets EN55022/VDE Class B emissions

standards.

1-4 Electrostatic Discharge - ESD

Static electricity is, simply, electricity that is not moving. It is harmless as long as it remains

static. Unfortunately, an electrical charge is unstable and is always looking for an opposite

charge to unite with. When a charge moves, it becomes a current, which is often greater

than a electronic circuit can handle.

The smallest static charge that can be felt is 3,000 volts; the smallest charge that can be

PantherPro Image Recorder TP 8250

1-5November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

seen is 5,000 volts; and the smallest charge that can be heard is 10,000 volts. Some semi-

conductor devices are susceptible to a static charge as little as 10 volts.

Electrostatic discharge has become more and more of a hazard as microcircuit compo-

nents have become smaller and more sensitive.

ESD Prevention Rules

These are the rules to be learned and followed in order to prevent ESD damage to elec-

tronic printed circuit boards and assemblies.

WARNING: Make sure you are NOT grounded when working on equipment that is

plugged in and ON.

1. Always use the antistatic portable field service kit when working on electronic parts of

PrePRESS Solution’s products or when handling printed circuit boards.

2. Make sure machine is plugged in a grounded outlet (and switched off) if using the ma-

chine frame as a grounding point.

3. Make sure your wrist strap and antistatic service kit are connected together and con-

nected to ground.

4. When replacing printed circuit boards, remove the old board from the machine before

removing replacement board from the antistatic bag. Then install replacement board

and place old board in the antistatic bag.

5. Always transport and store electronic components in an antistatic bag.

6. Use the correct size bag, not too big or not too small.

7. Keep antistatic bags in good condition. Bags with pin holes, rips, tears, or crumpled

bags are less efficient and may provide little or no protection.

8. Do not remove components from bags just to look at them. You can usually see through

the bag to identify the part.

9. Keep spare bags on hand.

10.Always ship back field returns in an antistatic bag. Even defective components should

be stored and transported in antistatic bags so that they are not damaged further.

11.Keep static producing materials such as polyester, plastic, and Styrofoam away from elec-

tronic parts.

12.Don’t pick up boards unless you are grounded or the boards are in antistatic bags. Do

not touch edge connectors on PCB’s, or exposed circuitry. Handle IC’s, and boards by

PantherPro Image Recorder

1-6 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

the edges, and never place components on metal surfaces.

13.Static is present at all times, more so when the humidity is low.

14.Educate customers about static protection, especially the ones who maintain their own

equipment.

PantherPro Image Recorder TP 8250

2-1November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

Section 2 Overview and Specifications

2-1 Product Overview

The PrePRESS PantherPro is a high speed, high-resolution, multiport image recorder. At a

recording speed of 53.3"/min, the Model PantherPro is the fastest image recorder on the

market.

