Pressure Tech SS-231 Series Service manual

1

THE SS-231 SERIES

Operating and Service Manual

Series includes all variants of SS-231

Issue A

March 2020

2

TABLE OF CONTENTS

1. Description.............................................................................................................................3

2. Installation .............................................................................................................................3

3. Operation...............................................................................................................................5

4. Special Conditions for Safe Use .............................................................................................5

5. Hazardous Location Usage.....................................................................................................5

6. Servicing and Maintenance....................................................................................................5

6.1. Servicing the SS-231 (Balanced Design)..................................................................6

6.1.1. Accessing the Main Valve Assembly (MVA)........................................................6

6.1.2. Accessing the Sensor Assembly (SA)...................................................................7

6.1.3. Adjusting the Set Point .....................................................................................10

6.1.4. Figure 1 –Sectional View of the SS-231 Balanced Design................................11

7. Technical Data......................................................................................................................12

8. Warranty Statement ............................................................................................................12

3

1. Description

The SS-231 is a versatile non-venting (NV), piston sensed ‘medium-flow’forward reducing

pressure regulator for gas and liquid applications.

The SS-231 as standard is a non-venting regulator, which features a balanced main valve

design as standard which minimises load on the seat and provides stable pressure control

under decaying inlet conditions. Additionally, servicing is simplified with easy access to the

seat cartridge from the base of the regulator.

Operating at depths of up to 3,000 metres (10,000ft), the SS231 features a (NV) 1:1 ratio

sensor assembly, as standard for sub-sea applications and incorporates, the option of the

following top works assemblies, dependant of the functionality requirements:

-‘SR’ - Spring Loaded with Reference to External Sea Water Pressure. (*Ref. 6.1.4 for

Reference Port detail, circled in red)

-‘SS’ – Spring Loaded with Sealed Chamber to remain completely unaffected by the

external sea water environment conditions. (Without Reference port)

Pressure Equipment Directive (PED) 2014/68/EC Declaration

This equipment is designed and manufactured in accordance with Sound Engineering Practice

(SEP) Article 4, Paragraph 3 of the directive 2014/68/EC. As such, CE marking must not be

applied. The equipment is marked under section 3.3 of Essential Safety Requirements of the

directive.

2. Installation

Before system start-up, it is recommended that all lines should be free from any form of

contaminations, as those can affect regulator performance and functionality. all systems be

pressure tested, leak tested and purged with an inert gas such as nitrogen.

Prior to placing into service ensure that the regulator is in the fully closed position, with the

adjusting mechanism turned completely anti-clockwise.

For pre-set regulators the supply pressure should be increased gradually and also to be

mindful that downstream pressure will be present.

Check the model number reference to ensure that the pressure range complies with the

installation requirements.

Visually inspect the regulator for any signs of damage or contamination. If any foreign

materials are present and cannot be removed from the regulator, or if the threads on the

regulator appear to be damaged, please contact the office immediately to arrange for the

regulator to be returned for service.

The Inlet and Outlet ports are clearly marked. Select the correct size and type of connection

fittings for these ports which are indicated in the regulators part number. Both British

4

Standard Pipe (BSPP) ‘B’ and National Pipe Thread (NPT) ‘N’ options are available on this

regulator. Use the correct dowty or bonded seal for BSPP connections, self-centring seals are

recommended. For NPT threads, ensure that PTFE tape is applied correctly to the fittings,

applying two overlapping layers in the direction of the thread, taking care that the tape does

not come into contact with the first thread. Any gauge ports on the regulator will be 1/4” NPT

unless otherwise stated. If any gauge port is not required, ensure that the port is plugged

prior to installation.

The media supplied to the regulator must be clean. Contamination can damage the seat which

may cause the regulator to fail. Filtration suited to the application is recommended upstream

of the regulator.

Should further assistance or information be required in relation to installation of any Pressure

Tech regulator please contact the office, giving reference to the regulators part number

and/or serial number.

