6

Tattoo™ Screens - Spine Screen Leveling & Connecting

Assembly Instructions

Leveling & Connecting Spine

Screens

Note: A single Spine Screen may

not be used as a freestanding screen

on its own. The Spine Screen must

always be mechanically attached

to another Spine Screen (with or

without electrical).

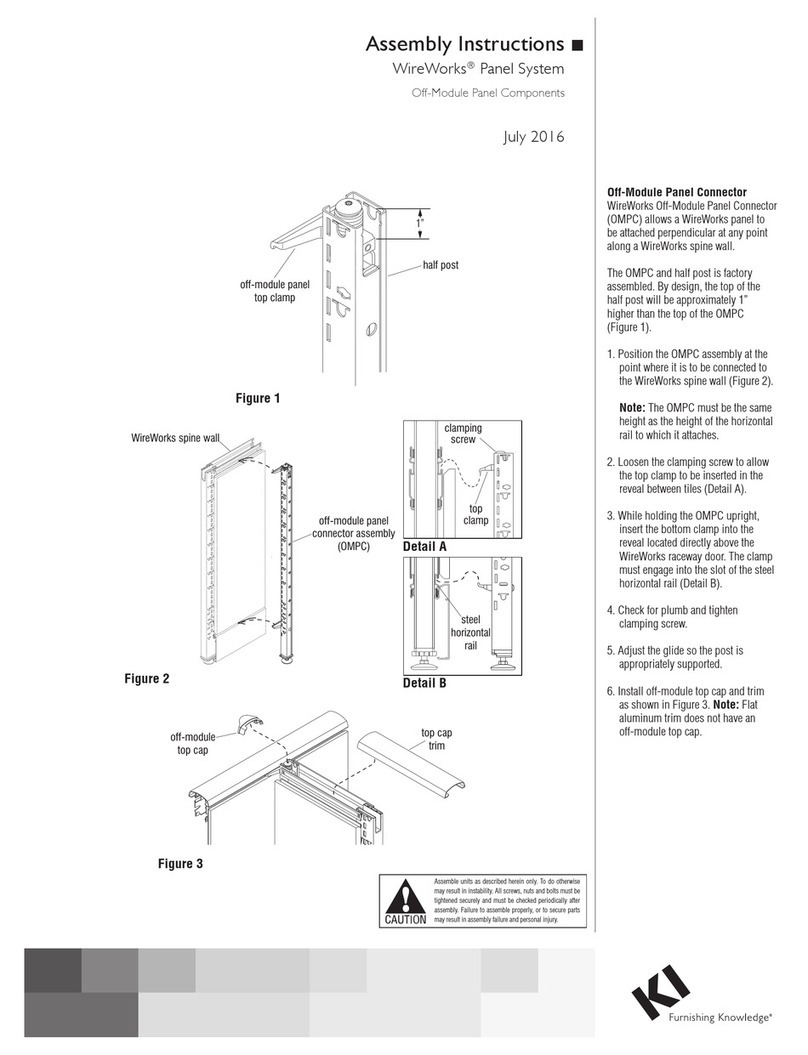

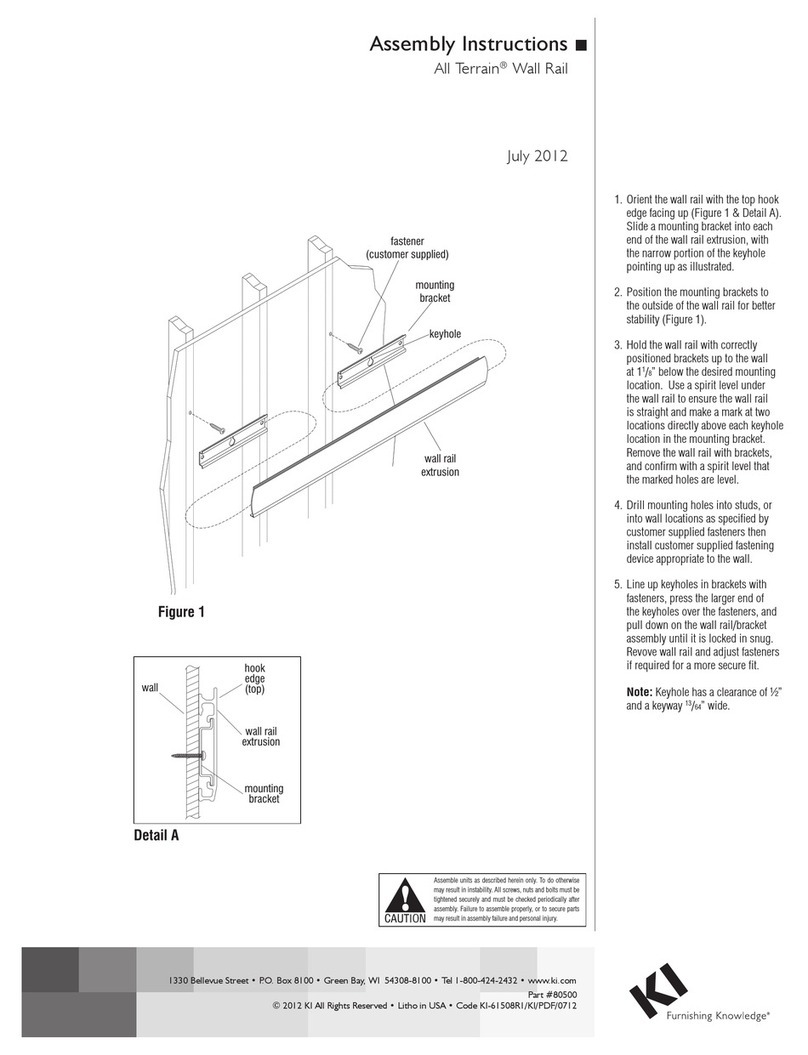

1. Check to make sure all

height-adjustable glides are

adjusted so the screens are at their

lowest position as illustrated in

Detail F on page 8. If glides are not

adjusted down fully to the bottom of

the screen, reference “Spine Screen

Foot Assembly” instructions on

page 5, step 3.

2. Carefully turn Spine Screens to the

upright position, and move to their

final installation location in-line to

each other per the space-planning

layout (Figure 2).

Important: Know and mark all high

and low spots on the floor. Make sure

to twist adjustable glides appropriate

to floor conditions. Always begin

assembling screens together at the

highest point of an un-even floor.

Note: If in-line Spine Screens

include change-of-height screen(s),

go now to “Leveling and Connecting

Change-of-Height Spine Screens”

instructions on page 8.

Using a laser alignment tool,

determine and mark all high and

low points on the floor. Adjust the

level and height of the Spine Screen,

beginning at the highest point in the

floor first. To raise the screen, rotate

the glide counter-clockwise. To lower

the screen, rotate the glide clockwise.

Only extend the glides as needed

to make the screen level and plumb

(Figure 2).

Note: If an in-line infeed power pole

or spacer is specified between two

screens, it must be installed between

the designated screens before

connecting the screens. If an in-line

10-wire top infeed power pole is to

be installed, reference “10-Wire Top

Power Infeed (In-Line) Installation”