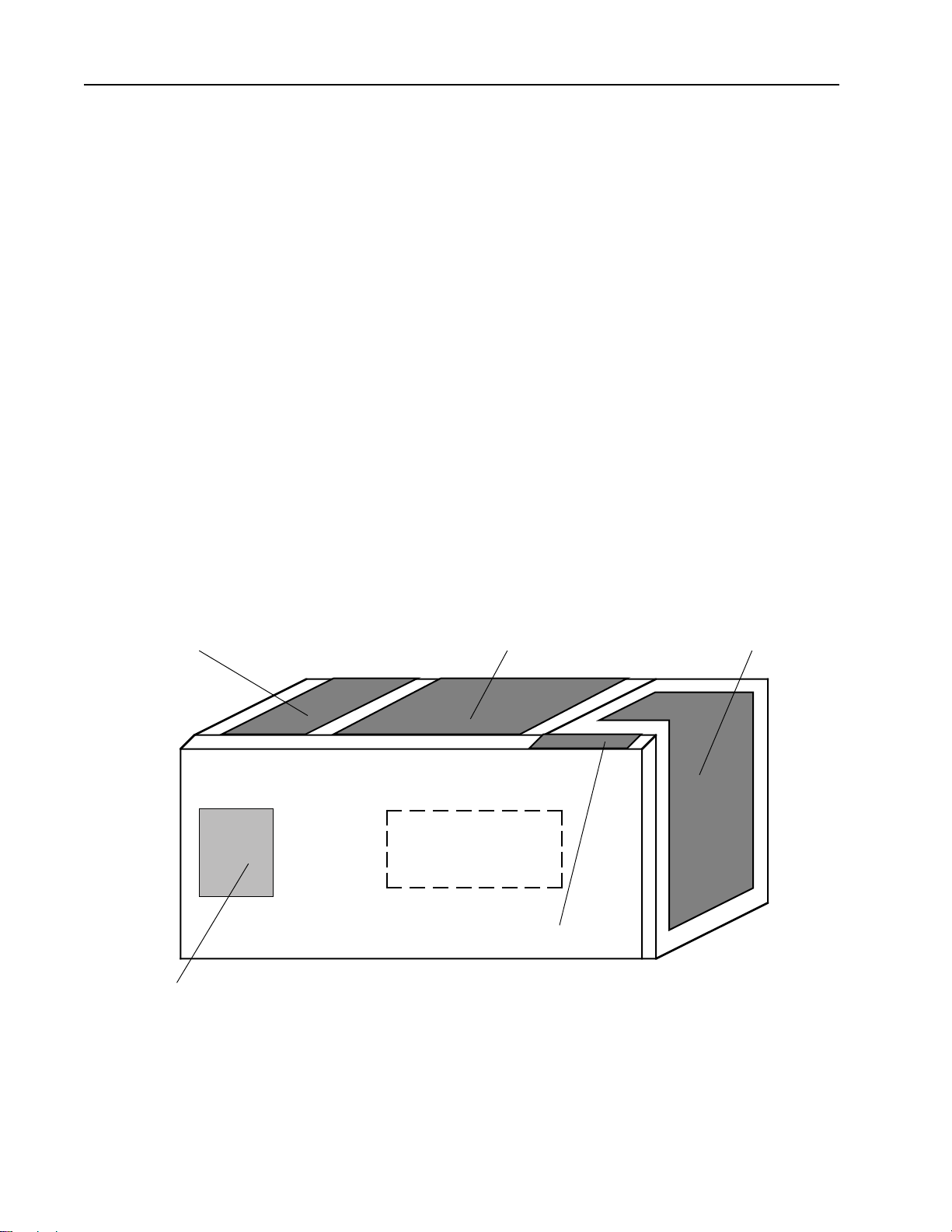

PantherPro with Base Cabinet

Figure 2-1

The Model PantherPro includes the Multiport option, which allows up to four RIPs to drive a

single PantherPro. The PantherPro is designed for configuration

PantherPro Image Recorder

2-2 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

with the Adobe CPSI Level 2 software RIP.The PantherPro is driven by a standand plat-

form microcomputer via a SCSI interface.The PantherPro offers VIM Intergrator as stan-

dard which provides OPI and DCS back-end intergration compatability.

A standard PantherPro offers ten standard resolution settings from 900 to 3048 dpi, one

input port and dual 500+ hard disk drives. Among the Pro's options are dual 1+GB Page

Buffer hard disk drives and up to three addional input ports can be added. A Pro may be

configured with either a single 500+MB or single 1+GB Page Buffer hard disk drive. All

Page Buffer Drives must be the same size.

2-2 Hardware Overview

The components of the PantherPro are located in four separate areas of the cabinet: card

cage/power supply, operator control panel, laser/optics and media transport. (Refer to Figure

2-2)

