primatech P250A User manual

Revision 10/10 Printed inCanada

PNEUMATICFLOORINGTOOL

P250A

OPERATINGINSTRUCTIONS

WARNING

Read theseinstructionsthoroughlybeforeusingthistooland keep it

handyforreference.

PRIMATECH PNEUMATIC TOOL P250A

The pneumaticflooring tool P250Aisaprofessional precision tool

speciallydeveloped forthe installationof5/8"to7/8"solid

hardwoodflooringinstandardversion,orfrom3/4"to33/32"forthe

GYM-version.It hasbeen designed foreasymaintenancewhere

majorcomponentscan be accessed within secondswithoutthe

need ofanytool.Weighting only11 pounds(5kg),thisergono-

micallydesigned tool makesthe installation ofhardwood floorvery

easy,allowing the operatortosetand fasten the boardsinthe

standing position. It isoffered in 3different configurations:

•standard L-type cleatsin lengthsof 1½" (38 mm), 1¾" (44 mm)

or2" (50 mm)

•T-type cleatsin lengthof 1½" (38 mm) or2" (50 mm)

•½"crown15½ga staplesin lengthsof1½"(38 mm),1¾"

(44 mm) or2" (50 mm)

The P250Aisbuilt around the

Primpact valveengine, a

breakthrough technologyfor

pneumatictools. Primpact main

featuresare:

•short noseand compact valvedesign withan all-

around striking surface

•high-speed action and fewmoving parts, fora

powerful yet soft strokeand increased precision.

•reciprocal striking systemthat regulatesthe depthof

penetration independentlyfromthe mallet impact

•finelythreaded screw-in cartridge assembly

Forbestresult, onlyPRIMATECH fasteners should be used.Read

carefullytheseinstructionsbeforeoperatingthistool.Itisimportant

tounderstand warnings/cautionsand the safetymeasuresto

ensuresafeuseof thistool.

Additional information isavailable directlyfromthe manufacturer:

1135 Jérémie-Fortin, Québec, QC

Canada, G1J1R8

Phone:1(800)363-1962 or1(418)522-7744

Fax:1(418)522-7466

email: support@primatech.ca

web: www.primatech.ca/support

SAFETYMEASURES

Theseimportantguidelinesshould alwaysbe followed towork

safelywiththe PRIMATECH pneumatictool model P250A:

1.Read theseinstructionsthoroughlybeforeusing thistool and

keep it handyforreferenceif necessary.

2.Alwayskeep hands,feetorotherbodypartsawayfromthe

fastenerejection area.

3.Neveraimthe tool in anydirection otherthan the working

area.

4.Alwayscarryormanipulatethe tool byitshandle while the air

supplyhoseisconnected.

5.Neverhitthehead capofthe actuatorifthe plasticbaseisnot

sitting perfectlyon the working surface.

6.Neverleavethe tool laying downon itsside while the air

supplyhoseisconnected;the tool should alwaysbe left on

the floor, standing on itsplasticbase.

7.Do not alterorremovesafety.

8.Alwaysdisconnectthe airsupplyhosewhen the tool isnotin

useorwhen movetoanotherworkarea.

9.Neverserviceorrepairthe tool,clearobstructionsormake

adjustmentswhile the airsupplyhoseisconnected.

10.Onlycompressedairshould beused topowerthistool;donot

exceed 110 psi(7.6bar).

11.Neveruseoxygen oranyothercompressed gasasapower

sourceforthistool.

12.AlwayswearOSHA-required Z-87 safetyglasseswithside

shields.

13.Alwayswearproperearand feetprotection while the air

supplyhoseisconnected.

14.Alwaysremovefasteners fromthe feederchannel before

servicing tool.

DO NOTREMOVE ORALTERSAFETY.NEVERDEPRESS THE

SAFETY CONTACTWITHYOUR HANDS WHENTOOLIS

CONNECTEDTO AIRSUPPLY.EXTREME CAUTIONIS

ADVISEDWHENUSING THIS TOOL.

CONNECTION & AIR SUPPLYSYSTEM

Toensuremaximumperformanceand efficiency,and alsoa

minimumofcare,thePRIMATECH pneumatictoolrequiresclean,dry

air. It isnecessarytouseafilterand apressureregulator.

Thistool needsadetachable male couplerwith3/8"NPTmale

treads.The useofa3/8"(1cm) diameterairsupplyhoseis

recommended.Asmallerhoseorahoselongerthan 50'(15 m)

could causeapressuredrop when the tool isactivated repeatedly.

ALWAYS USE AFREE-FLOWCONNECTIONFORTHE

COMPRESSEDAIRSUPPLY TO PREVENTTHATTHE TOOL

STAYS CHARGEDAFTERDISCONNECTING THE AIRSUPPLY

HOSE.

UNLOADTOOLBEFORE CONNECTING AIRTO PREVENT

ACCIDENTALDISCHARGE.

AFTERMOVING TOOLTO ADIFFERENTWORK AREA,OR

AFTERANY MAINTENANCE TO THE TOOL,ALWAYS ENSURE

PROPEROPERATIONBY ACTUATING TOOLSEVERALTIMES

WITHOUTFASTENERS OVERTHE SUBFLOORING .

Dirt, dust, and otherparticlesin the airsupplycan causesluggish

operationorprematurewearofmanycomponentsofthetool.Drain

waterfromthe compressortankregularly.The compressorstart-

stop limitsshould be settodeliveran airpressureofatleast

100 psi(7bar) atall time.Consultthe compressormanual or

dealerforinstructionson howtomakethisadjustment.

At80 psi(5.5bar) and 100 hitsperminute,thistool consumes

approximately4.7cu.ft (130 )ofairperminuteat70°F(21°C).

