Pressure Tech LF-690 Service manual

1

THE LF-690/691 SERIES

Operating and Service Manual

Series includes all variants of LF-690/691

Issue D

March 2020

2

TABLE OF CONTENTS

1. Description.............................................................................................................................3

2. Installation .............................................................................................................................3

3. Operation...............................................................................................................................4

4. Special Conditions for Safe Use .............................................................................................5

5. Hazardous Location Usage.....................................................................................................5

6. Servicing and Maintenance....................................................................................................5

6.1. Servicing the LF-690 regulator................................................................................6

6.1.1. Accessing the Unbalanced Main Valve Assembly (MVA)....................................6

6.1.2. Accessing the Domed Sensor Assembly (SA)......................................................7

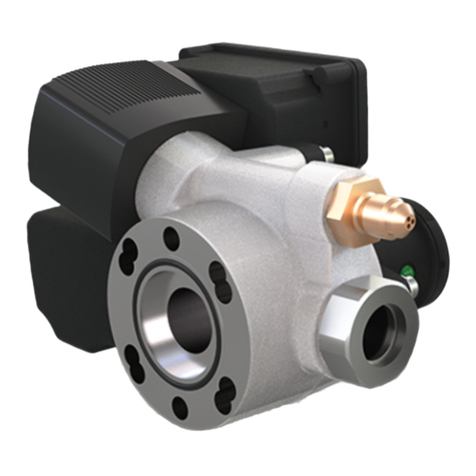

6.1.3. Figure 1 –Sectional View of the LF-690 (with Domed SA/Unbalanced MVA)....8

6.2. Servicing the LF-690 Balanced Regulator ...............................................................9

6.2.1. Accessing the Balanced Main Valve Assembly (MVA) ........................................9

6.2.2. Figure 2 –Sectional View of the LF-690 Balanced MVA...................................10

6.2.3. Accessing the Threaded Sensor Assembly........................................................11

6.2.4. Figure 3 –Sectional View of the LF-690 (with Threaded SA/Balanced MVA)...12

6.3. Servicing the LF-691 regulator..............................................................................13

6.3.1. Accessing the Main Valve Assembly .................................................................13

6.3.2. Accessing the Sensor Assembly ........................................................................14

6.3.3. Figure 4 –Sectional View of the LF-691 (Long TW) ..........................................15

7. Technical Data.........................................................................................................16

8. Warranty Statement ............................................................................................................16

3

1. Description

The LF-690 is a single stage piston sensed pressure regulator, capable of a maximum 690 bar

inlet pressure. This can then be controlled to a range of outlet pressures depending upon

the sensing arrangement. As standard, the LF-690 comes with a Tungsten Carbide main

valve and heat treated 17-4ph seat, which provides excellent resistance to erosion on

hydraulic media.

Ceramic Ball and Plug options are available which provide ultimate protection against the

harsh service encountered on hydraulic systems with the Ceramic Plug design allowing the

LF-691 to achieve up to 1380 bar inlet*.

The regulator is also available with balanced main valve options which allow high accuracy

control of both low and high downstream pressures.

The housing has been machined from 316 SS (17-4ph SS on the LF-691 high pressure option)

to ensure maximum protection against the media on which it will be used, and the

environment in which it will be placed.

*achievable with specific modification –Please contact the office for information.

2. Installation

Before system start-up, it is recommended that all systems be pressure tested, leak tested

and purged with an inert gas such as nitrogen.

Prior to placing into service ensure that the regulator is in the fully closed position, with the

adjusting mechanism turned completely anti-clockwise.

Check the model number reference to ensure that the pressure range complies with the

installation requirements.

Visually inspect the regulator for any signs of damage or contamination. If any foreign

materials are present and cannot be removed from the regulator, or if the threads on the

regulator appear to be damaged, please contact the office immediately to arrange for the

regulator to be returned for service.

The Inlet and Outlet ports are clearly marked. Select the correct size and type of connection

fittings for these ports which are indicated in the regulators part number. Both medium

pressure type (MP) ‘A’ and National Pipe Thread (NPT) ‘N’options are available on this

regulator. For NPT threads, ensure that PTFE tape is applied correctly to the fittings,

applying two overlapping layers in the direction of the thread, taking care that the tape does

not come into contact with the first thread.

Any gauge ports on the regulator will be 1/4” NPT unless otherwise stated. If any gauge port

is not required, ensure that the port is plugged prior to installation.