Power Supply

Drawer

Operator Panel

Page Buffers Figure 2-2 PantherPro Component Areas

Laser/OpticsHSCB / PB Module Media Transport

PantherPro Image Recorder TP 8250

2-3November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

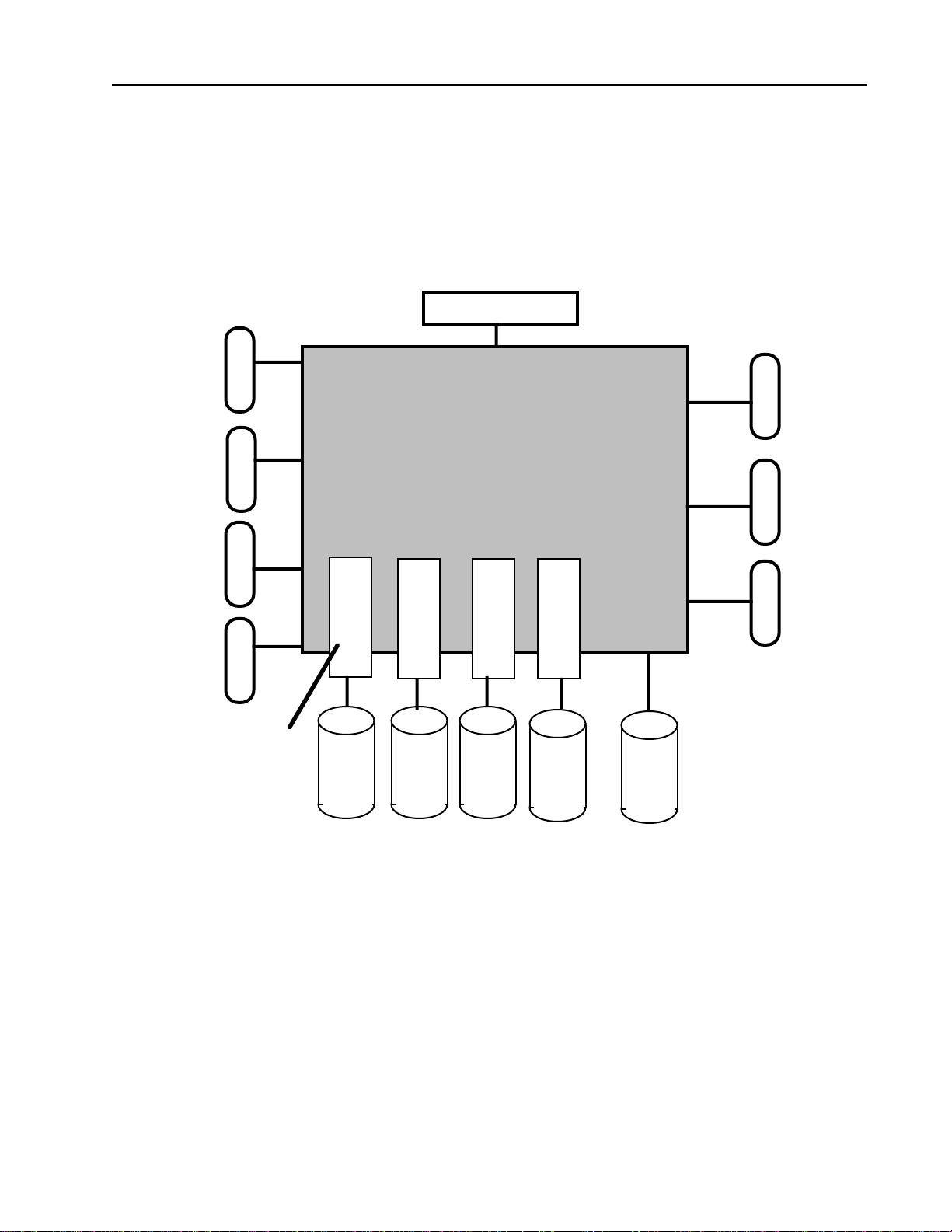

2-2.1 HSCB / PB Module (Refer to Figure 2-3, Electronics Block Diagram)

The HSCB / PB Module area is located on the left side of the cabinet and contains the High

Speed Controller Board and Page buffer Modules.

Refer to Section 3 for description of the High Speed Controller Board and Page buffer

Modules.

PantherPro Electronics Block Diagram

Figure 2-3

2-2.2 Operator Control Panel

The operator control panel is located in top front of the cabinet and is used for operator

HSCB

PB 4

Motors

Video

Debug

LCD / Keypad

S

C

S

N

P

U

T

S

Page Buffer Module PB 3 PB 2 PB 1 PB 0

I

I

interaction with the system and for displaying operational and error messages.

