2

GB Operating instructions two-hand grease gun

Pressol Schmiergeräte GmbH

This documentation is exclusively intended for the operating company and their sta.

Without our written consent, the content of this documentation (textes, gures, drawings, charts,

diagrams etc. ), must not be duplicated or distributed, neither in full or in part, utilized for the purpose

of competition or passed on/made availabe to third parties.

Pressol Schmiergeräte GmbH

Parkstraße 7

93167 Falkenstein | Germany

Phone +49 9462 17-0

Fax +49 9462 17-208

info@pressol.com

www.pressol.com

Operating instructions translation

Date of issue: 10/2019

We reserve the right to make design and product modications, which serve to improve the product.

Table of Contents

1. Introduction ________________________________________________________________________3

1.1 Preface ____________________________________________________________________________3

1.2 Obligations of the personnel __________________________________________________________3

1.3 Symbols in this manual _______________________________________________________________3

1.3.1 Structure of the warning notes _________________________________________________________3

1.3.2 General symbols ____________________________________________________________________3

2. Safety notes ________________________________________________________________________4

2.1 Authorized personnel_________________________________________________________________4

2.2 Intended conditions of use ____________________________________________________________4

3. Design and functional description ______________________________________________________4

4. Area of application __________________________________________________________________4

5. Technical data ______________________________________________________________________5

6. Hazards when handling the grease gun __________________________________________________5

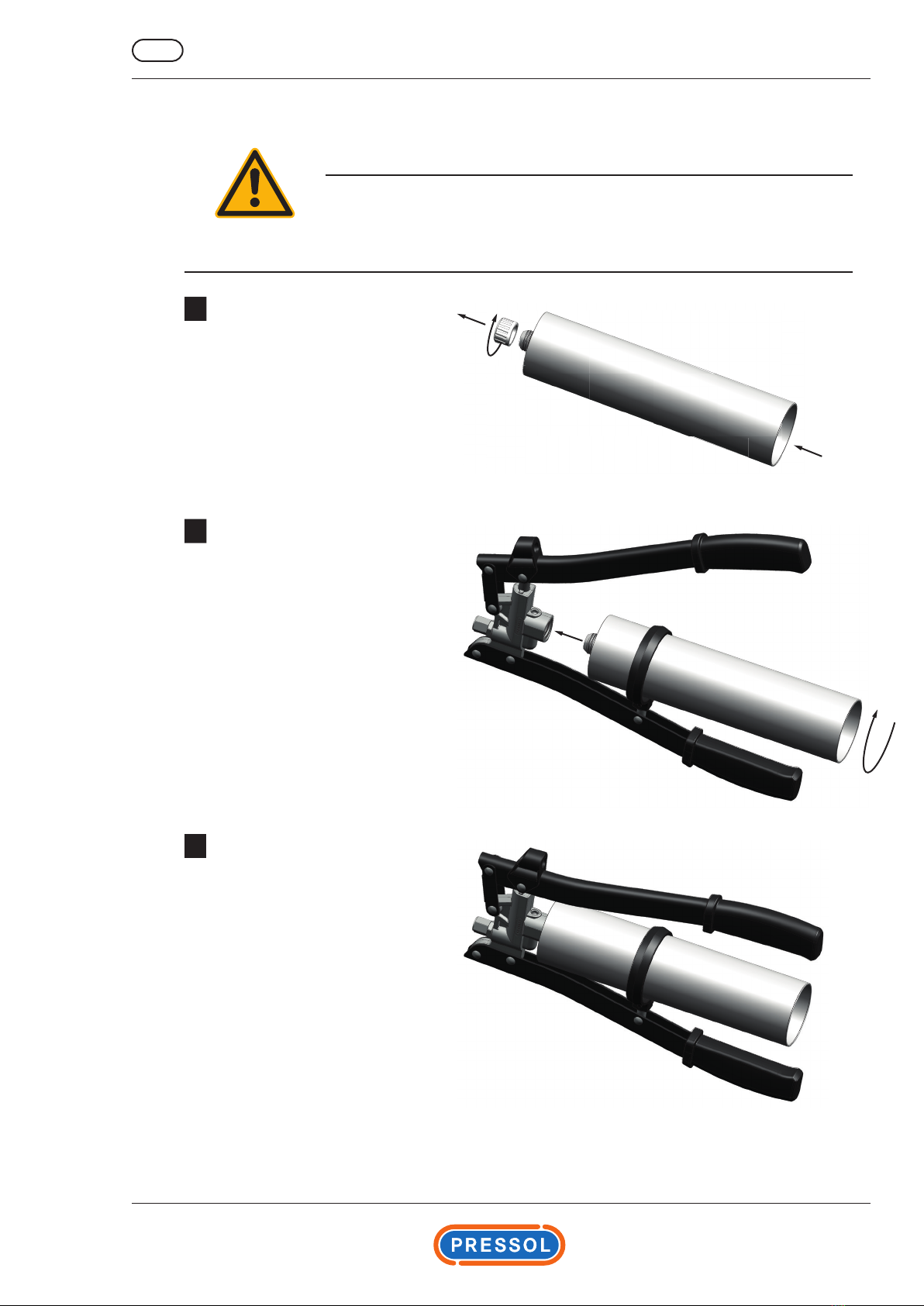

7. Assembly __________________________________________________________________________5

8. Making the grease gun ready for operation _______________________________________________6

8.1 Advises for an ideal operation __________________________________________________________7

9. Care/Maintenance __________________________________________________________________7

10. Accessories according to DIN 1283 ______________________________________________________7

11. Repair/Service ______________________________________________________________________7

12. Disposal ___________________________________________________________________________7