4

The media supplied to the regulator must be clean. Contamination can damage the seat

which may cause the regulator to fail. Filtration suited to the application is recommended

upstream of the regulator.

Should further assistance or information be required in relation to installation of any

Pressure Tech regulator please contact the office, giving reference to the regulators part

number and/or serial number.

3. Operation

Turning the hand wheel (or T-Bar) clockwise compresses the load spring, which in turn

opens the main valve, and allows the inlet pressure to pass through the orifice until the

outlet pressure is equivalent to the loading forces set by the compressed spring.

The LF-690 incorporates a segregated captured vent, which allows the outlet pressure to be

reduced whilst turning the hand wheel anti-clockwise. Excess pressure is vented off through

the ‘Vent’ port marked at the bottom of the regulator. This port should not be plugged or

blocked at any time.

The LF-690 series may be offered with pressure limiting, pressure locking or pre-set pressure

options:

Pressure limited regulators are fitted with locknuts on the adjusting mechanism in order to

limit the maximum allowable downstream pressure. Regulators fitted with pressure limiting

locknuts will state the limited pressure on the regulator label and this will also be indicated

in the part number.

Pressure locking regulators are fitted with a locking cap which may be set (when specified)

to pre-determined requirements. It is secured in place by three M5 grub screws which lock

against the bonnet of the regulator creating an anti-tamper device to ensure the pressure

cannot be adjusted accidentally.

Pre-set pressure regulators are adjusted (factory set) to specified customer requirements

within a given pressure range.

Both pressure locking and pre-set pressure regulators will be fully adjustable through a

given pressure range and the maximum allowable working pressures will be indicated on

the regulator label and in the part number.

*Note - A table is available on request defining allowable tolerances for set points within a

given pressure range.

5

4. Special Conditions for Safe Use

Turning the hand-wheel (or T-bar) anti-clockwise (with pressure on the outlet) should be

refrained on non-venting regulators. Pressure should be reduced in this case by venting

downstream of the regulator, and turning the hand wheel simultaneously anti-clockwise.

5. Hazardous Location Usage

This equipment has not been manufactured specifically for use in potentially explosive

atmospheres and as such an ignition hazard assessment has not been carried out on this

product. If the user should wish to use this product in such an environment where there

may be a potentially explosive atmosphere then it is the responsibility of the user to

conduct an ignition hazard assessment against 99/92/EC.

6. Servicing and Maintenance

With so many variants of the LF-690 available, the following section uses three examples

with the aim of covering most options. The product supplied may vary from these examples.

Should any assistance be required then please do not hesitate to contact the office.

Servicing and maintenance work on the LF-690 regulators should only be performed after

fully reading and understanding the Operating and Servicing Manual. Due to the

compressibility of gases, the operator should not endanger themselves or others by working

on this regulator without prior knowledge of the Health and Safety risks relating to handling

of technical gases. Any uncertainty should be clarified with Pressure Tech before working on

the regulator.

Pressure Tech Ltd recommends the use of the following Lubricants/Adhesives during

servicing:

-Krytox GPL 205 lubricant:For the O-rings.

-Molykote 1000 paste: For the adjusting screw.

-Loctite 638: For the lower spring rest thread.

Prior to commencing service, please ensure that:

-The equipment has been de-pressurised

-The load spring has been de-compressed by turning the adjusting mechanism fully

anti-clockwise

-Applications involving toxic, flammable or corrosive media have been fully purged

To ensure the best possible results from servicing, when re-assembling the regulator and

any assemblies within it, ensure that all areas of the components and the regulator body are

cleaned and free from contaminants which may result in failure of the regulator.

6

6.1. Servicing the LF-690 regulator

*Note: Fig 1 should be used as a reference for the following set of instructions

6.1.1. Accessing the Unbalanced Main Valve Assembly (MVA)

To access the Main Valve Assembly:

i. Firmly clamp the flats at the bottom of the regulator in the vice, with the bottom

nut (7) facing up.

ii. Remove the bottom nut (7) from the body (1).

iii. The valve spring (6), shuttle (4), seat cartridge (5), ceramic ball (9) and ceramic

seat (2) can now be removed from the assembly. It may be necessary to remove

the regulator from the vice to do so.

iv. The connector pin (8) may also be withdrawn at this point by up righting the

regulator with the main valve assembly removed.

