Printrbot Smalls User manual

Printrbot Smalls

Software, Calibration, & Your First Print

model 1704

You will need the following items to complete

this guide.

●REQUIRED DOWNLOADS folder

available at printrbot.com/smalls

○ Cura software

○Printrbot_testprint.stl

○ Smalls.GettingStarted.ini

○ USB driver for Windows users

● Sample of filament

● Print Bed Tape (optional)

*TIP: Turn OFF any “sleep” settings on your

computer. If the screen goes dark while you are

printing, the print will cancel.

Before You Begin

Load Your Filament

● Insert your filament into the top

of the fan shroud.

● Direct the filament down into

hole in the extruder arm.

● Pinch the extruder arm and

continue to push the filament

down into the hot end.

● Take a moment to add print bed

tape to your bed.

See a more detailed explanation of how to

load filament on the next slide.

● Insert your filament into the top of the

extruder arm,

○ ...between the drive gear and

pulley

○ ...through the extruder base

○ ...and down into the hot end.

Loading Your Filament ...a closer look

microUSB

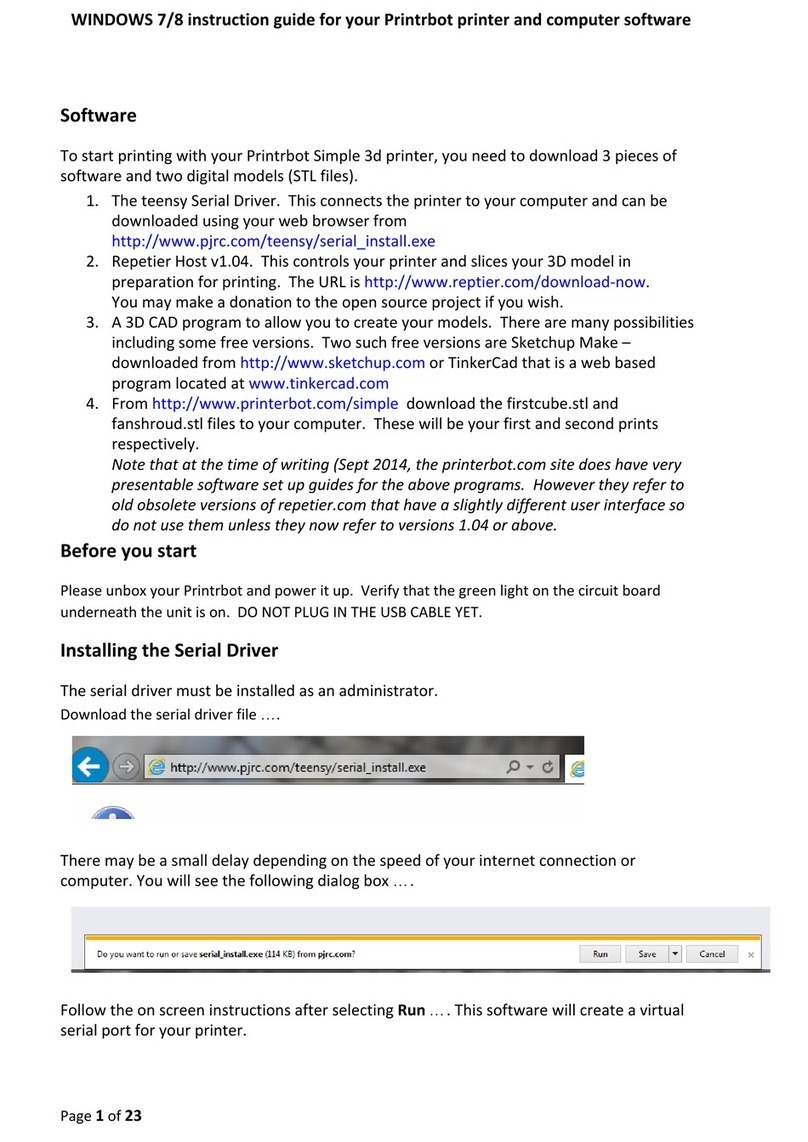

● Plug the microUSB cable into the USB

port.

●NOTE: DO NOT PLUG THE MICRO

USB CONNECTOR IN

IMPROPERLY. THIS WILL DAMAGE

YOUR PRINTRBOT.

● Connect the other end of the USB

cable to your computer.

● Connect the power cord to the laptop

power supply.

● Plug the laptop power supply into the

power port on the side of the bot.

● Filp the power switch to the ON

position.

Power & USB

POWER

Cura: Configuration Wizard

● After installing Cura on your

computer, open the software and

walk through the Configuration

Wizard.

○ Select “Printrbot”

○ Select “Play”

● Continue through the Configuration

Wizard by clicking “Next, Next…”

After completing the Configuration Wizard, the Cura control panel will open. Enable the Pronterface User Interface (UI).

● File

● Preferences…

● Pronterface UI

Click “Ok” to save.

Cura: Pronterface User Interface - IMPORTANT

Cura Control Panel

● The first time that you open

Cura, you will see the Ultimaker

Robot on the print panel.

● To remove this model, right

click on the robot and select

“Delete object”.

