PreView Sentry ST87 Series User manual

www.radar-electronics.com

e-mail.:info@radar-electronics.com

PreView®Sentry™

ST82 & ST87

Series

Sensor

Operating Manual

Contents

Overview ..................................................................................................................1

Product Description............................................................................................1

Other Sensor Features .......................................................................................3

Sensor Interfaces and Configuration .....................................................................4

Communication ..................................................................................................4

Alarm Output ......................................................................................................4

Sensor Input .......................................................................................................4

Cable Connection ...............................................................................................4

Technical Data....................................................................................................6

Regulatory Compliance ...........................................................................................8

Installation...............................................................................................................9

Sensor Mounting ................................................................................................9

Mounting Tolerances..........................................................................................9

Keep Out/Interference Zones..........................................................................10

Sensor Mounting Procedure ............................................................................10

Troubleshooting ....................................................................................................12

Object Detection Capability...................................................................................13

Notes on Safety and Risks....................................................................................15

Owner Responsibilities.....................................................................................15

PreView®Sentry™Daily Maintenance...................................................................16

Warranty Information ............................................................................................18

Figures

Figure 1. PreView®Sentry™Radar Sensor..................................................... 1

Figure 2. Adjustable Detection Zone ............................................................. 2

Figure 3. Detection Zone 6 m ........................................................................ 3

Figure 4. Detection Zone 30 m...................................................................... 3