Higherairpressurewill increasethe consumption ofcompressed

air.

Thistool isdesigned tobe operated withacompressed air

pressureof80 to100 psi(5.5-7.0bar).Anairpressureof90 psi

(6.2bar) isadequateformostsituations,although occasionally, a

higherpressurecould be necessary,forexample tousethe tool

withdifferentspeciesofharderwood.Inthesemoredifficultcases,

the compressed airpressurecan be increased up to100 psi

(7.0bar).It isveryimportantnottoexceed thismaximumpressure

toprevent leaks, prematurewearordamagestothe tool.

Checkthe compressed airsupplyhosebeforeconnecting to

ensurethattheyarefree fromdirtorparticlesthatcan alterthe

performanceofthe tool.Payspecial attention toanyairleaks.Do

notuseacompressed airpressurehigherthan 110 psi(7.6bar).

Higherpressurecan causeprematurewearordamage tocertain

components.Afterassembly,checkall the connectionstoprevent

the leaksand tohavemaximumefficiency.

TO PREVENTACCIDENTALDAMAGE TO THE FINISHED

SURFACE OFTHE INSTALLEDFLOOR,RESTTHE TOOLONTO

THE SUBFLOORING WHENCONNECTING AIR,LOADING TOOL

ORPERFORMING ANY MAINTENANCE TO THE TOOL.

LOADING THETOOL

Several feederchannel configurationsareavailable forthistool.

Conventionalfeederchannelscomewithan integratedpusherthat

mustbe engaged behind the nailsatall time.Forthose,simply

insertarowofPRIMATECH's cleatsorstaplesinside the feeder

channel and pull backon the plastictab gentlyuntil itengages

behind it. Torelease,simplysqueezethe tab withyourthumband

indexandallowthespring torecoil slowly.The clip mustbe

released slowlytoprevent damage.

Toolsfitted withthe LOADXTEND (Patent

Pending)automaticfeederchannelhold&feed

200 nailsin an assemblyno longerthan aconventional one.Its

exclusivepusherlocksintoapre-armed position,allowing nailsto

be fed bygravityuntil itautomaticallyengagesbehind.Withonly

one strip ofnails,the LOADXTEND feederchannel isoperated in the

samewaybysimplypullingthe pushertoengage itbehind the

nails.

The real time-saving featureistoallowatanytimetofill oradd

nailsintothe LOADXTEND feederchannel,up to200 nails.Simply

pull the pusherall the wayuntil it locksintoitspre-armed position

and ensurethatthe nailsarefullypushed intothe nail ejection

area.Thepusherwillautomaticallyengagebehind thenailsasthey

pass-by.

USE ONLY THE TYPE OFFASTENERS IDENTIFIEDONTHE

FEEDERCHANNEL.THE USE OFANY OTHERTYPE OF

FASTENERS WILL DAMAGE THE TOOL.

OPERATION

Unload tool and restitontothe subflooring,Connectthe hoseand

cycle tool onceortwicewithoutfastener.Afterloading the tool,the

tool isreadyforuse.

Useonlythe 2.5lbs(1.1kg)hammersupplied withthe tool.The

useofothertype ofhammers mayaffectperformance.The rubber

faceofthe hammercan be used withcaretohelp position the

boards.

Withthe flooring firmlyin place,position the tool

ontothe flooring,withthe resting blockP-534

againstthe tongue.Applydownwardpressureto

ensureproperseating ofthe fastener.Strikethe

head cap P-601 withthe hammertoactivatethe

tool, Use onlythe RUBBERFACE ofthehammer

toactivatethetool. Using thesteelend will

damagethetooland void thewarranty. Ifwood

isslightlytwisted,hitting the tool withmoreforce

will assistin pulling the boardup snugly. NEVER strikethe head cap

when the tool isnot sitting on the working surface.

OPERATING THE TOOLWHENTHE SAFETY CONTACTIS NOT

FULLY DEPRESSEDWILL CAUSE PREMATURE WEAROR

DAMAGE TO THE DRIVING BLADE,PISTONAND CYLINDER.

