Pressure Tech LF-301 SERIES Service manual

1

THE LF-301 SERIES

Operating and Service Manual

Series includes all variants of LF-301/311 and CYL-301/311

Issue B

January 2016

2

TABLE OF CONTENTS

1. Description .............................................................................................................................3

2. Installation .............................................................................................................................3

3. Operation ...............................................................................................................................4

4. Special Conditions for Safe Use .............................................................................................4

5. Hazardous Location Usage.....................................................................................................4

6. Servicing and Maintenance....................................................................................................4

6.1. Servicing the LF-301................................................................................................5

6.1.1. Accessing the Main Valve Assembly ........................................................5

6.1.2. Adjusting the Set Point ............................................................................6

6.1.3. Figure 1 –Sectional View of the LF-301...................................................7

7. Technical Data........................................................................................................................8

8. Warranty Statement ..............................................................................................................8

Annex A. LF-310/311 –‘Solid Disk’ Main Valve Design .............................................................9

A.1. Description..............................................................................................................9

A.2. Servicing..................................................................................................................9

A.2.1. Figure 2 –Detail A: LF-310/311 ‘Solid Disk’ MVA (sectional)..................9

A.2.2. Figure 3 –Exploded View of LF-310/311 ‘Solid Disk’ MVA .....................9

3

1. Description

The LF-301 provides a compact and economical solution for controlling pressures up to

180bar on low flow applications. Ideal for first stage pressure let down where basic pressure

control is required. A small piston sensing element allows low torque adjustment with a

range of springs with fine pressure adjustment. The unique soft seat design ensures

particles flow over its surface, rather than perpendicular to it, which helps minimise damage

from potential particles in the system.

Pressure Equipment Directive (PED) 2014/68/EC Declaration

This equipment is designed and manufactured in accordance with Sound Engineering

Practice (SEP) Article 4, Paragraph 3 of the directive 2014/68/EC. As such, CE marking must

not be applied. The equipment is marked under section 3.3 of Essential Safety Requirements

of the directive.

2. Installation

Before system start-up, it is recommended that all systems be pressure tested, leak tested

and purged with an inert gas such as nitrogen.

Prior to placing into service ensure that the regulator is in the fully closed position, with the

adjusting mechanism turned completely anti-clockwise.

Check the model number reference to ensure that the pressure range complies with the

installation requirements.

Visually inspect the regulator for any signs of damage or contamination. If any foreign

materials are present and cannot be removed from the regulator, or if the threads on the

regulator appear to be damaged, please contact the office immediately to arrange for the

regulator to be returned for service.

The Inlet and Outlet ports are clearly marked. Select the correct size and type of connection

fittings for these ports which are indicated in the regulators part number. Both British

Standard Pipe (BSPP) ‘B’ and National Pipe Thread (NPT) ‘N’ options are available on this

regulator. Use the correct dowty or bonded seal for BSPP connections, self centering seals

are recommended. For NPT threads, ensure that PTFE tape is applied correctly to the

fittings, applying two overlapping layers in the direction of the thread, taking care that the

tape does not come into contact with the first thread. Any gauge ports on the regulator will

be 1/4” NPT unless otherwise stated. If any gauge port is not required, ensure that the port

is plugged prior to installation.

The media supplied to the regulator must be clean. Contamination can damage the seat

which may cause the regulator to fail. Filtration suited to the application is recommended

upstream of the regulator. Should further assistance or information be required in relation

to installation of any Pressure Tech regulator please contact the office, giving reference to

the regulators part number and/or serial number.

4

3. Operation

Turning the adjusting mechanism clockwise compresses the spring, which in turn opens the

main valve and allows the inlet pressure to pass through the seat orifice until the outlet

pressure is equivalent to the loading forces set by the compressed spring. Increase the

outlet pressure in this way until the desired pressure is achieved.

To reduce the outlet pressure, the adjusting mechanism should be turned anti-clockwise

whilst the media is flowing, or whist venting downstream of the regulator.

The desired outlet pressure should be set whilst increasing the pressure. Do not exceed the

maximum inlet and outlet pressures of the regulator which are indicated on the regulator

label.