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

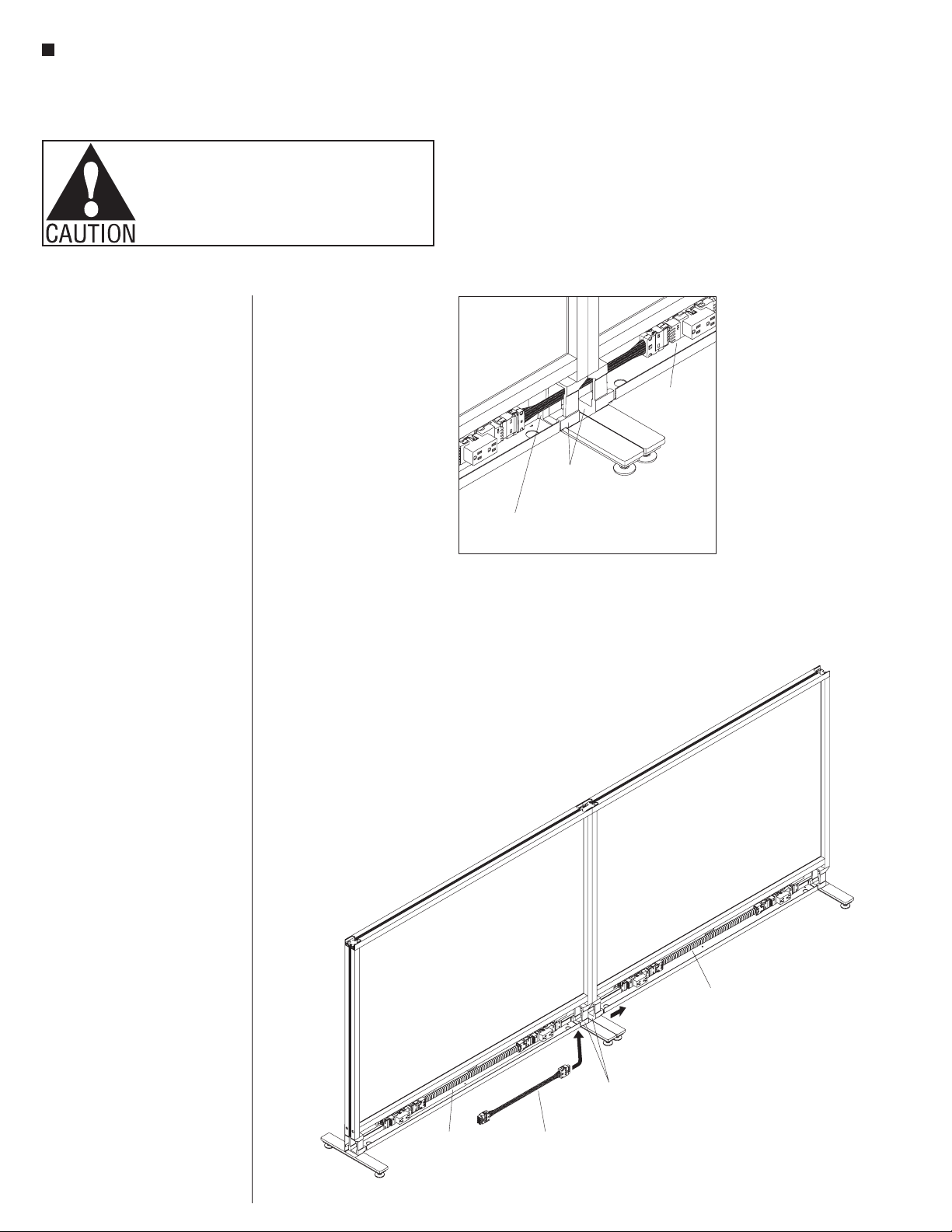

Spine Screen

(first)

Spine Screen

(second)

height-adjustable

glides (adjusted for

panels to be in the

lowest position)

(adjusted for the

panel to be in the

lowest position)