5

3. Operation

The SS-231 series of regulator are fitted with a stainless-steel Anti-tamper cap as standard. It

is recommended that for the pressure adjustment, the anti-tamper cap is removed, and a

13mm open ended spanner (or adjustable) is used to loosen the lock nut, a large flat headed

screwdriver is to be used to adjust and set the outlet pressure. Once correct set up is achieve

the lock nut should be reposition and engaged with bonnet to secure the set point. (*Ref.

6.1.3)

Turning the adjusting mechanism clockwise compresses the spring, which in turn opens the

main valve and allows the inlet pressure to pass through the seat orifice until the outlet

pressure is equivalent to the loading forces set by the compressed spring. Increase the outlet

pressure in this way until the desired pressure is achieved.

To reduce the outlet pressure, the adjusting mechanism should be turned anti-clockwise

whilst the media is flowing, or whilst venting downstream of the regulator. (*Ref. 6.1.3)

The desired outlet pressure should be set whilst increasing the pressure. Do not exceed the

maximum inlet and outlet pressures of the regulator which are indicated on the regulator

label.

4. Special Conditions for Safe Use

The SS-231 series are pressure regulators and should not be used as an isolation valve. When

adjusting Non-Venting (NV) option, the outlet pressure shall be reduced by venting

downstream of the regulator whilst simultaneously turning the adjusting mechanism anti-

clockwise. (*Ref. 6.1.3)

5. Hazardous Location Usage

This equipment has not been manufactured specifically for use in potentially explosive

atmospheres and as such an ignition hazard assessment has not been carried out on this

product. If the user should wish to use this product in such an environment where there may

be a potentially explosive atmosphere then it is the responsibility of the user to conduct an

ignition hazard assessment against 99/92/EC.

6. Servicing and Maintenance

Servicing and maintenance work on the SS-231 regulators should only be performed after

fully reading and understanding the Operating and Servicing Manual. Due to the

compressibility of gases, the operator should not endanger themselves or others by working

on this regulator without prior knowledge of the Health and Safety risks relating to handling

of technical gases. Any uncertainty should be clarified with Pressure Tech before working on

the regulator.

6

Pressure Tech Ltd recommends the use of the following Lubricants during servicing:

-Krytox GPL 205 lubricant: For the O-rings.

-Molykote 1000 paste: For the adjusting screw.

Prior to commencing service, please ensure that:

-The equipment has been de-pressurised

-The load spring has been de-compressed by turning the adjusting mechanism fully

anti-clockwise

-Applications involving toxic, flammable or corrosive media have been fully purged and

decontaminated sufficiently for safe service

To ensure the best possible results from servicing, when re-assembling the regulator and any

assemblies within it, ensure that all areas of the components and the regulator body are

cleaned and free from contaminants which may result in failure of the regulator.

6.1. Servicing the SS-231 (Balanced Design)

*Note: Fig 1 should be used as a reference for the following set of instructions

6.1.1. Accessing the Main Valve Assembly (MVA)

To access the Main Valve Assembly (MVA):

i. With the flats of the regulator body (26) secured in a vice*, carefully loosen and

remove the bottom nut (20) using a 30mm socket or open-ended spanner.

*NOTE: Soft vice jaws must be used, when securing the body within the vice

against flats. (as without may cause damage to sealing surface for BSP O ring) Due

to the position of the flats it may be necessary to angle the body in the vice with

the bottom nut upright for access.

ii. Lift the bottom nut (20) from the regulator body (26). The main valve (24) and

main valve spring (21) will be secured by the O-ring (4) and will likely come away

with the bottom nut (20), otherwise proceed to remove the main valve (24) and

main valve spring (21) from the assembly.

iii. Carefully remove the soft seat (23) and O-ring (5) from the assembly*.