PantherPro Image Recorder

2-4 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

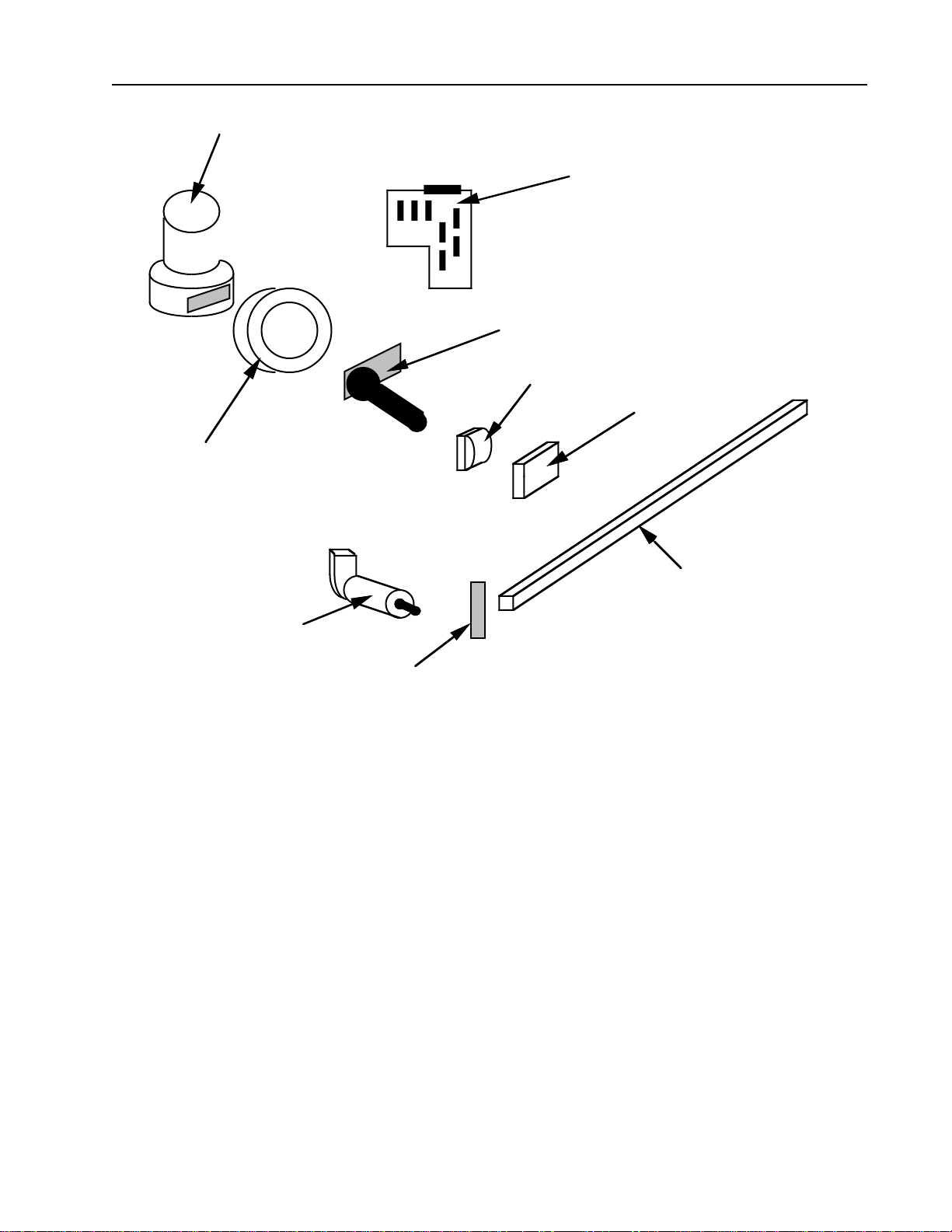

2-2.3 Laser, Optics and Media Transport

(Refer to Figure 2-4, Recorder Components Block Diagram)