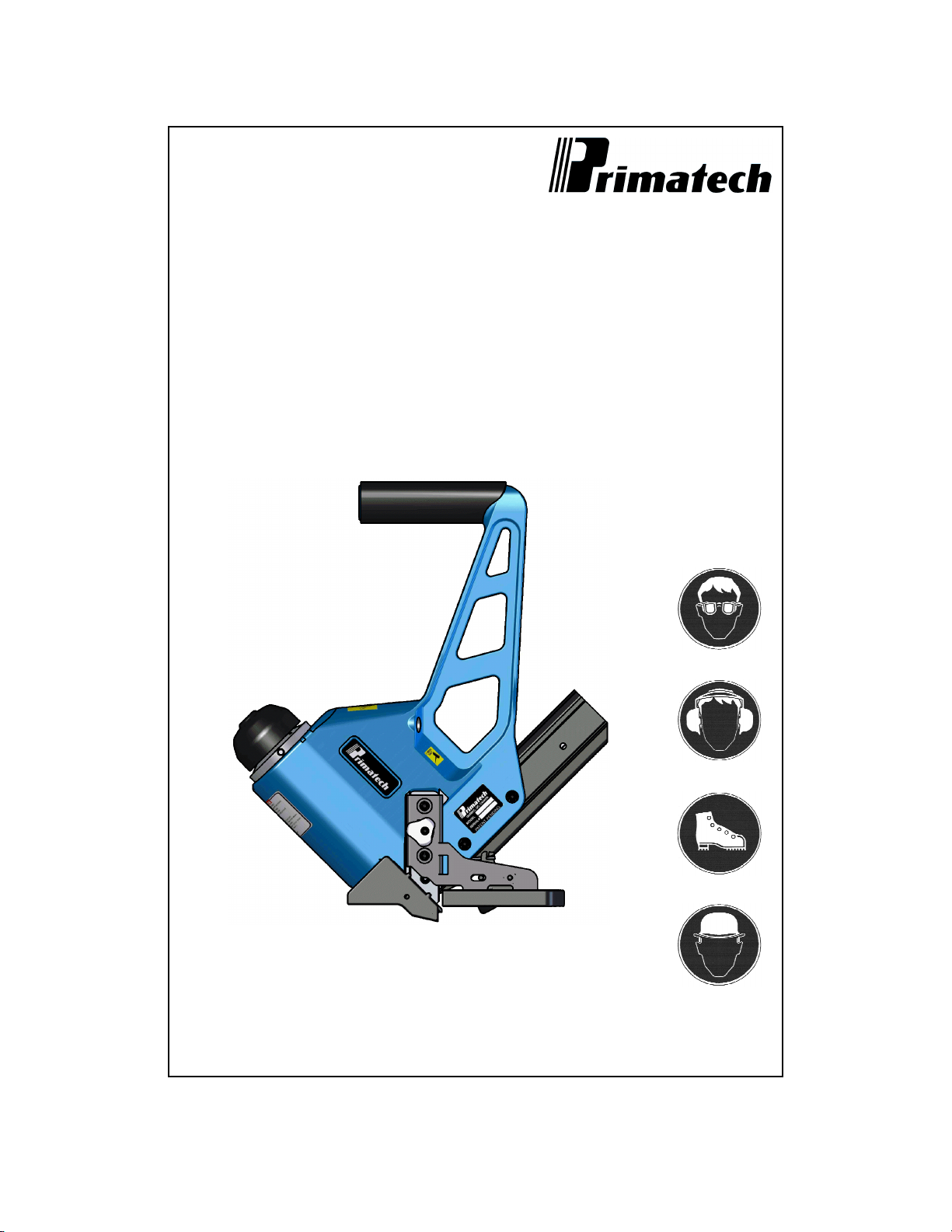

Eyeprotection isrecommended and should be

wornbytheoperatorand otherin working area.

Accidental ejection offasteners orwood debris

could causesevereeyeinjury.

Insomeenvironments, earprotection might be

required, asworking condition mayinclude

exposuretohigh noiselevelswhichlead to

hearing damage.

Wearingsafetybootsand safetyhatisalsohighly

recommended.

NOTE:All the personal protection equipments

must meet national standards.

Beitraw,factoryfinished orengineered,hardwood isanatural

material subjecttovariousfactors,suchashumidity,subflooring,

installation procedure,type oftools,fasteners, etc.Installershould

alwaysensureoptimal surfacepreparation,complywithall

manufacturer's recommendationsand conductapre-installation

test priorbeginning anyinstallation.

BEFORE STARTING ANINSTALLATION,FASTENDOWNFEW

BOARDS TO ASCERTAINTHATYOUARE USING THE RIGHT

FASTENERAND THATTHE TOOLIS PROPERLY ADJUSTED.

ADJUSTING FOR HARDWOOD THICKNESS

The P250Apneumatictool isfitted withafullyadjustableplastic

basedesigned topreventcontactwiththe top edge ofthe flooring.

It isimportanttoadjustthe tool tofitthe flooring priorany

installation.The P250Aalsofeaturesaresting blockwhichprevent

damage tothe top edge ofthe flooring bypositioning the tool

againstthe tongue,preventing the gate/footassemblyfrom

contacting the board.

Step 1: adjusting the baseforflooring thickness:

•Using the supplied Allen wrench,loosen butdo notremove

screws(A); twoon eachside of the tool.

•Withthe tool in an upside downposition,placeashortpiece

of flooring against the gate/foot assembly(P-429).

•Engagethe Allenwrenchin knob(B) asshown;rotatetomove

the baseup ordown. Notethatknob (B) hasarotation range

ofonlyabout1/2turn.Do notapplyforcewhen alimitis

reached.

•Adjustthe heightofthe plasticbasetoobtain asmall gap

betweenthe gate/footassemblyandthe topside ofthetongue

ofthe sample board.Agap of1/32"should be adequatefor

most situations.

•Tighten bothscrews(A).

Step 2: adjusting the resting blockforthe widthof the tongue:

•Using the Allen wrench,loosen byabout1/2turn do not

removethe twoscrews(C).

•Withthe shortpieceofflooring still againstthe gate/foot

assembly,adjustthe gap between the resting blockand the

tongue withscrew(D).Asmall gap of1/32"should be

adequateformost situations.

•Tighten bothscrews(C).

•Ensurethatscrew(D)isslightlytighten.Do notapplyforceon

screw(D)oncescrews(C)aretighten.

Aftercompleting the adjustmentprocedure,proceedwiththe

installationoffewboards.Carefullycheckfortheproperpositioning

ofthe fastenerontothe board.Checkagain afterfewmorerowsto

insurethatallpartsaresecured inplace.Tool mayloseadjustment

overtimeif thisprocedureisnot strictlyfollowed.

BEFORE STARTING ANINSTALLATION,FASTENDOWNFEW

BOARDS TO ASCERTAINTHATYOUARE USING THE RIGHT

TOOLAND FASTENER.

PREVENTIVE MAINTENANCE

Thistoolrequiresminimallubrication.Useonlydetergent-

freeoilsuchasPrimatechP-090.Fewdropsofoil weekly

in the airinletissufficient. Othertypesoflubricantmay

degrade the seals.