v. Care should be taken when reassembling not to damage the sealing face of the

connector pin (8). Needle nose pliers should be used to replace the connector pin

chamfer down into the body while the body is up-side down. The pin should

locate within the baffle plate (3).

vi. The new ceramic seat (2) should be placed in the seat cartridge (5) with the BS

806 ‘O’ ring (26).

vii. These can then be placed into the regulator body, being careful to ensure that

the ‘O’ ring (26) remains in place and that the seat cartridge (5) locates in the

correct place within the body (1).

viii. The ceramic ball (9) and shuttle (4) can then be placed into their location within

the seat cartridge (5).

ix. The main valve spring (6) can now be placed on the stem of the shuttle (4).

x. Replace the BS019 ‘O’ ring (25) and back up ring (28) on the bottom nut (7), then

assemble into the regulator body.

It is recommended that all parts in the repair kits are used. Any defect parts removed during

the service should be disposed of.

To ensure that the main valve assembly has been correctly and effectively installed it may

be required to perform the appropriate seat leak test as per ANSI/FCI 70-2.

7

6.1.2. Accessing the Domed Sensor Assembly (SA)

The loading mechanism and vent seat for the LF-690 can be accessed from the top of the

regulator. Ensure the spring is de-compressed by rotating the hand wheel fully anti-

clockwise and follow the instructions below:

i. Remove the securing grub screw (20) from the regulator body (1).

ii. Unscrew the pan screw (36) and remove the name plate (33) from the hand

wheel (35).

iii. Using a 24mm socket, unscrew the locknut (34) and remove the hand wheel (35)

from the adjusting screw (18).

iv. With the regulator secured up-right in a vice, remove the bonnet (31) by using a

torque wrench or equivalent with 47mm open end.

v. Un-screw and lift the top works from the assembly, inclusive of the bonnet (31),

load spring (15), adjusting mechanism (16, 17, 18 & 19) and lower spring rest (12)

from the body.

vi. The sensor assembly (10, 11, 13 & 14) can be removed from the body by using an

M5 bolt and pliers.

vii. If necessary, the baffle plate (3) and connector (8) can be withdrawn. Inspect the

connector for damage and replace if required.

viii. The vent seat (14) can be accessed by removing the sensor (10) from the sensor

holder (11) and gripping the sensor firmly in a vice with the vent seat nut (13)

facing upwards.

ix. The vent seat nut (13) can be removed using a 10mm open ended spanner and

the vent seat (14) can then be removed from the sensor (10) along with the 9mm

x 1mm ‘O’ ring (22).

x. Inspect the vent seat (14) for damage and replace if necessary.

xi. Replace all ‘O’ rings (21, 22, 23, 24, 29, 30 & 32) located on the sensor (10) and

sensor holder (11) prior to reassembly, ensuring adequate lubrication is used.

xii. Place the connector (8) into the baffle plate (3) and locate into the regulator

body, taking care not to damage the sealing edge of the connector.

xiii. After reassembling the sensor (10) and holder (11), place the assembly into the

regulator body (1) ensuring that it is firmly in place.

xiv. Remove the M5 screw from the sensor holder if used.

xv. Screw the top works onto the regulator body and using a torque wrench, tighten

to 120Nm.

xvi. Tighten the securing grub screw (20) against the bonnet (31).

xvii. The hand wheel (35) can now be secured on to the adjusting screw (18) using the

locknut (34).

xviii. The name plate (33) can then be secured using the pan screw (36).

It is recommended that all parts in the repair kits are used. Any defect parts removed during

the service should be disposed of.

Replacement ‘O’ rings should be lubricated with suitable non-hydrocarbon grease such as

Krytox GPL 205.

