OPERATING

INSTRUCTIONS

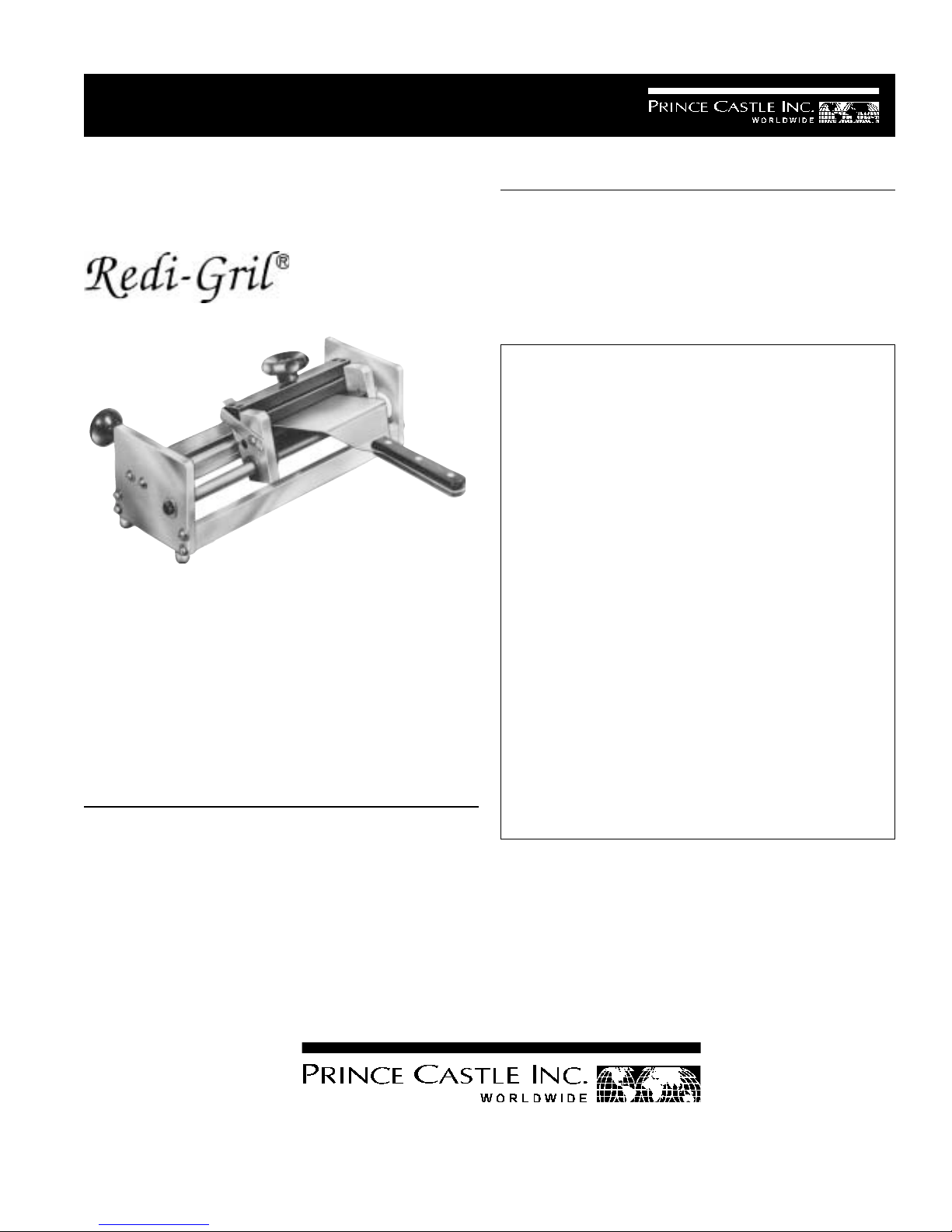

Manual Grill Tool Sharpener

Model No. 164-A

355 East Kehoe Blvd. l Carol Stream, IL 60188

Tel: (630) 62-8800 l Fax: (630) 62-1 60

Toll Free: 1-800-PCASTLE

Printed in September 1997

Prince Castle Inc. 164-504

SPECIFICATION

164-A Dimensions

Length 17 (43.18 cm)

Wi th 8 (20.32 cm)

Height 7 (17.78 cm)

Shipping Weight 22lbs. (10 kg.)

The Prince Castle manual grill tool sharpener gives a

quick sharpene straight e ge to scrapers an

spatulas. Sharp spatulas pick up grille meat

cleanly without tearing the seare surface. Natural

juices are kept in foo for more flavor, an a more

appetizing appearance. With precision e ges

cleanup is quick an easy without scratching. Plus,

compact size of the manual grill tool sharpener

saves valuable counter space.

LIMITED WARRANTY

This pro uct is warrante to be free from efects in

material an /or workmanship for a perio of one

year from ate of original installation, not to excee

18 months from ate of shipment from our factory.

Any component which proves to be faulty in material

an /or workmanship will be replace or repaire (at

the option of Prince Castle, Inc.) without cost to the

customer for parts or labor.

This warranty is subject to the following exceptions/

con itions:

lUse of any non-genuine Prince Castle parts

voi s this warranty. All genuine Prince Castle

replacement spare parts are warrante for ninety

(90) ays from ate of purchase.

lDamage cause by carelessness, neglect, an /

or abuse (e.g., ropping, tampering or altering

parts), equipment amage in shipment, by fire,

floo or an act of Go is not covere un er this

warranty.

lThis unit is portable, charges for on location

service (i.e. trip charges, mileage) are not in-

clu e in the provisions of the warranty.

TABLE OF CONTENTS PAGE

Installation..................................................................... 2

Operating ....................................................................... 2

Parts List....................................................................... 3

Troubleshooting ............................................................ 4

Non-sche ule Maintenance ....................................... 4