Checkperiodicallytomakesurethatall screwsaretight. Pay

particularattentiontothetwoscrewsholding thefeederchannelas

well asthe screwsand nutson the feederchannel assemblywho

mightloosen up overtime.The useofan mediumstrength

adhesivesealant isrecommended.

MAINTENANCE& REPAIR

Mostadjustmentstothe tool can bemadewiththe 3/16"Allen

wrenchsupplied withthe tool.

Disassemblyofthe tool mustbe done in aclean environment.

Somepartscan be easilydamaged ifdisassembled withimproper

toolsorbyinadequatemethods.Maintenanceshould onlybe

performed bytrained personnel.Useonlygenuine PRIMATECH

replacement parts.

TO PREVENTINJURY,ALWAYS DISCONNECTTHE AIR

SUPPLY HOSE WHENSERVICING ORDISASSEMBLING THE

TOOL.

When servicing the tool,do nottwistorforceanyparts.Damage

mayresultfromsuchabuse.If partsdo notcomelooseeasily,

contact yourPRIMATECH distributorformoreinformation.

When opening the tool formaintenance,alwaysclean all

componentsofdirt, grit, orparticles.Inspectthe tool carefullyfor

broken partsorexcessivewear,and replaceifnecessary.When

ordering parts,be suretospecifythe rightpartnumber,and also

the tool serial number.

NEVERapplythreadlocker

oradhesiveontocylinder

orhead threads.

Complete'cartridge'assembly

AFTERANY MAINTENANCE TO THE TOOL,REMOVE ALL

FASTENERS BEFORE CONNECTING AIRAND ACTUATE THE

TOOLREPEATEDLY OVERAPIECE OFWOODOR

SUBFLOORING TO INSURE PROPEROPERATION.

ASSEMBLING THEVALVE

All pneumaticcomponentsrequired arepacked in acartridge

assemblywhichissimplyinserted intothe tool.Thissection

describeshowtoassembleallthecomponentstogether.However,

itisusuallynotnecessarytocompletelydisassemble the valve.

Refertonextsection,"CLEANINGTHEVALVE"formoreinformation

on howtoopen the tool forregularmaintenance.The following

procedureassumesthatthegate/footassembly(P-429)along with

the resting blockP-534 arealreadyinstalled.Refertothe

"ReplacementParts" document foracompletelist and schematic

of the tool.

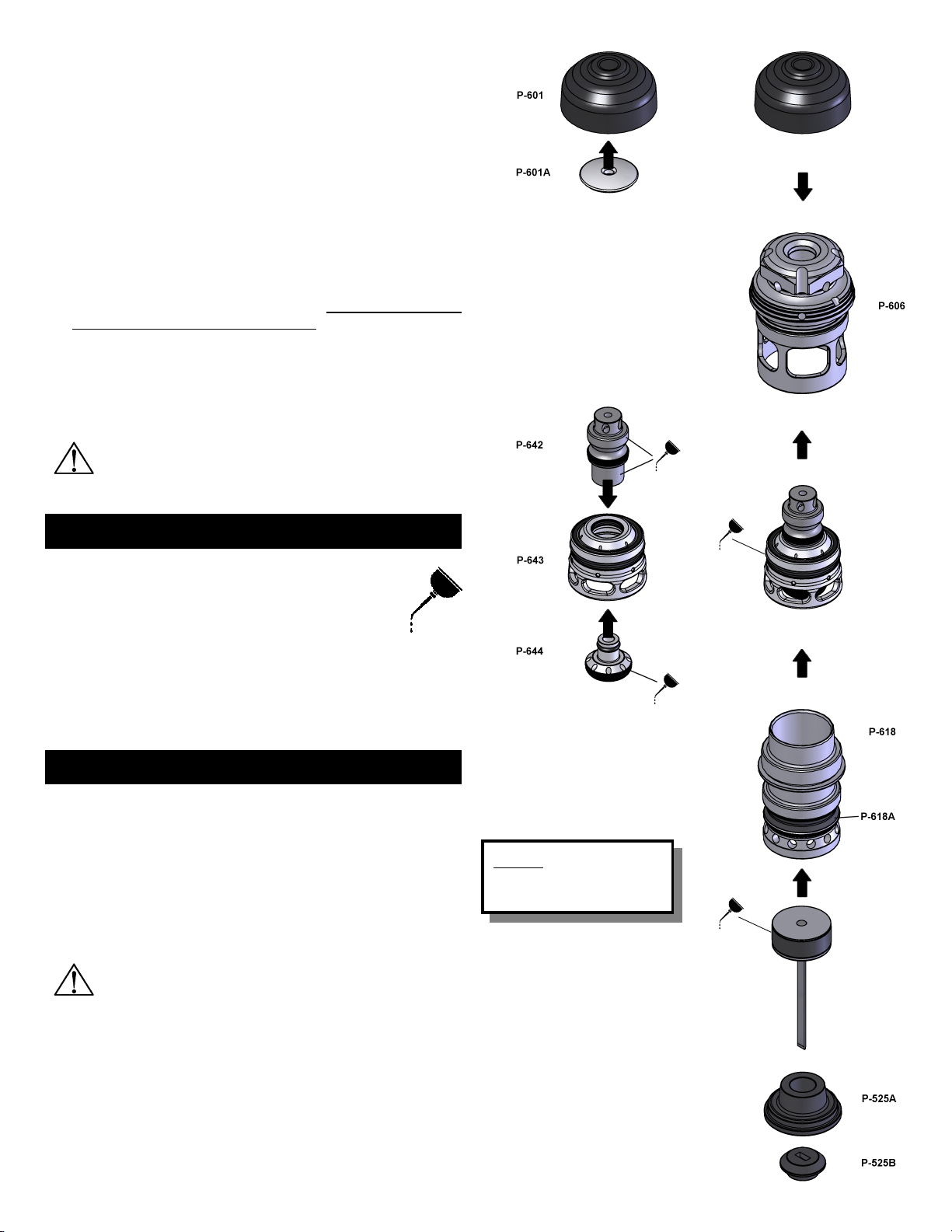

1.It isusuallynotrequired toseparatethe head diskP-601A

fromthe head cap P-601.If necessary,insertthe head disk

firmlyin placeintothe head cap.