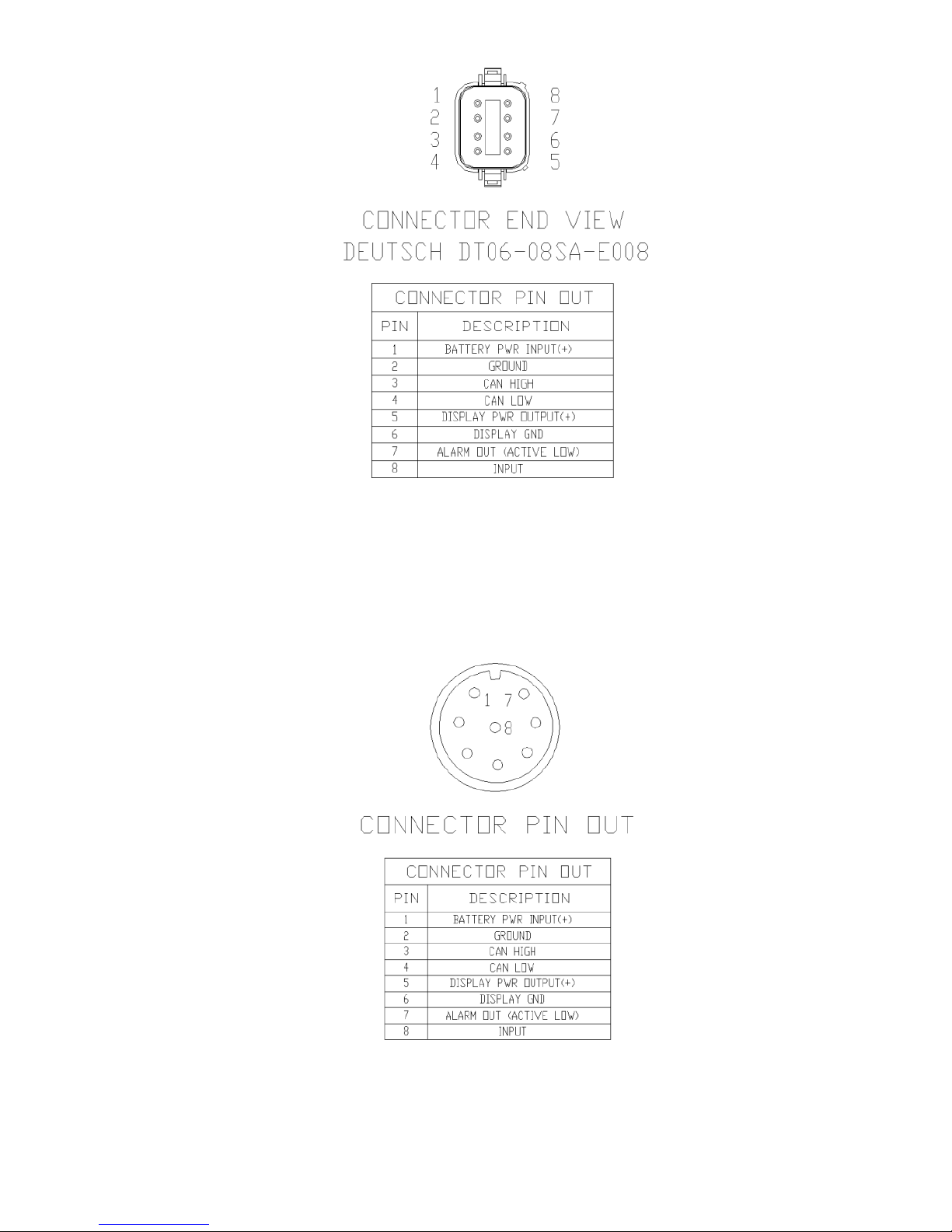

Figure 5. Deutsch Connector Pin Out (ST87 Series) ..................................... 5

Figure 6. Conxall Connector Pin Out (ST82 Series)....................................... 5

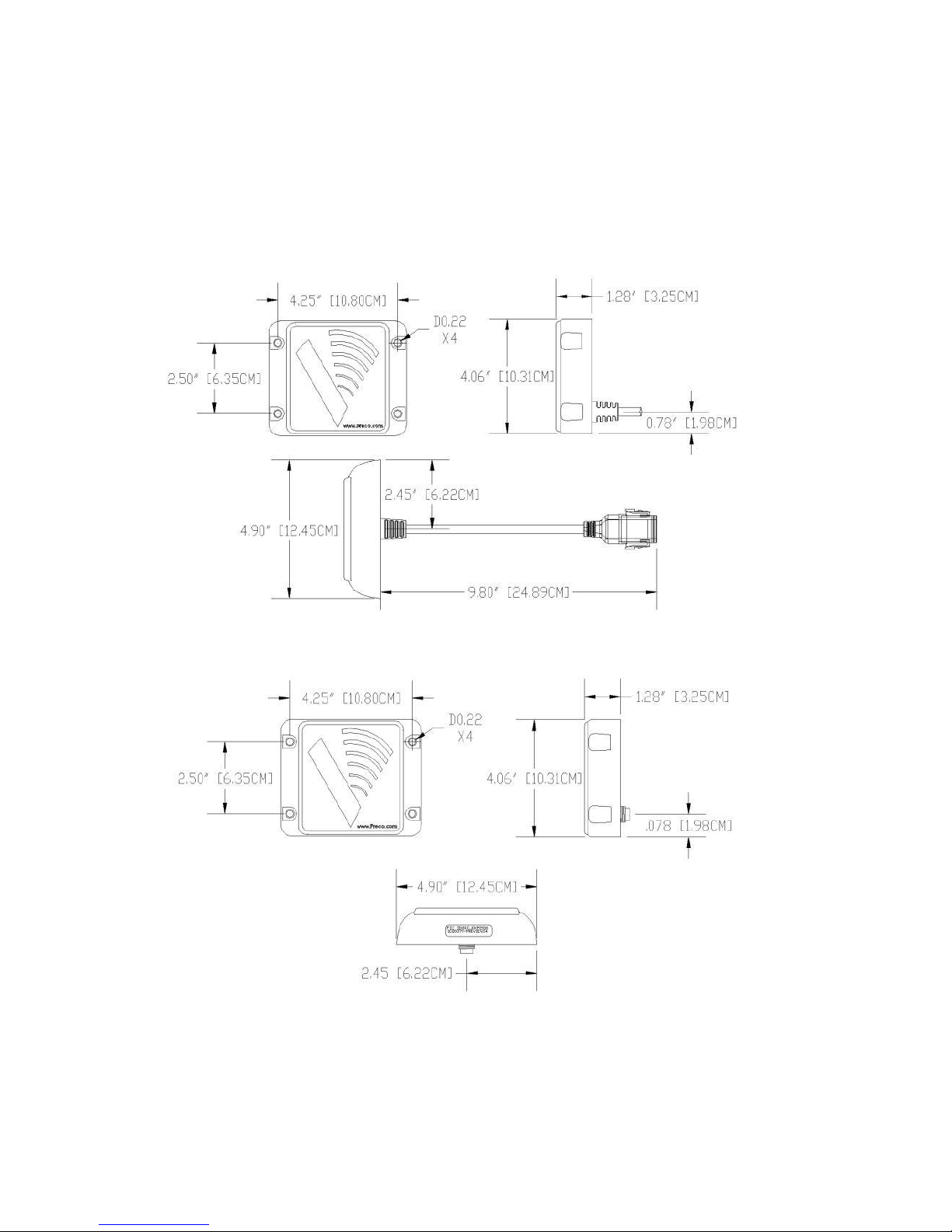

Figure 7. Sentry™Dimensions (ST87 Series)................................................. 6

