primatech P145 User manual

P145

PNEUMATIC FLOORINGTOOL

OPERATING INSTRUCTIONS

PNEUMATICTOOLP145

The pneumaticflooring toolP145 isatoolspecially

developed for the installation standard 3/4"to1/2"

hardwood flooring.It hasbeen designed for easy

maintenancewhere major components can be easily

accessed.It makesthe installation ofhardwood floor

veryeasy,allowing the operator tosetand fasten the

boards inthe standing position.

The P145 nailer/stapler takesbothstandard L-type

16GA flooring nailsand ½" crown15½GA flooring

staples.

Completedocumentation specifictoyour toolcan be

retrievedbyscanningthe QR-Code appliedon the tool.

You will find updated information suchasOperation

Manual,Partlist, Schematicspecifics and Technical

Notes specific toyour toolasitwasmanufactured; as

well asusefulinformation for ordering replacement

parts.

Technicalsupport, information &

schematics at

http://ts.primatech.ca/145

SAFETY MEASURES

Theseimportantguidelinesshouldalwaysbe followed

toworksafelywiththePrimatechpneumatictoolP145:

•Read theseinstructions thoroughlybefore using this

tooland keep it handyfor referenceif necessary.

•Alwayskeep hands, feetor other bodyparts away

fromthe fastener ejection area.

•Never aimthe toolinanydirection other than the

working area.

•Alwayscarryormanipulatethe toolbyits handle

whilethe airsupplyhoseis connected.

•Never hitthe head cap ofthe actuator ifthe baseis

not sitting perfectlyon the working surface.

•Never leavethe toollaying downon its side whilethe

airsupplyhoseis connected; the toolshouldalways

be left on the floor, standing on its base.

•Alwaysdisconnect the airsupplyhosewhen the tool

is not inuseor when movetoanother work area.

•Never serviceor repairthe tool,clear obstructionsor

makeadjustments whilethe airsupplyhoseis

connected.

•Onlycompressed airshouldbe used topower this

tool; do not exceed 110 psi(7.6bar).

•Never useoxygen or anyother compressed gasasa

power sourcefor this tool. Explosion mayoccur.

•AlwayswearOSHA-requiredZ-87safetyglasseswith

side shields.

•Alwayswear proper ear and footprotection whilethe

airsupplyhoseis connected.

•Alwaysremovefastenersfromthe magazine before

servicing tool.

Eyeprotectionisrecommendedandshould

be worn bytheoperator and other in

working area.Accidentalejection of

fastenersor wood debriscouldcause

severe eyeinjury.

Insomeenvironments,earprotectionmight

be required,asworking condition may

include exposure tohigh noiselevelswhich

lead tohearing damage.

Wearing safetyboots and safetyhatisalso

highlyrecommended.

Note:All the personalprotection

equipments must meetnationalstandards.

Printed in Canada v180 12/18

CONNECTION&AIRSUPPLY

Thistoolrequiresclean&dryair.The useofafilter and

apressure regulator is recommended.

Useadetachablemalecoupler with3/8"NPTmale

treads. The useofa3/8"(1 cm)diameter airsupply

hoseisrecommended.Asmallerhoseorahoselonger

than 50'(15 m)couldcauseapressure drop when the

toolis activated repeatedly.

Always useafree-flowconnection for the

compressed airsupplytoprevent that the

toolstays charged after disconnecting the air

supplyhose.

Unload toolbefore connecting airtoprevent

accidentaldischarge.

Toprevent injuryor accidentaldamage tothe

finished surfaceof the installed floor, rest the

toolontothe subflooring when connecting air,

moving tooltoadifferent work area, loading

the toolor performing anymaintenancetothe

tool.

Dirt, dust, and other particlesinthe airsupplycan

causesluggishoperation or premature wear.Drain

water fromthe compressor tankregularly.The

compressorstart-stop limits shouldbe settodeliver an

airpressure ofatleast 100 psi(7 bar) atall times.

Consultthe compressor manualor dealer for

instructions on howtomakethis adjustment.

Thistoolisdesignedtobeoperatedwithacompressed

airpressure of80 to100 psi(5.5-7.0bar).Airpressure

of90 psi(6.2bar) isadequatefor most situations,

although occasionally,ahigher pressure couldbe

necessary.Never notuseacompressed airpressure

higher than 110 psi(7.6bar).