2.Alignthe headcap P-601withthe twopinsonthe headP-606

and snap the cap in place.It isusuallynotrequired toremove

the head cap fromthe head.

3.Checkthe condition ofall ringsand sealson the actuator

P-642, actuatorcap P-644 and main valveP-643.

4.LightlylubricateactuatorP-642 asshownand insertitinto

valveP-643.

5.Lightlylubricatethe permanentseal ofactuatorcap P-644 as

shown.Do not lubricatethe small o-ring (see partP-644C on

schematic).Insertthe actuatorcap asshownand forcibly

snap it intothe actuatorP-642

6.Insertthevalvesub-assemblycompletelyintotheheadP-606.

7.Screwthe cylindercompletelyontothe head bodyP-606and

tighten firmlybyhand.Takecarenotdo damage the threads.

Pull downthe valveP-643 tosit it ontothe cylinder.

8.Checkthatthe band-valveP-618Aisproperlyinstalled onto

the main cylinderP-618.

ALWAYS CHECK THATTHE CYLINDERIS COMPLETELY

SCREW-ONTHE HEADBEFORE INSERTING THE ASSEMBLY

INTO THE TOOL.THE CYLINDERWILL LOOSEN-UP WHEN

THE CARTRIDGE IS TAKEN-OFF THE TOOL.

ALWAYS PULL DOWNTHE VALVE AGAINSTTHE CYLINDER

BEFORE INSERTING THE HEADASSEMBLY.

9.Checkthatthe piston sub-assembly,including ringsand

drivingblade,isslidingeasilyintothe cylinderP-618.Itshould

offersomeresistance,butifitmovestoo easily,itmaybe

required toreplacethe piston wear-ring P-622A.

10.Insertthe seal bushing P-525Bin the lowersection ofmain

bodyP-606 and engage itontothe upperportion ofthe

gate/footassembly(P-429).Aflatscrewdrivercan help

locationthe sealbushing correctly.Usethewooden handleof

the hammertotap the seal bushing completelyin place. It is

usuallynotnecessarytopull-outthe seal bushing P-525Bfor

maintenance.

11.Withthe tool in the uprightposition,pushthe bumperP-525A

in place,indexed ontothe seal bushing P-525Band usethe

wooden handle toseat the bumperin position.

12.Insertthe piston sub-assemblyintothe main bodyP-616 and

engage the driving blade P-423 in the seal bushing opening.

Depress the safetycontactP-562 toensurethatthe driving

blade hasengaged the gate/foot assemblyguiding channel.

13.Loosen the lockP-616D and insertthe whole head assembly

intothe main bodyP-616; the main cylinderP-618 engaging

ontothe piston assembly.Screwthe head assembly

completely.Takecarenotdodamagethethreads.Rotatethe

headlockP-616D clockwiseandtighten withmoderateforce.

NEVERLOCK THE HEADORCYLINDERINAVISE.IFMORE

TORQUE IS NECESSARY,INSERTTHE LONG ARMOFAN

ALLENKEY INTO ONE OFTHE SIDE HOLES OFTHE HEAD

AND/ORAROUND SCREWDRIVERTHROUGHTHE LARGE

HOLES OFTHE CYLINDER.ALWAYS (UN)TIGHTENBY HAND.

NEVER APPLY THREADLOCKERORADHESIVE ONTO

CYLINDERORHEADTHREADS.

ITIS MOSTIMPORTANTTHATTHE MAINCYLINDERBE FULLY

SCREWED &TIGHTENEDONTO THE HEADASSEMBLY

BEFORE BEING INSERTEDINTO THE MAINBODY.

AFTERREASSEMBLY,ALWAYS ACTUATE THE TOOL

REPEATEDLY WITHOUT FASTENERSAGAINSTAPIECE OF

WOODTO INSURE PROPEROPERATION.

Thistool featuresahead lockto

maintain firmlyin placethe head

assemblyduring operation.Before

inserting the head assembly,ensure

thatthe P-616D lockisfree toswivel

and rotateitawayfromthe head

opening.Afterinserting the head

assemblyin place,rotatetheP-616D

lockand tighten withthe Allen key

using moderateforce.

Toremovethe head assembly,simplyunscrewthe P-616D screw

¼turnand rotateit counter-clockwise.

CLEANING THEVALVE

If the tool becomessluggishordoesnotsetthe fastener,itmay

indicateexcessivedirt, dust, otherparticles, oreven water, in the

head assembly,therebyimpedingthe cycling ofthe valve.The first

step in troubleshooting istoclean up the head assembly.

1.Loosen (¼ turn)the head lockP-616D.

2.Unscrewthe head assemblyP-606 and takeitoutofthe tool.

The long arm ofaAllen wrenchmaybe inserted intoone of

hole at the baseofhead P-606 tohelp unlockthe assembly.

3.Pull-outthe piston assemblyand unscrewthe cylinderP-618.

Perform avisual inspection ofthe driving blade P-423,the

wear-ringP-622Aand theinnersurfaceofthe cylinderP-618.

Do not removethe driving blade fromthe piston.