8

6.1.3. Figure 1 –Sectional View of the LF-690 (with Domed SA/Unbalanced MVA)

© Copyright of Pressure Tech Ltd

Parts List

Item

Part Number

Description

1

PT-690-N-LF

BODY - N PORTING

2

PT-C-029-007

CERAMIC SEAT

3

PT-C-086

BAFFLE PLATE

4

PT-C-088-006-002

MAIN VALVE

5

PT-C-089-008

SEAT CARTRIDGE

6

PT-C-099

MV SPRING

7

PT-690-010

BOTTOM NUT

8

PT-690-011-011

CONNECTOR PIN

9

PT-690-017

CERAMIC BALL

10

PT-C-094

SENSOR

11

PT-C-093

SENSOR HOLDER

12

PT-C-095-001

DOMED SPRING REST

13

PT-C-091

VENT SEAT NUT

14

PT-C-029-013

PEEK VENT SEAT

15

PT-C-042

LOAD SPRING

16

PT-C-045

ADJUSTING NUT

17

PT-C-046

SCREW

18

PT-C-043-004

ADJUSTING SCREW

19

BEAR-51103-SS

SS BEARING

20

FIT-M3x6MM-SS-316-GRUBSCRW

M3 X 6mm GRUB SCREW

21

OR-0090-20

O' RING STD

22

OR-0090-10

O' RING STD

23

OR-0460-20

O' RING STD

24

OR-0420-20

O' RING STD

25

OR-BS019

O' RING STD

26

OR-BS806

O' RING STD

27

OR-0350-20

O' RING STD

28

ORB-BS019-PTFE

PTFE BACK UP RING

29

ORB-PT-C-139

PTFE BACK UP RING

30

ORB-PT-C-098-005

PTFE BACK UP RING

31

PT-C-040

BONNET

32

OR-0050-20

O' RING STD

33

PT-C-049

NAMEPLATE

34

PT-C-132

LOCK NUT

35

PT-C-048-001

LARGE HANDWHEEL

36

FIT-M3-08-A4-70.0-SKT-BTN

SCREW

9

6.2. Servicing the LF-690 Balanced Regulator

*Note: Fig 2 and 3 should be used as a reference for the following set of instructions

6.2.1. Accessing the Balanced Main Valve Assembly (MVA)

To access the Main Valve Assembly:

Disassembly

i. Firmly clamp the flats at the bottom of the regulator Body (1) in a vice, with the bottom nut (3)

facing up.

ii. Remove the bottom nut (3) from the body (1).

iii. The main valve spring (2), seat cartridge (9), main valve (8), washer (5), PTFE spacer (6), ‘O’ rings

and Backups (31,34,38,39,40) can then be removed Bottom Nut (3).

Note: It may be necessary to remove the regulator from the vice to do so.

iv. The connector pin (4) may also be withdrawn at this point by up righting the regulator with the

main valve assembly removed.

Reassembly

v. Use needle nose pliers to replace the connector pin chamfer down into the body, while the

body is up-side down. The pin should locate within the baffle plate (7).

Note: Care should be taken when reassembling not to damage the sealing face of the connector

pin (4).

vi. Place the soft seat (10) into the seat cartridge (9) with the ‘O’ ring groove on the seat facing

outwards and place the BS806 ‘O’ ring (32) into the groove.

vii. Holding the regulator upright, position the assembly (9,10,32) into the regulator body (1)

ensuring that it finds the locating bore, then turn the regulator body (1) upside down whilst

supporting the assembly (9,10,32) to ensure it does not fall out of place.

viii. Replace all of the ‘O’ rings and Backups (31,34,38,39,40) within and around Bottom Nut (3).

Note: The small back up ring (38) should be placed into the bottom nut (3) first, followed by the

3.6mm ‘O’ ring (34).

ix. Place the washer (5) into the small recess, on the top of the bottom nut (3).

x. Place/push the PTFE spacer (6), into the upper bore of the bottom nut (3)

Note: Add a small amount of Krytox lubricant to the underside of the PTFE spacer (6), before

placing into the bottom nut (3). This is to help the PTFE spacer from coming away from the

bottom nut, during assembly into the regulator body (1).

xi. Guide the main valve spring (2), over the stem of the main valve (8).

xii. Guide/place the main valve (8) and the main valve spring (2), into the central bore of the

bottom nut (3) and seated onto the washer (5). (which acts as a lower spring rest).

xiii. With the regulator remaining upside down, guide the full bottom nut assembly

(2,,5,6,10,31,32,34,38,40), with the domed sealing edge of the main valve (8), leading into the

central bore of the seat cartridge (9) and screw the bottom nut (3) into the regulator body (1)

xiv. Firmly clamp the flats at the bottom of the regulator Body (1) in a vice, with the bottom nut (3)

facing up.

xv. Use a torque wrench, tighten the bottom nut (3) against the body (1) to 40Nm

It is recommended that all parts in the repair kits are used. Any defect parts removed during the service

should be disposed of.