*NOTE: As the main valve assembly is a compression-based design, the soft seat

may be secured in the bottom nut upon its removal.

iv. Where necessary, disassemble the soft seat (23), main valve (24) and main valve

spring (21) from the bottom nut (20).

v. Visually inspect the sealing face (chamfer) of the soft seat (23) and the main valve

(24) for signs of damage and replace as required.

vi. Remove and replace the O-rings (4 & 5) as required.

vii. Install the 2x O-rings (6) around the bottom nut (20).

viii. Place the bottom nut (20) on a flat surface and drop the main valve spring (21) into

the bore.

7

ix. With O-ring (4) installed and suitably lubricated, lower the main valve (24) into the

bottom nut (20) through the main valve spring (21) and press down until the O-

ring (4) has engaged in the lower bore.

*NOTE: Press the main valve (24) down a couple of times, within the bottom nut

(20). The main valve should move freely, within the bottom nut and spring back to

start position.

x. Position the soft seat (23) over the main valve (24), taking care not to damage the

sealing face as it passes over the main valve stem.

xi. Install O-ring (5) around the soft seat (23).

xii. Remove the regulator body (26) from the vice and whilst holding upright, insert

the main valve assembly (MVA), ensuring that the main valve (24) passes through

the air deflector (22) and screw in place until finger tight.

xiii. Secure the assembly in a vice and proceed to tighten the bottom nut to 14Nm.

It is recommended that all parts in the repair kits are used. Any defect parts removed during

the service should be disposed of. Parts should be kept clean in line with media requirements.

Following re-assembly of the regulator, pressure tests should be made to both the inlet and

outlet side of the regulator, to ensure there is no internal or external leakage across the

regulator.

To ensure that the main valve assembly has been correctly and effectively installed it may be

required to perform the appropriate seat leak test as per ANSI/FCI 70-2.

6.1.2. Accessing the Sensor Assembly (SA)

To access the Sensor Assembly:

i. Secure* the regulator body (26) in a vice and use a 4mm Allen key to remove**

the 6x M5 cap screws (2) and 6x M5 spring washers (3) from the regulator body.

*NOTE: Soft vice jaws must be used, when securing the body within the vice

against flats. (as without may cause damage to sealing surface for BSP O ring).

**NOTE: It is recommended to loosen one screw, followed by the screw directly

opposite and then proceed in either clockwise or anti-clockwise direction until all

screws have been loosened before completely removing the screws.

ii. Lift the bonnet (25) from the assembly and remove the 10mm Ball Bearing (1),

Upper spring rest (17) and Load spring (16).

iii. Remove and replace the O-ring (11) from the base of the bonnet (25)

iv. Use pliers to grip the stem of lower spring rest (14) and lift/remove the sensor

assembly (7,9,12,14,15) from the Body (26).

v. Grip the flats of the lower spring rest (14) in a vice so that the base of the sensor

(12) is facing upwards.

vi. Remove the sensor (12) from the sensor holder (15) using an 21mm open ended

spanner or adjustable wrench, against the flats at the of the sensor (12).

vii. Replace all ‘O’ rings (7&9) located on the sensor holder (15), prior to reassembly,

ensuring adequate lubrication is used.

viii. The air deflector (16) is accessible at this point and can be removed* with a 20mm

socket.

8

*NOTE: It is not necessary to remove the air deflector. If it is required to replace

or reassemble the part, install finger tight and then tighten to 12Nm using a 20mm

socket.

9

Reassembly

xiv. Position/guide the Sensor (12) into the Sensor Holder (15)

*IMPORTANT: Ensure that the Sensor Holder is correctly oriented, such that the

counter bore is upright to accommodate the Lower Spring Rest (14) (*Ref. 6.1.4)

ix. Screw the Lower Spring Rest (14) into the Sensor (12). To secure, grip stem the

spring rest into a vice and use a 21mm open ended spanner or adjustable to

tighten the sensor.

x. Guide/Place the sensor assembly into the Regulator Body (26)

xi. Position the Load Spring (16) on to the Lower Spring Rest (14) and place the Upper

Spring Rest (17) and 8mm Ball Bearing (1) to the assembly

xii. Guide the bonnet (25) over the top work assembly (1,14,16,17)

*IMPORTANT: Ensure that the O-ring (11), is correctly located into the O-ring

groove at base of the bonnet, before placing on to the regulator body (26)

xiii. Position Bonnet (25) carefully onto the regulator body (26) ensuring the holes of

the PCD are all correctly in line.

xiv. Locate the 6x M5 cap screws (2) and 6x M5 spring washers (3) through the bonnet

(25) into the regulator body (26) and screw until finger tight. Proceed to tighten

the screws using the correct pattern*.