4.Pull-outthe valveassemblyP-643 and perform avisual

inspection ofall rings.Checkthatthe actuatorassembly

P-642/P-644 issliding easilyon valveP-643.Clean and

lubricatelightly.It isusuallynotnecessarytotakeapartthe

actuatorassembly.

5.If necessary,actuatorcap P-644 maybe unsnaped from

actuatorP-642 byinserting the long arm ofanAllen wrench

through the hole on top ofthe actuatorand using ahammer

withmoderateforcetoget the partsapart.

6.Clean the inside wall ofthe head bodyP-606 andlubricate

lightlywithanon-detergentoil.Checkthe o-ring P-606A.It is

generallynot necessarytoremovethe head cap P-601.

REPLACING THEDRIVING BLADE

The driving blade issold separatelyorsupplied asacomplete

subassemblywiththe piston P-622.

1.Unscrewthe head assemblyP-606 and takeitoutofthe tool.

2.Pull-outthe piston assemblyfromthe cylinder.Removeany

debrisand assess condition ofcylinderP-618.If marked or

grouged,useafine sand papertosmoothoutwalls.The

piston P-622 mustbe allowed tomovewithoutrestriction.

Skip tostep(7)ifyou arereplacing withapiston/driving blade

subassembly.

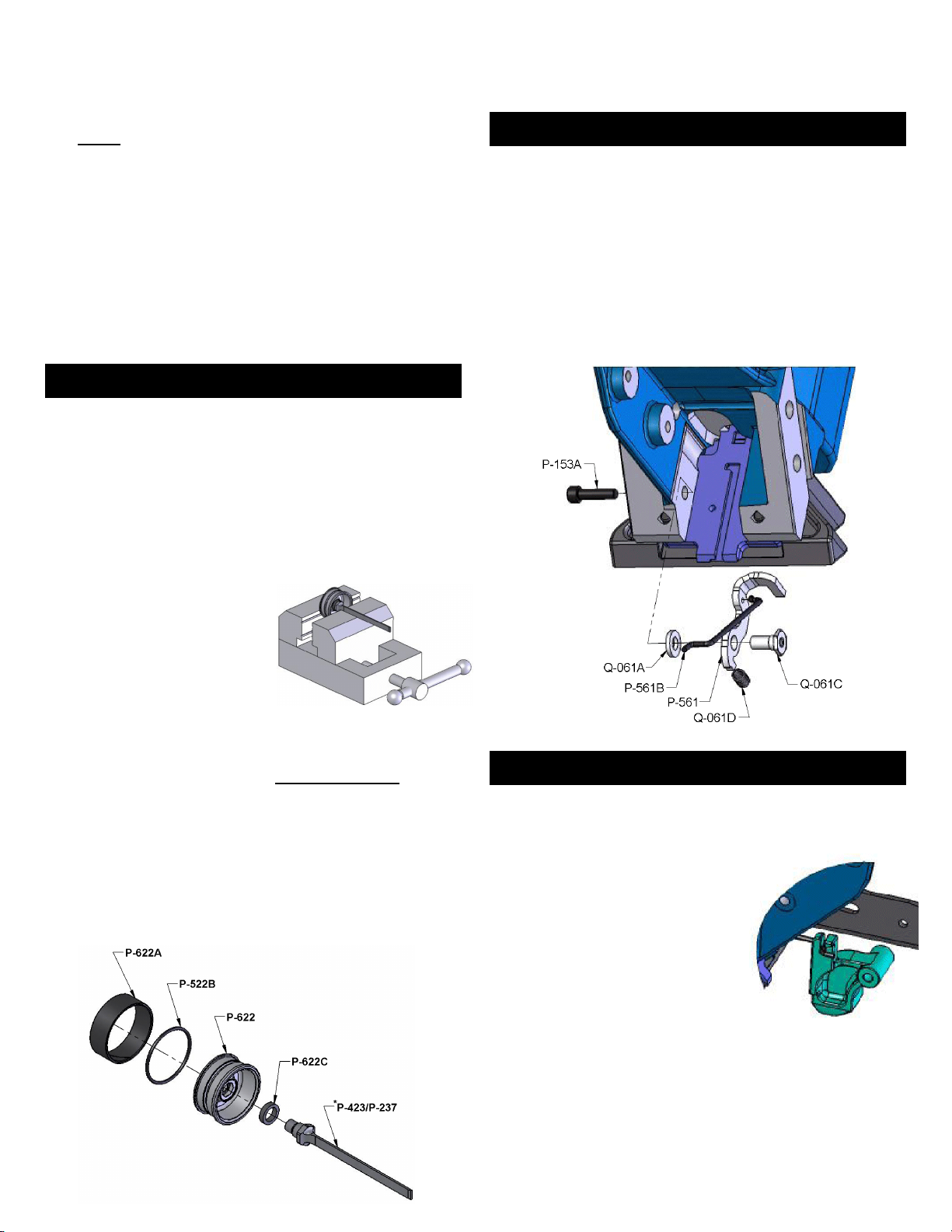

3.Lockthe piston in avise,using

aragtopreventscoring.

Alwaysusethetop andbottom

facestosecurethe piston in

place.

4.Removethe broken driver

using a1/2" closewrench.

5.Putone drop ofmedium

strengthadhesivesealantontothe threadsofthe piston

P-622.

6.Insertthe P-622C lockwasherand screwthe newdriving

blade ontothe piston P-622.Tighten veryhard (140 lbin

minimum).Makesurethatthe lockwasherP-622C is

completelyflattened.

Note: select the appropriatedriving blade:

•useP-423 driving blade forthe "L" or"T" bailers

•useP-237 driving blade forstaplerconfiguration

7.Insertthe piston sub-assemblyintothe main bodyP-616 and

engage the driving blade P-423 in the seal bushing opening.