The major components contained in the recorder area include:

Laser Amplifier PCB

Laser Driver PCB/Laser Diode Assembly

Leading Motor/Encoder

Polygon Motor

Polygon Drive PCB

Paper Transport Assembly

Optical System

Sensors and Switches

HSCB

Polygon High Speed Transport Motors

Driver Laser Amp Leading/Cutter

Polygon High Speed

Motor Laser Driver

Panther Pro Recorder Components Block Diagram

Figure 2-4

The recorder components, upon input from the HSCB, generates typographic characters

and graphics onto visable red sensitive paper, film or plate material.

The images are formed on the media by a laser beam output which is generated by the

video data received from the image controller. The video data is received by the laser

amplifier PCB, which then output the data to the laser driver PCB and onto the laser diode.

The laser diode generates the visable red laser beam which is dispersed across the imag-

ing area by a polygon scanner motor and optical system. The paper is moved across the

imaging area by a servo leading motor.

PantherPro Image Recorder TP 8250

2-5November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

PantherPro Recorder Components

Figure 2-5

2-3 Electrical Power Requirements

Power line to be minimum 15 amp rating, isolated with 3rd wire insulated ground wire. AC

receptacle should be Hubbel outlet Part Number IG5262 or equivalent. Refer to Figure 2-6.

Input Voltage/Power Line 115 VAC+/-10%, 60 Hz+/-3 Hz

230 VAC+/-10%, 50 Hz+/-3 Hz

Input Current Rating 2 amps/115 VAC

1 amps/230 VAC

Power Consumption 150 watts

POLYGON SCANNER MOTOR

LASER AMPLIFIER PCB

LASER DRIVER/LASER DIODE ASSEMBLY

FIRST CYLINDRICAL LENS

SECOND CYLINDRICAL LENS

SOL SENSOR

SERVO MOTOR/

ENCODER

ASSEMBLY

SCAN LENS

BEAM STEERING MIRROR

PantherPro Image Recorder

2-6 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

Heat Dissipation 500 BTU/hr.

Input Voltage Power Line

Figure 2-6

2-4 PantherPro Product Specifications

Maximum Line Length: 13.3 inch (338 mm)

Resolutions (H x V): 1800 x 1800, 900 x 900 (can be imaged 900 x 1800)

2032 x 2032, 1016 x 1016 (can be imaged 1016 x 2032)

2400 x 2400, 1200 x 1200 (can be imaged 1200 x 2400)

2540 x 2540, 1270 x 1270 (can be imaged 1270 x 2540)

3048 x 3048, 1524 x 1524 (can be imaged 1524 x 3048)

Spot Size: Spot size varies with resolution, from 15µm @ 1800 dpi to

3048 dpi; 30µm at 900 dpi to 1524

115 VAC (Black)

Neutral (White)

Third Wire Ground (Green or Green/Yellow Earth Ground

Main

Building

Ground

15

AMP

From Power Source

Neutral

115 VAC

Main

Entrance

Box

Dedicated

AC Outlet

Voltage Requirements

Hot to Neutral 115V ±10%

Hot to Ground 115V ±10%

Neutral to Ground .5V Max

PantherPro Image Recorder TP 8250

2-7November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

Absolute Accuracy: ±0.004 inch over 18 inch

Repeatability *: ±0.001 inch typical over 8 contiguous color separations nomi-

nal 18" in length

*Tolerance based on four consecutive pages using

PrePRESS’s High Capacity take-up cassette with 12 inch

prefeed. Actual results may vary depending on environmental

conditions and media used.