*Tighten one screw followed by the screw directly opposite. Then tighten the next

screw over in either a clockwise or anti-clockwise direction, then followed by the

screw directly opposite to it. Continue until all screws are tightened. It is advisable

to perform this tightening procedure two times to ensure correct engagement.

Use 5Nm when tightening.

10

6.1.3. Adjusting the Set Point

Should it be required to adjust the set point please follow the instructions below:

i. Using a 34mm open ended spanner or adjustable wrench, Remove the Top Cover

(27), from the Bonnet (25)

ii. Loosen the Locking Nut (18), using a 13mm open ended spanner or adjustable

wrench

iii. Connect the correct fittings to the Inlet and Outlet ports of the regulator. Ensure

that any gauge ports are plugged or that the correct gauge is fitted

iv. Connect the Outlet port to a calibrated pressure test gauge appropriate to the

required set pressure. As the regulator is non-venting, ensure that a ball/needle

valve is fitted to allow pressure to be relieved downstream of the regulator

v. With the Regulator Body (26) secured in a vice apply the Maximum Working

Pressure (MWP) to the Inlet of the regulator

vi. Using a slotted screwdriver, turn the Adjusting Screw (13) clockwise until the

desired set point has been reached

vii. Ensure repeatability by allowing flow through the regulator by opening/closing the

ball/needle valve

viii. With the outlet pressure set, screw/tighten the Lock Nut (18) to the base of the

Adjusting Screw (13) and against the Bonnet (17).

ix. Using a 13mm open ended spanner or adjustable wrench, ensure that the Lock

Nut (18) is sufficiently tightened, taking care not to adjust the set point

x. If the set point is not correct, repeat steps vi. to ix.

xi. Isolate the upstream pressure, then allow pressure to be released by opening the

downstream valve until flow diminishes completely –then the regulator can be

removed from test set up.

11

6.1.4. Figure 1 –Sectional View of the SS-231 (with ‘SR’ Top Works)

© Copyright of Pressure Tech Ltd

PARTS LIST

ITEM

QTY

PART NUMBER

DESCRIPTION

1

1

BALL-010-SS-316

10MM BALL BEARING

2

6

FIT-M5-25-A4-70.0-SKT-CAP

M5x25 SOCKET CAP SCREW

3

6

FIT-M5-SS-A4-SPR-WASHER

SPRING WASHER

4

1

OR-0045-15

O' RING STD

5

1

OR-0101-16

O' RING STD

6

2

OR-0170-20

O' RING STD

7

2

OR-0190-20

O' RING STD

8

1

OR-BS027

O' RING STD

9

1

OR-BS028

O' RING STD

10

1

OR-BS4518-0091-16

O' RING STD

11

1

OR-BS4518-0291-16

O' RING STD

12

1

PT-101-001

20MM SENSOR

13

1

PT-101T-002

ADJUSTING SCREW

14

1

PT-BP-301-003

SPRING REST

15

1

PT-BP-301-011

SENSOR HOLDER

16

1

PT-C-011-003-002

LOAD SPRING

17

1

PT-C-017

UPPER SPRING REST

18

1

PT-C-020

LOCKNUT

20

1

PT-MF-230-001-001

CONCENTRIC NUT

21

1

PT-MF-230-003-001

MAIN VALVE SPRING

22

1

PT-MF-230-005-001

AIR DEFLECTOR

23

1

PT-MF-230-006

PCTFE SEAT CV 1.0

24

1

PT-MF-230-009

MAIN VALVE - 60 DEG

25

1

PT-SS-230-003-002

BONNET

26

1

PT-SS-231-01-SS-06B-N

BODY - N PORTING

27

1

PT-SSC-300-002

TOP COVER

12

7. Technical Data

Fluid Media:

All gases and liquids compatible with materials of

construction

Max Inlet Pressure:

Valve

Assembly

Seat Material

Pressure

Balanced

Balanced

Balanced

PTFE

PCTFE

PEEK®

35 bar (510 psi)

230 bar (3350 Psi)

230 bar (4350 Psi)

Outlet Pressure Range:

0-35 bar (510 psi)

Nominal Operating Temperature:

-20°C to +80°C

Materials:

Body / Trim

HT Brass

316 SS

Seat

PTFE

PCTFE

PEEK®

Flow Capacity (Cv):

1.0

Leakage:

Gas

Liquid

Bubble tight

Zero drops of water at max inlet

8. Warranty Statement

Pressure Tech Ltd guarantee all products correspond with their specification at the time of

delivery and, with exception to wear and tear, wilful damage, negligence, and abnormal

working conditions, will be free from defects for a period of 12 months from date of delivery.

Table of contents

Other Pressure Tech Controllers manuals

Pressure Tech

Pressure Tech MF-414 Series Service manual

Pressure Tech

Pressure Tech LF-690 Service manual

Pressure Tech

Pressure Tech LF-540 Series Service manual

Pressure Tech

Pressure Tech THE SS-414 Series Service manual

Pressure Tech

Pressure Tech LF-792 Series Service manual

Pressure Tech

Pressure Tech LF-301 SERIES Service manual

Popular Controllers manuals by other brands

Induction Solutions

Induction Solutions Boogie Box NPC-1006 user manual

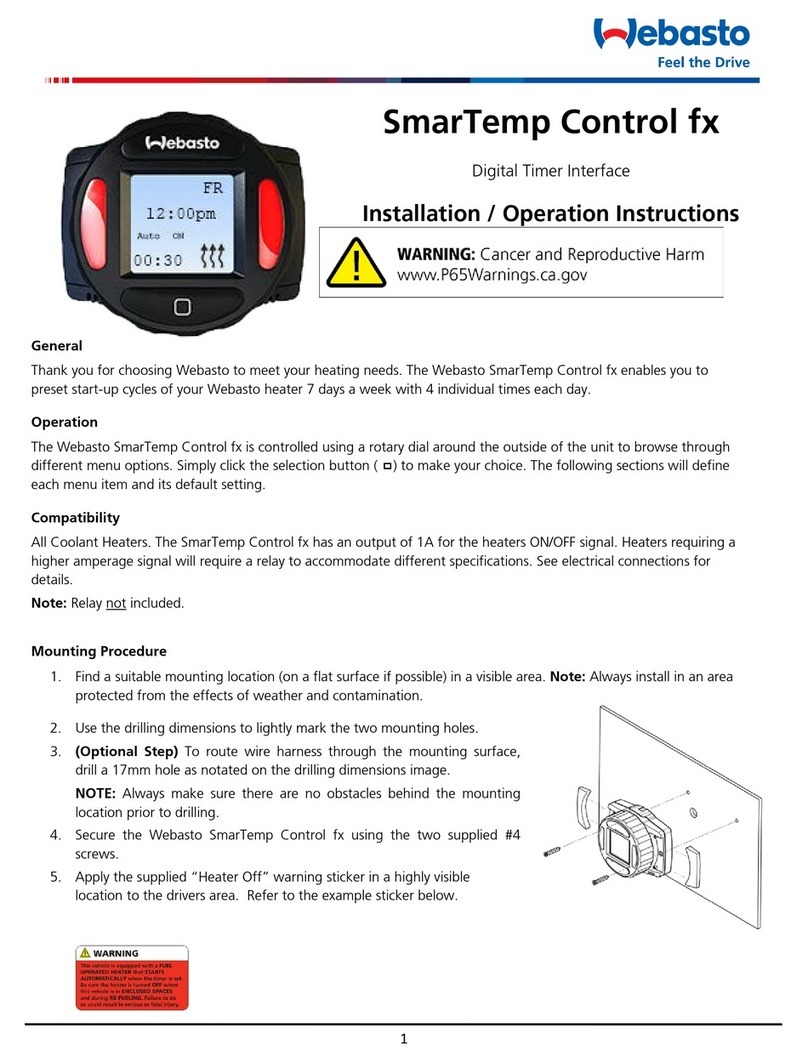

Webasto

Webasto SmarTemp Control fx Installation and operation instructions

Taconova

Taconova FWCK Installation and operating instructions for manual and remote control options

Eldes

Eldes ESIM010 manual

Vescent

Vescent D2-105 manual

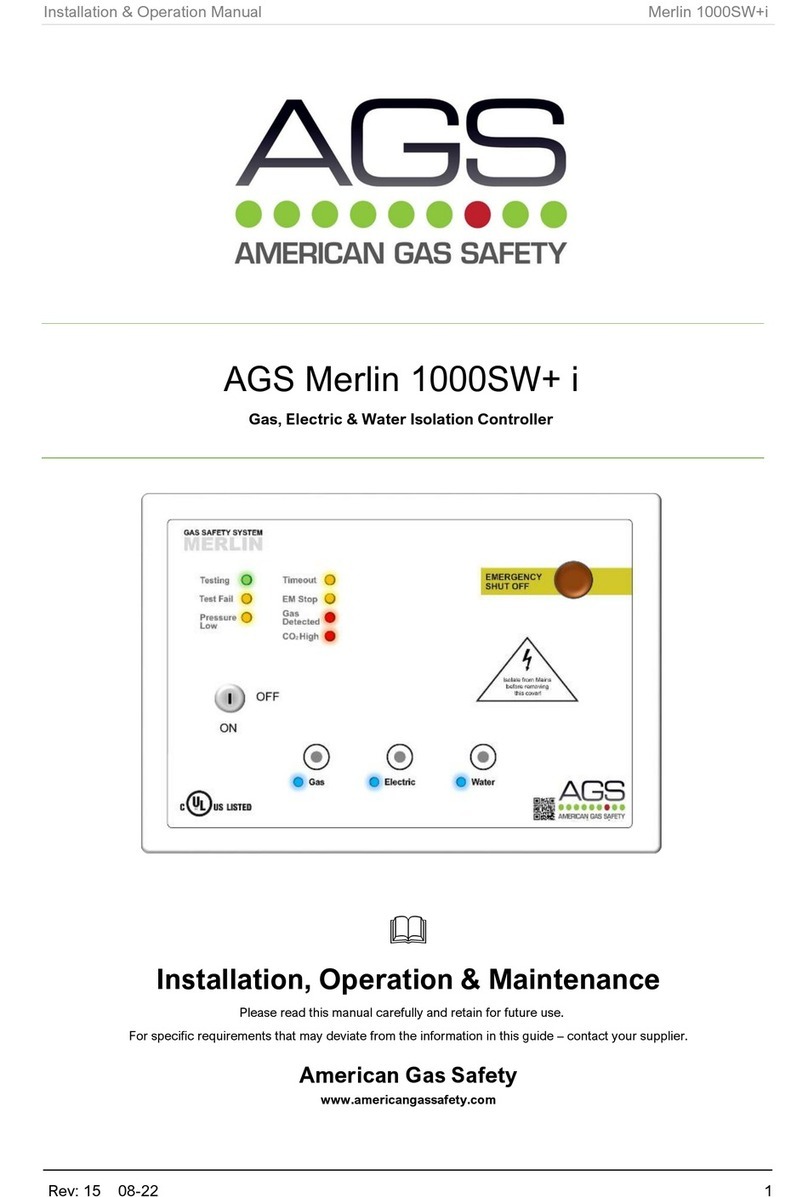

AGS

AGS Merlin 1000SW+ Installation operation & maintenance