To ensure that the main valve assembly has been correctly and effectively installed it may be required to

perform the appropriate seat leak test as per ANSI/FCI 70-2

10

6.2.2. Figure 2 –Sectional View of the LF-690 Balanced MVA

11

6.2.3. Accessing the Threaded Sensor Assembly

The loading mechanism and vent seat for the LF-690 can be accessed from the top of the regulator. Ensure

the spring is de-compressed by rotating the hand wheel fully anti-clockwise and follow the instructions

below:

i. Remove the securing grub screw (26) from the regulator body (1).

ii. Unscrew the pan screw (27) and remove the name plate (24) from the hand wheel (23).

iii. Using a 24mm socket, unscrew the locknut (25) and remove the hand wheel (23) from the

adjusting screw (19).

iv. With the regulator secured up-right in a vice, remove the bonnet (18) by using a torque wrench

or equivalent with 47mm open end.

v. Un-screw and lift the top works from the assembly, inclusive of the bonnet (18), load spring

(17), adjusting mechanism (19,20,21,22) from the Regulator body (1).

vi. The sensor assembly (11-16,28-30,33,35-37) can be removed from the regulator body (1) firmly

gripping the flats of the lower spring rest (13) with pliers and lifting.

vii. If necessary, the baffle plate (7) and connector pin (4) can be withdrawn. Inspect the connector

for damage and replace if required.

viii. Grip the flats of the lower spring rest (13) in a vice so that the vent seat nut (16) is facing upwards.

ix. The vent seat nut (16) can be removed using a 10mm open ended spanner and the vent seat (11)

can then be removed from the sensor (15) along with the 9mm x 1mm ‘O’ ring (28).

x. Inspect the vent seat (23) for damage and replace.

xi. Replace all ‘O’ rings and backups (29,30,33,35-37) located on the sensor (15) and sensor holder

(14) prior to reassembly, ensuring adequate lubrication is used.

xii. Insert the sensor (15) into the sensor holder (14).

xiii. Apply a small droplet of Loctite 638, to the thread of the lower spring rest and screw the lower

spring rest (13) into the top of the sensor (15).

xiv. Grip the flats of the lower spring rest (13) in a vice and tighten the sensor (15) against it using the

flats at the base of the sensor.

xv. Secure the vent seat nut (16) using a 10mm open ended spanner.

xvi. Place the connector pin (4) into the baffle plate (7) and locate into the regulator body, taking

care not to damage the sealing edge of the connector pin.

xvii. After reassembling the sensor (15) and holder (14), place the assembly into the regulator body

(1) ensuring that it is firmly in place.

xviii. Place the load spring (27) onto the spring rest (25).

xix. Screw the top works (18-22) onto the regulator body ensuring that the adjusting screw properly

locates within the load spring (17) and using a torque wrench with 47mm open end, tighten to

120Nm.

xx. Tighten the securing grub screw (26) against the bonnet (18).

xxi. The hand wheel (23) can now be secured on to the adjusting screw (19) using the locknut (25).

xxii. The name plate (24) can then be secured using the pan screw (27).

It is recommended that all parts in the repair kits are used. Any defect parts removed during the service

should be disposed of.

Replacement ‘O’ rings should be lubricated with suitable non-hydrocarbon grease such as Krytox GPL 205.