Figure 8. Sentry™Dimensions (ST82 Series)................................................. 6

Figure 9. Sensor Specifications ..................................................................... 7

Figure 10. Vertical and Horizontal Angle Mounting Tolerances ...................... 9

Figure 11. Keep Out Zones ............................................................................10

Figure 12. Provided SD-BK90 (90° Mounting Bracket)................................11

Figure 13. ST-ASB (Adjustable Mounting Bracket) ........................................11

Figure 14. Object Reflection...........................................................................14

FCC STATEMENT

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Warning: Changes or modifications to this unit not expressly approved by

the party responsible for compliance could void the user’s authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits

of a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try and correct

the interference.

INDUSTRY CANADA STATEMENT

Per RSS-Gen, Section 8.4 This device complies with Industry Canada

license-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may cause

undesired operation of the device.

Par RSS - Gen, Section 8.4 Cet appareil est conforme àIndustrie Canada

exempts de licence standards RSS. Le fonctionnement est soumis aux

deux conditions suivantes : (1 ) ce dispositif ne peut pas provoquer

d'interférences et ( 2) cet appareil doit accepter toute interférence , y

compris les interférences qui peuvent causer un mauvais fonctionnement

de l'appareil.

TRADEMARKS

The names of actual companies and products mentioned herein may be

the trademarks of their respective owners. Any rights not expressly

granted herein are reserved.

Patent pending.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 1

Overview

This document describes the PreView®Sentry™radar sensor manufactured

by PRECO Electronics®, located in Boise, Idaho, USA. The document does

not claim to cover all the possible applications or deployment areas for

these devices. This document may be amended, corrected, and enhanced

in keeping with the sensor development progress.

Product Description

The PreView®Sentry™is a small, rugged, short/medium range radar sensor

designed by PRECO Electronics®for use in heavy duty applications, such as

trucks/busses, construction, mining, waste, utilities, and other applications

requiring a robust, high-performance radar. This frequency band is legal

throughout most of the world, but check with PRECO Electronics®or your

country’s regulations before purchasing.

Figure 1. PreView®Sentry™Radar Sensor

The Sentry™works in adverse weather conditions, has a wide operating

temperature range, is sealed to meet IP69K, withstands high vibration and

shock levels, and is maintenance free.