You can use this model as your first print if you

really want to. No hard feelings :).

● Go to File/Open profile

● Select the “Smalls.GettingStarted.ini” from your Required Downloads folder.

● TIP: You can verify that the new settings are in place by checking your Layer height (mm). It should read “0.2064”.

Load Configuration Profile

Load Your Model

● Click the “Load” icon.

● Find the “printrbot_testprint.stl” in

your Required Downloads folder

and click “Open”.

● The Printrbot logo model will

appear in your print panel.

Begin Print ● Click “Print”

● The hot end will begin to

raise to “Printing

temperature” (208C)

● Once temperature has

been reached, the print

will begin.

○ X Axis home

○ Y Axis home

○ 3-point probe

○ Begin print.

●IMPORTANT: Do NOT

let your hot end sit at

temp while you are not

printing. If your printer is

sitting still, turn the hot

end off. For more, click

here.

Z Offset Too High

● Your first print will likely look

“stringy”. This is because the Z

offset (M212) needs to be

adjusted.

● Cancel the print job and remove

the filament from the print bed.

● The next slide will explain how

to adjust the Z offset in order for

the first layer to lay down better.

Adjust M212 Z

(and X) Values

● Enter the following code in the

command line of your

Pronterface UI. ...Click “Send”

after each of these lines.

○ M212 X0 Z-0.2

○ M500

○ M501

● After entering M501, you will

see the settings that you just

entered in the readout.

●Pro Tip: Send an “M106” command

between prints to power ON your fan

and keep the heat sink on your hot

end cool.

● If you adjust the M212 too

dramatically, the first layer will

appear “choppy”. You may also

notice the filament almost looks

transparent because such a

small amount was allowed out

of the nozzle.

● If your extruder is clicking, that

is another sign that the Z offset

is too low.

Z Offset Too Low

Test Again ...and

Again ...and Again.

● Send the following commands.

Press “Send” after each one.

○ M212 Z-0.2

○ M500

○ M501

● After adjusting your M212

value, click “Print” again.

● You may not see much difference

between this print and the first one.

Keep testing: Start the print

...cancel ...adjust M212 ...start the

print, etc. Continue to adjust the

M212 Z offset into the negative

direction in small increments. No

more than 0.2 each time. So for

example ...M212 Z-0.2 ...M212

Z-0.4 ...M212 Z-0.6, and so on.

● NOTE: Your “perfect” M212 value

may not be Z-0.4. You will have to

test and find the proper value for

your printer.

M212 Z0.0 - TOO HIGH

M212 Z-0.4 - PERFECT

M212 Z-0.6 - TOO LOW

The Perfect “Bead

● You’re looking for the perfect

bead. If the value is too high,

you will not achieve first layer

adhesion. If the value is too

low, you will hear the extruder

click as the filament backs up in

the hot end.

● When the M212 value is set

properly, the first layer sticks

well, without jamming the hot

end.

Nice Work! First Print Complete.

NEXT STEPS:

●Visit youmagine.com for loads of free printable

files, including parts specifically designed for your

Printrbot Smalls.

● See the next slide for more insight on Cura

settings/terminology.

●Download Fusion 360 and make your own

designs!

●Note: The card lists an expiration of 3/31/17, but Autodesk

has been generous to extend their offer!

One year of Fusion 360 FREE with the offer code:

printrbotoffer

● No luck? Don’t be discouraged. 3D printing is

hard.

● Visit our forum at support.printrbot.com. We have

section specifically for Smalls Kit builders!

Commonly Used Icons and Settings

● “Print with USB” icon

● “Load” model file icon

●Layer height (mm): Layer height in millimeters.

The default Cura setting is 0.1. A setting of 0.2

is the “PB recommended” value for high

resolution as well as higher success rate.

● Fill Density (%): The amount of “infill” that will

be used in the print. 20% is great for most

models. 0% is what you would use for

something like a vase.

● Print Speed (mm/s): 40 is an optimum value for

Printrbot, in terms of print quality vs print time. If

you are having trouble with print quality, slowing

the print speed is an effective way to improve

this.

●Printing temperature (C): Temperature that the

hot end will reach to melt the filament. 208C is

great for PLA.

●Support type: You may find that your parts are

“saggy” if you are printing something with

overhang, i.e; the shape of the letter “T”. You

can use support to aid your prints and then

remove the support material after the print

completes.

● Platform adhesion type: If you are having

trouble with adhesion on the first layer, try

experimenting with a brim.

Cura Settings Quick Reference for Printrbot Users

Rotate Scale Mirror

Object Manipulation

This manual suits for next models

1

Table of contents

Other Printrbot 3D Printer manuals

Popular 3D Printer manuals by other brands

Zcorporation

Zcorporation Spectrum Z 510 Maintenance manual

re:3D

re:3D gigabot quick start guide

3D Upfitters

3D Upfitters Ender 3 V2/CR-6 Enclosure Kit installation manual

2PrintBeta

2PrintBeta Beta Prusa Standard Assembly instructions

QIDI

QIDI Avatar IV user manual

3D Systems

3D Systems ProX DMP 300 user guide