12

6.2.4. Figure 3 –Sectional View of the LF-690 (with Threaded SA/Balanced MVA)

Parts List

Item

Part Number

Description

1

PT-690-N-LF-03A-002

BODY - N PORTING

2

PT-690-004

MAIN VALVE SPRING

3

PT-690-010-001

BOTTOM BODY NUT

4

PT-690-011-013

CONNECTOR PIN

5

PT-690-020

WASHER

6

PT-690-041

PTFE SPACER

7

PT-C-086

BAFFLE PLATE

8

PT-C-088-010

BALANCED MAIN VALVE CV 0.3

9

PT-C-089-016

SEAT HOLDER

10

PT-C-029-015

CERAMIC SEAT CV 0.3

11

PT-C-029-013

PEEK VENT SEAT GF30

12

PT-C-037

SLIDE RING

13

PT-C-039

SPRING REST

14

PT-C-085

SENSOR HOLDER

15

PT-C-087

12mm SENSOR

16

PT-C-091

VENT SEAT NUT

17

PT-C-042

MAIN LOAD SPRING 500KG

18

PT-C-040

BONNET

19

PT-C-043-004

ADJUSTING SCREW

20

PT-C-045

ADJUSTING NUT

21

PT-C-046

ADJUSTING NUT SCREW

22

BEAR-51103-SS

SS BEARING

23

PT-C-048-001

LARGE NYLON HAND WHEEL

24

PT-C-049

NAMEPLATE

25

PT-C-132

LOCK NUT

26

FIT-M3x6MM-SS-316-GRUBSCRW

M3 X 6mm GRUB SCREW

27

FIT-M3-08-A4-70.0-SKT-BTN

SCREW

28

OR-0090-10

O' RING STD

29

OR-0420-20

O' RING STD

30

OR-0460-20

O' RING STD

31

OR-BS019

O' RING STD

32

OR-BS806

O' RING STD

33

ORB-PT-C-139

PTFE BACK UP RING

34

OR-0036-24

O' RING STD

35

OR-0080-20

O' RING STD

36

OR-0120-20

O' RING STD

37

ORB-PT-C-051-001

BACK UP RING

38

ORB-PT-C-183

BACK UP RING

39

ORB-BS019-PTFE

PTFE BACK UP RING

40

OR-BS4518-0251-16

O' RING STD

13

6.3. Servicing the LF-691 regulator

*Note: Fig 4 should be used as a reference for the following set of instructions

6.3.1. Accessing the Main Valve Assembly

To access the Main Valve Assembly:

i. Firmly clamp the flats at the bottom of the regulator in the vice, with the bottom nut (7) facing

up.

ii. Remove the bottom nut (7) from the body (1).

iii. The valve spring (6), shuttle (4), seat cartridge (5), ceramic plug (9) and ceramic seat (2) can now

be removed from the assembly. It may be necessary to remove the regulator from the vice to

do so.

iv. The connector pin (8) may also be withdrawn at this point by up righting the regulator with the

main valve assembly removed.

v. Care should be taken when reassembling not to damage the sealing face of the connector pin

(8). Needle nose pliers should be used to replace the connector pin chamfer down into the body

while the body is up-side down. The pin should locate within the baffle plate (3).

vi. The new ceramic seat (2) should be placed in the seat cartridge (5) with the BS 806 ‘O’ ring (26).

vii. These can then be placed into the regulator body, being careful to ensure that the ‘O’ ring (26)

remains in place and that the seat cartridge (5) locates in the correct place within the body (1).

viii. The ceramic plug (9) and shuttle (4) can then be placed into their location within the seat

cartridge (5).

ix. The main valve spring (6) can now be placed on the stem of the shuttle (4).

x. Replace the BS019 ‘O’ ring (25) and back up ring (28) on the bottom nut (7), then assemble into

the regulator body.

It is recommended that all parts in the repair kits are used. Any defect parts removed during the service

should be disposed of.

To ensure that the main valve assembly has been correctly and effectively installed it may be required to

perform the appropriate seat leak test as per ANSI/FCI 70-2.

14

6.3.2. Accessing the Sensor Assembly

The loading mechanism and vent seat for the LF-691 can be accessed from the top of the regulator. Ensure

the spring is de-compressed by rotating the T-Bar fully anti-clockwise and follow the instructions below:

i. Remove the T-Bar (32, 33) by unscrewing one side whilst firmly gripping the other.

ii. With the regulator secured up-right in a vice, remove the bonnet (31) by using a torque wrench

or equivalent with 47mm open end.

iii. Un-screw and lift the top works from the assembly, inclusive of the bonnet (31), load spring

(15), adjusting mechanism (16, 17, 18 & 19) and lower spring rest (12) from the body.

iv. The sensor assembly (10, 11, 13 & 14) can be removed from the body by using an M5 bolt

(supplied with kit) and pliers.

v. If necessary, the baffle plate (3) and connector (8) can be withdrawn. Inspect the connector for

damage and replace if required.

vi. The vent seat (14) can be accessed by removing the sensor (10) from the sensor holder (11) and

gripping the sensor firmly in a vice with the vent seat nut (13) facing upwards.

vii. The vent seat nut (13) can be removed using a 10mm open ended spanner and the vent seat

(14) can then be removed from the sensor (10) along with the 6.85mm x 2mm ‘O’ ring (22).

viii. Inspect the vent seat (14) for damage and replace if necessary.