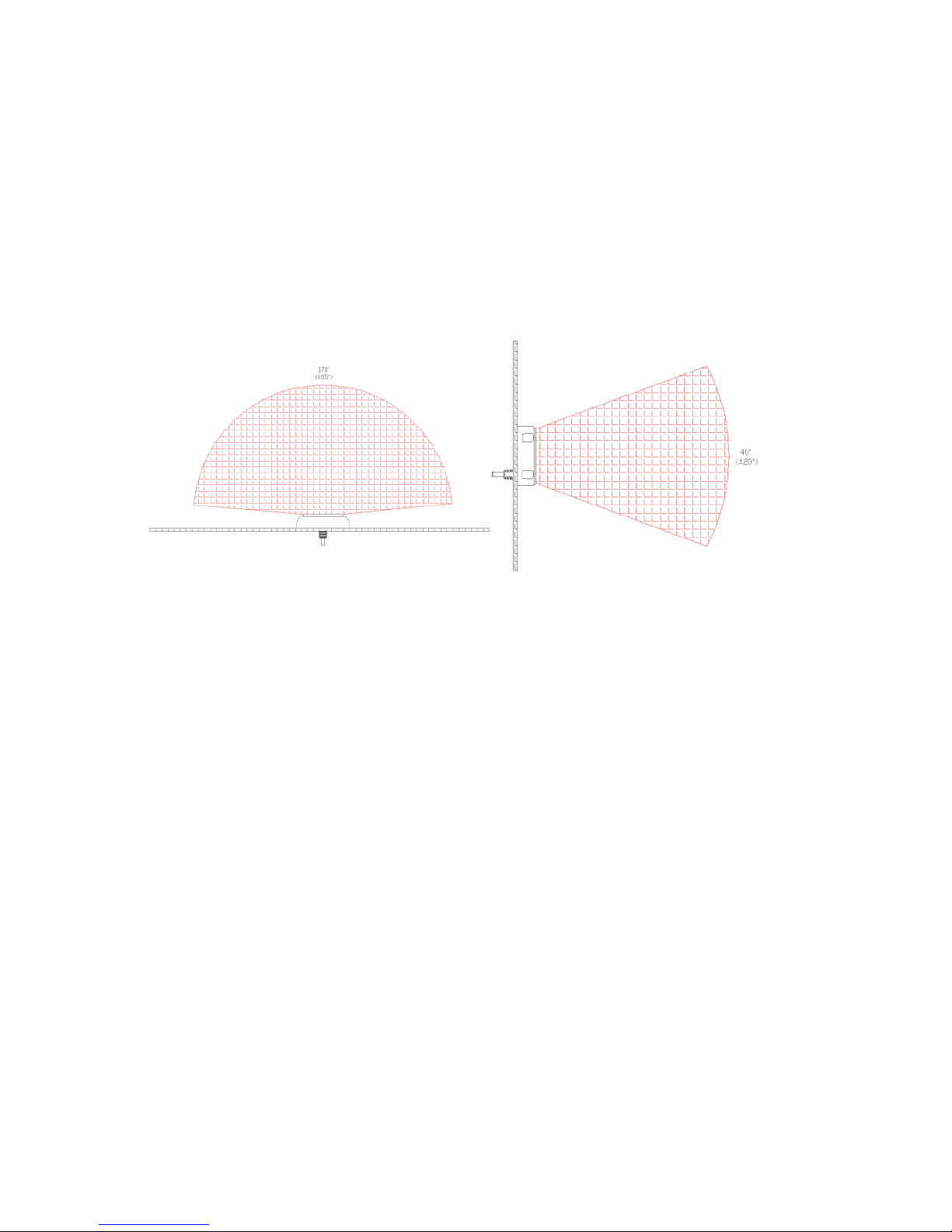

Using a frequency modulated transmit waveform, the Sentry™measures

radial range, speed and angle, reflectivity, and other parameters of

multiple stationary and moving targets simultaneously. This radar sensor

has a wide horizontal field of view up to +/-75°, providing coverage

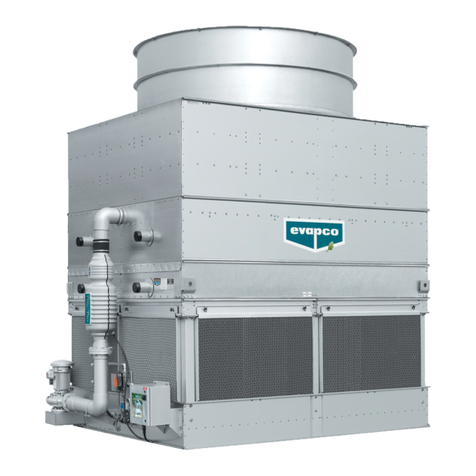

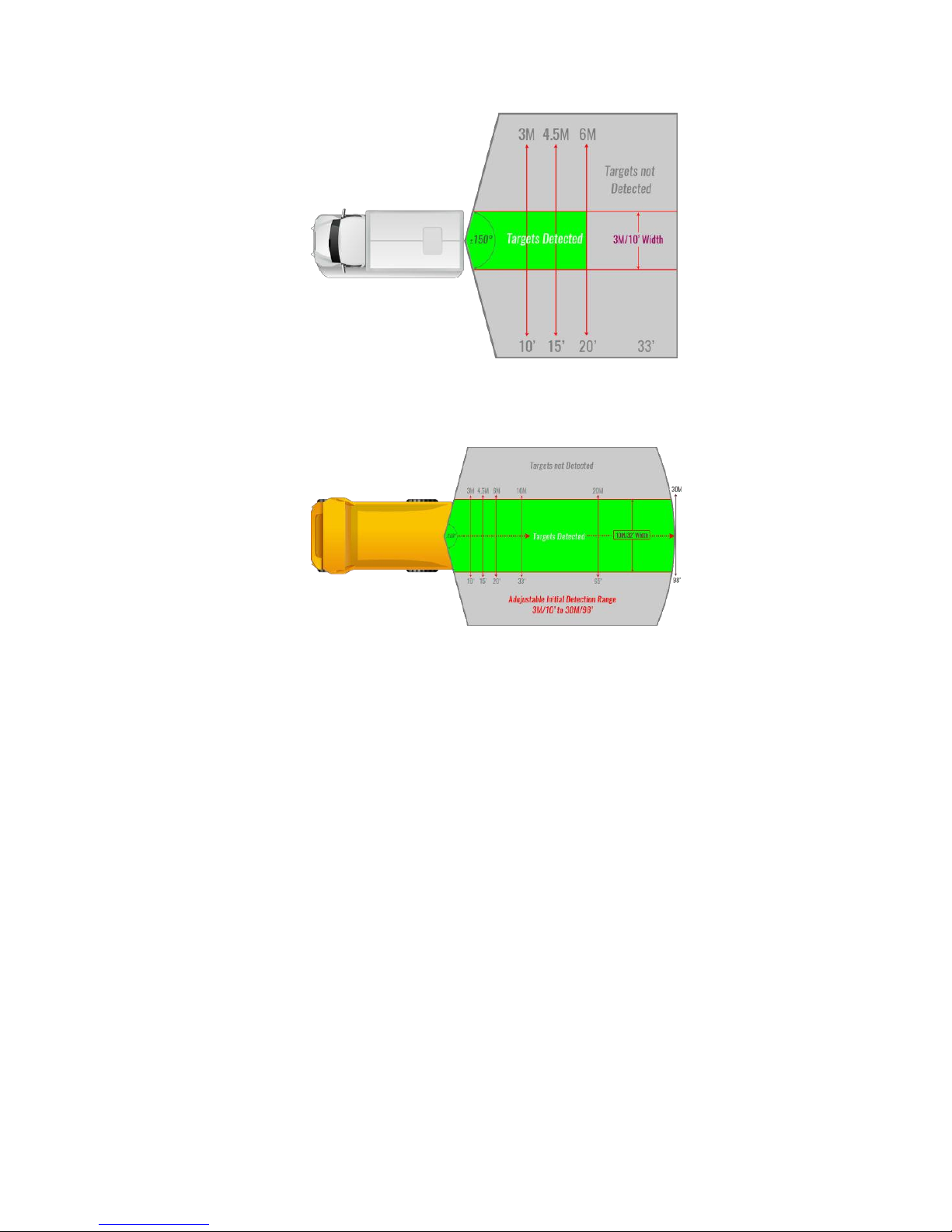

flexibility to be a solution for virtually any application. Figure 2 illustrates

an example of the Sentry™sensor’s adjustable detection zone.

+1.866.977.7326

www.preco.com

3702008A

Copyright 2016

Page 2

Figure 2. Adjustable Detection Zone

The Sentry™has multiple models with preconfigured detection zones: both

range and width of detection zone. Note: the www.preco.com website

contains the most current data on radar sensor models.

Sentry™ST87 Series radar sensors include an 8-pin Deutsch connector

pigtail as shown in Figure 1. The Sentry™ST82 Series radar sensors use

an 8-pin Conxall connector on the back of the radar.

The Sentry™model numbering system is as follows:

Model ST8XYYZ, where:

X defines the connector type - 7 is for Deutsch and 2 is for

Conxall

YY defines the sensor’s detection range in meters

Z defines the detection width in meters

Example: Model ST87063 describes a sensor with a

Deutsch connector, a 20 feet (6 m) detection range and a

10 foot (3 m) detection width.

Please contact PRECO Electronics®or refer to www.preco.com for available

