AB-7352-U

3

CAUTION (2/2)

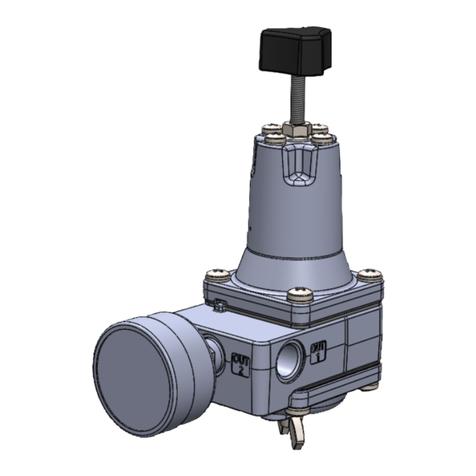

Use full face gaskets for flat face flanges to prevent the product damage or fluid leakage.

For installation, do not mount the valve in an improper position or overtighten the bolts on the flange. Doing so

might damage the product.

After installation, make sure no fluid leaks from the valve-pipe connections. Incorrect installation might cause fluid

leakage.

Install the product so that no foreign objects remains inside the pipes. Be sure to provide a strainer on the inflow

side of the piping. Flush the piping to remove the foreign objects after installation. Foreign objects inside the piping

might damage the product..

Do not allow the fluid to freeze. Doing so might damage the valve body and cause fluid leakage.

Do not put load or weight on the actuator of the product. Doing so might damage the product.

Do not install the product nearby a steam coil, pressurized hot-water coil, or any high heat source. High

temperature radiation might cause malfunction of its actuator.

Do not use the product in an atmosphere corrosive to the actuator, valve, and their components. Doing so might

damage the product.

Do not carelessly touch this product when being used to control hot water or steam. The product temperature is hot,

and you might get burned.

Use crimp terminals with insulation for connections to the product terminals. Failure to do so might cause short

circuit leading to fire or device failure.

Firmly tighten the terminal screws. Insufficient tightening of the terminal screws might cause fire or overheating.

Do not touch the moving parts of the product. Doing so might cause injury.

Dispose of this product as industrial waste in accordance with your local regulations. Do not reuse all or part of the

product.

Do not allow any shock on the product. Doing so might damage the product.

Do not disassemble the product. Doing so might cause device failure.

During engineering work, do not touch the uninstructed area other than the setting switches. Doing so, you might

be burned. Temperature of some parts of the actuator becomes high.

IMPORTANT:

In case an Azbil Corporation product fails, you are required to provide your Equipment with safety design such

as fool-proof design*1, and fail-safe design*2(anti-flame propagation design, etc.), whereby preventing any

occurrence of physical injuries, fires, significant damage, and so forth. Furthermore, fault avoidance*3, fault

tolerance*4, or the like should be incorporated so that the said Equipment can satisfy the level of reliability and

safety required for your use.

*1. A design that is safe even if the user makes an error.

*2. A design that is safe even if the device fails.

*3. Avoidance of device failure by using highly reliable components, etc.

*4. The use of redundancy.

IMPORTANT:

When installing the product with a flange gasket, do not allow the gasket going inside the pipe.

The service life of ACTIVAL operated with small dead band can be shortened since the ACTIVAL operates

more frequently with small dead band than with normal dead band.

To operate the product with small dead band, provide shielded cable for input/output signal lines and power

line. Unshielded cable might cause error due to noise