ix. Replace all ‘O’ rings (21, 22, 23, 24, 29 & 30) located on the sensor (10) and sensor holder (11)

prior to reassembly, ensuring adequate lubrication is used.

x. Place the connector (8) into the baffle plate (3) and locate into the regulator body, taking care

not to damage the sealing edge of the connector.

xi. After reassembling the sensor (10) and holder (11), place the assembly into the regulator body

(1) ensuring that it is firmly in place.

xii. Remove the M5 screw from the sensor holder if used.

xiii. Screw the top works onto the regulator body and using a torque wrench, tighten to 120Nm.

xiv. Tighten the securing grub screw (20) against the bonnet (31).

xv. Place the T-Bar piece with the male thread (32) through the hole on the adjusting screw and

tighten the second T-Bar piece (33) against it.

It is recommended that all parts in the repair kits are used. Any defect parts removed during the service

should be disposed of.

Replacement ‘O’ rings should be lubricated with suitable non-hydrocarbon grease such as Krytox GPL205.

15

6.3.3. Figure 4 –Sectional View of the LF-691 (Long TW)

© Copyright of Pressure Tech Ltd

Parts List

Item

Part Number

Description

1

PT-690-N-LF-03A-001

BODY –‘N’PORTING 3/8”MP

2

PT-C-029-007

CERAMIC SEAT

3

PT-C-086

BAFFLE PLATE

4

PT-C-088-006-001

MAIN VALVE

5

PT-C-089-011

SEAT CARTRIDGE

6

PT-C-099

MV SPRING

7

PT-690-010-002

BOTTOM NUT

8

PT-690-011-015

CONNECTOR PIN

9

PT-690-018

CERAMIC PLUG

10

PT-C-155-001

SENSOR

11

PT-C-156-001

SENSOR HOLDER

12

PT-C-095-001

DOMED SPRING REST

13

PT-C-091-003

VENT SEAT NUT

14

PT-C-029-013-001

PEEK VENT SEAT

15

SPR-G40X89

LOAD SPRING

16

PT-C-045

ADJUSTING NUT

17

PT-C-046

SCREW

18

PT-C-043-001

ADJUSTING SCREW

19

BEAR-51103-SS

SS BEARING

20

FIT-M3x6MM-SS-316-GRUBSCRW

M3 X 6mm GRUB SCREW

21

OR-0061-25

O' RING STD

22

OR-0068-20

O' RING STD

23

OR-0418-22

O' RING STD

24

OR-0457-22

O' RING STD

25

OR-BS019

O' RING STD

26

OR-BS806

O' RING STD

27

OR-0350-20

O' RING STD

28

ORB-PT-C-168

PTFE BACK UP RING

29

ORB-PT-C-167

PTFE BACK UP RING

30

ORB-PT-C-166

PTFE BACK UP RING

31

PT-C-040-008

BONNET

32

PT-C-180

T BAR HANDLE

33

PT-C-107

T BAR HANDLE

16

7. Technical Data

Fluid Media: All gases and liquids compatible with materials of construction

Max Inlet Pressure: LF690 Standard –690 bar

LF691 Standard –1380 bar

Balanced Main Valve –1034 bar

Max Outlet Pressure Range: LF690 Standard –690 bar

LF691 Standard –1380 bar

Balanced Main Valve –1034 bar

Operating Temperature: -20°C to +80°C

Materials: Body and Trim: 316 SS

Seat: Ceramic

Flow Capacity (Cv): Standard –0.1

High Pressure –0.05

Balanced –0.3

Leakage: Liquid: Zero drops of water at max inlet

Gas: Bubble tight

8. Warranty Statement

Pressure Tech Ltd guarantee all products correspond with their specification at the time of delivery and,

with exception to wear and tear, wilful damage, negligence, and abnormal working conditions, will be free

from defects for a period of 12 months from date of delivery.

This manual suits for next models

1

Table of contents

Other Pressure Tech Controllers manuals

Pressure Tech

Pressure Tech LF-301 SERIES Service manual

Pressure Tech

Pressure Tech SS-231 Series Service manual

Pressure Tech

Pressure Tech LF-792 Series Service manual

Pressure Tech

Pressure Tech MF-414 Series Service manual

Pressure Tech

Pressure Tech LF-540 Series Service manual

Pressure Tech

Pressure Tech THE SS-414 Series Service manual