PREVENTIVE MAINTENANCE

Thistoolrequiresminimallubrication.Use

onlydetergent-free oil suchasPrimatech

P-090.Fewdropsofoil weeklyinthe airinlet

issufficient. Other typesoflubricantmay

degrade the seals.

Checkperiodicallytomakesure thatthe head

assemblyisfullyscrewedontothemainbody.Aloosen

head will damage the tool.

LOADING THE TOOL

Thistoolcan be used witheither standard 16ga

flooring cleats or with15½ga flooring staples:

•L-type 16GA nailsinlengthsof1½"(38 mm),1¾"

(45 mm)or 2" (50 mm)

•½" crown15½GA staples inlengths of 1½" (38 mm),

1¾" (45 mm)or 2" (50 mm)

Useonlythe type of fasteners identified on

the magazine. The useof anyother type of

fasteners will damage the tool.

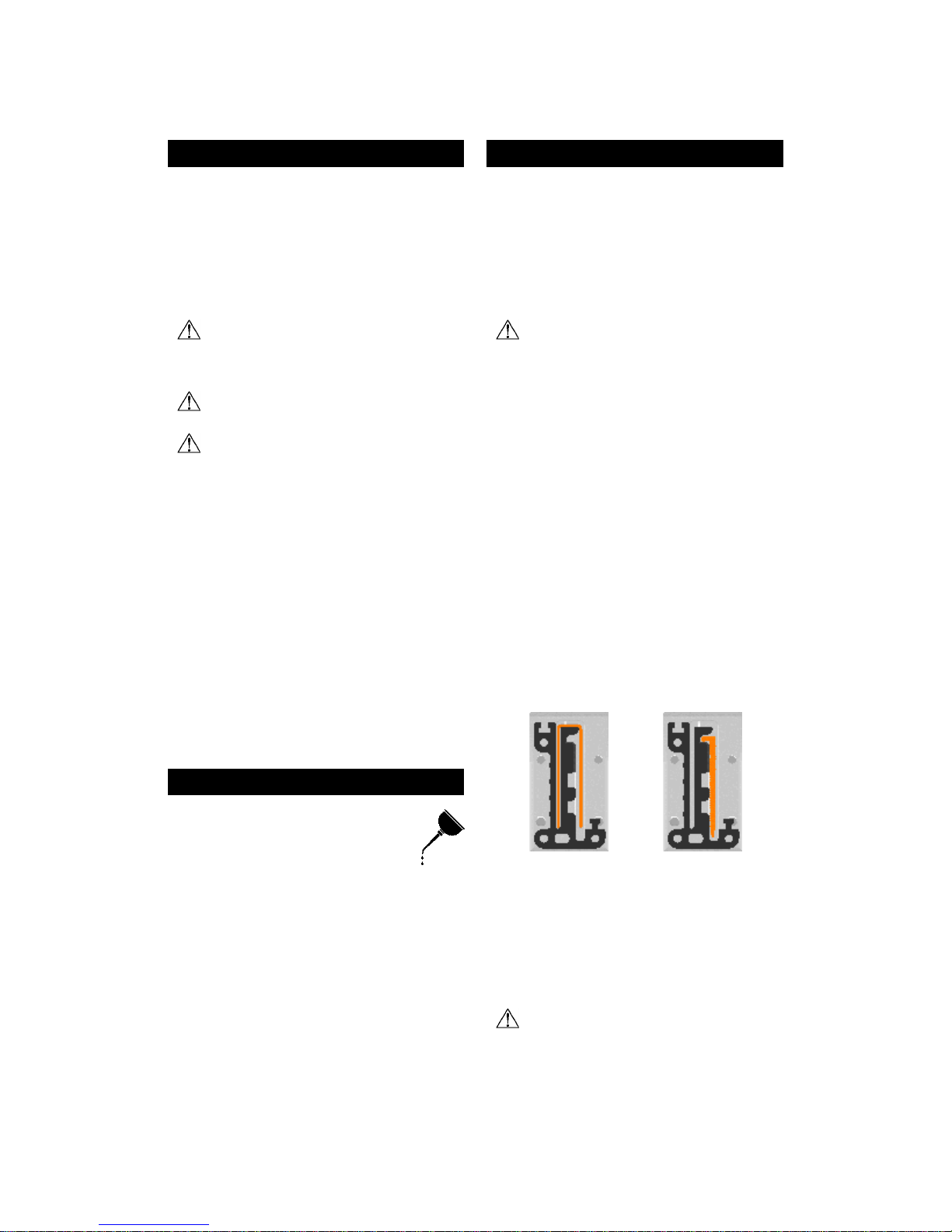

Loading the toolwithflooring staples:

•Press the lock and open the magazine cover.