4. Special Conditions for Safe Use

The LF-301 series are non-venting type regulators, therefore the outlet pressure shall be

reduced by venting downstream of the regulator whilst simultaneously turning the adjusting

mechanism anti-clockwise.

5. Hazardous Location Usage

This equipment has not been manufactured specifically for use in potentially explosive

atmospheres and as such an ignition hazard assessment has not been carried out on this

product. If the user should wish to use this product in such an environment where there

may be a potentially explosive atmosphere then it is the responsibility of the user to

conduct an ignition hazard assessment against 99/92/EC.

6. Servicing and Maintenance

Servicing and maintenance work on the LF-301 regulators should only be performed after

fully reading and understanding the Operating and Servicing Manual. Due to the typical

nature of the gases the regulator can be used with, the operator should not endanger

himself/herself or others by working on this regulator without prior knowledge on the

Health and Safety concerns relating to handling of technical gases. Any uncertainty should

be clarified with Pressure Tech before working on the regulator.

Pressure Tech Ltd recommends the use of Krytox GPL 205 during servicing.

Prior to commencing service, please ensure that:

-The equipment has been de-pressurised

-The load spring has been de-compressed by turning the adjusting mechanism fully

anti-clockwise

-Applications involving toxic, flammable or corrosive media have been fully purged

5

To ensure the best possible results from servicing, when re-assembling the regulator and

any assemblies within it, ensure that all areas of the components and the regulator body are

cleaned and free from contaminants which may result in failure of the regulator.

6.1. Servicing the LF-301

*Note: fig 1 should be used as a reference for the following set of instructions

6.1.1. Accessing the Main Valve Assembly

To access the Main Valve Assembly (MVA):

i. With the flats of the Regulator Body (1) secured in a vice, loosen and remove the

Bonnet (15) using a 47mm wrench ensuring that the Hand Wheel (17) is fully

wound anti clock wise (*Ref. 6.1.2)

ii. Remove the 10mm Ball Bearing (9), Upper Spring Rest (8) and Load Spring (24)

iii. Using needle nosed pliers, remove the Lower Spring Rest (5), then remove the

Sensor Assembly (6, 7)

iv. The Seat Nut (4) can then be removed using a 12mm socket

v. Remove the Main Valve (2, 21) and Main Valve Spring (3) from the assembly

vi. Visually inspect the seat nut and soft seat (7) for damage under a microscope

vii. Replace the Main Valve Spring (3) and Main Valve (2, 21) and place into the

Regulator Body (1)

viii. Replace Seat Nut (4) fitted with new 5x1 mm O-ring (18) taking care not to

damage its sealing face against the tip of the valve

ix. Replace the O-rings (13, 14, 15, 17) around the Sensor (7) and Sensor Holder (6)

x. Position the Sensor (7) into the Sensor Holder (6) and then place the assembly

into the Regulator Body (1)

xi. Replace the O-ring (16) around the Lower Spring Rest (5) and then place into the

Sensor Holder (6)

xii. Position the Load Spring (24) around the Lower Spring Rest (5) and place the

Upper Spring Rest (8) and 10mm Ball Bearing (9) to the assembly

xiii. Screw the Bonnet (10) onto the assembly and using a torque wrench with a

47mm open ended attachment, tighten to 90Nm

It is recommended that all parts in the repair kits are used. Any defect parts removed during

the service should be disposed of. Parts should be kept clean in line with media

requirements. Following re-assembly of the regulator, pressure tests should be made to

both the inlet and outlet side of the regulator, to ensure there is no internal or external

leakage across the regulator.

To ensure that the main valve assembly has been correctly and effectively installed it may

be required to perform the appropriate seat leak test as per ANSI/FCI 70-2.