Depress the safetycontactP-562 toensurethatthe driving

blade hasengaged the gate/foot assemblyguiding channel.

8.TightenthecylinderP-618 ontotheheadP-606andfollowthe

proceduretocompletethe assemblyof the head.

INSTALLING THESAFETY

You shouldn'tneed toremovethe safetystop mechanism unless

the element P-561 do not swivel orhasabroken tip.

1.Assemble togetherpartsP-561,Q-061A,Q-061C and

Q-061D.

2.Insert the short end of P-561Basshown.

3.Puttwodropsofadhesivesealantontothe thread area of

Q-061C,nearitscylindrical end.Makesureno sealantis

retained on the end orexteriorwall.

4.Insert the assemblyintothe hole in the tool bodyasshown.

5.Tight togetherwithscrewP-153A, holding Q-061C.

INSTALLING THEBASE ASSEMBLY

The plasticbasecan beinstalled orremoved withoutthe need of

atool.

1.First, insertconnecting stem

P-561BtothesafetycontactP-562.

2.Lift the safetycontactandfully

slide-in the plasticbaseP-533onto

the bracketsP-535A&B.

3.The safetycontactshould simply

drop intoplace.Insertthe locking

rod P-562 until itsnaps.It should

engage the safetycontact.

TROUBLESHOOTING

Thissectionwillhelptodiagnosecommonproblemsandwillgive

suggestionstosolvethem.Consultouron-lineTechnicalSupport

siteat www.primatech.ca/support forupdated documentsand

moretips.

TO PREVENTINJURY,ALWAYS DISCONNECT THE

AIR SUPPLY HOSE WHENADJUSTING,SERVICING OR

DISASSEMBLING THE TOOL.

FIRST:CHECK THE COMPRESSEDAIRSUPPLY

Manyofproblems comefromafaultyorinadequate

compressed airsupplysystem. Beforeattempting torepair

the tool, the following pointsshould be checked:

a)checkthe pressureatthe outputofthe compressor;

adjust to80-100 psi(5.5-7.0bar) asrequired

b)checkthe tankpressureof the compressor&adjust the

start/stop limits

c)checkthe airdeliverysystem;a3/8"hoseis

recommended

d)usefewertoolssimultaneously;do notexceed the

capacityof the compressororof the deliverysystem

e)drain waterfromthe compressor

SECOND:CHECK FORAIRLEAKS

Atrest, thistool should nothaveanyairleak.Before

attempting torepairthe tool and replaceparts,checkthe

following:

a)CheckringsP-606A,P-516B,P-009,P-543Aand

P-543D; replaceif necessary

b)The top edge ofmain cylinderP-618should be free of

dents.

c)Clean &lubricatethe head assembly;re-assemble the

head assemblycarefully

d)Checkinteriorof head P-606 forscratches

HEADASSEMBLYLOOSENS UP DURING OPERATION

Removethe head assemblyand insurethatthe cylinderis

fullyscrewed on.Re-insertthe head assemblyin placeand

insurethat the head lockP-616D iscorrectlyin place.

TOOL DOES NOTDRIVE FASTENERS

a)Checkthat therearefasteners in the feederchannel

b)Makesurethe feederclip isengaged behind the

fasteners

c)Checkthe frontend ofthe feederchannel forburrsor

damages

d)Checkthe safetymechanism

e)Checkifthe driverisstuckin downposition (see 6

below)

f)Checkforobstruction in the fastenerejection area

FASTENERS ARE NOTSETCOMPLETELY

a)First, verifyairsupply(see 1above)

b)Clean tool and lubricatetool;particularlythe head

assembly

c)Increaseairpressurewhen working withharderwoods;

do not exceed 110 psi(7.6bar)

d)Checkthe driving blade forbroken end

e)Checkpiston wear-ring P-622A;replaceifpiston is

sliding toeasily

f)Checkseal bushing P-525B

g)Checkthe adjustmentofthe baseand ensurethe tool is

well seated on the floorwhile ejecting

TOOL DOES NOTACTIVATE

a)Checkthe airsupply

b)Inspectthe head assemblyand checkall seals;

reassemble carefully

DRIVING BLADE DOES NOTRETURN

a)Checkforjammed fastenerorobstruction

b)Checkgate/footand end offeederchannel fordamages

orburrs.

c)Checkthe driving blade P-423

d)Inspect the head assemblyand checkall seals; clean &

lubricate.

e)Checkband-valveP-618A.

f)CheckthatthebumperP-525Aand sealbushingP-525B

arein place.

BROKENORWORN DRIVING BLADE

Replacethe driving blade P-423.Failuretofollowthe

instructionscarefullywill resultin repeated breakage of the

driving blade.

POORFEEDORTOOLJAMMING

a)Makesurethe feederclip engagesbehind the fasteners

b)Checkthe gate/foot assemblyfordamagesorwear

c)Check the frontend ofthe feederchannel forburrs or

damages

OTHERPROBLEMS

Contact Primatech:

byphone1(800)363-1962

1(418)522-7744

byemail support@primatech.ca

consult ouron-line Technical Support siteat

http://www.primatech.ca/support

TOOL WARRANTYAND LIMITATIONS

Primatechwarrantsthatnewlypurchasedfastening tools,parts

and accessorieswill be free fromdefectsin materialand

workmanship (excluding wearparts)forthe period shown

below,afterthe dateofpurchasebythe original useras

evidenced byavaluable purchaseinvoice.

ONE-YEARLIMITEDWARRANTYwillapplytoallparts,except

thosesubjected tonormal wear

SEVEN-YEAREXTENDEDLIMITEDWARRANTYcovers tool

casing.