Recommended environment for color separations accuracy:

Temperature 70°F ±3°F, Relative Humidity: 55% ±5%

Imaging Speed: 3048 x 3048 dpi: 7.8 inches/minute (200mm/min)

2540 x 2540 dpi: 18.9 inches/minute (480mm/min)

2400 x 2400 dpi: 20 inches/minute (508mm/min)

2032 x 2032 dpi: 23.6 inches/minute (600mm/min)

1800 x 1800 dpi: 26.7 inches/minute (677mm/min)

1524 x 1524 dpi: 31.5 inches/minute (800mm/min)

1270 x 1270 dpi: 37.8 inches/minute (960mm/min)

1200 x 1200 dpi: 40 inches/minute (1016mm/min)

1016 x 1016 dpi: 47.2 inches/minute (1200mm/min)

900 x 900 dpi: 53.3 inches/minute (1,354mm/min)

(Imaging speed does not include processing and RIPing time)

Recording Method: Laser diode (670nm nominal)

Output Media: Visible red sensitive resin-coated paper, polyester film, and

plate material (up to 0.008" thickness)

Capable of accepting 8"(203mm), 11/12"(279mm/305mm),

and 13.3"(338) media

Special cassette required for .007"/.008" thickness

Output Format: Positive or negative, right or wrong reading

Supply Capacity: Up to 246' (75m) paper, film, or plate material( depending on

vendor packaging configurations)

Takeup Cassette Cassette capacity: up to 50' (15.2m) for .004" thickness film or

paper (plate material may vary)

One cassette per media width:8" (203mm), 11"/12" (279mm/

305mm), and 13.3" (338mm)

Certifications: UL 1950, CSA C22.2, FCC (Class A), Canadian DOC; EN

60950/IEC 950; all requirements of European Community

EMC Directive 89/336/EEC: Vfg 243/EN55022 Class B/VDE

Class B; EN 50082/IEC 801-2/3/4 (EM Immunity)

PantherPro Image Recorder

2-8 November 1994

TP 8250

PrePRESS SOLUTIONS CONFIDENTIAL

Operating Environment

Temperature: 60 to 90 degrees F (16 to 32 degrees C)

Humidity: 40% to 80% non-condensing

Heat dissipation: Approximately 500 BTU/hr

Noise emission: Less than 55db

Altitude: Sea level to 7,500 ft

Recorder Dimensions: 39.5"(height) x 16.5"(width) x 24"(depth)

Recorder Weight: 165 lbs. (74.8kg)

Base Cabinet Weight 75 lbs. (34kg)

PantherPro Image Recorder TP8250

3-1November 1994 PrePRESS SOLUTIONS CONFIDENTIAL

Section 3 Theory of Operation

3-1 Overview

The PantherPro Imagesetting System's primary distinguishing feature is its recorder output

speed. It is approximately twice that of the Panther recorder. In addition, the PantherPro

offers up to 4 independent SCSI input ports which are accommodated by up to 5 page

buffers drives. This allows four RIPs to share the recorder.

The PantherPro Imagesetting System contains a casting, optical components, laser, laser

amplifier, leading motor/encoder, rollers, cutter, power supply, LCD/Keypad, a High Speed

Control Board, page buffer module, and page buffers.

3-1.1 Functional Overview

The High Speed Control Board interfaces the RIP Controller to the image recorder and

contains the following features:

• Up to four independent SCSI interfaces

• Minimum of 2, maximun of 5 page buffer disks

• Keypad/LCD User Interface

• Serial Port for Debug/Diagnostics

• Self-test Capabilities

• High Speed:

15.75 ipm @ 3048 DPI

18.90 ipm @ 2540 DPI

20.00 ipm @ 2400 DPI

23.63 ipm @ 2032 DPI

26.67 ipm @ 1800 DPI

• Supply Cassette configuration memory

• On-line Processor Interface

The logic circuitry is contained in the following modules:

• Input Interface

• CPU and peripherals Section

• Recorder Output Module

• Page Buffer Module

• SCSI MUX Module

Table of contents

Other PrePRESS Office Equipment manuals

Popular Office Equipment manuals by other brands

Zenbooth

Zenbooth Solo Build instructions

Bush Business Furniture

Bush Business Furniture WC65570 Assembly instructions

OYPLA Home

OYPLA Home 3038 user manual

Uchida Yoko

Uchida Yoko AeroCut X Operation manual

KI

KI Tattoo Flex Screen Assembly instructions

OCEE DESIGN

OCEE DESIGN DEN SASS-0082 Assembly instructions