•Insertone or twostripsofflooring staplesover the

centralguide ofthe magazine asillustrated below

(left).

•Pushthe magazine cover forward intoits locked

position.

Loading the toolwithL-type 16GA flooring nails:

•Press the lock and open the magazine cover.

•Placeastripofflooring cleats against the inner side

ofthe magazine,the “L” head ofthe cleats engaging

thegrooveasillustratedbelow(right).Smallmagnets

will holdit inplace.

•Pushthe magazine cover forward intoits locked

position.

Unloading cleats or staples

•Toremovefastener fromthe magazine,press the

lock and open the magazine cover

•Tiltthe tooltoslide back remaining fastener and take

themout.

Always operatethe toolwithfasteners in

magazine. Damage mayoccur if the toolis

operated without fasteners.

OPERATION

Unload tooland rest itontothe subflooring,Connect

thehoseandcycletoolonceortwicewithoutfasteners.

After loading the tool,the P145 nailer/stapler isready

for use.

Useonlythehammer supplied withthe tool.Theuseof

other type ofhammersmayaffect performance.The

rubber faceofthe hammer can be used withcare to

helpposition the boards.

Withthe flooring firmlyinplace,position the toolonto

the flooring and applydownwardpressure toensure

proper seating ofthe fastener.Strikethe head cap with

the hammer toactivatethe tool, Use onlythe RUBBER

FACE ofthehammertoactivate thetool. Using the

steelend will damagethetooland voidthe

warranty. Ifwoodisslightlytwisted,hittingthe toolwith

more forcewillassist inpulling the board up snugly.

NEVER strikethe head cap when the toolisnotsitting

on the working surface.

Before starting an installation, fasten down

fewboards toascertainthat the toolis

properlyadjusted. Always complywithall

manufacturers recommendations.