WARRANTYSTATEMENT

Primatech‘ssole liabilityhereunderwill be toreplaceanypart

oraccessorywhichprovestobe defectivewithin the specific

timeperiod.Anyreplacementpartoraccessoriesprovided in

accordancewiththiswarrantywill carryawarrantyforthe

balanceofthe period ofwarrantyapplicable tothe partit

replaces.Whenrepairorreplacementofpartortoolisrequired,

the completetool orpart(s) mustbe returned toPrimatechorat

suchauthorized warrantyservicepointofPrimatech,

transportation prepaid,withacopyofproofofpurchase

evidencing that the part ortool iswithin the warrantyperiod.

Thiswarrantyisvoid astoanytool whichhasbeen subjected

tomisuse,abuse, accidental orintentional damage, used with

fasteners notmeeting Primatechspecifications,sizeorquality,

improperlymaintained,repaired withotherthan genuine

Primatechreplacementparts,damaged in transitorhandling,

orwhich,in Primatech‘ssole opinion,hasbeen altered,

modified orrepaired in awaythataffectsordetractsfromthe

performanceof the tool.

PRIMATECH MAKESNOWARRANTY,EXPRESSEDOR

IMPLIED,RELATINGTOMERCHANTABILITY,FITNESS,OR

OTHERWISE,EXCEPTAS STATEDABOVE,and primatech

‘sliabilityAS STATEDABOVE AND AS ASSUMEDABOVE is

in lieu ofall otherwarrantiesarising outof, orin connection

with,the useand performanceofthe tool,excepttothe extent

otherwiseprovided forbyapplicable law.

PRIMATECH SHALL INNOEVENTBE LIABLEFORANY

DIRECT,INDIRECT,ORCONSEQUENTIALDAMAGES

WHICH MAYARISE FROMLOSS OF ANTICIPATED

PROFITSORPRODUCTION,SPOILAGEOF MATERIALS,

INCREASEDCOSTOF OPERATION,OROTHERWISE.Any

liability,ifany,connectedwiththe useofthetool shallterminate

upon the expiration of the warrantyperiod specified above.

Other manuals for P250A

1

Table of contents

Other primatech Tools manuals

Popular Tools manuals by other brands

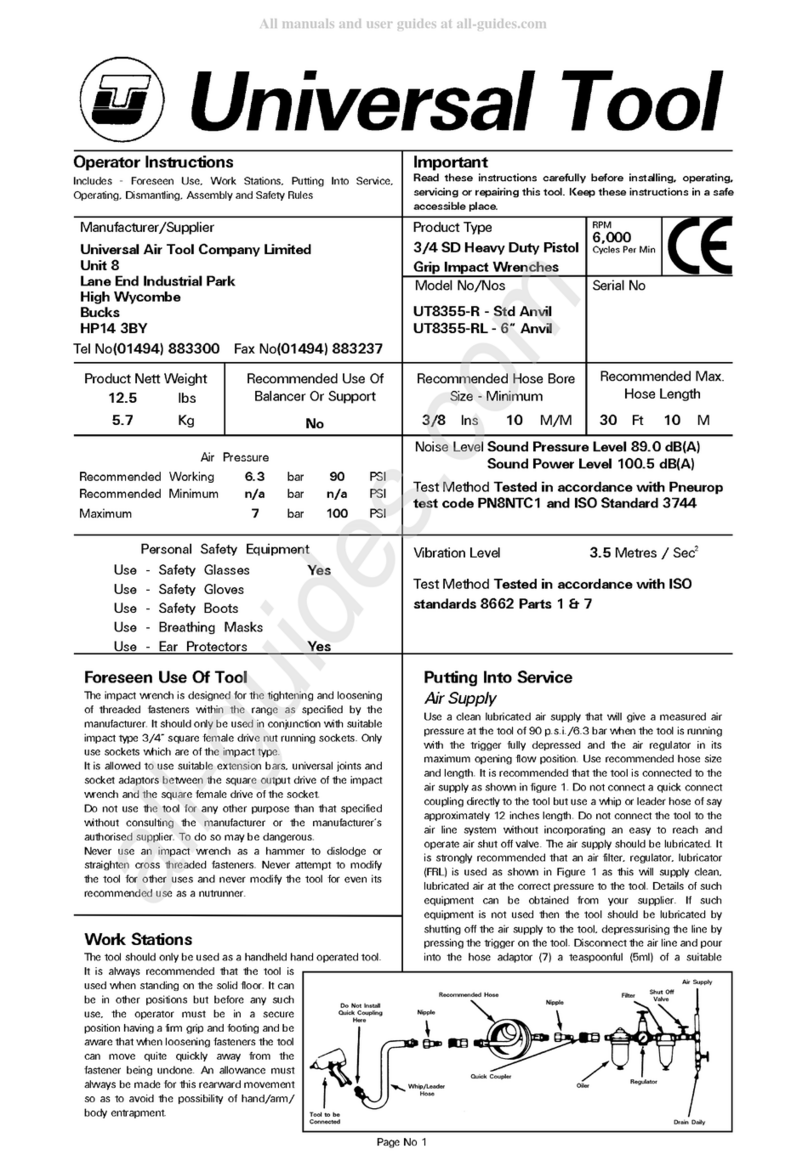

Universal Tool

Universal Tool UT8355-RL quick start guide

BGS technic

BGS technic 8261 instruction manual

Record Power

Record Power SC1 Original instruction manual

Würth

Würth DIGA CS-3 Original operating instructions

Matco Tools

Matco Tools GG50B operating instructions

Triton

Triton T1 Operating/safety instructions