6

6.1.2. Adjusting the Set Point

It is not recommended (or necessary) to remove the Hand Wheel during service as this will

affect the set point of the regulator. Should it be required to adjust the set point please

follow the instructions below:

i. Remove the Nameplate (22) and Cap from the Hand Wheel (23) and loosen the

Lock Nut (12) such that the Hand Wheel is able to spin freely on the Adjusting

Screw (11)

ii. Connect the correct fittings to the Inlet and Outlet ports of the regulator. Ensure

that any gauge ports are plugged or that the correct gauge is fitted

iii. With the Regulator Body (1) secured in a vice apply the Maximum Working

Pressure (MWP) to the Inlet of the regulator

iv. Connect the Outlet port to a calibrated pressure test gauge appropriate to the

required set pressure. As the regulator is non-venting, ensure that a ball/needle

valve is fitted to allow pressure to be relieved downstream of the regulator

v. Using a slotted screwdriver, turn the Adjusting Screw (11) clockwise until the

desired set point has been reached

vi. Ensure repeatability by allowing flow through the regulator using the ball/needle

valve

vii. With the outlet pressure set, screw the first Lock Nut (12) to the base of the

Adjusting Screw (11) against the Bonnet (10)

viii. Position the Hand Wheel (23) onto the Lock Nut (12). Ensure that the Lock Nut

and Hand Wheel become engaged

ix. Fasten the second Lock Nut (12) against the Hand Wheel (23) and gently begin to

tighten using a 13mm socket until it begins to secure itself

x. At this point, whilst holding the Hand Wheel (23) continue to tighten whilst

simultaneously turning slightly anti-clockwise to prevent it from locking against

the Bonnet (10)

xi. Ensure that the Lock Nut (12) is sufficiently tightened, taking care not to adjust

the set point

xii. Turning of the Hand Wheel (23) should now also turn the Adjusting Screw (11)

which will control the pressure

xiii. Turn the Hand Wheel clockwise until it reaches its set point and check to make

sure that the desired outlet pressure is correct.

xiv. If the set point is not correct, repeat steps v. to xiii.

xv. Reduce the pressure downstream by venting the pressure through ball/needle

valve and then turning the Hand Wheel anti-clockwise until the regulator closes

xvi. The Cap and Nameplate (22) can now be placed into the Hand Wheel (23).

Ensure that the information stated on the Nameplate is in accordance with the

set pressure of the regulator

7

6.1.3. Figure 1 –Sectional View of the LF-301

© Copyright of Pressure Tech Ltd

PARTS LIST

ITEM

PART NUMBER

DESCRIPTION

1

PT-301-X-SS

LF-301 Body ¼” NPT

2

PT-C-001-013

MAIN VALVE

3

PT-C-006-002

MAIN VALVE SPRING

4

PT-C-007-002

SEAT Cv 0.06

5

PT-C-018-006

LOWER SPRING REST

6

PT-C-105-001

8mm SENSOR HOLDER

7

PT-C-106

8mm SENSOR

8

PT-C-017

UPPER SPRING REST

9

BALL-010-SS-316

10mm BALL BEARING

10

PT-C-015

BONNET

11

PT-C-019-003

ADJUSTING SCREW

12

PT-C-020

LOCK NUT

13

PT-C-104

PTFE BACK UP RING

14

PT-C-176

PTFE BACK UP RING

15

OR-BS008

O-RING STD

16

OR-0171-16

O-RING STD

17

OR-0190-20

O-RING STD

18

OR-0050-10

O-RING STD

19

CIR-BS3673/1-B010M

CIRCLIP

20

FILT-SCRM31040405-A

10mm SCREEN FILTER

21

PT-C-002-XXX

SOFT SEAT

22

PT-C-022

NAMEPLATE

23

PT-C-021

SMALL HAND WHEEL

24

PT-C-011-XXX

LOAD SPRING

8

7. Technical Data

Fluid Media: All gases and liquids compatible with materials of

construction

Max Inlet Pressure*: 300 bar (4350 Psi) (with PEEK Seat)

210 bar (3000 Psi) (with PCTFE Seat)

Outlet Pressure Range: 0-180 bar

Operating Temperature: -20°C to +80°C

Materials: Body and Trim: 316 SS

Seat: PCTFE / PEEK® / PTFE / FEP

Flow Capacity (Cv): 0.06 (also available in 0.03 and 0.15)

Leakage: Gas: Bubble tight

Liquid: Zero drops of water at max inlet

*Max Inlet Pressure determined by seat material and Cv of regulator.