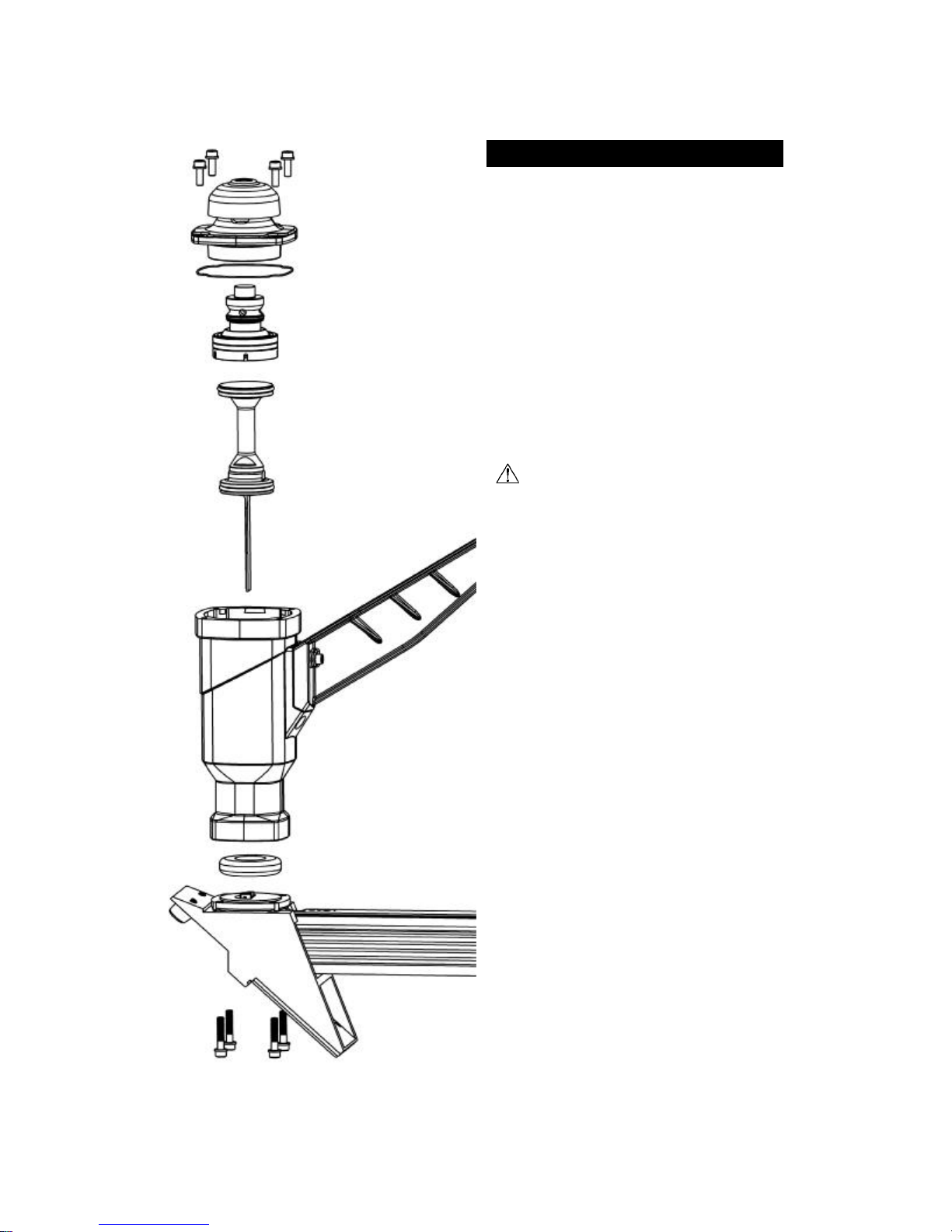

DISASSEMBLING THE TOOL

Allpneumaticcomponentscanbeeasilyaccessedwith

the useofan Allen key.Thissection describes howto

disassemblethetooltoaccessitsinternalcomponents.

Toaccess valveand piston assemblies:

•Removethe 4screws and takeoff the head.

•Pull outthe valveassembly.Inspect wear ring &

lubricate.Do notattempttodisassemblethe valve

assembly.

•Pull outthe piston assembly.Inspect wear ringand

lubricate.

It isusuallynotnecessarytopull-outthe bumper for

maintenance. Toreplacethe bumper:

•Removethe4screwsandtakeoffthebase/magazine

assembly.

•Pull out and replacethe bumper.

MAINTENANCE &REPAIR

Most maintenancetothe toolcan be made withthe

5mm Allen wrenchsupplied withthe tool.

Disassemblyofthe toolmust be done inaclean

environment. Somepartscan be easilydamaged if

disassembled withimproper toolsor byinadequate

methods. Maintenanceshouldonlybe performed by

trained personnel.Useonlygenuine Primatech

replacement parts.

Toprevent injury, ALWAYS disconnect the

airsupplyhosewhen servicing or

disassembling the tool.

When servicing the tool,donottwist or forceanyparts.

Damagemayresultfromsuchabuse.Contact your

Primatechdistributor for more information.

When opening the toolfor maintenance, always clean

allcomponents ofdirt, grit, or particles. Inspect the tool

carefullyforbroken parts or excessivewear,and

replaceifnecessary.When ordering parts, be sure to

specify the rightpartnumber,aswell asthe toolserial

number.

After anymaintenancetothe tool, REMOVE

ALL Fasteners before connecting airand

actuatethe toolrepeatedlyover apieceof

wood or subflooring toinsure proper

operation.

CLEANING THE VALVE

If the toolbecomessluggishor doesnotsetthe

fastener correctly, it mayindicateexcessivedirt, dust,

other particles, or even water,inthe tool.The first step

introubleshooting is toclean up the head assembly.

•Disassemblethe head assemblyasdescribed in

previous section.

•Performavisualinspection ofthe valveassembly.

Ensure thatthe actuator issliding easily.Clean and

lubricatelightly.Donotattempttotakeapartthe

actuator assembly.

•Clean the inside wall ofthe head and lubricatelightly

withanon-detergentoil.Insertthe valveassembly

intothe head and ensure that it is sliding easily.

•Ensure the piston assemblyissliding easilyintothe

cylinder.It shouldoffer someresistance,butifit

movestoo easily,itmaybe required toreplacethe

piston wear-ring.

ASSEMBLING THE TOOL

Thissection describeshowtore-assemblethe tool

after maintenance.The following procedure assumes

that the base/magazine is alreadyinstalled.

•Insertthe piston assemblyintothe tooland engage

the driving blade thru the opening ofgate/foot

assemblyguiding channel.

•Insert the valveassemblyintothe head.

•Inspect the head gasket; replaceifnecessary.Place

the gasketintothe grooveon the head flange.Some

oil or greasewillhelptokeep itinplaceduring

assembly.