model numbers.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 3

Figure 3 illustrates a truck backing application with the radar detection

zone set to a range of 6 m and a width of 3 m.

Figure 3. Detection Zone 6 m

Figure 4 illustrates a mining haul truck backing application with the radar

detection zone set to a range of 30 m and a width of 10 m.

Figure 4. Detection Zone 30 m

The sensor is active and starts reporting detections within 300

milliseconds (ms) after power up.

The Sentry™performance is not affected by other PreView®Sentry™or

similar sensors operating in close proximity with each other.

Other Sensor Features

The Sentry™sensor has a continuous Built-In-Self-Test (BIST) that notifies

the operator display of sensor failure within a fraction of a second. This

test functions by monitoring the transmit and receive performance as well

as other internal operations.

The Sentry™sensor can also determine if the face of the sensor is blocked

with excessive ice, mud, or snow that is impeding proper operation. This

blockage is then reported to the operator display.

Both the self-test and blockage detection features are important to fail-

safe operation.

+1.866.977.7326

www.preco.com

3702008A

Copyright 2016

Page 4

Sensor Interfaces and Configuration

Communication

The Sentry™communicates with the operator display using a CAN interface

as specified in ISO 11898-2. The CAN bus operates at 250 KBits/second

and is not terminated in the sensor.