laser

alignment

tool

2

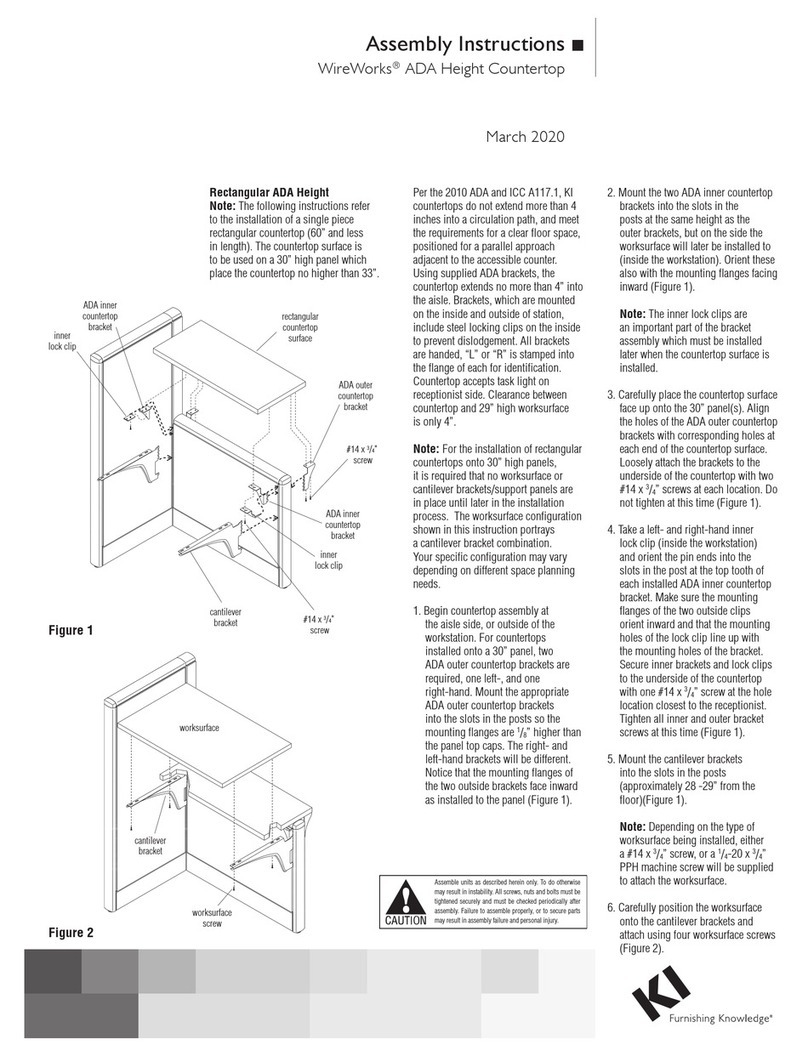

molding

clips

bottom

screen

connector

Detail C

bottom

screen

connector

molding clip

(come installed

from factory)

vertical

frame

channel

Spine

Screen

Spine

Screen

instructions on page 14. If an

in-line 10-wire top infeed power pole

is to be installed with a Flex Screen

intersection, reference “10-Wire Top

Power Infeed (In-Line) Installation

with Flex Screen Intersection”

instructions on page 16. If an

in-line 10-wire base infeed spacer is

to be installed, reference “10-Wire

Base Power Infeed Spacer (In-

Line) Installation” instructions on

page 24. If an in-line 10-wire base

infeed spacer with a Flex Screen

intersection is to be installed,

reference “10-Wire Base Power

Infeed Spacer (In-Line) Installation

with Flex Screen Intersection”

instructions on page 26. If an in-line

spacer is to be installed, reference

“In-Line Spacer Installation”

instructions on page 33. If in-line

spacer is to be installed with a

flex screen intersection, reference

“In-Line Spacer Installation with Flex

Screen Intersection” instructions on

page 34. After the spacer or in-line

infeed power pole has been installed,

proceed to step 4 on this page to

connect Spine Screens.

3. Locate the bottom screen connector

(Detail C) and take note that it

contains two molding clips installed,

one at each side. Figure 2 shows the

molding clips separated

for clarity. Each clip will press-fit

into the appropriate screen’s channel

to help join screens together.

Assure that the first Spine Screen

is level and plumb, and at its final

installation location. Position the

bottom screen connector up to the

bottom of the vertical channel of the

first Spine Screen and firmly press

it in, oriented as shown (Figure 2 &

Detail C).

4. Position the second Spine Screen

in-line against the first Spine Screen,

which has been adjusted level

and plumb. Level and plumb the

second screen to the first screen by

twisting the height-adjustable glides

clockwise or counter-clockwise until

the frame’s vertical edges are aligned

and tops of screens are at the same

height. Connect the screens together

by holding the first Spine Screen in

place while pressing firmly on the

second, into the first so the bottom

screen connector in the first engages

the second screen (Figure 2 &

Detail D).

5. Repeat the process in steps 4 & 5 to

add, level, plumb and connect the

remaining screens in the row. If the

remaining screens to be connected

are different heights, go now to

“Leveling & Connecting

Change-of-Height Spine Screens”

instructions on page 8, step 2.