8. Warranty Statement

Pressure Tech Ltd guarantee all products correspond with their specification at the time of

delivery and, with exception to wear and tear, wilful damage, negligence, and abnormal

working conditions, will be free from defects for a period of 12 months from date of

delivery.

9

Annex A. LF-310/311 –‘Solid Disk’ Main Valve Design

A.1. Description

The ‘solid disk’ type main valve assembly was introduced as an alternative to the unique

‘cone type’ assembly and could be applied where greater resistance to both temperature

and pressure were required. The new disk design allows for a wider range of seat material

options as well as increased Cv and Pressure combinations.

The model number ‘LF-310/311’ was assigned to denote the requirement for the new disk

type main valve arrangement. The LF-310/311 ‘solid disk’ option allows for a Maximum

Working Pressure of 300 Bar (4350 Psi) or 414 bar (6000 Psi) when fitted with a PEEK seat.

The LF-310 is capable of accurately controlling pressures of up to 35 bar (510 Psi).

A.2. Servicing

The servicing of the LF-311 regulator should be performed in line with the service

instructions for the LF-301 as defined in Section 6 of this manual, taking account for the

difference in valve assembly. The figures below detail the alternate main valve assembly for

reference purposes only.

A.2.1. Figure 2 –Detail A: LF-310/311 ‘Solid Disk’ MVA (sectional)