Since CAN is a standard communication interface, the sensor can be

connected to other CAN controllers, telematics interfaces, displays, etc.

For custom installations, the CAN bus protocol is available from PRECO®

Electronics. However, it is not described in this document.

Alarm Output

The Sentry™provides an auxiliary output that becomes active whenever the

Sentry™detects an object. This output can be used to activate an external

backup alarm or other devices as desired. The output is switched from a

high impedance state to ground when active and is protected against an

over-current or electrical short condition. The maximum operating current

is approximately 1 amp, including any inrush current.

Sensor Input

The PreView®Sentry™ST87 series radar sensor provides an auxiliary input

that can be used to activate the alarm output, if configured. Contact

PRECO Electronics®for more information.

Cable Connection

The Sentry™comes equipped with a pigtail harness terminated with either

a Deutsch DT connector (ST87 series) or a Conxall Connector (ST82

Series). The pinout for the Deutsch connector is defined in Figure 5. The

mate for the Deutsch connector is the Deutsch DT04-08PA-C015.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 5

Figure 5. Deutsch Connector Pin Out (ST87 Series)

Figure 6 shows the pin out for the Conxall connector (ST82 Series). The

mate for the Conxall connector is the 6280-8SG-XXX.

Figure 6. Conxall Connector Pin Out (ST82 Series).

+1.866.977.7326

www.preco.com

3702008A

Copyright 2016

Page 6

PRECO Electronics®provides a variety of different cable lengths and

configurations for the PreView®Sentry™radar sensor, as well as solution

kits of radar, cabling, and displays. Please contact PRECO Electronics®for

a list of available cables and kits.

Technical Data

The following figures provide the dimensions and specifications for the

PreView®Sentry™radar sensor.

Figure 7. Sentry™Dimensions (ST87 Series)

Figure 8. Sentry™Dimensions (ST82 Series)

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 7

Measuring Performance

Range:

0 –30 m (10 dBsm target) depending on model

number

Range Accuracy: 0.3 m

Azimuth Field of View: ±75 degrees (10 dBsm target)

Elevation Field of View: ±10 degrees (10 dBsm target)

Angle Accuracy: ±2° @ ±10° FOV, ±5 @ ±30° FOV, ±10 @ ±75°

FOV

Velocity Range: ±9 m/sec (± 20 mph)

Velocity Accuracy: 0.2 m/sec (0.5 mph)

Target Resolution: 1.4 m for static targets, approaching 0.3 m for

dynamic targets

Cycle Time: 120 ms (A CAN bus target message is provided in

every cycle.)

Operating Conditions

Frequency:

24.00 –24.25 GHz

Power Supply: 9 –33 VDC, Reverse polarity and over-voltage

protected

Current:

<0.5 A

Operating Temperature:-40°C to +85°C

Storage Temperature: -55°C to +105°C

Shock:

50 G

Vibration:

25 G, random, all three axis

Protection Rating: IP69K

Operating Modes

Detection Pattern: Fixed based on model number

Target Detection Time: 300 ms

Power On to Active Time: 300 ms

Communications Interface

J1939 CAN Bus: 250 Kbits/sec, not terminated

LED Interface Switch to ground, sink up to 1A, over current

protected

Physical Characteristics

Sealing:

IP69K

Housing Material: Polycarbonate radome

Dimensions:

4.90” (w) x 4.06” (h) x 1.28” (d) (12.4 cm x 10.3

cm x 3.25 cm)

Weight:

1.0 lb (0.45 kg).

Mounting:

Four 0.22" (5.6 mm) diameter mounting holes.

Figure 9. Sensor Specifications

+1.866.977.7326

www.preco.com

3702008A

Copyright 2016

Page 8

Regulatory Compliance

The Sentry™is compliant with the following countries/regions and their

regulations as of the published date of this manual. The sensor may be

compliant in other countries/regions. Please check your local regulations.

United States - FCC- Part 15.249

o

FCCID: OXZJCKP2016

Canada - RSS-210 Radio Standards Specification

European Union - ETSI EN300 440-1 Electromagnetic

Compatibility and Radio Spectrum Matters (ERM)

Australia/New Zealand - AS/NZ 4268 Radio Equipment and

Services –Short Range Devices

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 9

Installation

Sensor Mounting

The Sentry™mounting location is important for proper system operation.