•Insertthehead assemblyontothe body,making sure

that the gasket stays inplace. Screwinplace.

After reassembly, always actuatethe tool

repeatedlyWITHOUTFASTENERS against

apieceof wood toinsure proper operation.

TROUBLESHOOTING

TO PREVENTINJURY,ALWAYS

DISCONNECT THE AIR SUPPLY HOSE

WHEN ADJUSTING,SERVICING OR

DISASSEMBLING THE TOOL.

FIRST:CHECK THE COMPRESSED AIR SUPPLY

Manyofproblemscomefromafaultyor inadequate

compressed airsupply system.Before attempting to

repairthe tool,the following points shouldbe

checked:

•Checkthe pressureattheoutputofthecompressor;

adjust to80-100 psi(5.5-7.0bar) as required.

•Checkthetankpressureofthecompressor&adjust

the start/stop limits.

•Check the airdeliverysystem;a3/8"hoseis

recommended.

•Usefewer tools simultaneously;do not exceed the

capacityofthe compressor or ofthe delivery

system.

•Drainwater fromthe compressor.

SECOND:CHECK FOR AIR LEAKS

At rest, thistoolshouldnothaveanyairleaks. Before

attempting torepairthe tooland replaceparts, check

the following:

•Check all sealsinhead,valveand piston

assemblies; replaceif necessary.

•Check the top edge ofmaincylinder for burrsor

dents.

•Clean &lubricatethe head and valveassemblies;

re-assemblethe head assemblycarefully.

•Check the interior of the head for scratches.

A more comprehensivelist of tips and

hints at

http://ts.primatech.ca/tips

SCHEMATICS

Withyour toolSerialNumber at hand,

go toour support web sitetoretrieve

the schematic specific toyour tool:

http://ts.primatech.ca/145

For more information, contact technicalsupport:

byphone 1 (800) 363-1962

byemail support@primatech.ca

TOOL WARRANTYAND LIMITATIONS

Primatechwarrants thatnewlypurchased fastening

tools,parts and accessorieswill be free fromdefectsin

materialand workmanship(excluding wear parts)for

the period shownbelow, after the dateof purchaseby

the originaluser asevidenced byavalidpurchase

invoice.

ONE-YEARLIMITEDWARRANTYwill applytoall

parts, except thosesubjected tonormalwear

WARRANTYSTATEMENT

Primatech‘ssoleliabilityhereunder will be toreplace

anypartor accessorywhichprovestobe defective

withinthespecifictimeperiod.Anyreplacementpartor

accessoriesprovided inaccordancewiththiswarranty

will carryawarrantyfor the remainder ofthe period of

warrantyapplicabletothe partitreplaces. When repair

or replacementofpartor toolisrequired,the complete

toolor part(s)mustbe returned toPrimatechor atsuch

authorized warrantyservicepointofPrimatech,

transportationprepaid,withacopyofproofofpurchase

evidencing thatthe partor tooliswithinthe warranty

period.Serial#must be intact and legiblefor warranty

toapply.

Thiswarrantyisvoidastoanytoolwhichhasbeen

subjected tomisuse,abuse,accidentalor intentional

damage,used withfastenersnotmeeting Primatech

specifications, sizeor quality,improperlymaintained,

repaired withother than genuinePrimatech

replacementparts, damaged intransitor handling,or

which,inPrimatech‘ssoleopinion,hasbeen altered,

modified or repaired inawaythataffects or detracts

fromthe performanceof the tool.

PRIMATECHMAKESNOWARRANTY,EXPRESSED

ORIMPLIED,RELATINGTO MERCHANTABILITY,

FITNESS, OROTHERWISE, EXCEPTAS STATED

ABOVE, and Primatech‘sliabilityASSTATEDABOVE

AND AS ASSUMEDABOVEisinlieu ofall other

warrantiesarising outof, or inconnection with,the use

and performanceofthe tool,excepttothe extent

otherwiseprovided for byapplicablelaw.

PRIMATECH SHALL INNOEVENTBE LIABLE FOR

ANYDIRECT,INDIRECT,ORCONSEQUENTIAL

DAMAGES WHICH MAY ARISE FROMLOSS OF

ANTICIPATEDPROFITSORPRODUCTION,

SPOILAGEOF MATERIALS, INCREASEDCOSTOF

OPERATION,OROTHERWISE. Anyliability,ifany,

connected withthe useofthe toolshall terminateupon

the expiration of the warrantyperiod specified above.

Table of contents

Other primatech Tools manuals