A.2.2. Figure 3 –Exploded View of LF-310/311 ‘Solid Disk’ MVA

Table of contents

Other Pressure Tech Controllers manuals

Pressure Tech

Pressure Tech LF-792 Series Service manual

Pressure Tech

Pressure Tech LF-690 Service manual

Pressure Tech

Pressure Tech MF-414 Series Service manual

Pressure Tech

Pressure Tech THE SS-414 Series Service manual

Pressure Tech

Pressure Tech LF-540 Series Service manual

Pressure Tech

Pressure Tech SS-231 Series Service manual

Popular Controllers manuals by other brands

Sony

Sony PS4 DUALSHOCK 4 instruction manual

Omron

Omron E5CD instruction manual

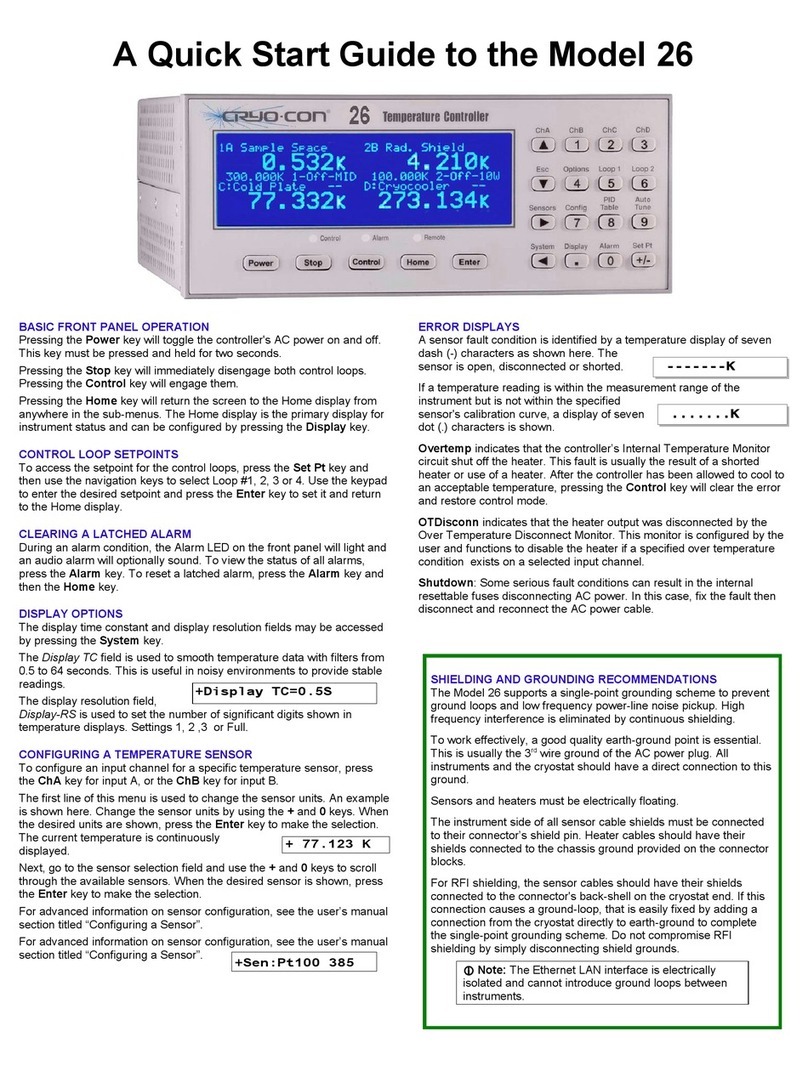

Cryo-con

Cryo-con 26 quick start guide

TECO-Westinghouse

TECO-Westinghouse EQ7 Series instruction manual

HydroPoint

HydroPoint WeatherTRAK ET Pro2 SWM Upgrade Installation Guide

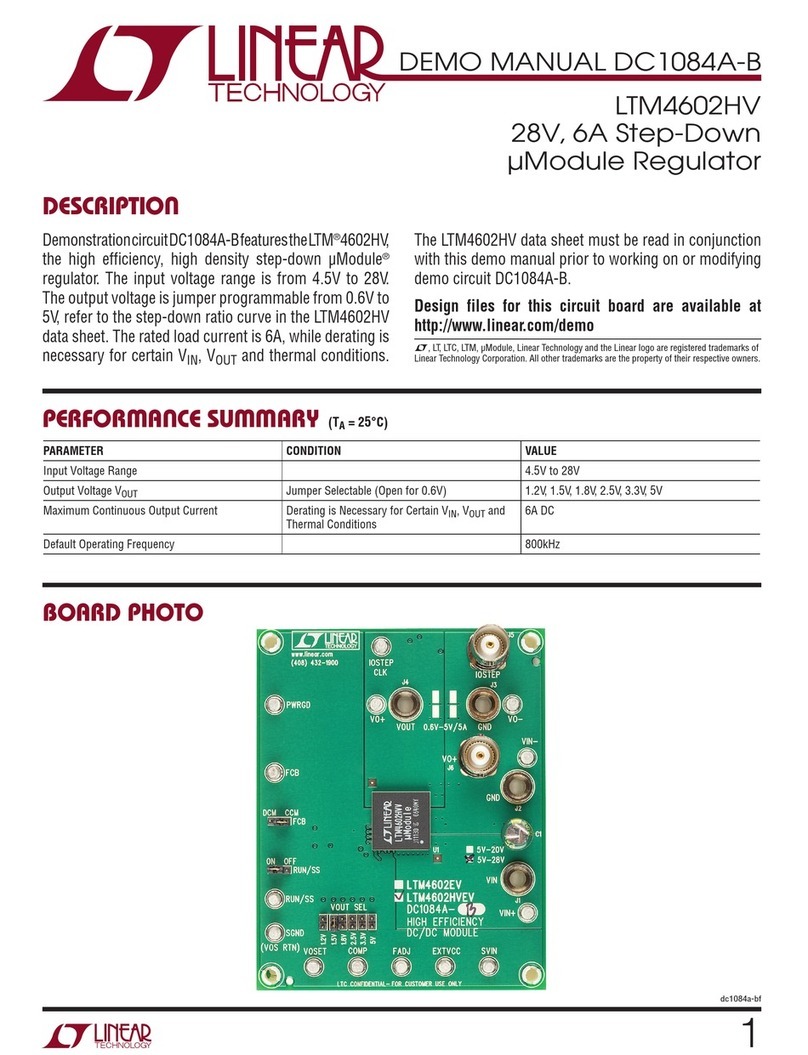

Linear Technology

Linear Technology DC1084A-B manual