Ideally the sensor should be mounted on the rear of the vehicle as close to

the center as possible at roughly 36” (1 m) above the ground. The sensor

face should be perpendicular to the ground with the small end of the “V”

graphic on the sensor face pointing down. Select a location that will

provide some protection from impact and debris while allowing an

unobstructed view of the target hazard area. Refer to the Keep

Out/Interference Zones listed in Figure 11.

Mounting Tolerances

Mounting height tolerance at 36” (1 m) should be within +/- 12” (0.3 m).

For optimal performance at 36” (1 m), the vertical angle (Up/Down)

tolerances are +5 degrees (up) and -2 degrees (down), and the horizontal

angle tolerance is +/- 5 degrees.

Figure 10. Vertical and Horizontal Angle Mounting Tolerances

Exceptions: if mounting higher than 4 feet (1.3 m), the sensor can be

angled down a few degrees as necessary (less than 5 degrees in most

applications).

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 11

The performance of the sensor can be negatively impacted if the sensor is

angled down, causing false detection from the ground. Any time the

sensor is not perpendicular to the ground, the performance should be

tested. In some instances, mainly with longer range models, the sensor

may need to be angled upward to reduce false detections from the ground.

Keep Out/Interference Zones

Metallic and any other strong radar reflecting objects must remain outside

of the keep out zones defined in Figure 11. If radar reflecting objects

reside within the keep out zones, testing must be performed to determine

their influence on the sensor’s performance.

Horizontal “Keep Out” Zone Vertical “Keep Out” Zone

Figure 11. Keep Out Zones

The sensor’s horizontal field of view is +/- 75 degrees and the vertical field

of view is +/- 10 degrees. For optimal performance, the sensor should

protrude beyond any other portion of the vehicle.

Important!

Before permanently installing the Sentry™on the vehicle, verify that the

selected sensor mounting location provides a clear detection zone. Take

the machine to a clear area, temporarily attach the sensor in the proposed

mounting location, apply power to the system, and verify that nothing is

being detected.

Sensor Mounting Procedure

PRECO Electronics®supplies two different brackets for the Sentry™radar

sensor. If the provided 90° bracket shown in Figure 12 is not appropriate,

an adjustable mounting bracket is available, shown in Figure 13.

Tel: +386 3 4900 800

http://radar-electronics.com

3702008A

Copyright 2016

Page 10

Figure 12. Provided SD-BK90 (90° Mounting Bracket)

If mounting to the vehicle using the provided bracket, follow the procedure

outlined below.

1.

Select the appropriate sensor mounting location.

2.

The standard mounting configuration is with the small end of the “V”

graphic pointing down, as shown below.

3.

Using the provided bracket as a drill template, scribe position marks

through the holes. Drill 1/4” (6 mm) holes centered at the marks.

4.

If needed, a 1.5” (40 mm) diameter clearance hole is required for the

sensor connector and mating cable connector.

5.

Secure the sensor to the bracket with the four supplied #10-24 UNC

button head screws, washers, and locking nuts or equivalent. Apply a

maximum torque of 22 lb-inch (25 kg-cm) when securing the sensor.

Figure 13. ST-ASB (Adjustable Mounting Bracket)

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 12

Troubleshooting

The troubleshooting below is for the most common PreView®display.

Refer to the particular display manual for errors code descriptions.

Display Status LED is not illuminated.

Verify that DC power (9-33 V) is applied to the sensor.

Verify that the cable between the sensor and display is connected.

Display Status LED is RED.

Check connection between display and sensor.

Display Status LED is RED and one Yellow LED is illuminated.

LED Error Code

Possible Reason

LED #5 on

No communication with any sensor(s)

LED #4 on

Built in Self-Test Error –Contact Factory

LED #3 on

Missing sensor(s)

Display Status LED is RED and all yellow LEDs are illuminated.

A sensor blockage indication - verify that the sensor face is clean.

All the display LEDs are illuminated when sensor is mounted.

Verify the sensor is pointing outward from the vehicle in an open area

with no obstructions. This may require removing the mounting screws

and lifting the sensor out and away from the rear of the vehicle. If the

display LEDs are not active when moved away from the vehicle, but

are active when mounted, then the sensor’s mounting position will

have to be moved.

Sensor is detecting the ground, indicated by a few of the display LED’s

being lit.

In an open field, either move the sensor up higher or slightly angle the

sensor upward 2 to 5 degrees. The minimum recommended mounting

height is 24 inches.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 13

Object Detection Capability

The PreView®Sentry™system is a blind spot collision warning system

designed to supplement other safety practices and/or devices. The

machine operator is always the first line of defense when safely operating

a vehicle. The person or owner responsible for the equipment must ensure

that all operators understand the installation, operation, limitations and

safe use of the system.

The Sentry™can detect most objects within the detection zone. However,

there are some instances where objects can go undetected. Obstacle size,

shape, relative location, and composition are all factors determining if,

when, and where an object is detected. The Sentry™operates by

transmitting low power electromagnetic energy. Any energy that strikes an

object reflects a certain amount of this energy back to the PreView®

Sentry™radar sensor. If the returned energy is of sufficient magnitude, it is

used to indicate object presence and determine the object’s distance.

While the Sentry™can resolve multiple objects, only the object closest to

the vehicle is reported to the operator display since it represents the most

significant collision threat.

The amount of energy returned is based on a few factors:

Size –a larger object usually reflects more energy than a smaller

object.

Composition –a metal object typically reflects more energy than a

non-metallic object.

Scattering –a solid object reflects more energy than a non-solid

object such as tree branches, gravel, bushes, etc.

Shape –complex shapes cause energy to be returned in a very

non-uniform way. Very small variations or movement can change

detection status.

Angle –an object flat side perpendicular to the sensor will reflect

more energy than an object at an angle. See Figure 14 for an

example of how angle can affect return energy.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 14

Figure 14. Object Reflection

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 15

Notes on Safety and Risks

Owner Responsibilities

The owner is responsible for ensuring that the device (and equipment) are

used for their intended purpose, for the actions of the employees, for

giving instruction to the employees, and for the operational safety of the

equipment. The owner must understand the safety information for the

device and the instructions given in the operating manual.

Lacking or incomplete training can lead to incorrect operation or improper

usage. This may result in accidents involving serious injury or damage to

property, assets, or the environment.

Always make sure that the device or equipment is not operated, serviced,

or used by personnel who have not been properly trained to do so.

Tel: +386 3 4900 800

http://radar-electronics.com/

3702008A

Copyright 2016

Page 16

PreView®Sentry™Daily Maintenance

Detach this page and place with daily operator maintenance procedures.

Safety Message to Operators of Vehicles with PreView®Sentry™Systems

1. The PreView®Sentry™system is intended as an Object Detection System and

should not be relied upon as your first line of defense for the safe operation of

the vehicle. It should be used in conjunction with established safety programs

and procedures to augment the safe operation of the vehicle, ground

personnel, and adjacent property. Should the system become inoperative, it

could jeopardize the safety or lives of those who depend on the system for

safety.

2. Testing and inspection of the system in accordance with these instructions

and a record of the results should be listed on the daily maintenance report.

The units on operating vehicles must be tested each day prior to the vehicle's

operation. Results of this test must be recorded in the maintenance log.

3. People operating this equipment MUST check for proper operation at the

beginning of every shift or safety inspection period.

4. If a PreView®system is found to be inoperative upon test, the operator should

flag or cover the driver display and mark as “inoperative” prior to the

machine/vehicle operation.

5. People's lives depend on the proper installation of this product in conformance

with these instructions. It is necessary to read, understand, and follow all

instructions shipped with the product.

6. Failure to follow all safety precautions and instructions may result in property

damage, serious injury, or death.

7. The PreView®Sentry™is intended for commercial use. Proper installation

requires a good understanding of vehicle/machine electrical systems and

procedures, along with proficiency in the installation.

8. Store these instructions in a safe place and refer to them when maintaining

and/or reinstalling the product.

Testing and Maintenance

NOTE: A walk-around test shall be performed every day to verify proper function of

the system and to familiarize the operator with the zone of detection. More

frequent inspections should be performed when:

The vehicle is operating in a particularly dirty or harsh environment.

The operator has reason to suspect the system has been damaged.

This test should be performed with two people, one who remains in the cab (the

operator), and one who walks through the sensor detection field (the assistant).

The below example illustrates the test for a backing sensor application. Use a

similar procedure for front, side or multiple radar systems by confirming detection

of each radar sensor in the operator display.

1. Clean the sensor face of any accumulation of dirt, mud, snow, ice, or debris.

2. Visually inspect the attached wiring and cable and verify that they are properly

secured, not chafing or dangling free where they could become snagged and

damaged. Inspect the Radar Sensor and Operator Display Module and verify

that they are securely attached to the vehicle.

This manual suits for next models

1

Table of contents